Assembled type anchor rod frame beam structure containing EPS elastic cushion layer and suitable for expansive soil slope

A technology of elastic cushion and frame beam, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of high cost, difficulty in prefabrication of cross lattice beam components, failure and other problems, and achieve low cost and reduce manufacturing difficulty , The effect of simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

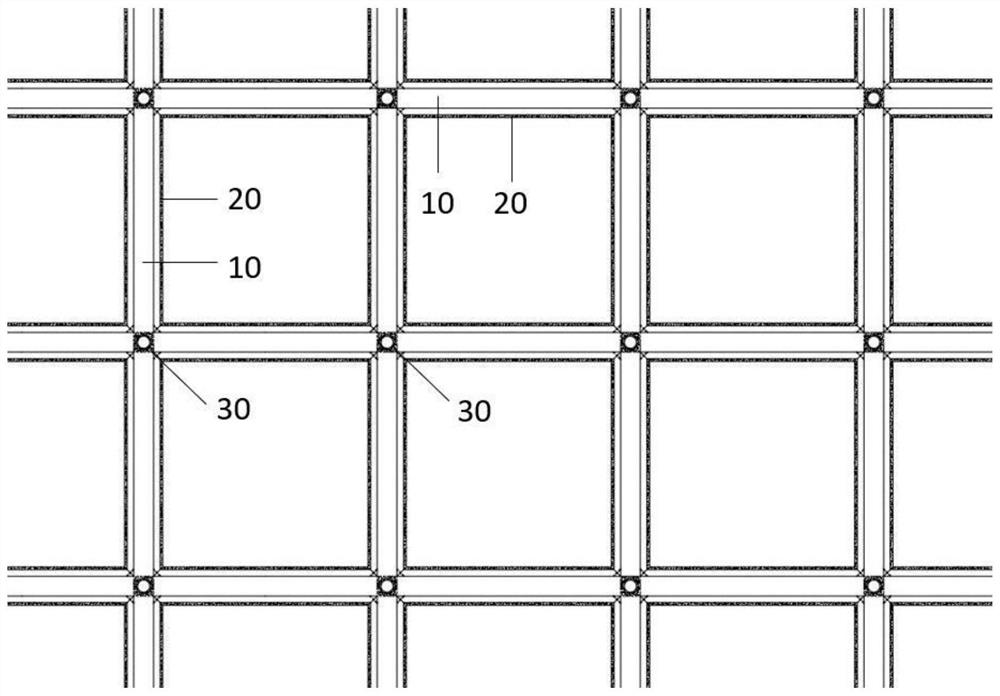

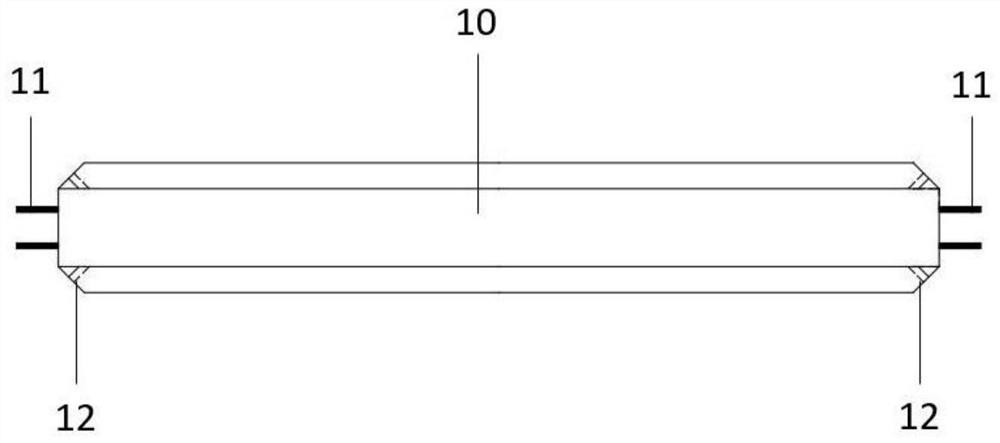

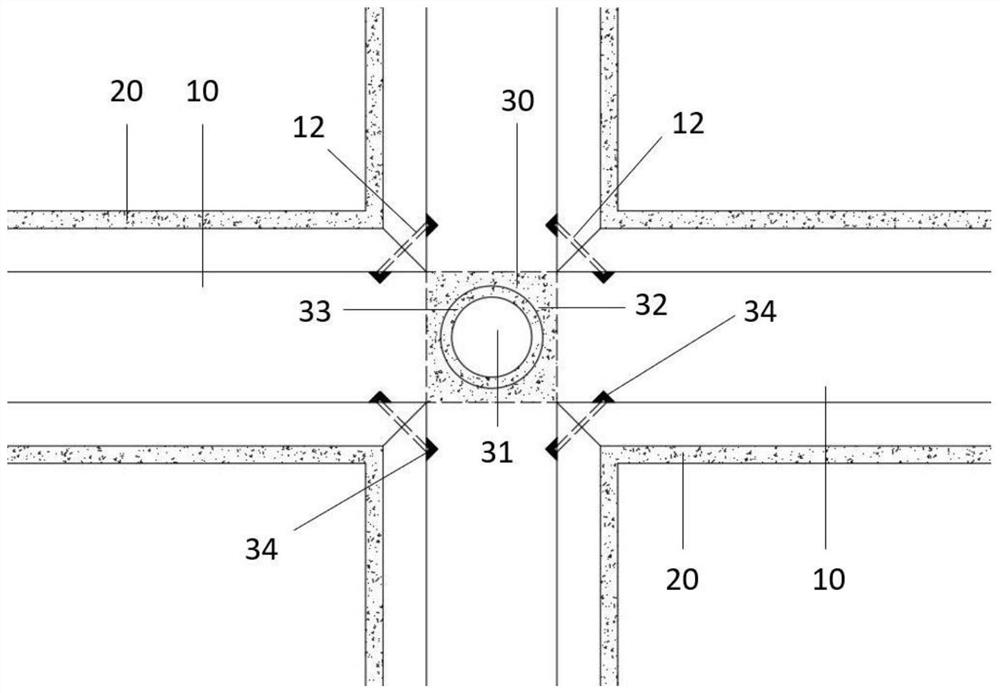

[0032] see figure 1 with image 3 , an assembled anchor frame beam structure containing EPS elastic cushion suitable for expansive soil slopes, including reinforced concrete concave beam prefabricated units 10, the reinforced concrete concave beam prefabricated units 10 are arranged horizontally and vertically, and nodes 30 pass through The cast-in-place reinforced concrete 32 is connected with the bolt 34, and the bolt 34 passes through the bolt hole 12 provided at the connecting portion of the adjacently connected reinforced concrete concave beam prefabricated unit 10, and reserves the anchor hole 31 for installing the anchor rod to form an assembled Anchor frame beam structure.

[0033] The reinforced concrete frame beam in this embodiment is assembled by reinforced concrete concave beam prefabricated units and joints with cast-in-place concrete and bolts, which greatly reduces the difficulty of making prefabricated units, and first installs anchor rods, and then casts in-...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0036] see figure 1 with image 3 , the cast-in-place concrete 32 at the node 30 forms the cut-off edge 33 structure of the anchor rod, closes the exposed section of the anchor rod, closely connects the anchor rod and the frame beam structure, and assembles to form a reinforced concrete frame beam.

[0037] The joints 30 of this embodiment are connected by cast-in-place reinforced concrete 32 and bolts 34, and anchor holes 31 are reserved. After the anchor is poured and installed, an anchor cut-off edge 33 is formed by cast-in-place concrete 32 to make the anchor and the frame beam tight connection. In this embodiment, the cast-in-place method is adopted to form the anchor bolt water-cutting edge 33 structure, which enhances the waterproof measures of the anchor bolt, ensures the overall strength of the assembled anchor bolt frame beam structure, and makes the assembled a...

Embodiment 3

[0039] This embodiment is basically the same as the above-mentioned embodiment, and the special features are as follows:

[0040] see Figure 1-Figure 4 The two sides of the reinforced concrete concave beam prefabricated unit 10 are provided with EPS elastic cushion 20, and the EPS elastic cushion 20 is flush with the concave beam.

[0041] In this embodiment, the EPS cushion layer arranged on both sides of the concave beam allows certain deformation of the expansive soil slope, and offsets part of the expansion force through self-compression to reduce the expansion force on the concave beam, thus greatly saving the reinforcement cost of the concave beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com