Beam-column joint connection device of fabricated reinforced concrete frame

A technology of reinforced concrete beams and reinforced concrete columns, which is applied in the field of beam-column joint connection devices of prefabricated reinforced concrete frames, and can solve problems such as large stress concentration, easy damage of concrete, and reduced bending resistance of beam-column joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention is further described below with reference to the accompanying drawings and specific embodiments of the specification.

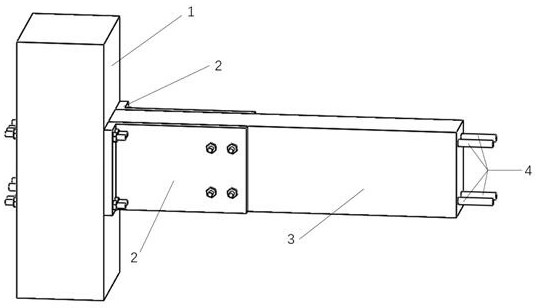

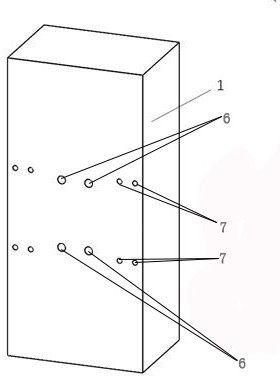

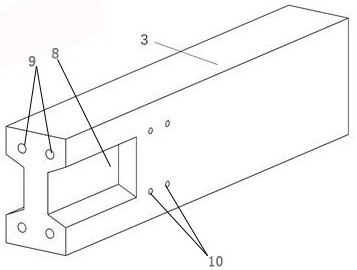

[0026]Such asfigure 1 As shown, the beam column node connection apparatus assembled reinforced concrete frame includes a prefabricated reinforced concrete column 1 and a prefabricated reinforced concrete beam 3, the prefabricated reinforced concrete column 1 and the prefabricated reinforced concrete beam 3 adopt a plurality of prestressed ribs 4 connections Each of the pre-reinforced concrete beams 3 axial arrangement is parallel to the prefabricated reinforced concrete column 1 by each pre-restred curier 4, and the pre-formed reinforced concrete column 1 is passed through the prefabricated reinforced concrete column 1, and the prefabricated reinforced concrete column 1 and Both sides of the connection of the prefabricated reinforced concrete beam 3 are provided, and the connection metal member 2 is a "L" type flap, and the connection metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com