Anti-coking cyclone separator capable of achieving dynamical material seal

A cyclone separator and anti-coking technology, which is applied in the direction of the cyclone device and the device where the axis of the cyclone can be reversed, etc., can solve the failure of the cyclone separator, the danger caused by the mixing of air and pyrolysis gas, and the clogging of coke blocks Legs and other problems to achieve the effect of reducing deposition and coking, ensuring long-term safe operation, and increasing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

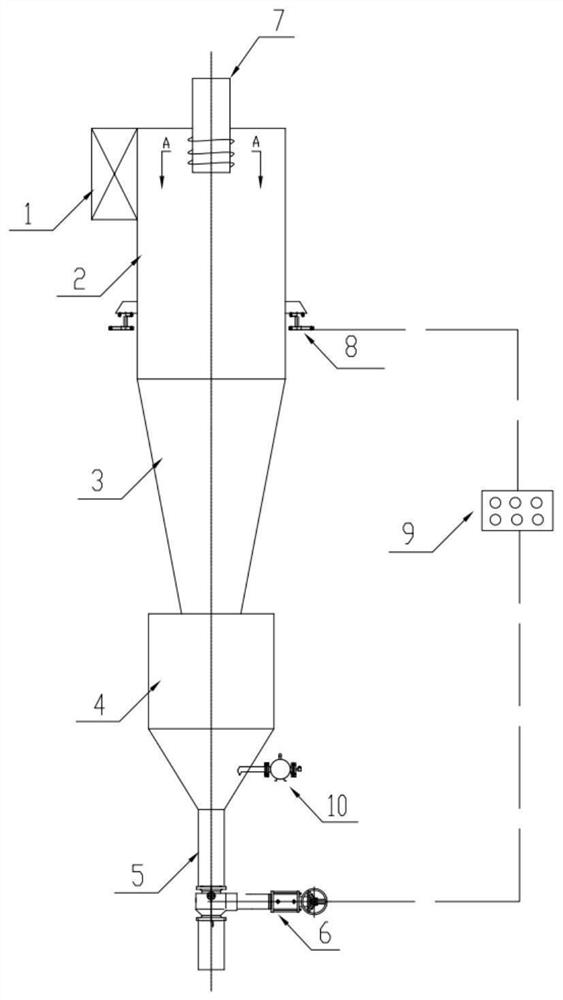

[0029] like figure 1 As shown, an anti-coking cyclone separator capable of dynamic material sealing includes a feed inlet 1, a cylinder body 2, a cone body 3, a storage bin 4, a material leg 5, a feeding controller 6, a center pipe 7, a weighing Heavy sensor 8, electric control system 9, arch breaking device 10, etc.

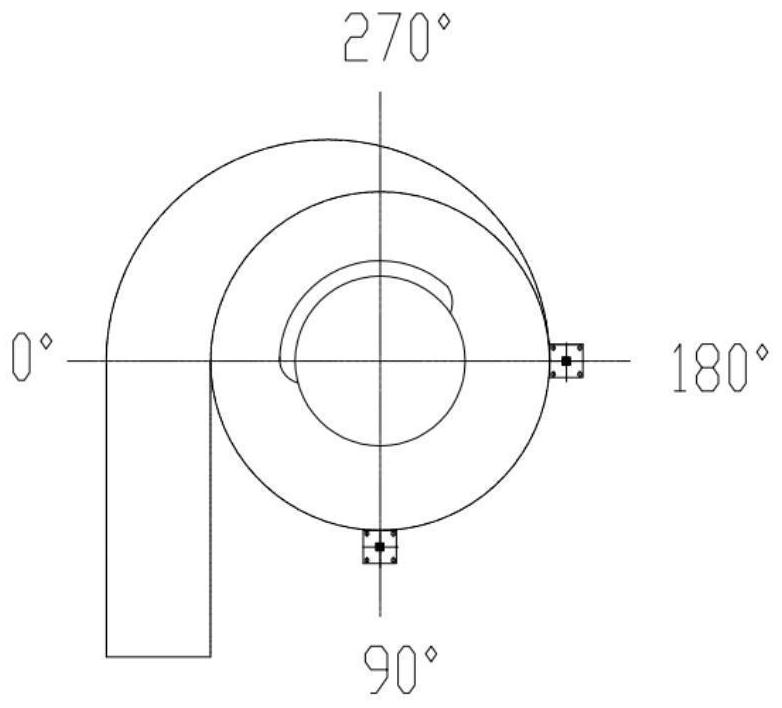

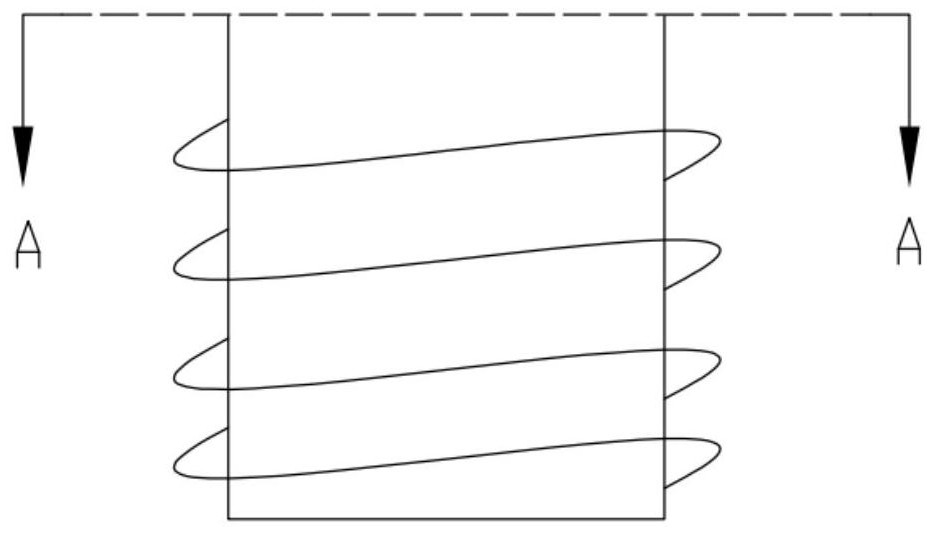

[0030] The shape of the feed inlet 1 can be circular, trapezoidal or rectangular. The feed port 1 is connected tangentially to the cylinder body 2, and the high-temperature dust-laden pyrolysis gas enters the interior of the cylinder body 2 tangentially from the feed port 1, and an external vortex is generated inside the cylinder body 2. The outer vortex is a high velocity gas flow rotating in a helical pattern from the top of the barrel 2 along the conical taper to the narrow end region at the bottom of the cone 3 . The dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com