Building unit combined type heat preservation and decoration integrated outer wall hanging plate and mounting method

A building unit and combined technology, applied in the direction of construction, building structure, covering/lining, etc., can solve the problems of easy formation of cold bridges, insecurity, falling off, etc., and achieve good fire performance, long service life, and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

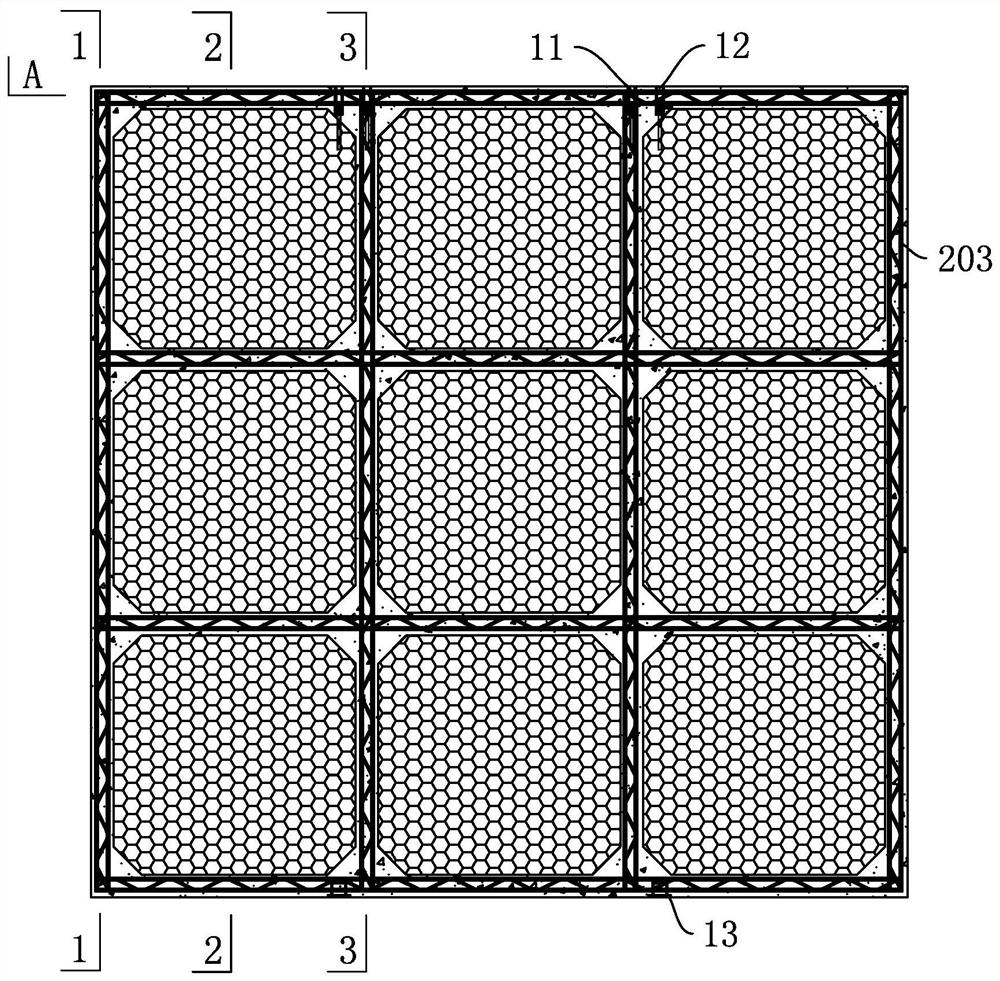

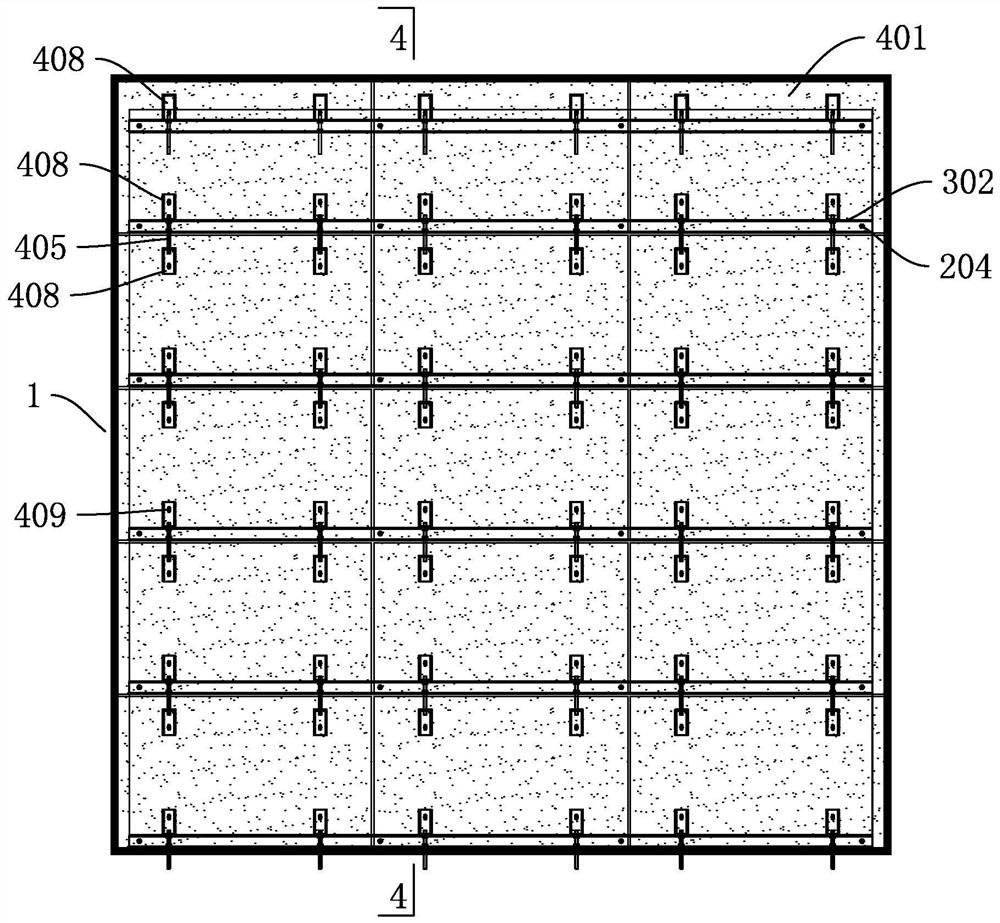

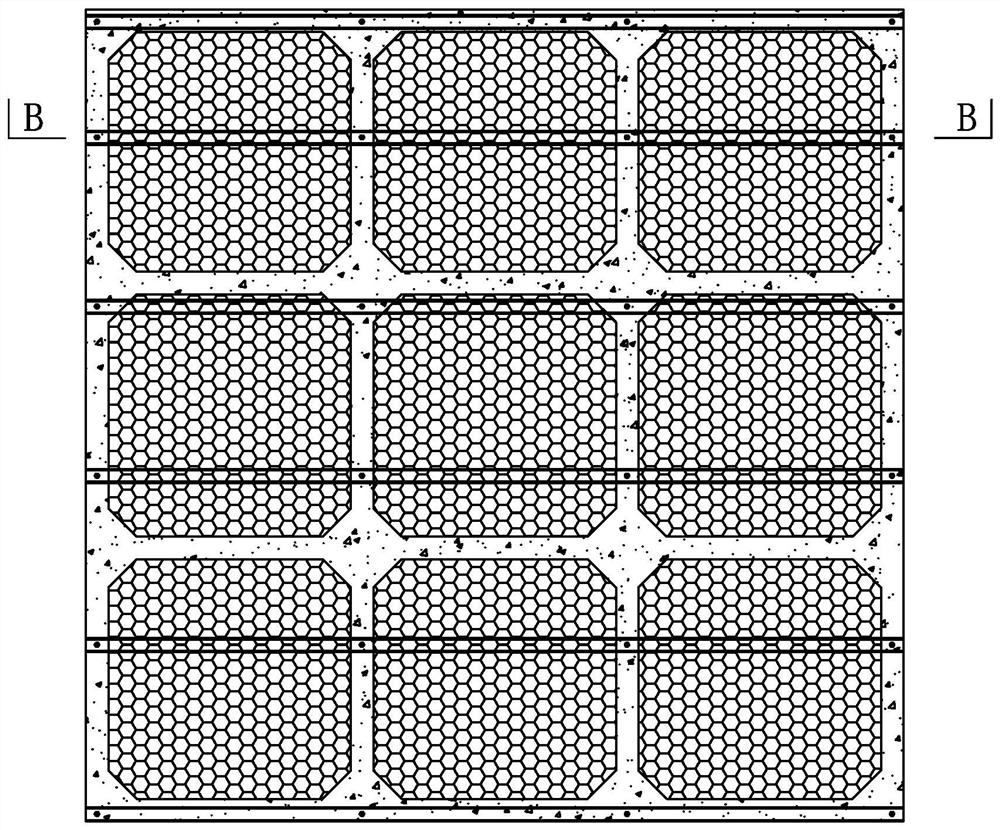

[0101] Such as Figure 1-9 and Figure 16-17 As shown, the building unit combined thermal insulation and decoration integrated exterior wall hanging board 1 is a layered structure, which is the inner thermal insulation layer 101, the reinforced concrete frame, the fireproof thermal insulation layer 301 and the decorative plate layer from the inside to the outside; the reinforced concrete frame is located on the four sides It is formed by connecting with the internal reinforced concrete frame ribs 201; a thermal insulation filling layer 202 is embedded between the reinforced concrete frames; two horizontally evenly distributed reinforced concrete frame ribs 201 and two longitudinally uniform The reinforced concrete frame ribs 201 of the cloth are vertically connected to each other, and the two ends of the internal reinforced concrete frame ribs 201 are connected with the reinforced concrete frame ribs 201 located on the edge; The reinforced concrete frame ribs 201 and the rect...

Embodiment 2

[0122] Such as Figure 10-13 , Figure 22 As shown, a connection and installation structure for two upper and lower building unit combined thermal insulation and decoration integrated exterior wall hanging panels as shown in Embodiment 1: the outer end surface of each floor slab 500 is pre-embedded with a corbel pre-embedded Nut 501, and the outside of floor slab 500 is provided with corbel support 502, and described corbel support 502 is made up of back seal plate 504 and the channel steel 505 that is fixedly connected with the side of back seal plate 504, and the back seal of described corbel support 502 The plate 504 is fixed together with the corbel pre-embedded nut 501 through bolts; the bottom surface of the channel steel 505 is provided with a bolt through hole, and the positioning vertical bolt 503 passes through the bolt through hole and is fixed with the channel steel 505. The concrete frame at the bottom of the building unit combined thermal insulation and decorati...

Embodiment 3

[0126] Such as Figure 20 As shown, a connection and installation structure for two upper and lower building unit combined thermal insulation and decoration integrated exterior wall hanging panels as described in embodiment 1, compared with embodiment 2, the difference is that: the embodiment 2 The bracket of the corbel is replaced by angle steel, and the elevation of the angle steel is fixed together with the embedded nut 501 of the corbel; the top surface of the angle steel is provided with a bolt through hole, and the positioning vertical bolt 503 passes through the bolt through hole and is connected with the The angle steel is fixed together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com