Cyclone type biomass powder combustor

A biomass powder, cyclone technology, applied in burners, burners for burning powder fuel, combustion methods, etc., can solve the problems of short-circuit escape of slag, impure combustion of carbon particles, and inexhaustible combustion, so as to solve the problem of tuyere knots. The effect of slag clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples can make those skilled in the art of the present invention understand the present invention more specifically, but do not limit the specific implementation of the present invention.

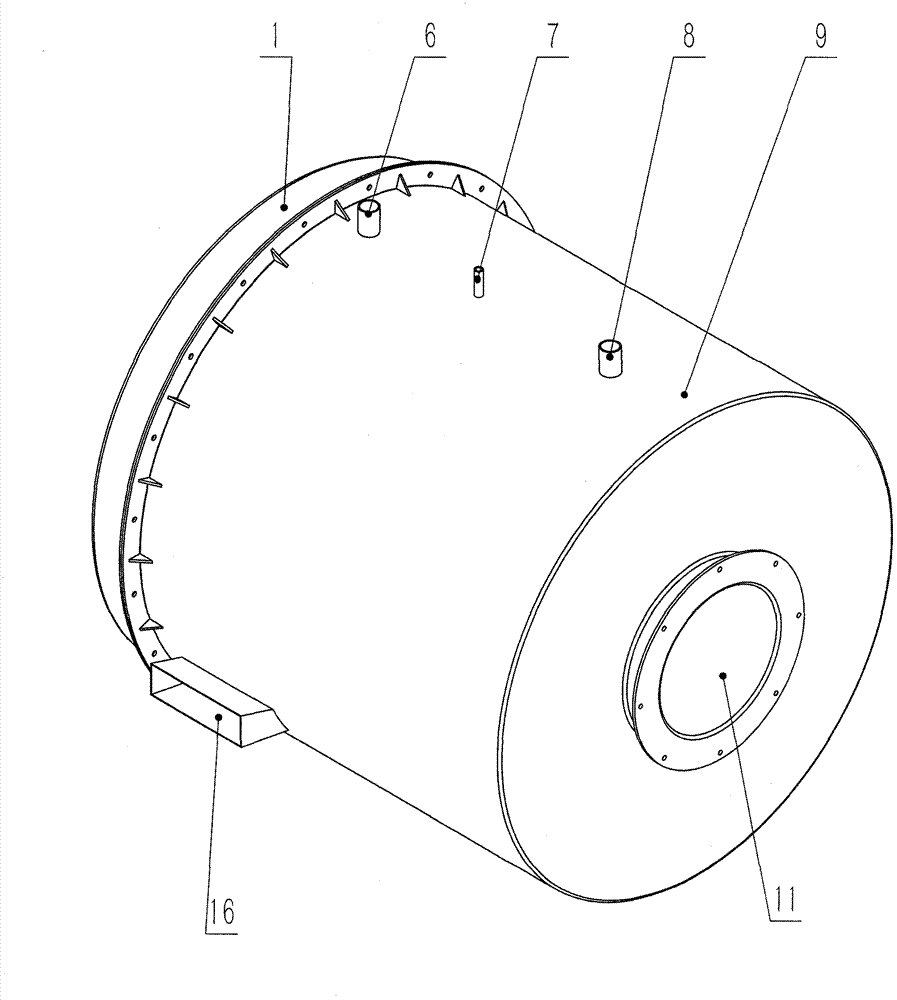

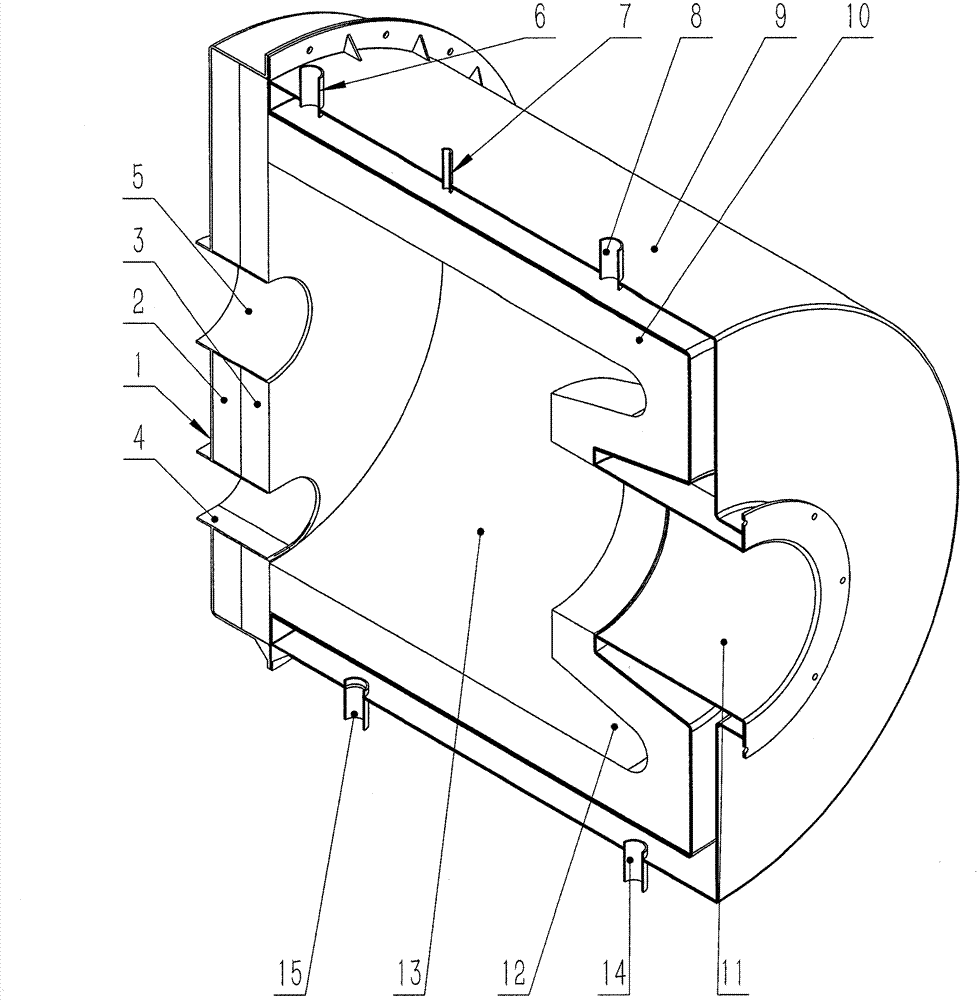

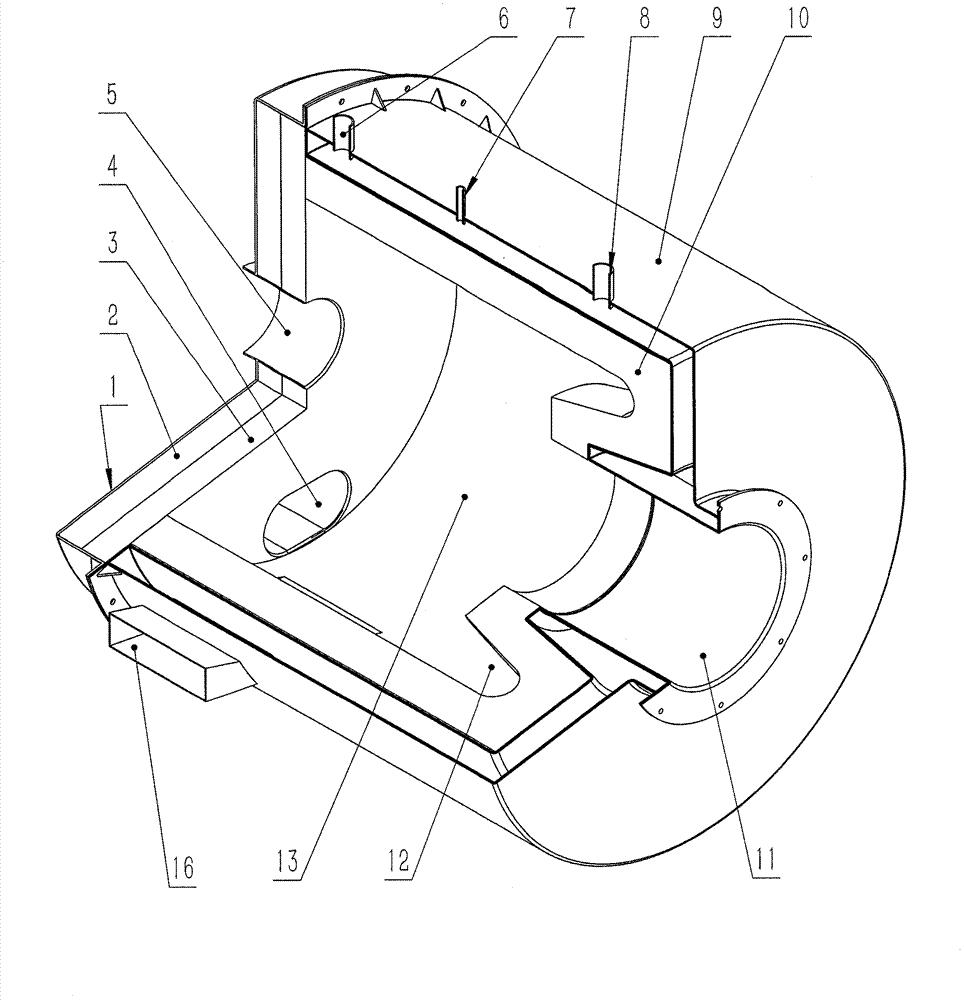

[0041] Example one, there is a cyclone type biomass powder burner with a right-angle fire tuyere 11, such as Figure 1 to Figure 6 shown.

[0042] The burner is composed of a water-cooling sleeve 9, an end cover 1, an end cover refractory layer 3, an end cover insulation layer 2, and a body refractory layer 10. The gradually narrowing cyclone port 16 penetrates into the cyclone combustion chamber 13 from the tangential direction of the main body, provides a strong cyclone for the cyclone combustion chamber 13, and forms a swirling flow field of wall-attached combustion and suspension combustion. One end of the cyclone combustion chamber 13 is the cyclone port 16, the feeding port 5 and the ash outlet 4, and the other end is the fire tuyere 11, and there is no hole t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com