Low-damage self-resetting fabricated concrete two-way frame beam-column joint

A technology of beam-column joints and frame beams, which is applied in the direction of architecture and building construction, can solve problems such as complex construction on site, difficult control of construction quality, and inability to achieve lightening, so as to improve seismic performance, improve repairability, and be easy to replace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

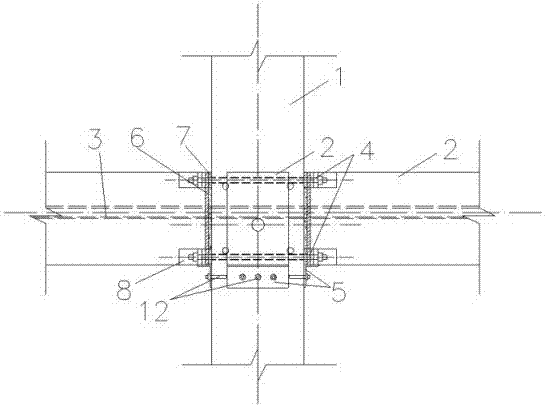

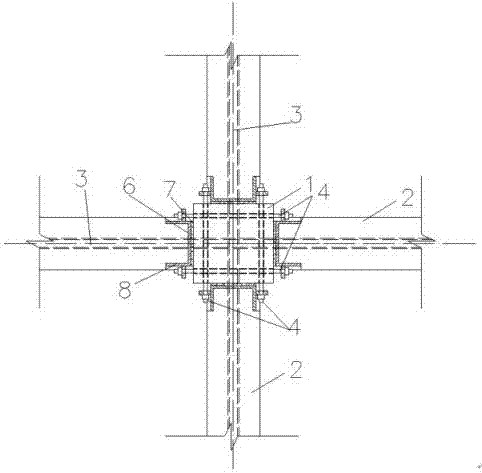

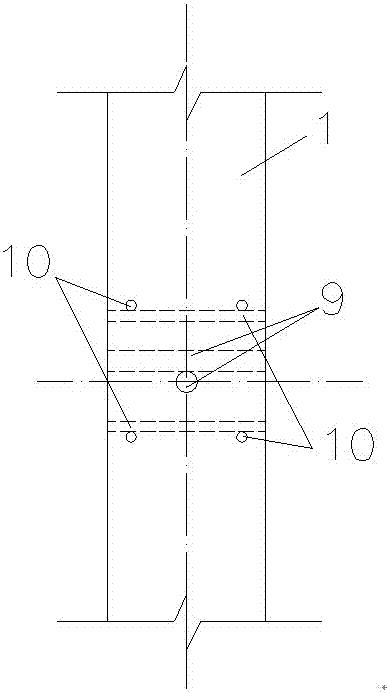

[0025] Combine below Figure 1 to Figure 4 , the present invention is further described:

[0026] Such as figure 1 , 2 As shown, the connection node includes a prefabricated concrete frame column (1) and a two-way prefabricated concrete frame beam (2). The concrete frame column (1) can be prefabricated in multiple layers or single layer. The joints of the frame column (1) along the height are arranged in the storey, and pass through continuously at the beam-column node area. The concrete frame beam (2) in two directions They are all single-span prefabricated, the prefabricated frame beam (2) is interrupted in the node area, and the beam end and the column side are used as the contact surface of the node connection. The pre-embedded steel plate (6) at the beam end can on the one hand protect the beam end during hoisting, and on the other hand can enhance the pressure bearing capacity of the beam end and reduce its damage under earthquake action. A gap of about 20 mm is rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com