Two-way brush cleaning device of equipment for extracting and separating oil from water and water surfaces

A technology for lowering brushes and cleaning brushes is applied in the field of oil slick recovery ships, which can solve the problems of poor structural design of the brush cleaners, inability to achieve bidirectional operation, and insufficient removal of oil slicks, so as to achieve remarkable application effects and improve work efficiency. The effect of quality and work efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

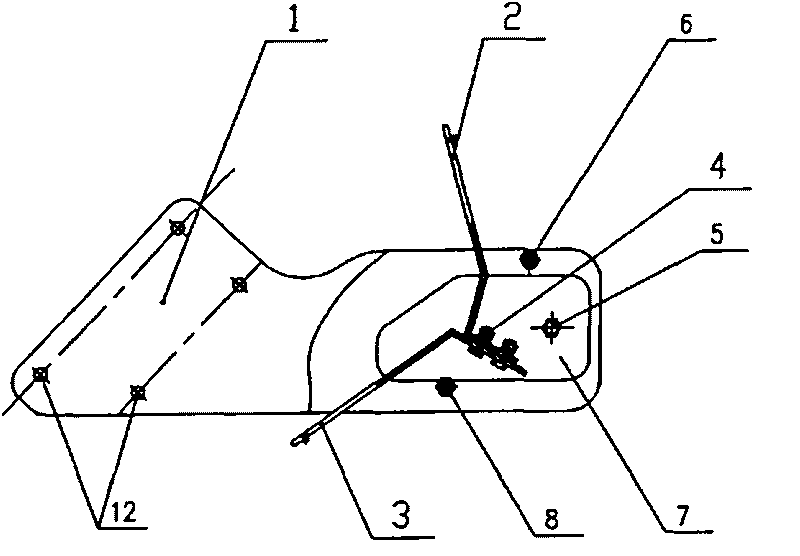

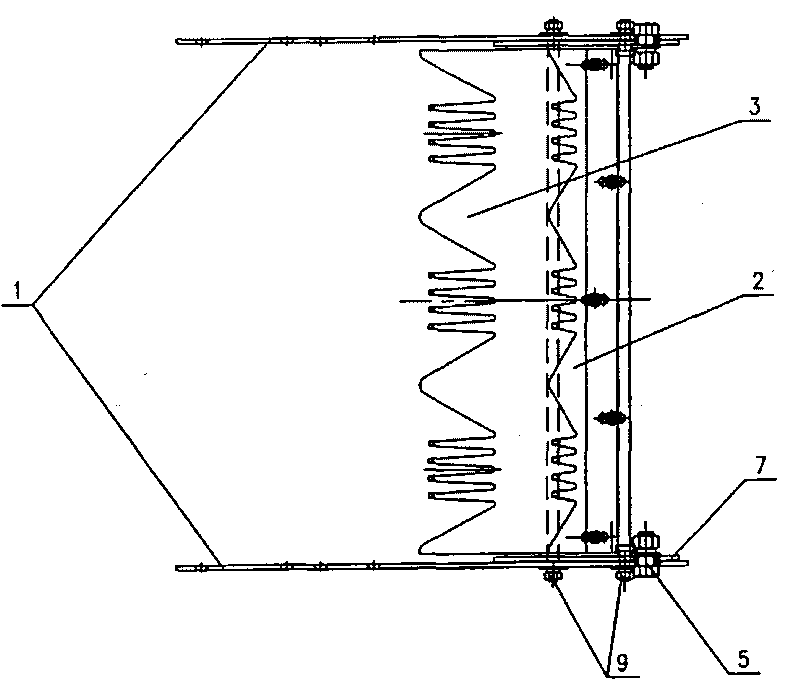

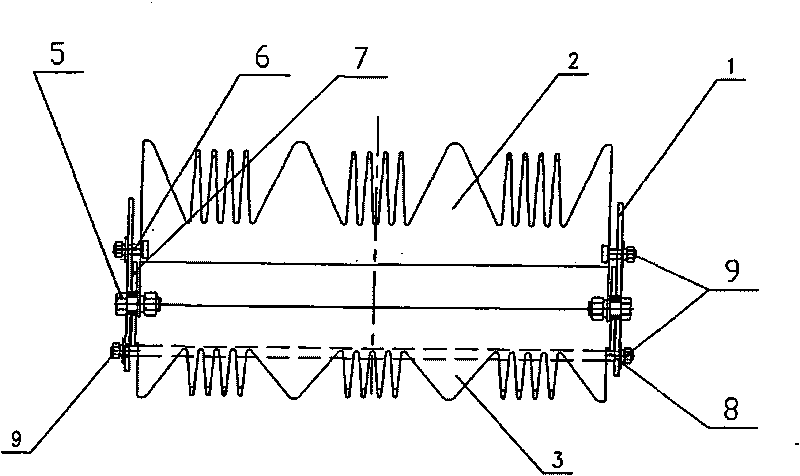

[0022] Such as Figure 1-Figure 5 As shown, a two-way brush cleaner for extracting and separating oil from water and water surface, the two-way brush cleaner includes two fixed support plates 1, an upper brush cleaner 2, a lower brush cleaner 3, and fastening bolts 4 , support center pin shaft 5, limit pin 6, rotating connecting plate 7, limit support rod 8 and lock nut 9; the rear parts of the two fixed support plates 1 are respectively provided with bolt holes 12 fixedly connected with the hard brush frame , that is, the two fixed support plates 1 are symmetrically fixed on the hard brush frame by bolt connection; the inner side of the front part of the fixed support plate 1 is respectively provided with a rotating connection plate 7 that can rotate around the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com