Large-diameter sealing element

A seal and large-diameter technology, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as unachievable sealing, unsatisfactory, and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

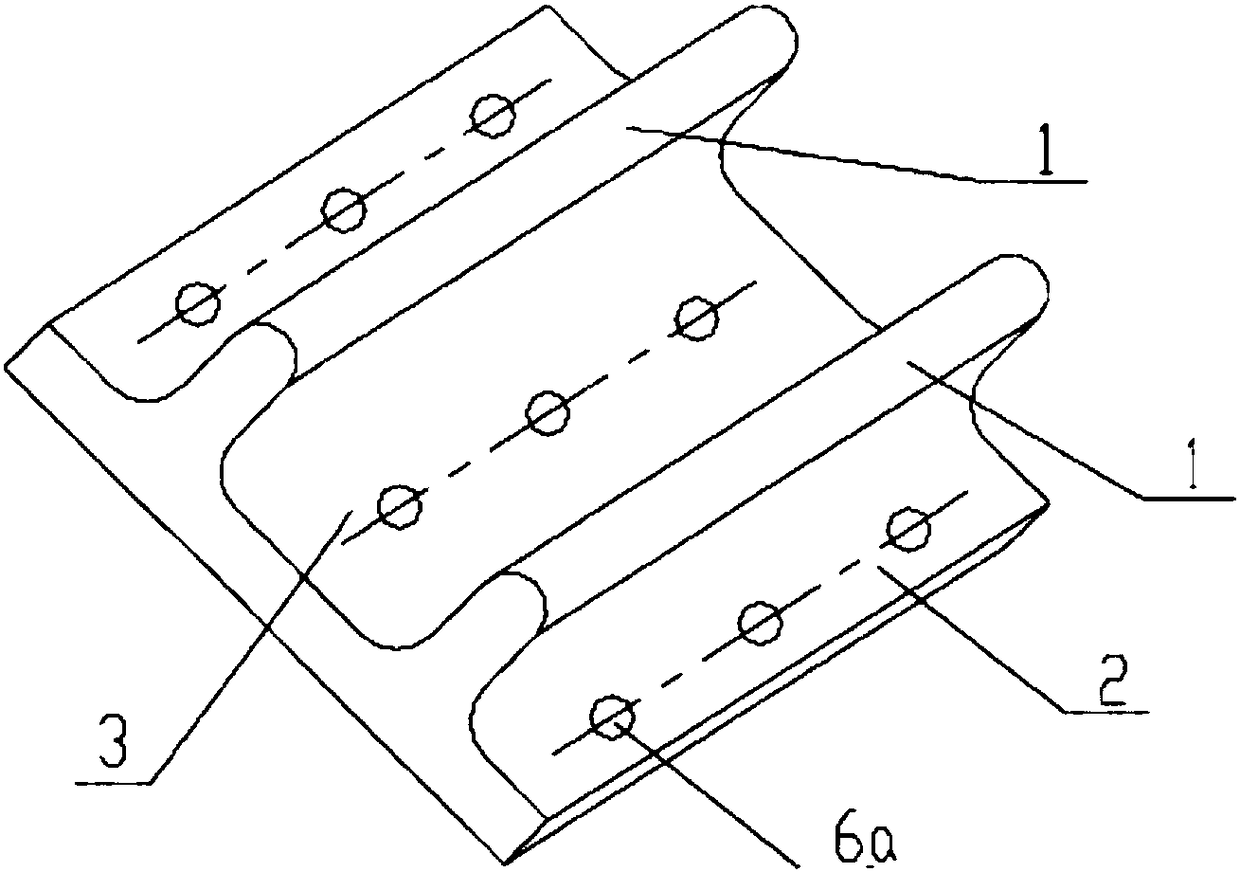

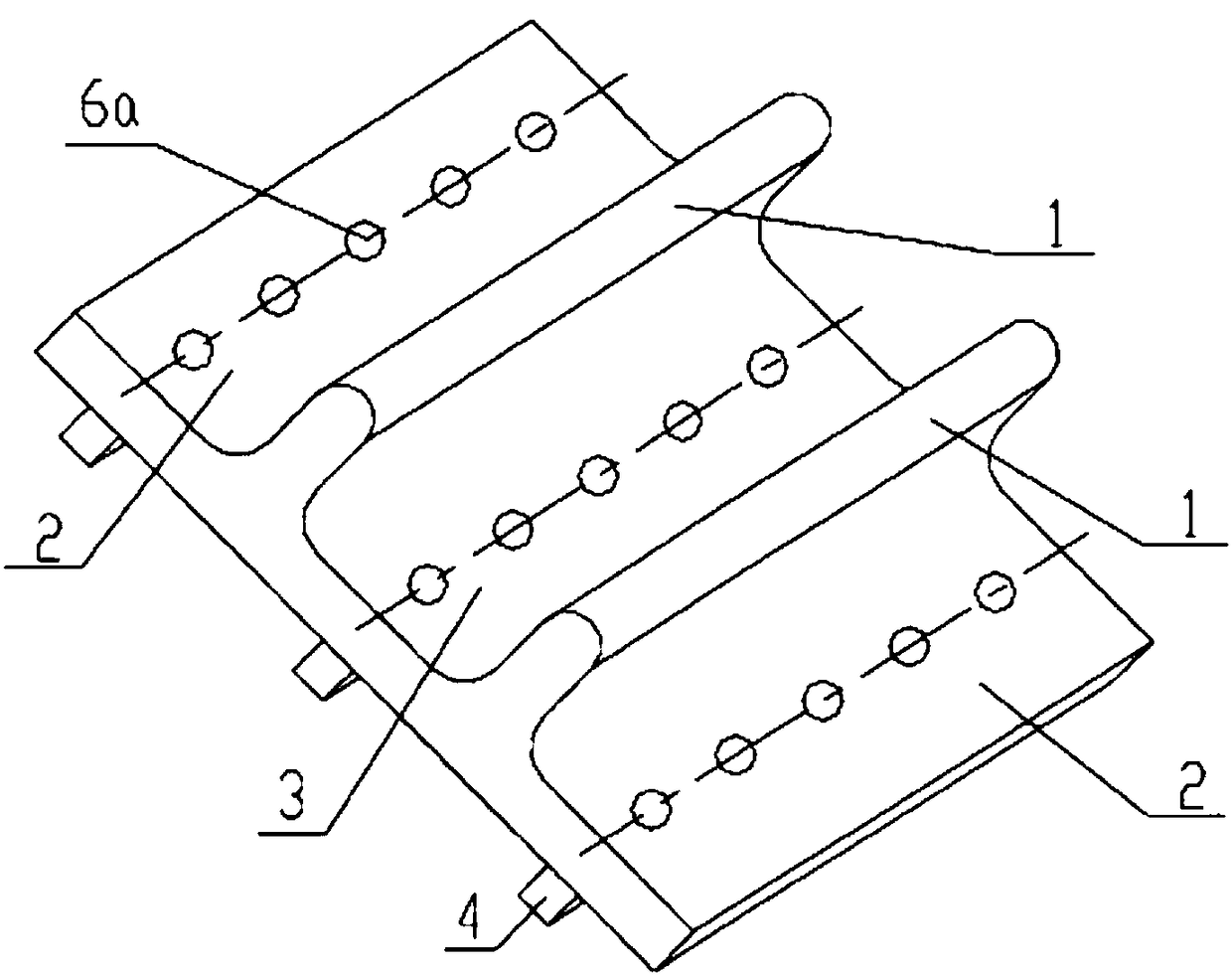

[0025] The invention provides a large-diameter sealing element, which is used to ensure the sealing effect of the plane or arc surface between two parts that need to be sealed.

[0026] In order to make the above-mentioned purpose, features and advantages of the present invention more obvious and easy to understand, the large-diameter sealing member of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

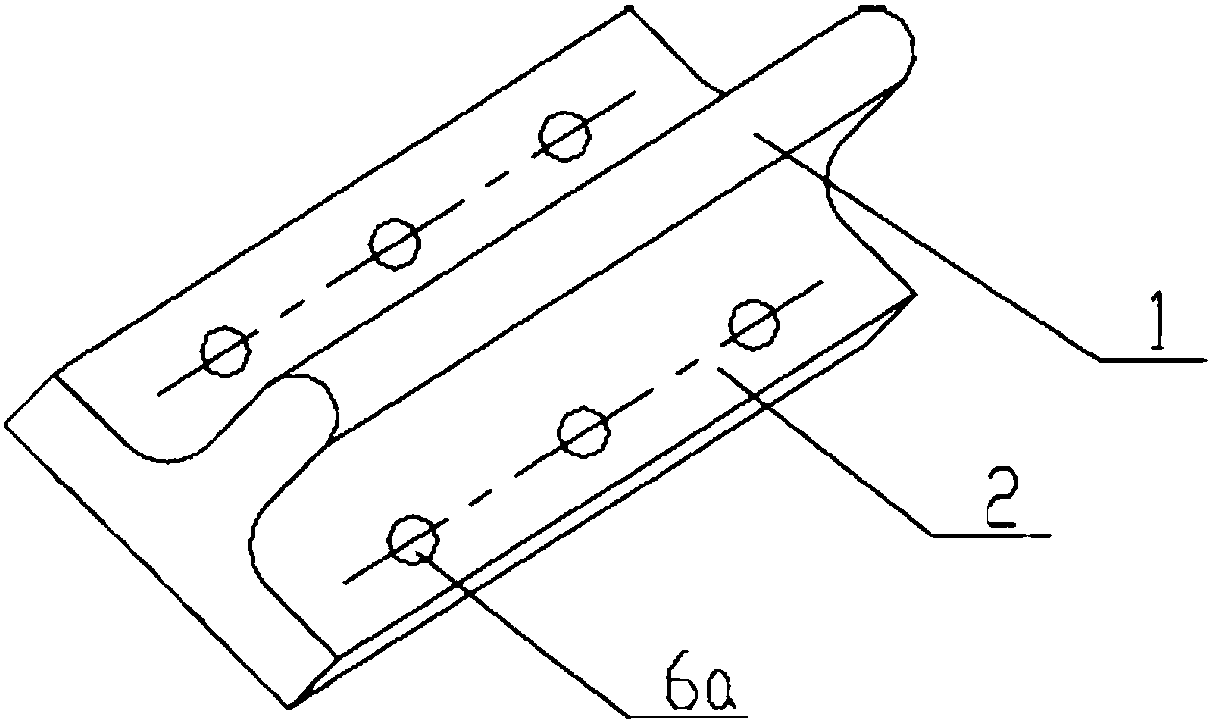

[0027] see figure 1 , which is an axonometric view of the first embodiment of a large-diameter seal according to the present invention.

[0028] The large-diameter seal described in the embodiment of the present invention can be used for sealing a plane or an arc or a curved surface between two parts that need to be sealed.

[0029] The large-diameter sealing member described in the first embodiment of the present invention includes a protrusion 1, and the length of the protrusion 1 is equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com