Reinforced concrete frame joint HDC wire winding reinforcing device and construction method thereof

A reinforced concrete and reinforcement device technology, applied in building maintenance, construction, building construction, etc., can solve the unfavorable changes in the failure form of the reinforced structure, the inconvenient application of primer and structural adhesive, and the reinforcement of the core area of the joint and the end of the column and other issues, to achieve the effect of earthquake resistance, simple construction, and increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

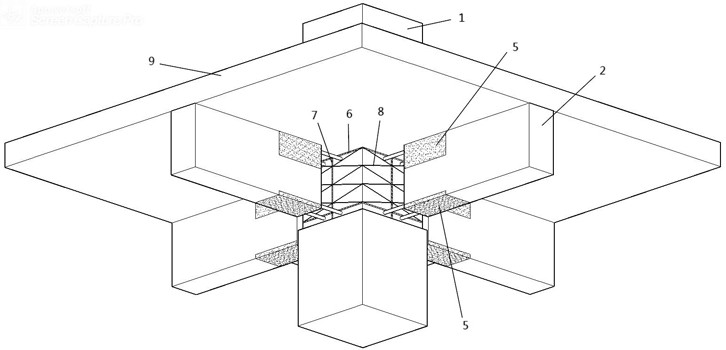

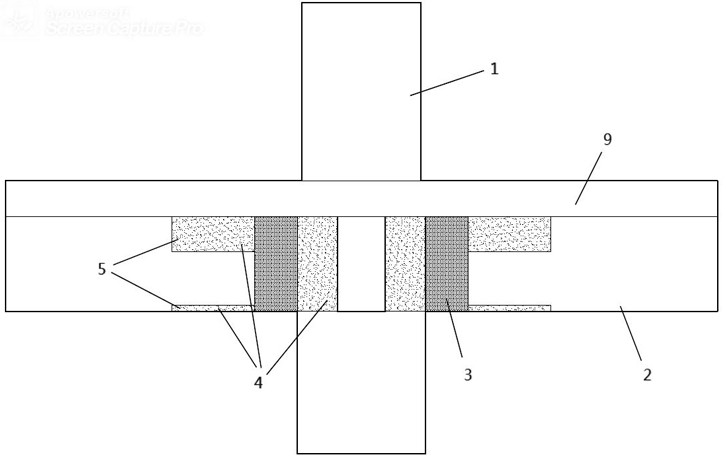

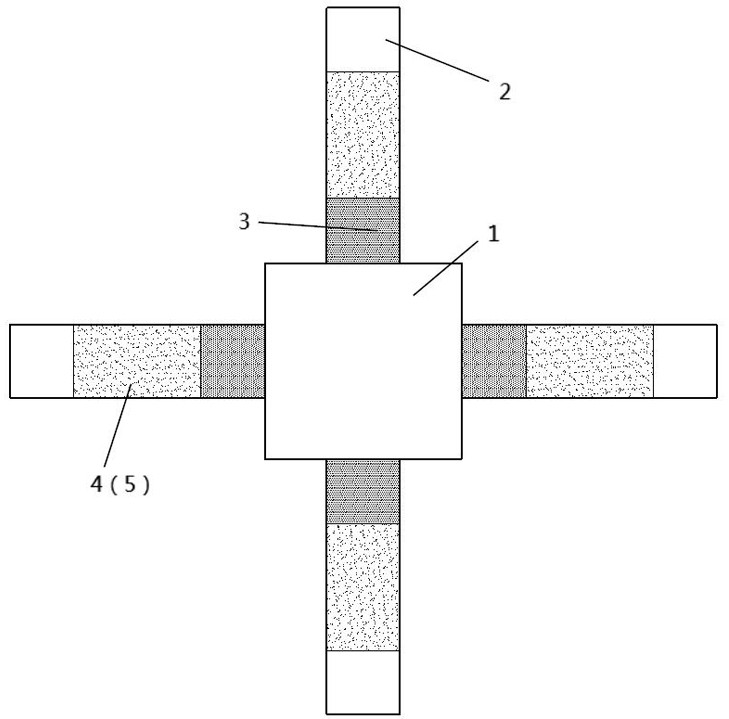

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0029] Such as Figure 1~5 As shown, the reinforced concrete frame node HDC wire-wound reinforcement device includes a vertical frame column 1 and a horizontally extending frame beam 2 around it, and the reinforcement area of the reinforcement device includes a connected full-height replacement area 3 and a partial replacement area. Zone 4, the full-height replacement area is formed by chiseling through the frame beam itself and the contact end of the frame column, and the partial replacement area is formed by chiseling inward from the outer peripheral surface of the frame column to the core area of the internal node of the frame column, and the core area of the node is exposed Vertical steel bars 7 are fixedly connected to the midpoints of the stirrups 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com