Method for dismantling and splicing cast-in-place reinforced concrete frame structure building components

A reinforced concrete and frame structure technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of not being able to fully utilize the potential of abandoned buildings, building dumping and damage, and increasing the cost of waste, so as to avoid building materials. Generation of waste and dust, reduction of disposal, effects of land pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Embodiment: dismantling cast-in-place reinforced concrete frame structure building.

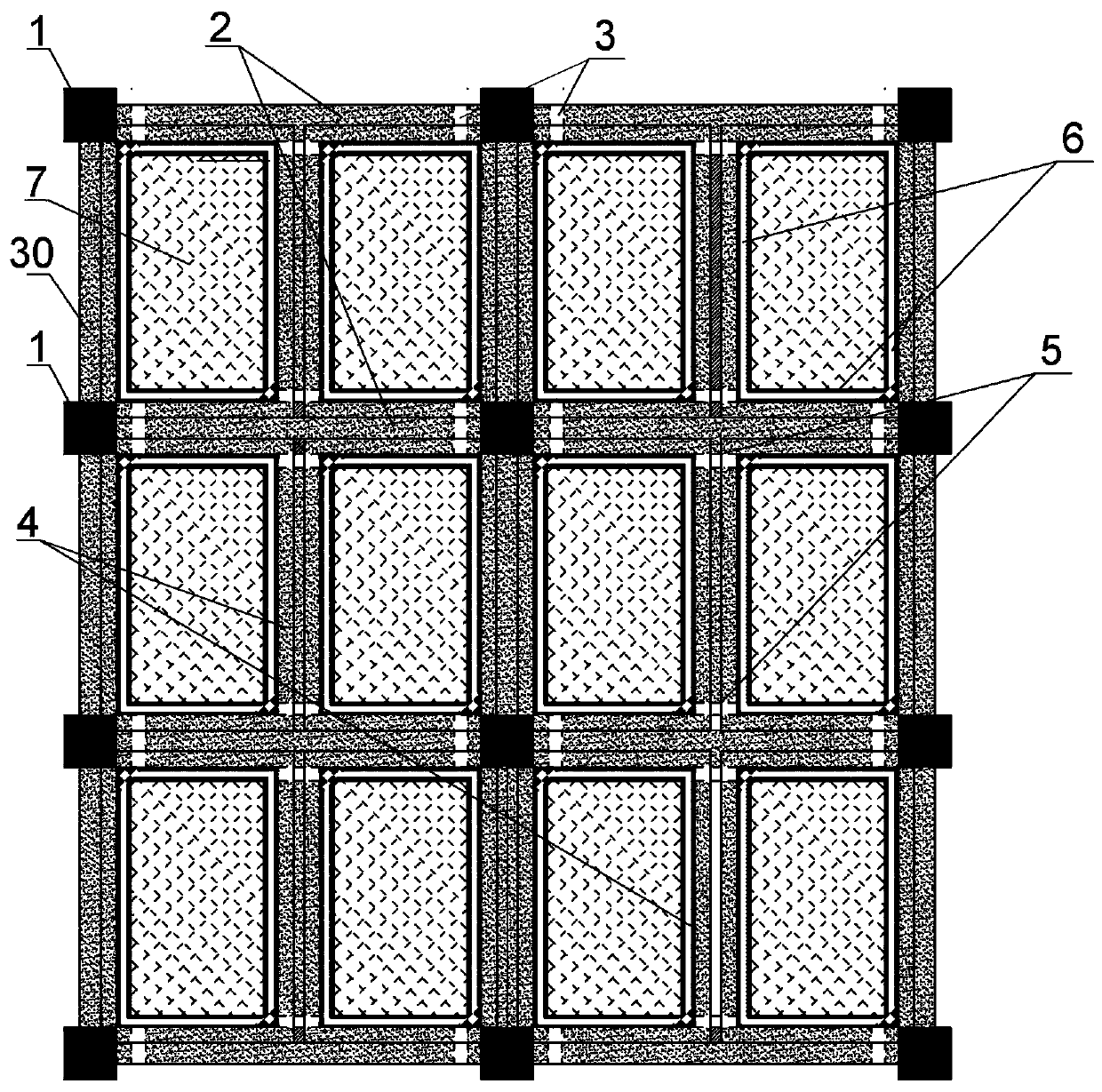

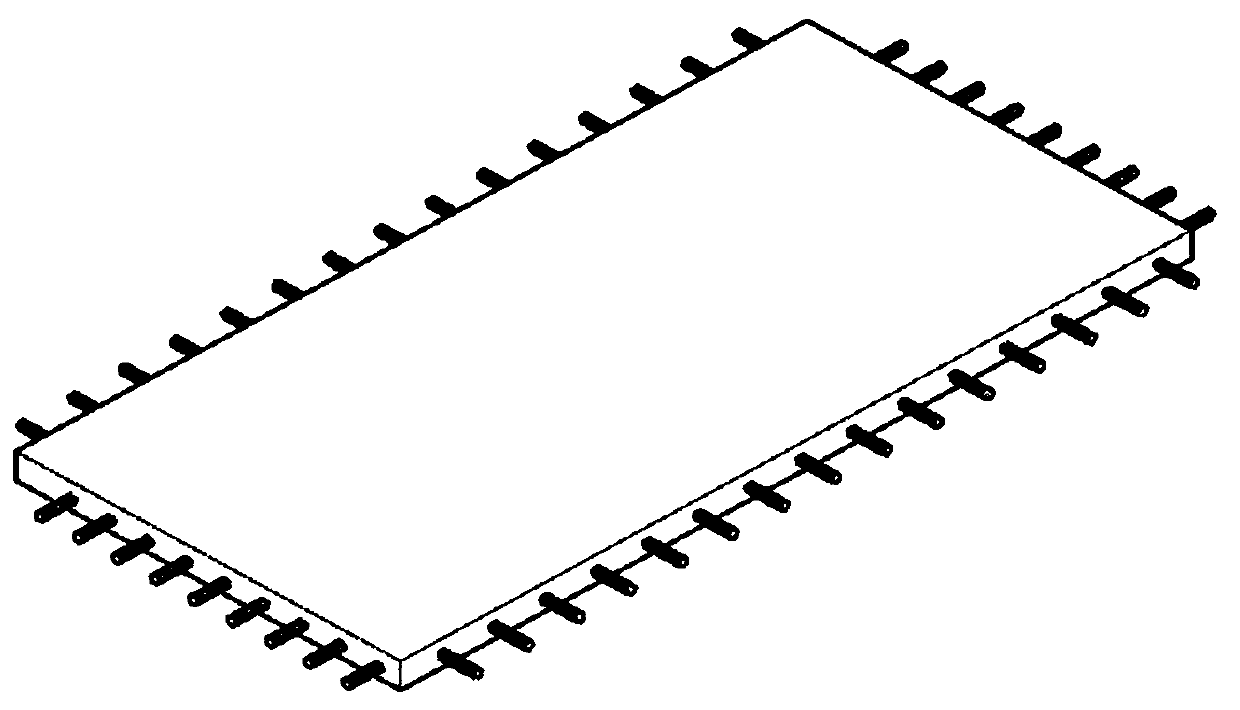

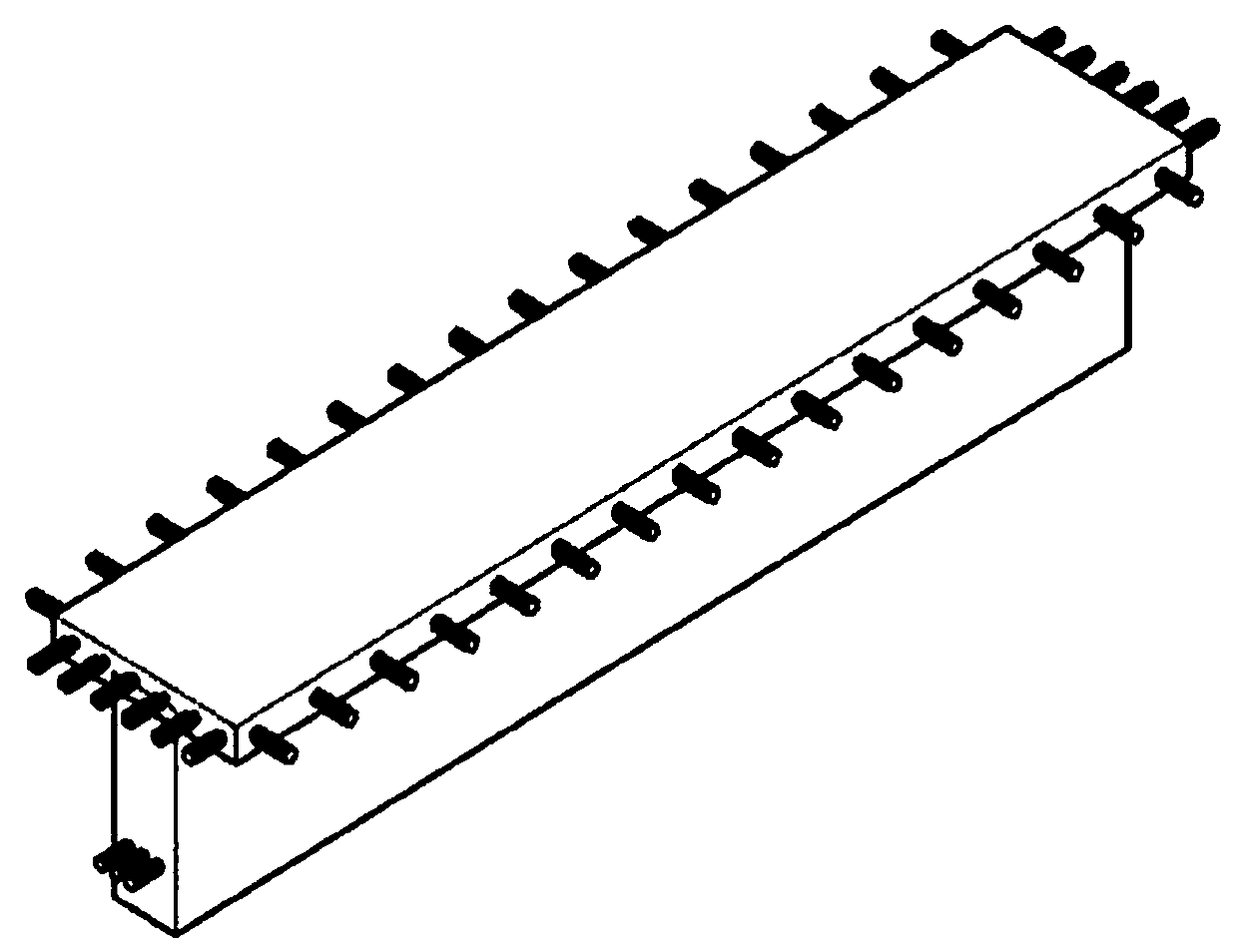

[0059] Step 1. Remove all walls, doors, windows and other non-load-bearing parts of the cast-in-place reinforced concrete frame structure building to be dismantled, leaving only the space force skeleton composed of beams, floors, and column load-bearing components. Depend on figure 1 As shown, in this embodiment, the spatial force frame contains three transverse frames, and each transverse frame is connected by four longitudinal connecting beams, and a secondary beam is arranged between the opposite longitudinal connecting beams, which is located in the middle of the longitudinal connecting beams.

[0060] Step 2. Divide the space force skeleton

[0061] The width direction of the house is set as the main force direction of the horizontal load, which is called the transverse direction, and the length direction perpendicular to it is recorded as the longitudinal direction. The entire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com