Steam turbine high-pressure steam guide pipe drainage system and drainage method

A steam duct and steam turbine technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems affecting the operation safety of the unit, water or cold steam in the high-pressure cylinder, and hydrophobic accumulation in the steam duct, so as to eliminate the problems. Risk of ingress of water or cold steam, reduction of steam generation, and effect of preventing water ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

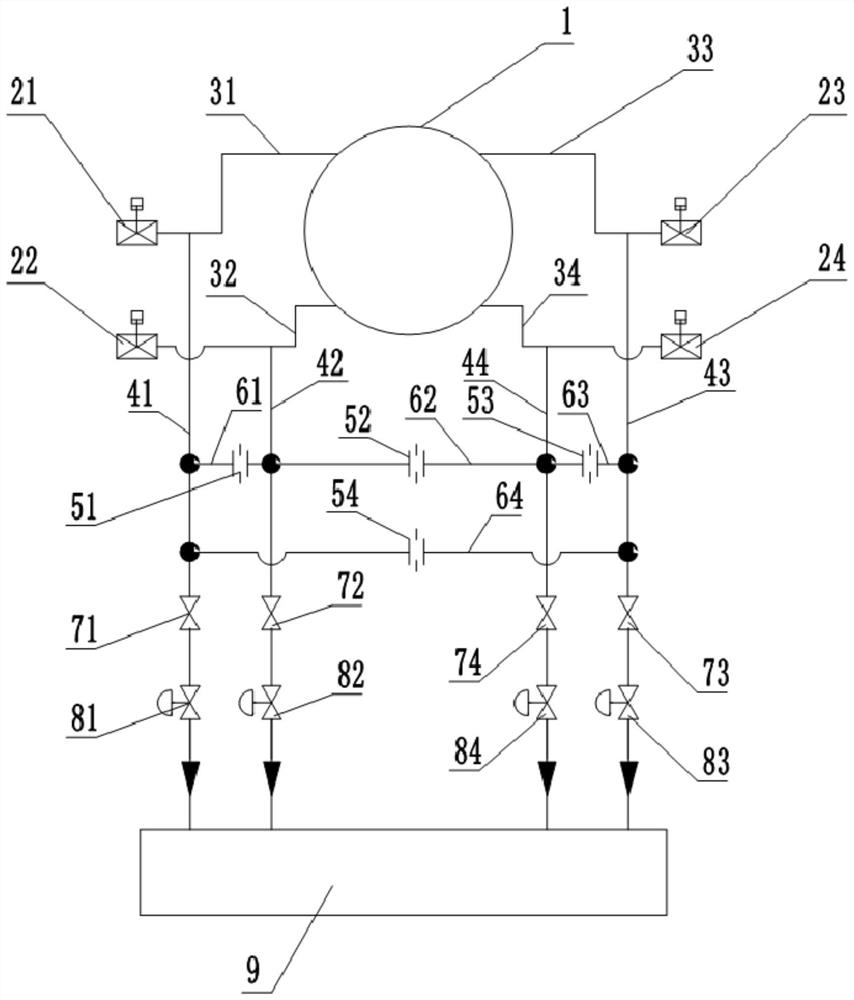

[0033] A steam turbine high-pressure steam guide pipe drainage system, such as figure 1 As shown, it includes a high-pressure cylinder 1 applied to the field of steam turbines. The high-pressure cylinder 1 is provided with 4 steam guide pipes, each of which is provided with a main steam regulating valve, and each of the steam guide pipes is also provided with a main steam control valve. The drain pipes are connected respectively, and the drain pipes are connected to the drain expander through the valve assembly;

[0034] Warm pipes are arranged between the drain pipes, and the drain pipes are connected in series through the warm pipes, or the drain pipes are connected in pairs through the warm pipes;

[0035] A throttling component is also arranged on the pipeline of the warming pipe, so as to ensure the amount of steam in the warming pipe while reducing the steam passing between the steam guiding pipes.

[0036] In this embodiment, different from the traditional structure, i...

Embodiment 2

[0046] A steam turbine high-pressure steam guide tube drainage method adopts a steam turbine high-pressure steam guide tube drainage system in embodiment 1, comprising the following steps:

[0047] a. During the start-up and shutdown phases of the steam turbine unit, the manual steam trap and the power steam trap are opened, and the water generated by each steam guide line is discharged to the water expansion container through the water pipe;

[0048] b. When the steam turbine unit is running at high load, all the main steam control valves are opened, the manual steam trap is normally open, the power steam trap is closed, and the steam enters the high-pressure cylinder through various main steam control valves and steam guide pipes;

[0049] c. When the steam turbine unit is in deep peak regulation or partial load, the manual traps on the drain lines of each steam guide are normally open, the power traps are closed, and the pressure in the steam guide behind the closed main ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com