Composite Roll Collar

A technology of guide rollers and roller surfaces, which is applied in the direction of guiding/positioning/alignment devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

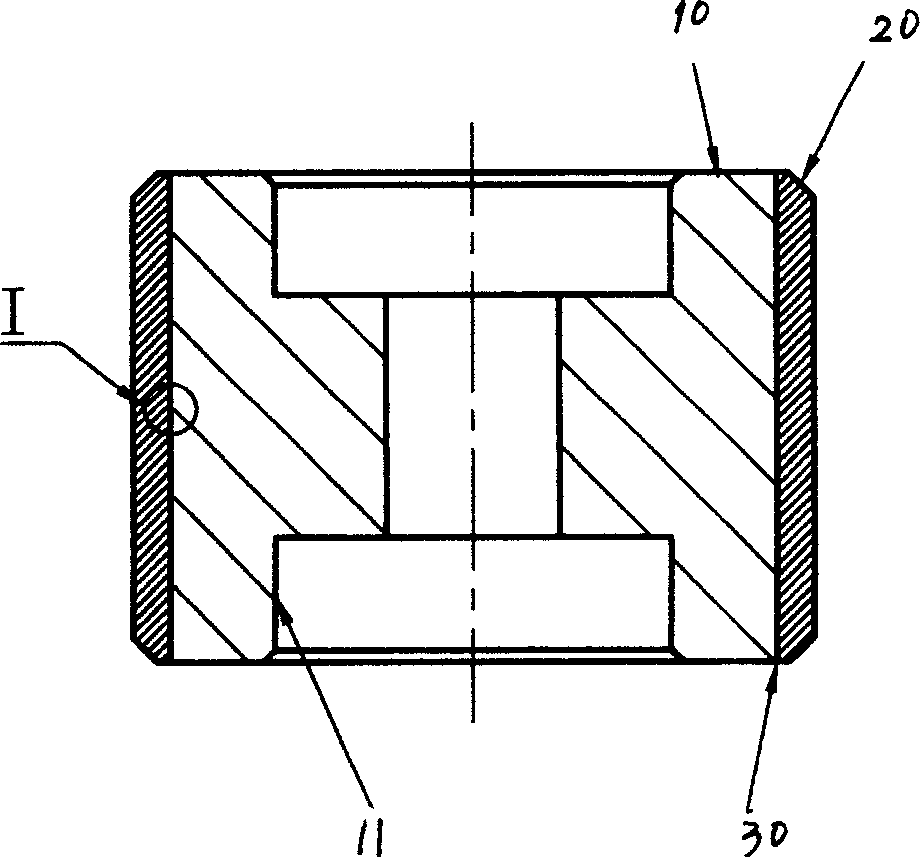

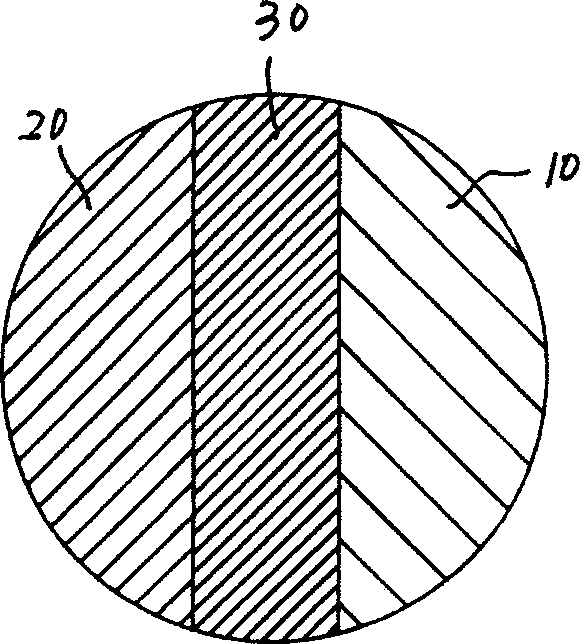

[0015] The following combination figure 1 , 2 Describe the specific structure of the composite guide roller provided by the present invention.

[0016] The roller base 10 of the guide roller is made of ordinary carbon steel, and the roller surface of the roller base 10 is coated with a heat-resistant and wear-resistant hard surface layer 20. The roller surface of the roller base 10 and the surface layer 20 There is a metallurgical bonding layer 30 in between.

[0017] exist figure 1 Among them, the medium carbon steel is used to process the roller base 10 first, and its specific structure is a conventional mechanical part, including machining a bearing hole 11 in the middle of the roll base 10, which is very convenient to process, and then the hard surface layer 20 is processed. .

Embodiment 2

[0019] The processing method of composite guide roller comprises the following steps:

[0020] a. Select carbon steel to process the roller base of the guide roller and clean the surface; and configure alloy powder;

[0021] b. Slurry the above-mentioned qualified alloy powder and apply it on the surface of the roller base of the guide roller;

[0022] c. Place the guide roller coated with alloy powder in an oven at a temperature of 80-100°C for 1-2 hours, and finish the shape after leaving the box;

[0023] d. Put the dried guide roller in the vacuum furnace, and the vacuum degree is controlled at 10 -5 ~10 -6 Mpa, heated at 1030-1050°C and kept for 5 minutes;

[0024] e. After the above-mentioned guide roller is kept warm, it is cooled to 180-200°C with the furnace and cooled to normal temperature.

[0025] Vacuum sintering is used to form a metallurgical bond between the steel base and the hard material layer, and the bond is very firm; sintering in a vacuum environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com