Graphene dye sensitized solar cell and production method thereof

A technology of solar cells and dye sensitization, which is applied in the field of graphene dye-sensitized solar cells and its production, to achieve the effects of expanding the application range, simplifying the production process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

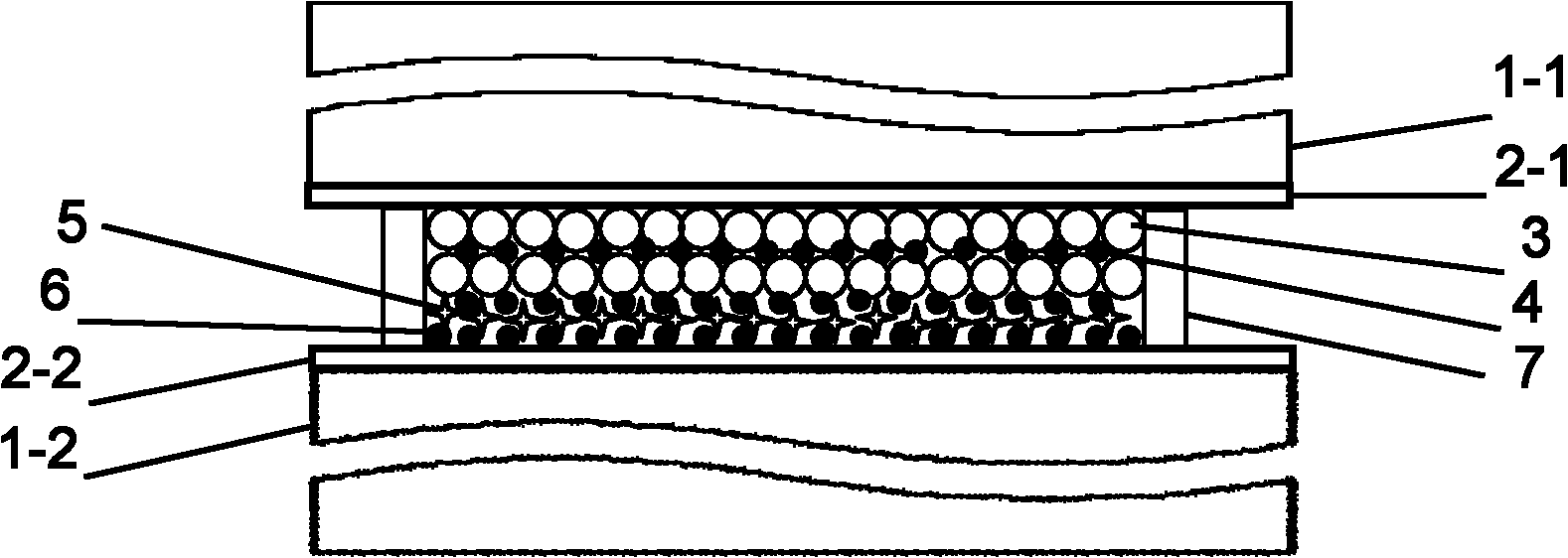

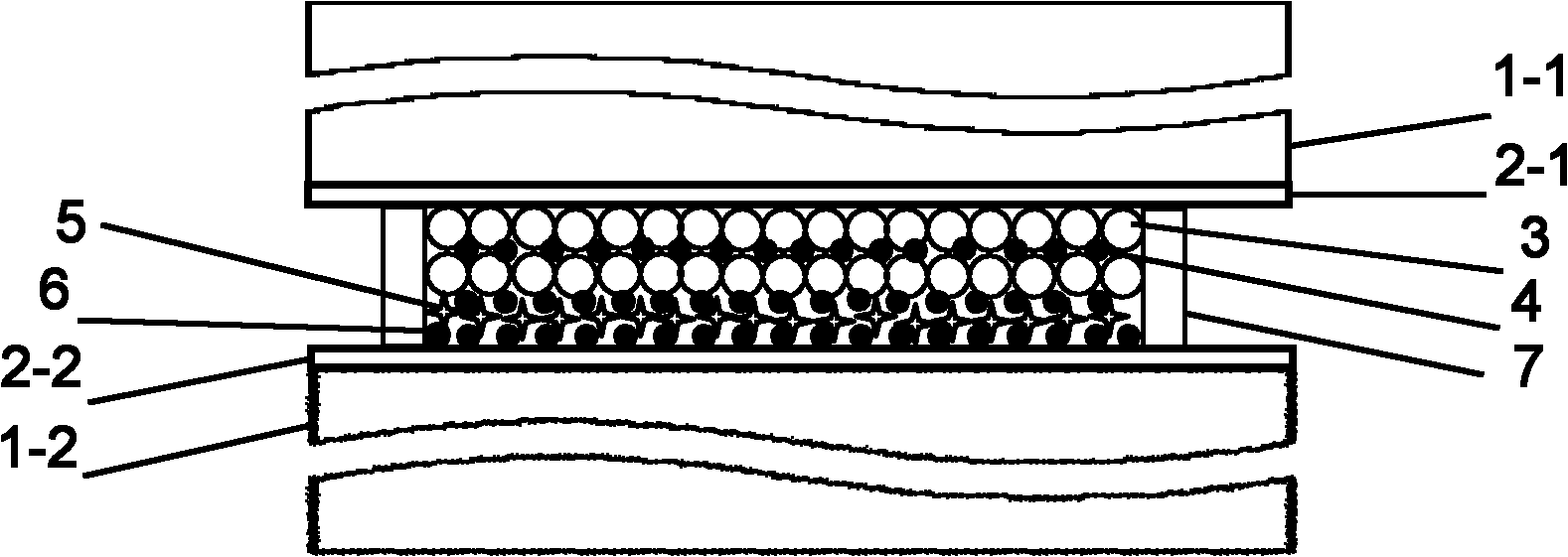

Image

Examples

Embodiment 1

[0019] Embodiment 1: Take solar cells using transparent glass as the upper and lower substrates 1-1, 1-2 as an example:

[0020] Step A. Preparation of photoanode:

[0021] A 1 . Lay the graphene conductive layer on the surface of the transparent glass substrate: firstly, the transparent glass with a thickness of 2 mm and an area of 2 × 2 cm as the substrate 1-1 is cleaned with deionized water and ethanol in sequence, and dried in vacuum before use The present embodiment adopts the graphene thin film gained by conventional chemical vapor deposition method as conductive layer, namely on the surface of the graphene thin film with the method for conventional chemical vapor deposition on the copper foil, after the organic colloid is spin-coated on the upper surface of the graphene thin film , dried at 100°C for 10 minutes; then the obtained copper foil with graphene film and organic adhesive layer was fed into FeCl with a concentration of 1mol / L 3 solution, etch off the copper...

Embodiment 2

[0028] Embodiment 2: Take PET (polyethylene terephthalate) in the transparent polyester plastic as the solar cell of upper and lower substrate 1-1, 1-2 as example:

[0029] Step A. Preparation of photoanode:

[0030] A 1 . Lay the graphene conductive layer on the surface of the PET substrate: first, the PET with a thickness of 0.2 mm and an area of 2 × 2 cm as the substrate 1-1 is cleaned with deionized water and ethanol in sequence, and vacuum-dried before use; 5 mg of graphene prepared by chemical method is ultrasonically dispersed in 10 ml of absolute ethanol to form graphene absolute ethanol solution, PET (transmittance 90%, thickness 0.2 mm) upper substrate 1-1 is placed on a rotary glue coater, This solution was added dropwise on the substrate 1-1. Rotate at a speed of 1000r / min for 30s to obtain a layer of graphene film, then dry at 80°C for 5min, and repeat rotation-drying to obtain a graphene conductive layer 2-1 with a thickness of about 1 μm;

[0031] A 2 . La...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com