Method for metallurgically bonding a cylinder liner into a bore in an engine block

An engine block, metallurgical combination technology, applied in the direction of engine components, machines/engines, cylinders, etc., can solve problems such as growth, achieve the effect of reducing weight, improving durability and performance, and reducing hole deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

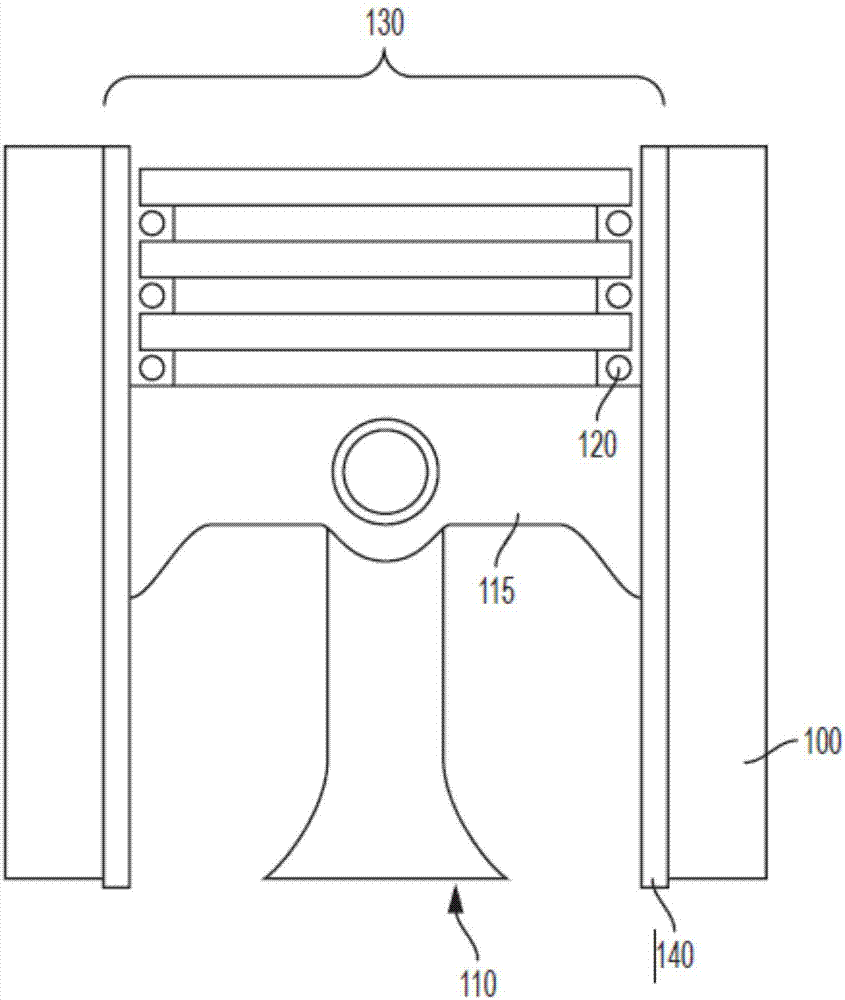

[0038] refer to figure 1 , the piston 110 is positioned within the cylinder bore 130 of the engine block 100 . Piston 110 includes a head 115 having one or more piston rings 120 . The cylinder liner 140 is installed in the cylinder bore 130 . During a combustion cycle of an internal combustion engine (ICE), an air / fuel mixture is provided to cylinders of the ICE (eg, cylinder 130 ). The air / fuel mixture is compressed and / or ignited and combusted to provide output torque via a piston (eg, piston 10 ) located within the cylinder. During operation of the ICE, cylinder liner 140 may be in contact with one or more rings 120 and / or piston 110 . Cylinder liner 140 may serve to prevent wear or degradation of engine block 100 from contact with piston 110 and / or one or more fuels and combustion gases. The engine block side profile on the exterior of cylinder liner 140 may substantially conform to the internal profile of cylinder 130 .

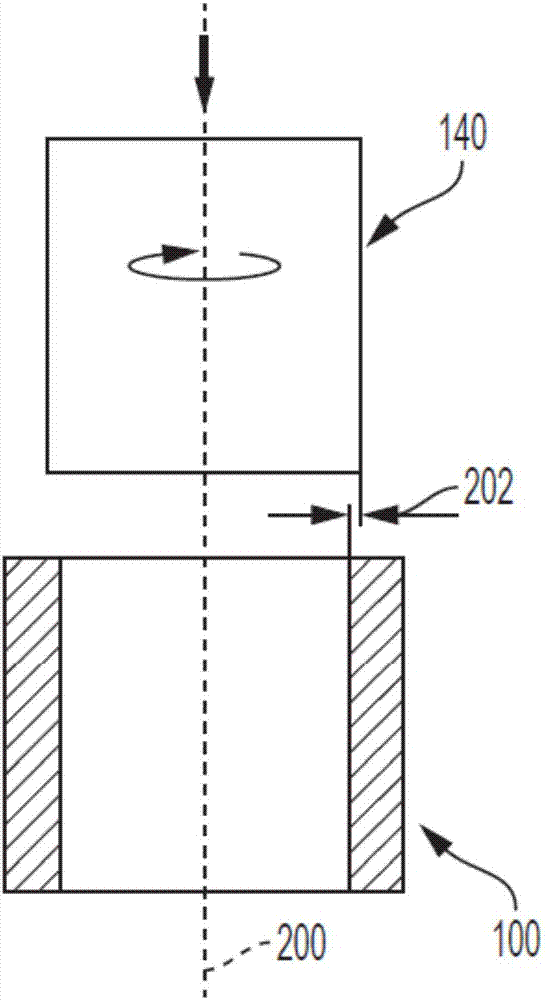

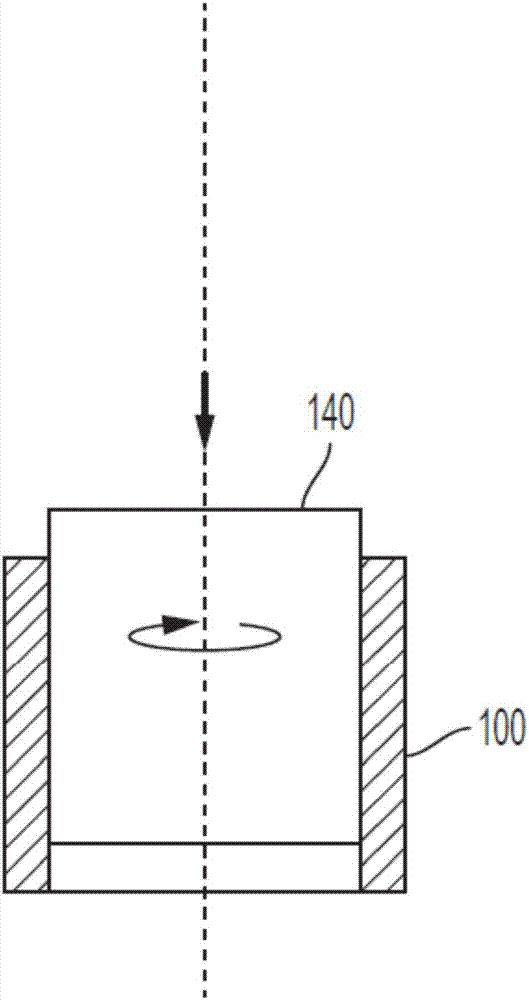

[0039] In an exemplary embodiment, cylinder l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com