Straight thread connector with steel reinforced end and connection thereof

A reinforced, straight thread technology, applied in the processing of building reinforcements, building components, building materials, etc., can solve the problems of low efficiency, slow construction speed, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

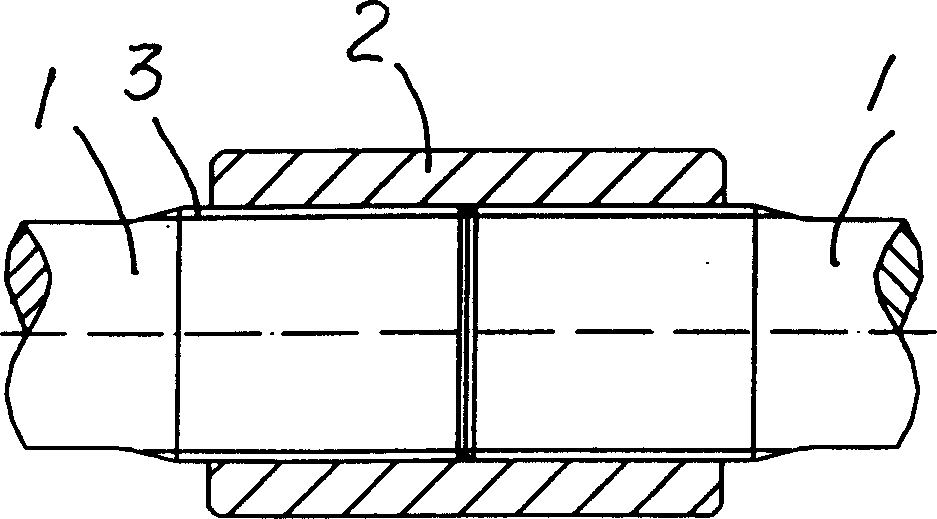

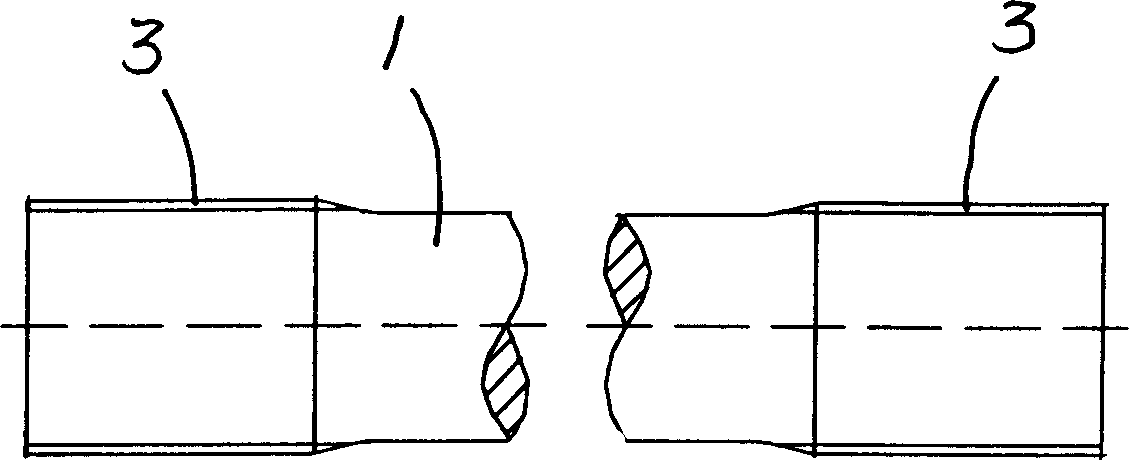

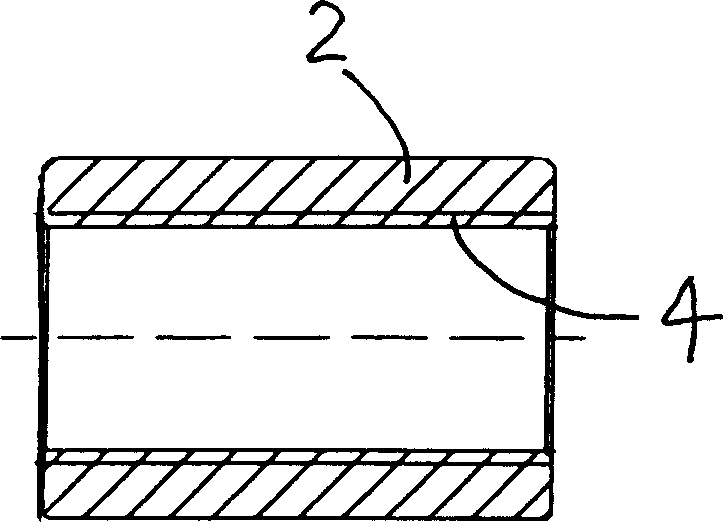

[0009] Embodiment 1: refer to figure 1 , figure 2 , image 3 . first to figure 2 The two ends of the shown screw are covered with external straight threads, and then the image 3 The screw sleeve shown in the figure taps out the internal straight thread, and finally at the construction site according to the architectural design requirements, several screws and screw sleeves are pressed figure 1 The structures shown are connected in sequence, and the interface between the two screws is roughly in the middle of the screw sleeve. figure 1 The connection method shown is one unit and has no limitation in three dimensions.

Embodiment 2

[0010] Embodiment 2: refer to figure 1 , figure 2 , Figure 4 . This embodiment is suitable for the situation that the two adjacent screws are inconvenient to rotate, and the same purpose as that of Embodiment 1 can be achieved only by rotating the screw sleeve. In this example, figure 2 Screw shown with Figure 4 The illustrated threaded sleeve with an undercut has opposite helix threads at both ends, and the threaded direction at one end of the screw rod is the same as the helical direction at one end of the helical sleeve. by figure 1 For example, as the left end of the left screw 1 is left-handed ( figure 1 Not given in), the right end is right-handed; then the left end of the screw sleeve 2 adjacent to it is right-handed, and the right end is left-handed.

Embodiment 3

[0011] Embodiment 3: refer to figure 1 , figure 2 , Figure 5 . This embodiment is suitable for connecting two screws with different diameters. Furthermore, there is no doubt that the screw rod and the screw sleeve in this embodiment can have the same helical direction as the screw rod and the screw sleeve in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com