Continuous vacuum coating sealing lock for metal strip

A metal strip, vacuum coating technology, applied at the entrance and/or exit of the metal strip. field, it can solve the problems of large vacuum chamber, difficult vacuuming, high energy consumption, etc., and achieve the effect of good sealing and reducing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will facilitate further understanding of the present invention in any form of techniques, but will not limit the invention in any form.

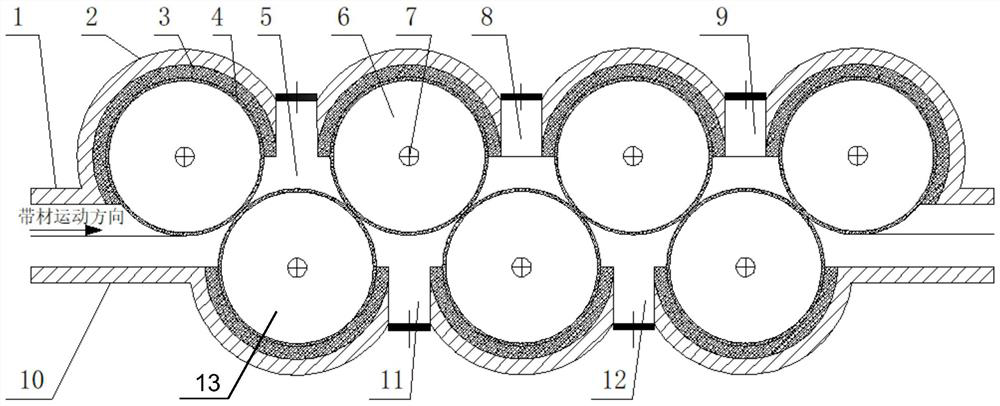

[0026] like figure 1 As shown, the continuous vacuum coating sealing lock of the metal strip provided in this embodiment includes a detachable upper sealing 1 and a lower sealing cover 10, provided between the upper sealing cover 1 and the lower sealing cover 10. Sealing roller;

[0027] The upper sealing cover 1, the lower sealing cover 10 is made of stainless steel; the upper sealing cover 1 and the lower sealing cover 10 are provided with the shaft case 2 adapted to the sealing roller, i.e., the upper sealing cover 1 and the lower sealing cover 10 and the sealing roller. The surface is arranged in the form of the shaft case 2; the inner surface of the shaper casing 2 is provided with an axle shell flexible layer 3; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com