Abrasion system and method for simulating various motions of metal in lead-bismuth alloy environment

A lead-bismuth alloy and metal technology is applied in the field of abrasive systems simulating multiple movements of metals in a lead-bismuth alloy environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

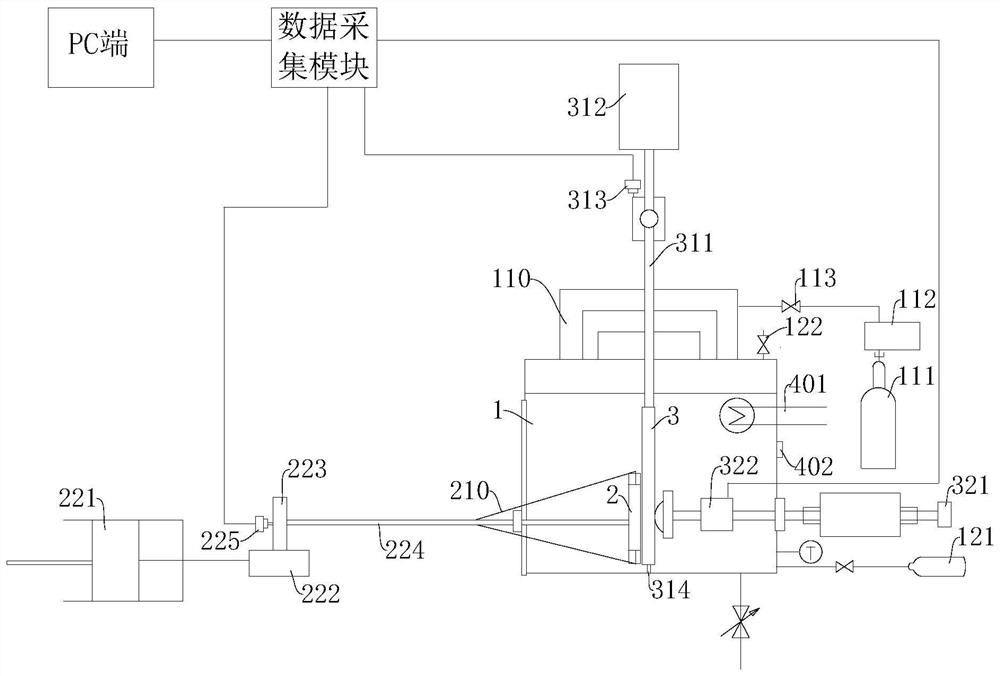

[0038] Please refer to figure 1 , figure 1 Shown is an embodiment of the invention.

[0039] In the first aspect, the present embodiment provides an abrasion system for simulating various movements of metals in a lead-bismuth alloy environment, which includes a lead-bismuth alloy environment simulation chamber 1, and the lead-bismuth alloy environment simulation chamber 1 is provided with first contact surfaces abutting against each other. The metal body 2 and the second metal body 3, the first metal body 2 is fixed by a clamping device 210, the clamping device 210 is connected with a horizontal circumferential reciprocating mechanism 220, and the second metal body 3 is connected with an axial reciprocating mechanism 310;

[0040] The lead-bismuth alloy environmental simulation chamber 1 is provided with a heating system 4, and the side of the lead-bismuth alloy environmental simulation chamber 1 away from the horizontal circumferential reciprocating mechanism 220 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com