Device and method for examining sealing performance of rubber hoses

A technology of rubber hose and sealing performance, which is applied in the use of liquid/vacuum for liquid tightness measurement, and by detecting the appearance of fluid at the leak point, etc., can solve problems such as failure to seal, leak, rubber aging, etc. Easy maintenance, reliable inspection data, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

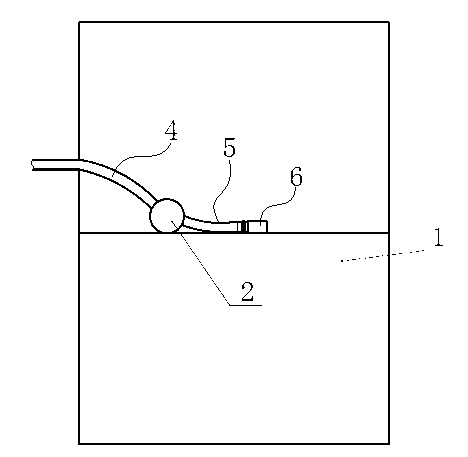

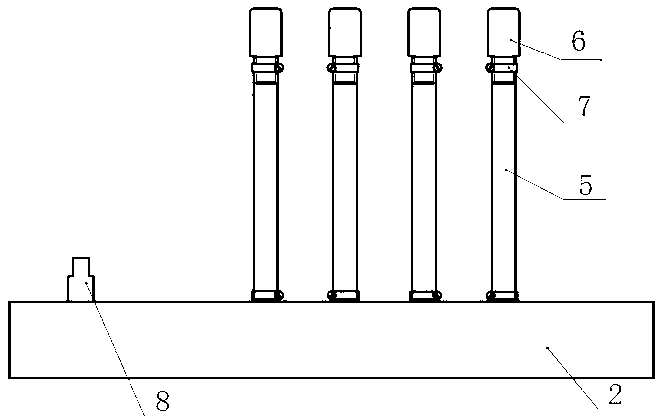

[0039] The invention selects the test material and designs the test device, assembles the test material and the test device, conducts the high and low temperature aging assessment test and the waterway pressure test in the aging test box, and simulates the running environment of the locomotive to test whether the rubber hose will Leakage occurs to prove whether the sealing performance of the rubber hose meets the functional requirements of the product.

[0040] Carry out rubber hose sealing performance testing test, the flow chart of the whole experiment is as follows figure 2 shown.

[0041] For the material selection and tooling design of the functions required for the test, see the following table for relevant information:

[0042]

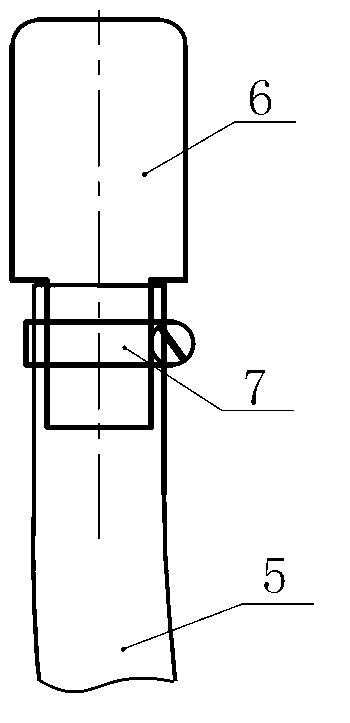

[0043] Then carry out the assembly of the sealing performance testing device:

[0044] Cut a total of 4 rubber hoses, each with a length of about 450mm. One end of each rubber hose is fastened to the hose connection seat of the inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com