Powder spraying chamber with automatic gun collection beam inlet-outlet groove openings using dynamic sealing structures

A technology of dynamic sealing structure and automatic gun, which is applied in spray booths, spraying devices, etc., can solve the problems of rubber sheets that cannot be sealed, rubber sheets that are difficult to clean, and leaks, and achieve powder leakage that is not easy, cleaning is convenient, and the sealing effect is good. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

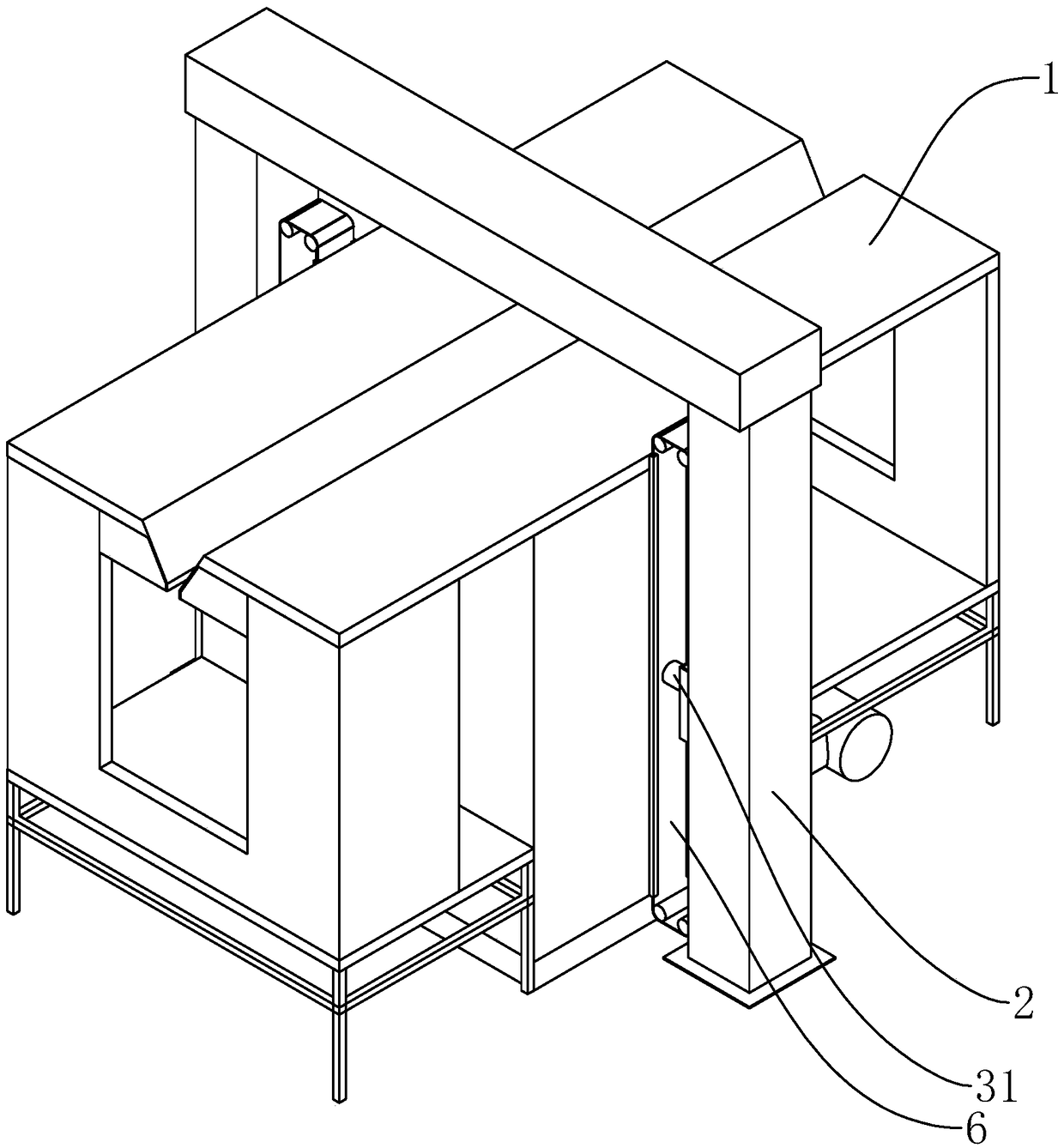

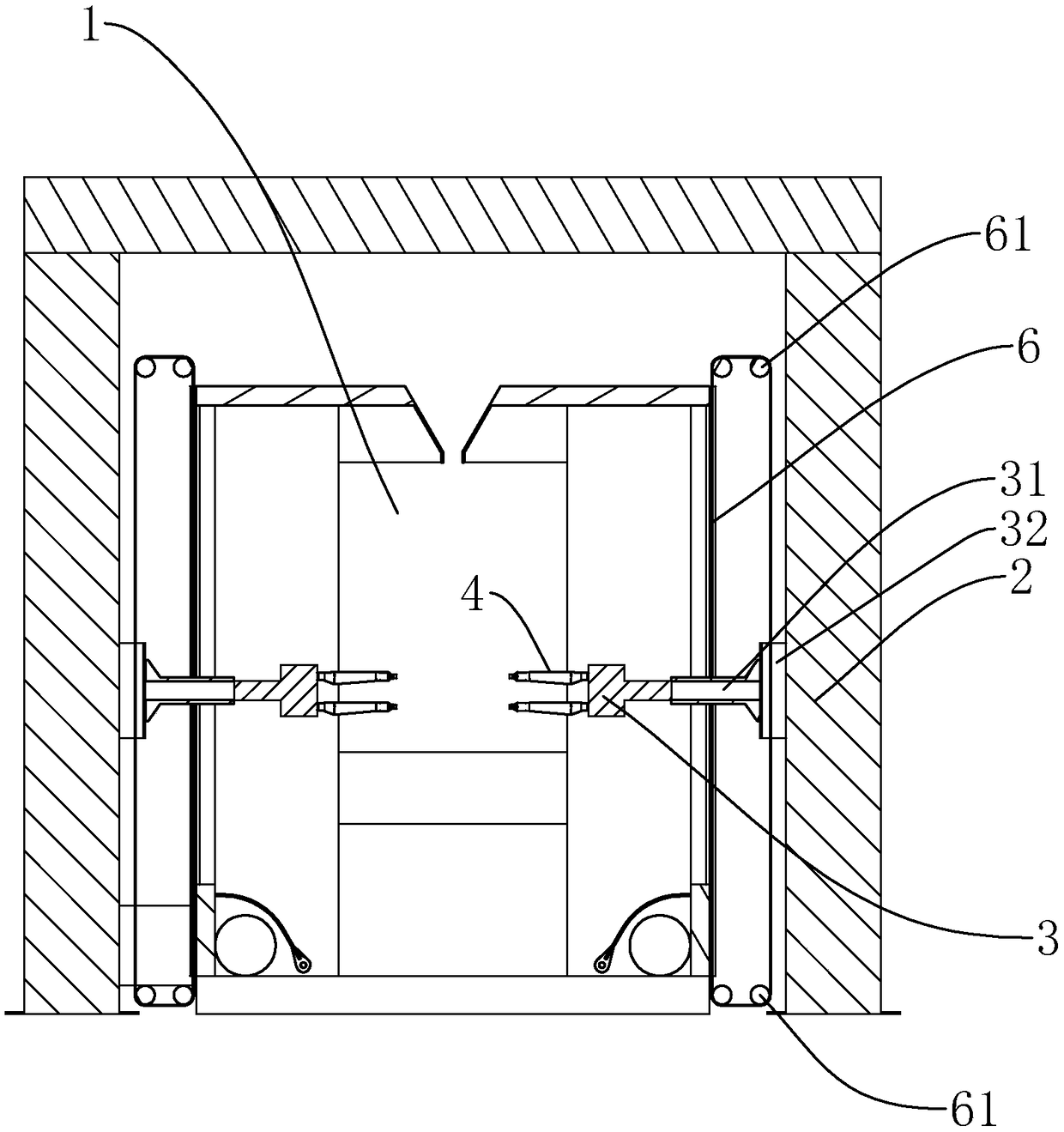

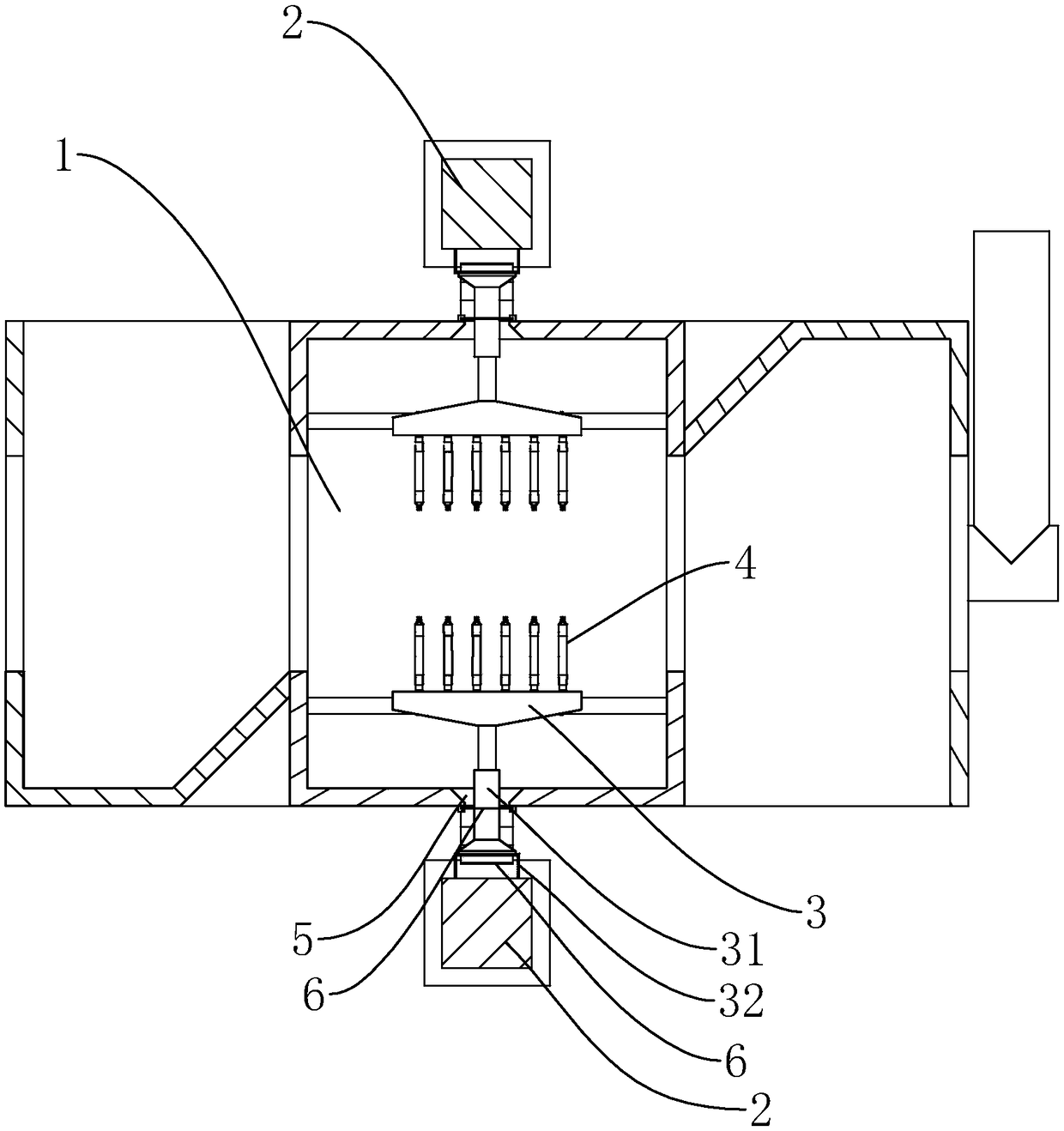

[0021] refer to Figure 1 to Figure 4 , Figure 1 to Figure 4 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a powder spraying room with a dynamic sealing structure for the inlet and outlet slots of the automatic gun collection beam includes a main body 1 of the spraying room and a powder spraying system. The powder spraying system includes An elevator 2 arranged on the outside of the main body 1 of the spraying room, an automatic gun collection beam 3 that can be driven up and down by the elevator 2, and a spray gun 4 arranged on the automatic gun collection beam 3, and the automatic gun collection beam 3 passes through a connecting rod 31 is connected to the lifter 2, on the side wall of the spray booth main body 1, there is a long entry and exit slot 5 that can pass through the connecting rod 31, and the entry and exit slot 5 provides the up and down reciprocating movement of the connecting rod 31 required sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com