Novel liquid metal transfer pump

A technology for conveying liquid metal and cadmium is applied in the field of new liquid metal conveying pumps, which can solve the problems of crystal blockage and harm, and achieve the effect of prolonging the service life and ensuring the integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

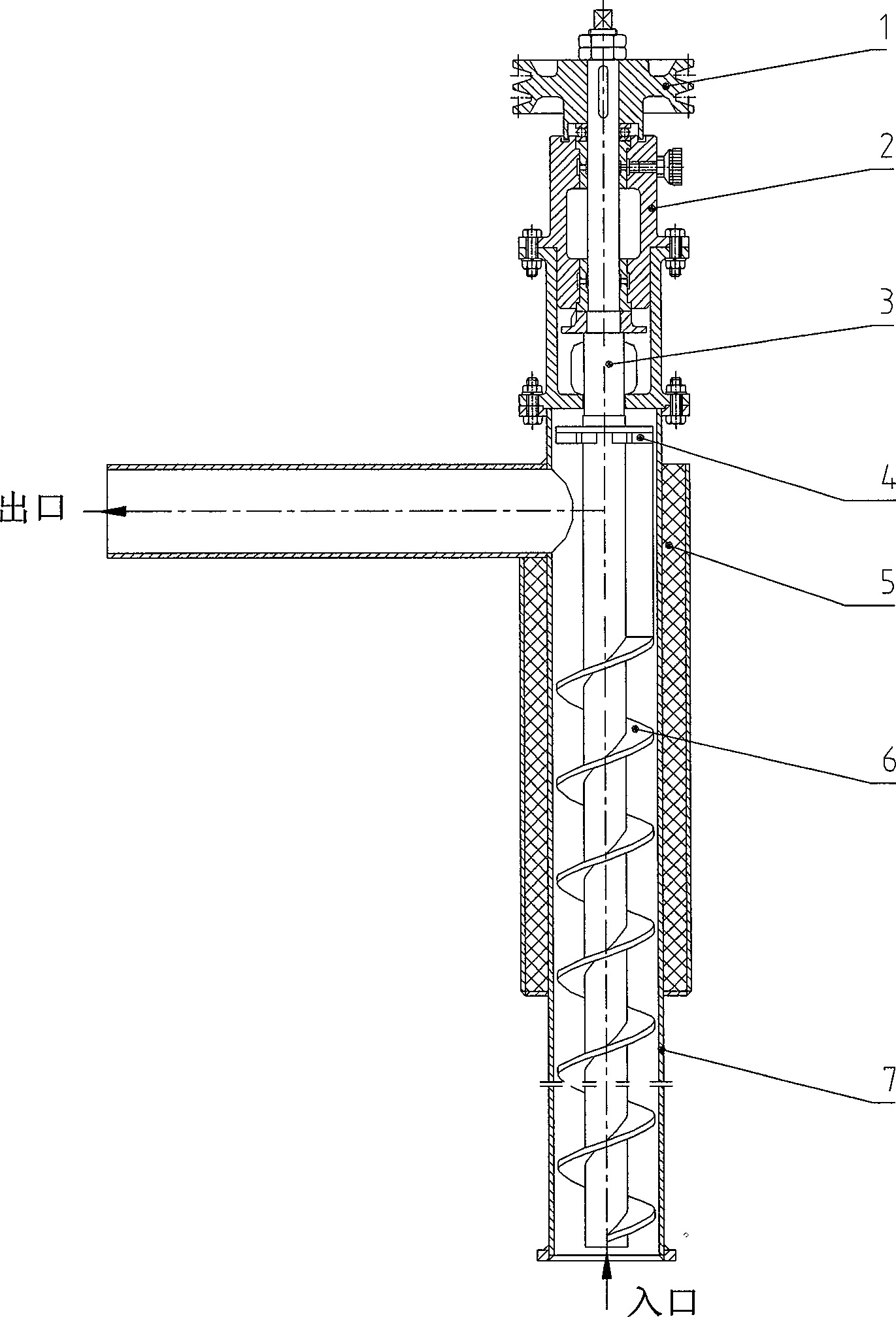

[0021] A liquid metal cadmium transfer pump such as figure 1 As shown, it includes a pump casing 7, a drive shaft, and a vane. The pump casing 7 is an upright cylinder, and the upper section outside the cylinder is covered with an insulating layer 5, and the insulating layer 5 covers the part of the cylinder exposed to the air. The transmission shaft is the screw shaft 3 installed in the cylinder, the screw shaft 3 is driven by the pulley 1 arranged at its tail end, the blade is the screw blade 6 surrounding the screw shaft, and the screw shaft 3 is driven by the transmission bearing fixed on the top of the cylinder Support, the transmission shaft is supported by the transmission bearing seat 2 coaxially coupled with the cylinder. The sealing impeller 4 is used to seal the transmission bearing seat 2 and the cylinder, and the sealing impeller 4 is a disc with three blades whose blade angles are opposite to those of the helical blades.

Embodiment 2

[0023] A liquid metal cadmium transfer pump such as figure 1 As shown, it includes a pump casing 7, a drive shaft, and a vane. The pump casing 7 is an upright cylinder, and the upper section outside the cylinder is covered with an insulating layer 5, and the insulating layer 5 covers the part of the cylinder exposed to the air. The transmission shaft is the screw shaft 3 installed in the cylinder, the screw shaft 3 is driven by the pulley 1 arranged at its tail end, the blade is the screw blade 6 surrounding the screw shaft, and the screw shaft 3 is driven by the transmission bearing fixed on the top of the cylinder Support, the transmission shaft is supported by the transmission bearing seat 2 coaxially coupled with the cylinder. The transmission bearing seat 2 and the cylinder are sealed by a sealing impeller 4, which is a disc with four blades whose blade angles are opposite to those of the helical blades.

Embodiment 3

[0025] A liquid metal cadmium transfer pump such as figure 1 As shown, it includes a pump casing 7, a drive shaft, and a vane. The pump casing 7 is an upright cylinder, and the upper section outside the cylinder is covered with an insulating layer 5, and the insulating layer 5 covers the part of the cylinder exposed to the air. The transmission shaft is the screw shaft 3 installed in the cylinder, the screw shaft 3 is driven by the pulley 1 arranged at its tail end, the blade is the screw blade 6 surrounding the screw shaft, and the screw shaft 3 is driven by the transmission bearing fixed on the top of the cylinder Support, the transmission shaft is supported by the transmission bearing seat 2 coaxially coupled with the cylinder. The sealing impeller 4 is used to seal the transmission bearing seat 2 and the cylinder, and the sealing impeller 4 is a disc with 8 blades whose blade angles are opposite to those of the helical blades.

[0026] The invention works like this:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com