Ultrasonic spiral flat tube heat exchanger

An ultrasonic and heat exchanger technology, applied in the field of ultrasonic spiral flat tube heat exchangers, can solve the problems of fouling, coking and clogging of crude oil heat exchangers, short service life of heat exchangers, and low dehydration temperature of crude oil, etc. The effect of internal scaling, small energy loss, and avoiding coking and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

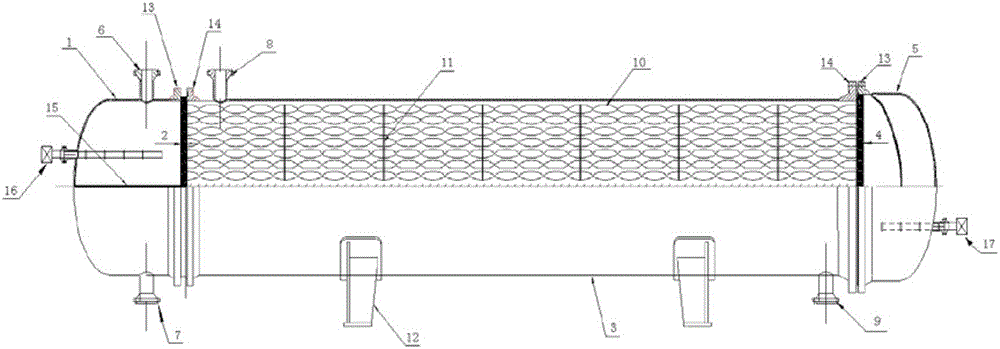

[0014] Such as figure 1 As shown, an ultrasonic spiral flat tube heat exchanger of the present invention includes a left end face head 1 connected in sequence from left to right, a porous left tube sheet 2, a heat exchanger shell 3, and a porous right tube sheet 4 and the right end face head 5, the top of the left end face head 1 is provided with a heated fluid inlet 6, the bottom is provided with a heated fluid outlet 7, the top of the heat exchanger shell 3 is provided with a heating fluid inlet 8, and the bottom is provided There is a heating fluid outlet 9 and a saddle 12, and a spiral flat tube 10 is arranged horizontally inside, and the tube bundles of the spiral flat tube 10 are fixed by pipe clamps 11, which not only ensures the stable support of the pipeline, but also does not affect the flow of liquid in the shell side , the spiral flat tube 10 adopts a stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com