Device for treating kitchen waste slurry fermentation wastewater

A technology for food waste and fermented wastewater, which is applied in water/sewage treatment, water treatment parameter control, special compound water treatment, etc. It can solve problems such as high operating costs, reverse osmosis membrane clogging, and unsatisfactory conditions, and improve operating efficiency. , Effective denitrification and avoid frequent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

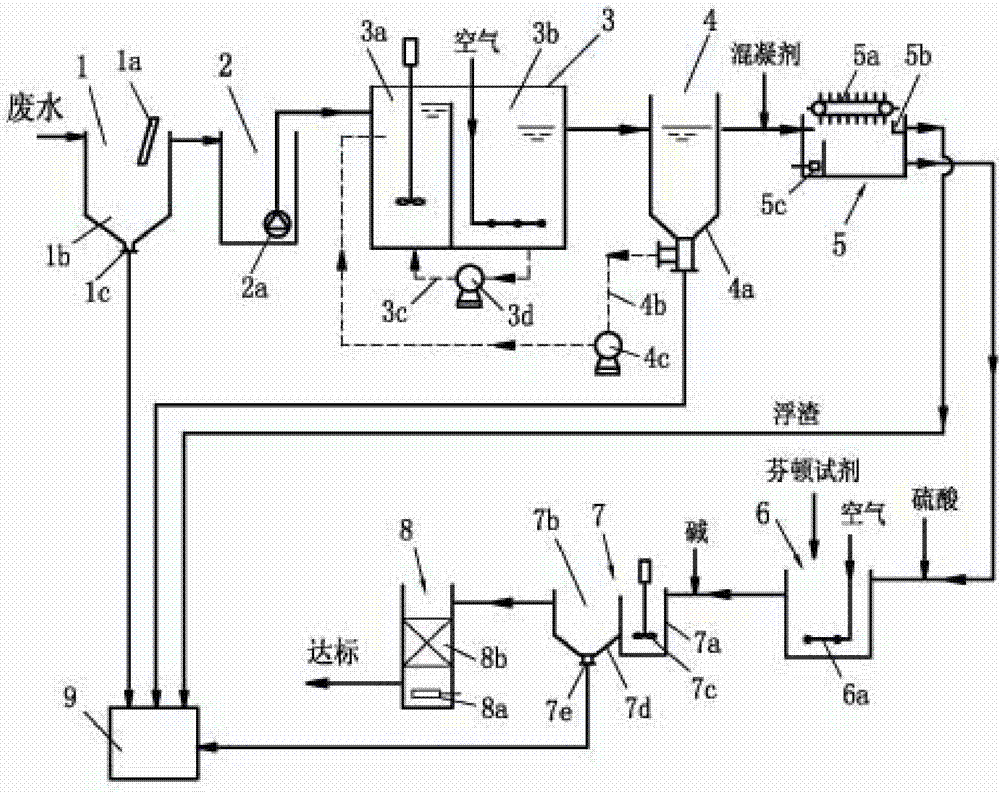

[0024] See the attached picture for a treatment scale of 100m 3 / d of kitchen waste wastewater as an example, the specific implementation is as follows:

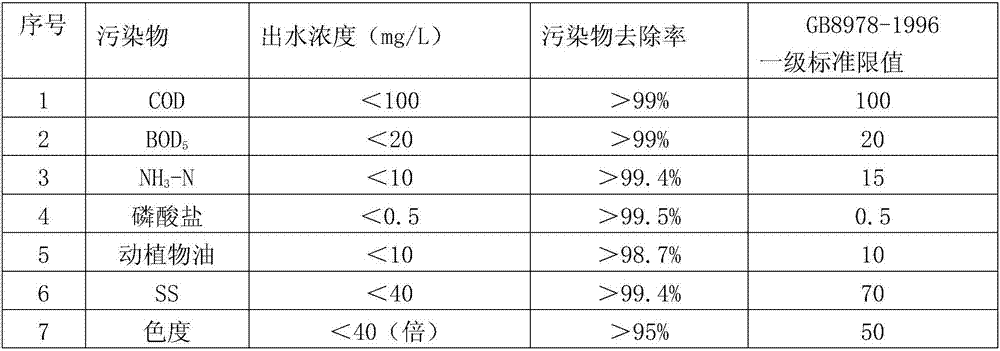

[0025] Wastewater after anaerobic digestion and dehydration of food waste slurry and waste water produced in other processes of food waste treatment Water quality: COD: 12000-15000mg / L, BOD 5 : 4500~5000mg / L, TN: 2100~2400mg / L, NH 3 -N: 1800~2000mg / L, TP: 110~130mg / L, SS: 7000~10000mg / L, animal and vegetable oil: 800~1000mg / L, pH: 7.5~8, chromaticity: 800~1000 times.

[0026] Referring to the accompanying drawings, the present invention includes an oil separation primary sedimentation tank 1, a regulating tank 2, an A / O biochemical treatment device 3, a sedimentation tank 4, an air flotation device 5, a Fenton reactor 6, a coagulation sedimentation tank 7, an aeration Biological filter 8;

[0027] The oil-separating primary sedimentation tank 1 has an oil slick baffle 1a on the top, a sludge chamber 1b on the bottom, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com