Joint material for SO2 flue joint connection construction and preparation method of joint material

A technology of gap connection and joint material, which is applied in the field of joint material for SO2 flue gap connection construction and its preparation, can solve problems such as being easily corroded, and achieve good construction performance, good strength and thermal shock resistance, and good erosion and the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

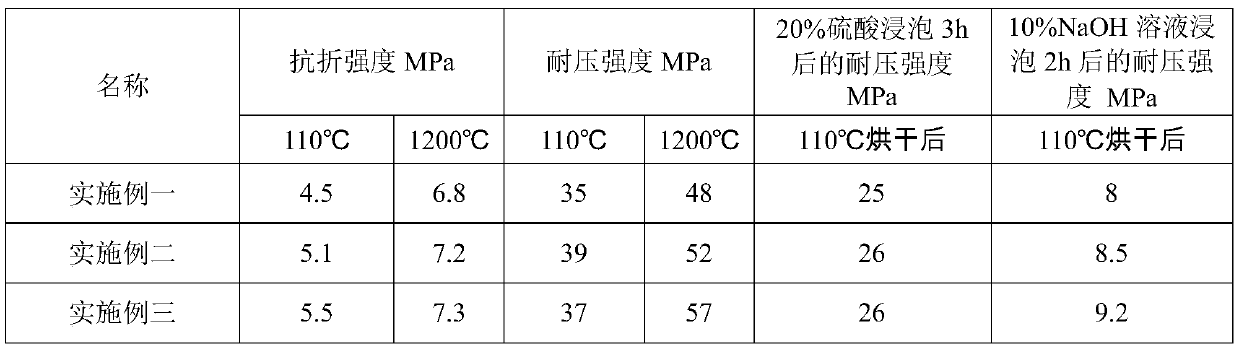

Examples

Embodiment 1

[0043] a kind of SO 2 The joint material for the construction of the gap connection of the flue, including the following components in parts by mass:

[0044] 22 parts of super-grade high-bauxite with a particle size of 0.01-4mm

[0045] 30 parts of mullite with a particle size of 0.01-4mm

[0046] 8 parts of corundum with a particle size of 0.01-2mm

[0047] 7 parts clay

[0048] 3 parts kaolin

[0049] 5 parts of silicon dioxide superfine powder with a particle size of 10 μm

[0050] 10 parts of mullite superfine powder with a particle size of 10 μm

[0051] 5 parts of α-alumina powder

[0052] Quartz fine powder 2 parts

[0053] Silicon carbide superfine powder 2 parts

[0054] Kyanite 3 parts

[0055] 3 parts andalusite

[0056] 0.2 parts of lignosulfonate

[0057] 25 parts of pulp waste liquid.

[0058] The preparation method of the present embodiment is as follows:

[0059] S1. Weigh each material according to the proportion, first put the materials except l...

Embodiment 2

[0063] a kind of SO 2 The joint material for the construction of the gap connection of the flue, including the following components in parts by mass:

[0064] 5 parts of super high alumina bauxite with particle size 0.01-4mm

[0065] 35 parts of mullite with a particle size of 0.01-4mm

[0066] 18 parts of corundum with a particle size of 0.01-2mm

[0067] 5 parts clay

[0068] 3 parts kaolin

[0069] 6 parts of silicon dioxide superfine powder with a particle size of 10 μm

[0070] 11 parts of mullite superfine powder with a particle size of 10 μm

[0071] 8 parts of α-alumina powder

[0072] Quartz fine powder 3 parts

[0073] Silicon carbide superfine powder 2 parts

[0074] 6 parts of andalusite

[0075] Sodium hexametaphosphate 0.3 parts

[0076] 28 parts of pulp waste liquid.

[0077] The preparation method of the present embodiment is as follows:

[0078] S1. Weigh each material according to the proportion, first put the materials except sodium hexametaphospha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com