Electrolytic tank used for post-treatment of copper foil

An electrolytic cell and copper foil technology, applied in the electrolytic process, electrolytic components, etc., can solve the problems of high cost, difficult transmission, low transmission precision, etc., achieve the effects of convenient installation and adjustment, anti-corrosion and power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

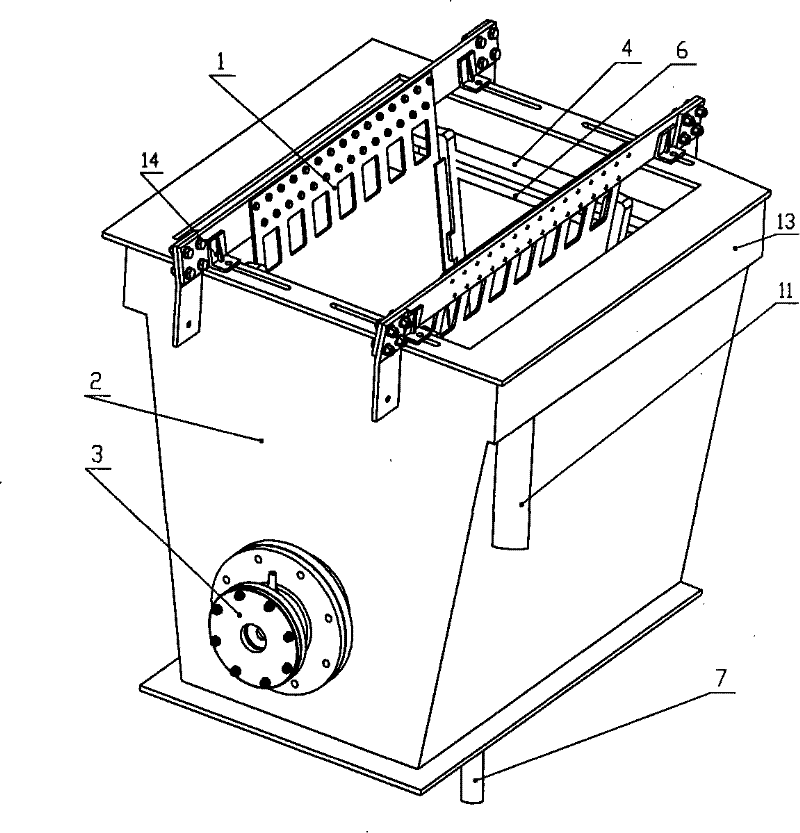

[0029] Such as figure 1 , this embodiment includes a tank body 2 and two anode plate devices 1 . The anode plate device is an anode plate device with a holding frame.

[0030] Such as figure 1 , The tank body 2 is a symmetrical structure, which is welded by PVC material. The two opposite end plates of the tank body are inverted isosceles trapezoidal plates; the other two opposite tank body side plates are rectangular plates, forming a bucket-shaped tank body with a large upper part and a smaller bottom part in the inner cavity and shape. The angle between the plate and the base plate is the same as the angle between the anode plate arrangement and the base plate.

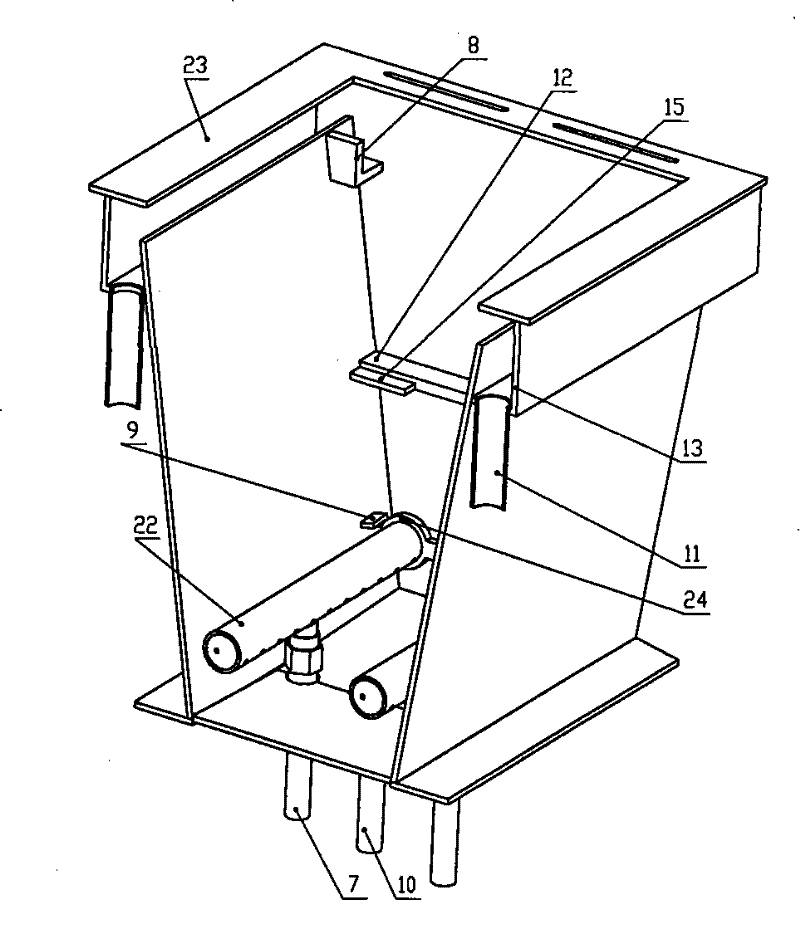

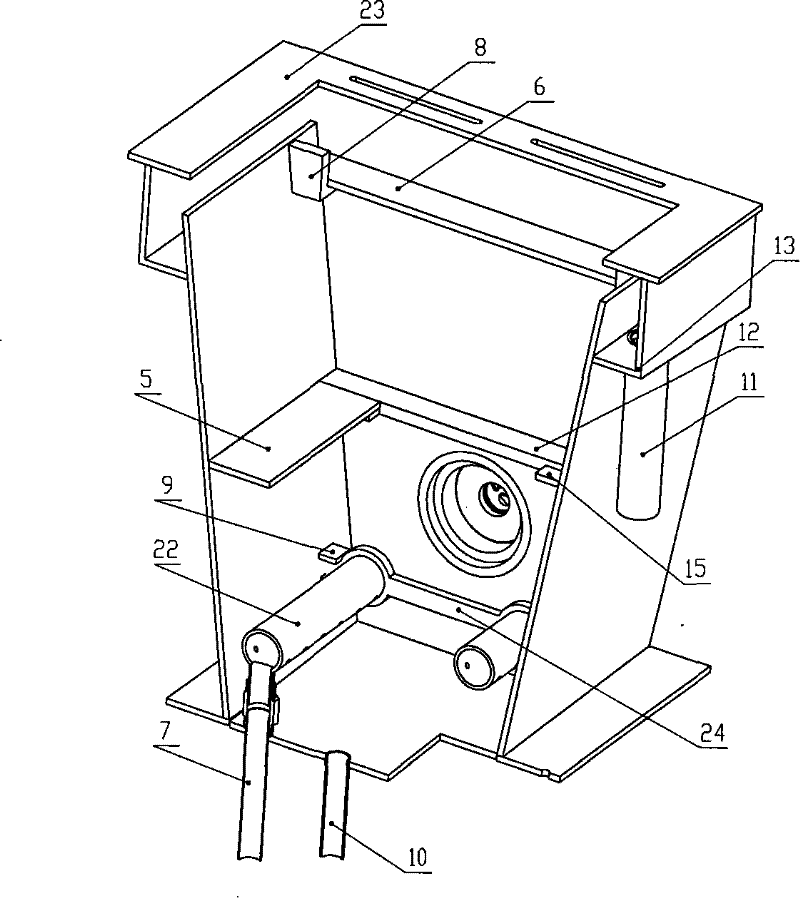

[0031] As shown in Figure 2(a) and Figure 2(b), in the inner cavity of the tank body 2, the top of the side plate of the tank body is fixed with corner plates near the four corners of the tank body, and the corner plate and the inner surface of the end plate The installation groove 8 of the upper supporting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com