Powerful sports sealed suction device

A sporty and powerful technology that can be used in vacuum cleaners, household appliances, cleaning equipment, etc., to solve problems such as inability to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

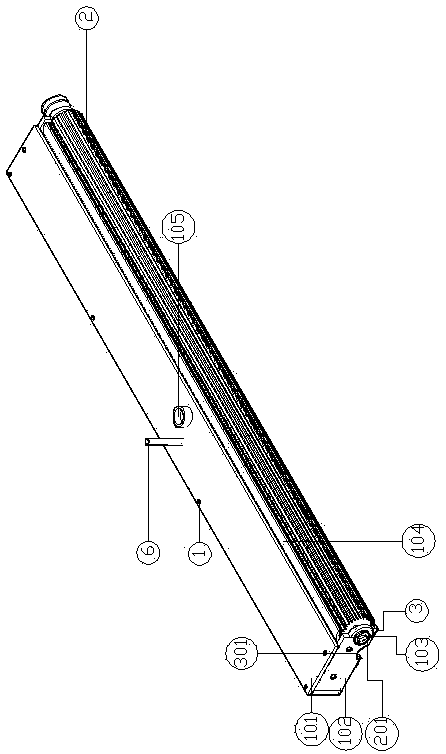

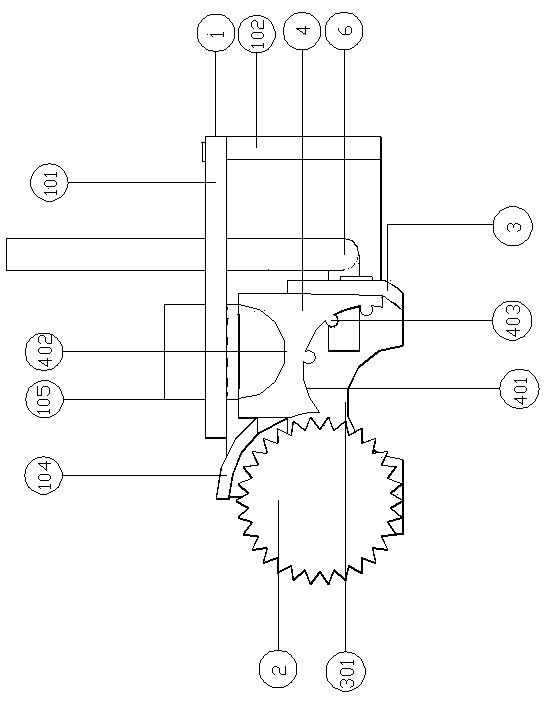

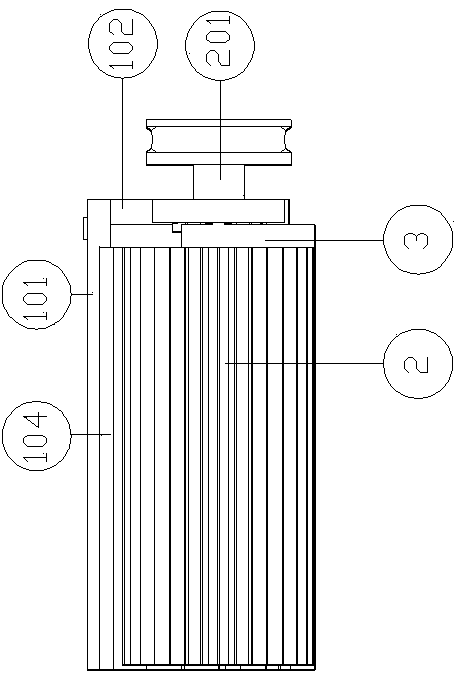

[0030] Embodiment one: if Figure 1-6 , a powerful motion sealed suction device, including a casing 1, a straight-toothed rubber roller 2, and a rubber scraper 3, wherein the casing 1 is composed of a horizontal plate 101 and a vertical plate 102, wherein the horizontal plate 101 and the vertical plate 102 Both are plastic plates or metal plates, and the bottom surface of the horizontal plate 101 is connected with a vertical plate 102 by bolts, wherein the vertical plate 102 is formed by bending two ends of a plastic plate or a metal plate, wherein the two ends of the vertical plate 102 are fixed There is a bearing seat, and a bearing 103 is fixed in each bearing seat, and a rotating shaft 201 is fixed in the inner ring of each bearing 103 through a flat key, and a straight-toothed rubber roller 2 is inserted on the rotating shaft 201, and the straight-toothed rubber roller The cylinder 2 is a cylindrical roller with straight tooth grooves on the surface. The teeth of the stra...

Embodiment 2

[0031] Embodiment two: except that following structure is different, all the other are all with embodiment one:

[0032] Such as Figure 7 , the teeth of the straight-toothed rubber roller 2 are consistent with those of the shifting gear, which increases the service life of the straight teeth of the straight-toothed rubber roller 2 and prevents the glass from easily displacing the straight teeth of the straight-toothed rubber roller 2 Cuts result in reduced sealing performance.

Embodiment 3

[0033]Embodiment three: except that following structure is different, all the other are all with embodiment one:

[0034] Such as Figure 8 , where the rear end face of the vertical plate 102 and the bottom of the bearing seats at both ends of the vertical plate 102 are welded with threaded sleeves 501, and each threaded sleeve 501 is screwed into a matching bolt, and the bottom of the bolts is welded with floor rollers 5. The landing roller 5 is a universal wheel, and the direction can be adjusted freely. By rotating the bolt to adjust the length of the bolt extending out of the threaded sleeve 501, the relative position of the straight-toothed rubber roller 2 to the ground can be adjusted, so that the straight-toothed rubber roller The straight teeth of the roller 2 will not generate greater frictional force with the ground, resulting in the non-rotation of the straight toothed rubber roller 2, thus losing the functions of sealing and cleaning dirt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com