Antirust corrosion-resistant concrete and preparation method thereof

A concrete and anti-corrosion technology, applied in the field of anti-rust and anti-corrosion concrete and its preparation, can solve the problems of economic loss, many processes, corrosion of steel structure, etc., and achieve the effect of good anti-rust and anti-corrosion performance and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

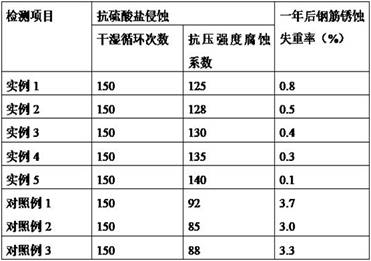

Examples

example 1

[0052] Mix gallic acid and distilled water at a mass ratio of 1:10 to obtain a mixed solution, then add a 30% sodium hydroxymethanesulfonate solution with a mass fraction of half the mass of distilled water to the mixed solution, and keep the reaction at 75°C for 4h, filter , take the filtrate rotary evaporation, concentrated to 20 Baume degrees, to get the concentrate; in parts by weight, add 10 parts of glycidyl methacrylate, 15 parts of epoxy resin E-44, 15 parts of the above-mentioned concentrate and 5 parts of triphenylphosphine are heated to 100°C, stirred and reacted at a speed of 200r / min for 40 minutes, and then discharged to obtain an esterified prepolymerized product, which is set aside; p-phenylenediamine and polyvinyl alcohol Mix butyral at a mass ratio of 1:2 to obtain a mixture, then mix the mixture with acetone and ethyl acetate at a mass ratio of 1:2:3 and stir for 15 minutes to obtain a composite curing agent; take pig bones and put them into a grinder Grindi...

example 2

[0054] Mix gallic acid and distilled water at a mass ratio of 1:10 to obtain a mixed solution, then add a 30% sodium hydroxymethanesulfonate solution with a mass fraction of half the mass of distilled water to the mixed solution, and keep the reaction at 76°C for 4h, filter , get the filtrate rotary evaporation, concentrated to 20 Baume degrees, to get the concentrate; in parts by weight, add 11 parts of glycidyl methacrylate, 16 parts of epoxy resin E-44, 16 parts of the above-mentioned concentrate and 6 parts of triphenylphosphine were heated to 104°C, stirred and reacted at a speed of 220r / min for 44 minutes, and then discharged to obtain an esterified prepolymerized product, which was set aside; p-phenylenediamine and polyvinyl alcohol Mix butyral at a mass ratio of 1:2 to obtain a mixture, then mix the mixture with acetone and ethyl acetate at a mass ratio of 1:2:3 and stir for 16 minutes to obtain a composite curing agent; take pig bones and put them into a grinder Grind...

example 3

[0056] Mix gallic acid and distilled water at a mass ratio of 1:10 to obtain a mixed solution, then add a 30% sodium hydroxymethanesulfonate solution with a mass fraction of half the mass of distilled water to the mixed solution, and heat at 77°C for 4 hours, filter , take the filtrate rotary evaporation, concentrated to 20 Baume degrees, to get the concentrate; in parts by weight, add 13 parts of glycidyl methacrylate, 17 parts of epoxy resin E-44, 17 parts of the above-mentioned concentrate and 7 parts of triphenylphosphine were heated to 110°C, stirred and reacted at a speed of 250r / min for 50 minutes, and then discharged to obtain an esterified prepolymerized product, which was set aside; p-phenylenediamine and polyvinyl alcohol Mix butyral at a mass ratio of 1:2 to obtain a mixture, then mix the mixture with acetone and ethyl acetate at a mass ratio of 1:2:3 and stir for 17 minutes to obtain a composite curing agent; take pig bones and put them into a grinder Grinding in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com