Patents

Literature

34results about How to "Guaranteed thickness accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin composition used for forming dielectric layer of dielectric substrate for antenna and application of resin composition

ActiveCN103351578ASmall coefficient of thermal expansionLittle change in thicknessSynthetic resin layered productsMetal layered productsEpoxyDielectric substrate

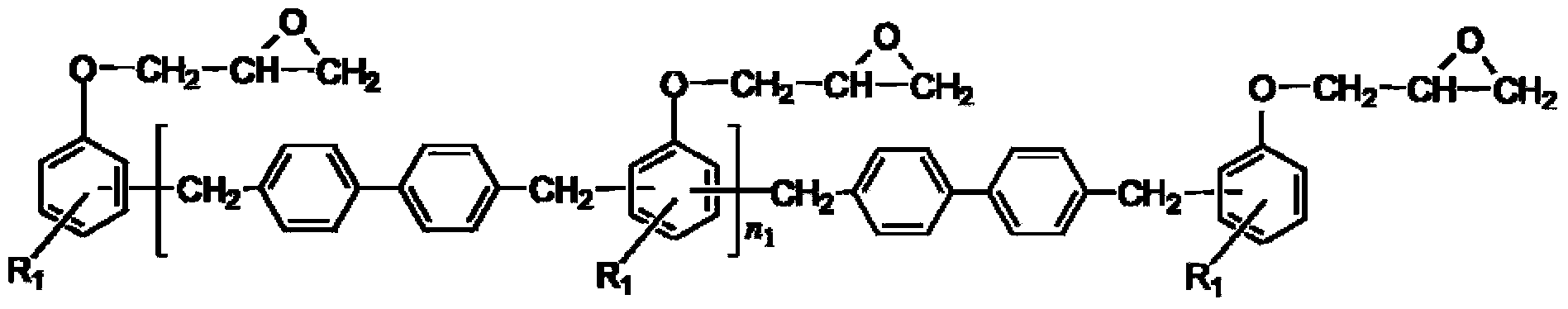

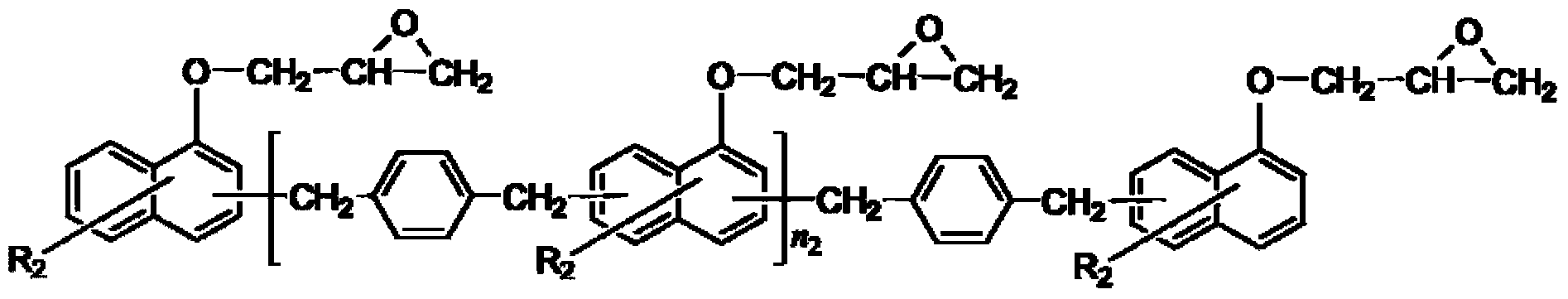

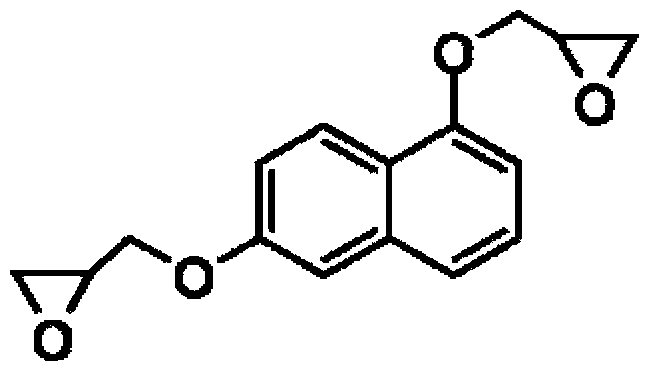

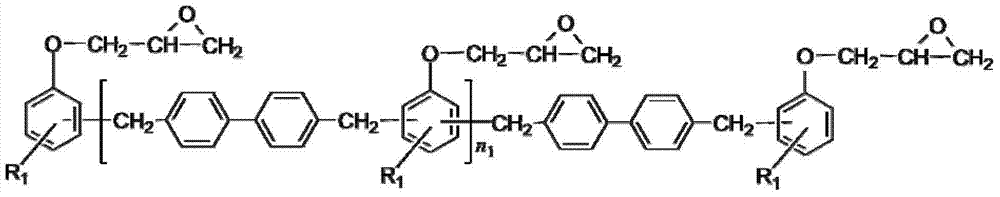

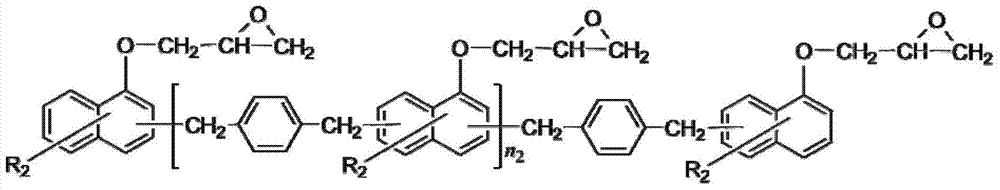

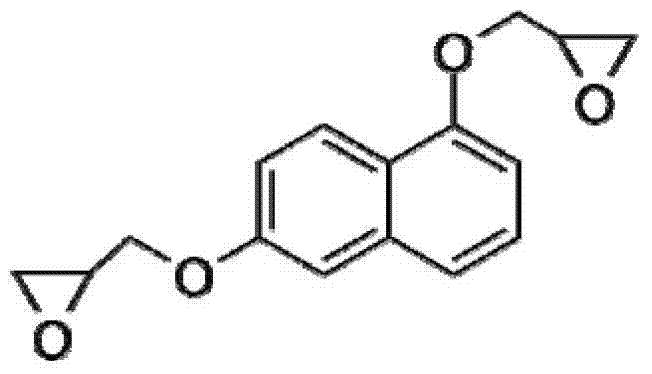

The invention relates to a resin composition used for forming a dielectric layer of a dielectric substrate for an antenna. The resin composition comprises (A), epoxy resin containing a naphthalene nucleus or diphenyl structure, (B), any one of or a mixture of at least two of tri(4-hydroxyphenyl) methane type epoxy resin, o-cresol type novolac epoxy resin and phenol type novolac epoxy resin, (C), a resin fusion viscosity modifier, and (D), spherical ceramic powder after presintering treatment. With the adoption of the resin composition, the obtained dielectric substrate has a high dielectric constant, high peeling strength, a low thermal expansion coefficient and very good thickness consistency, and can meet a performance requirement of the high dielectric constant antenna substrate.

Owner:江苏生益特种材料有限公司

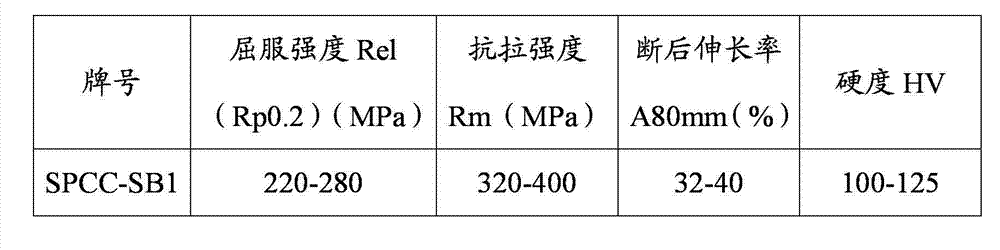

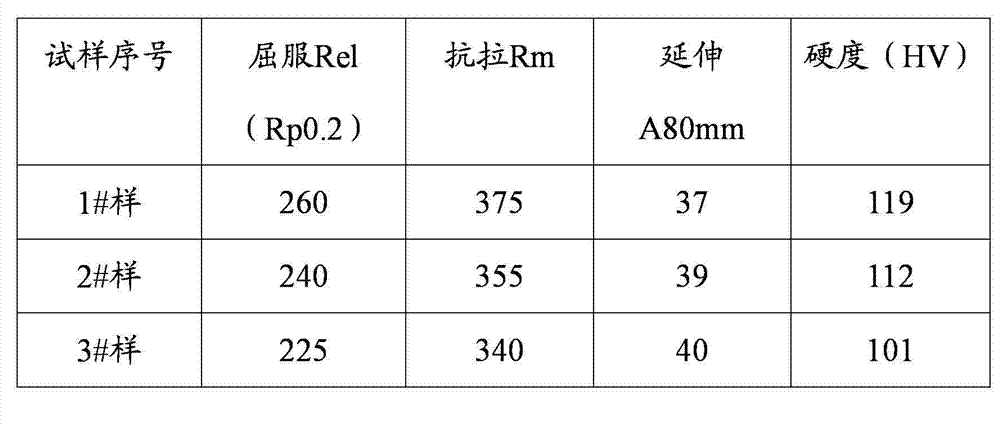

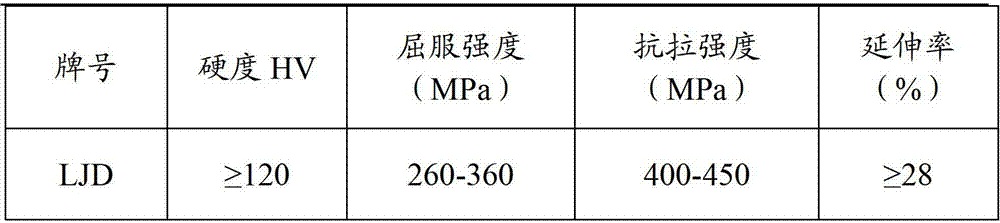

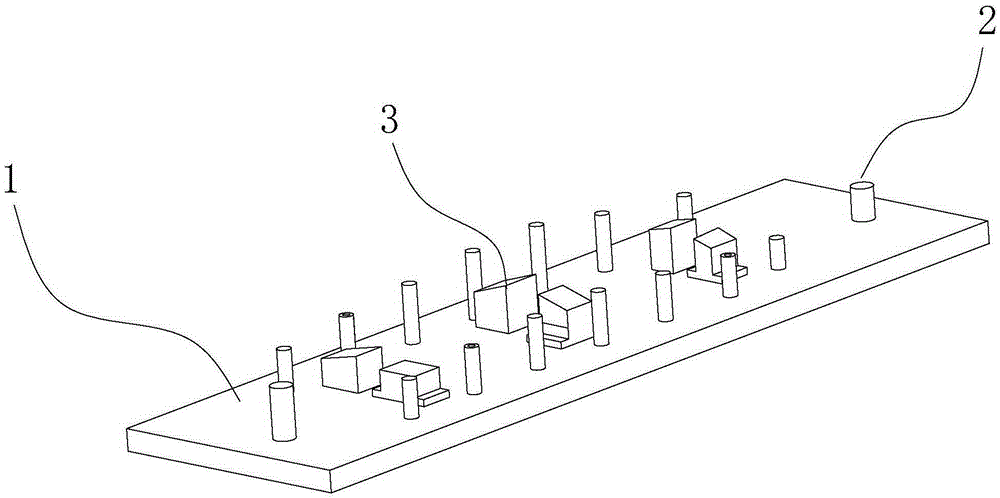

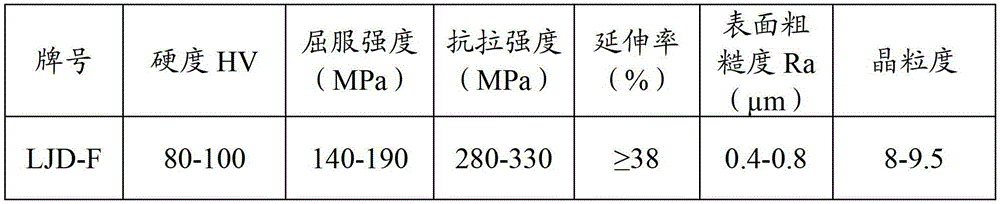

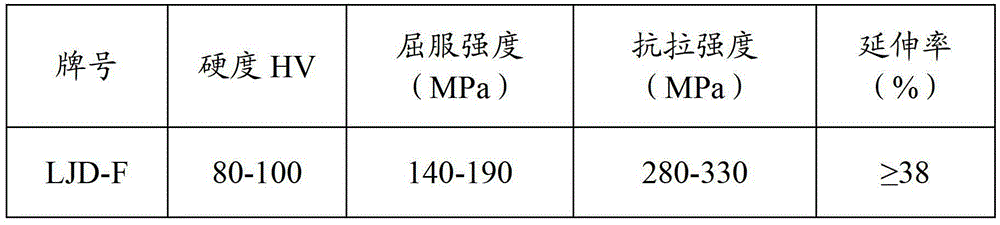

Steel strip for LED bracket and manufacturing method thereof

The invention provides a steel strip for an LED bracket and a manufacturing method thereof. The steel strip comprises the following chemical compositions by mass percent: 0.03%<=C<=0.07%, 0.01%<=Si<=0.03%, 0.2%<=Mn<=0.3%, 0%<P<0.02%, 0%<S<0.02%, 0.01%<=Al<=0.035% and the balance of Fe, as well as a trace of inevitable impurities. Repeated tests and trials show that the LED steel strip completely satisfies the quality requirements on the strength, the rigidity and the extensibility, which ensure that the LED bracket is free from cracks after being punched and bent for 6 times, and at present, the LED steel strip gains popularity of customers; and as the LED new material cold-rolled strip has a very wide development prospect, the popularization and application values are extremely high and the prospect is very wide.

Owner:浙江龙盛薄板有限公司

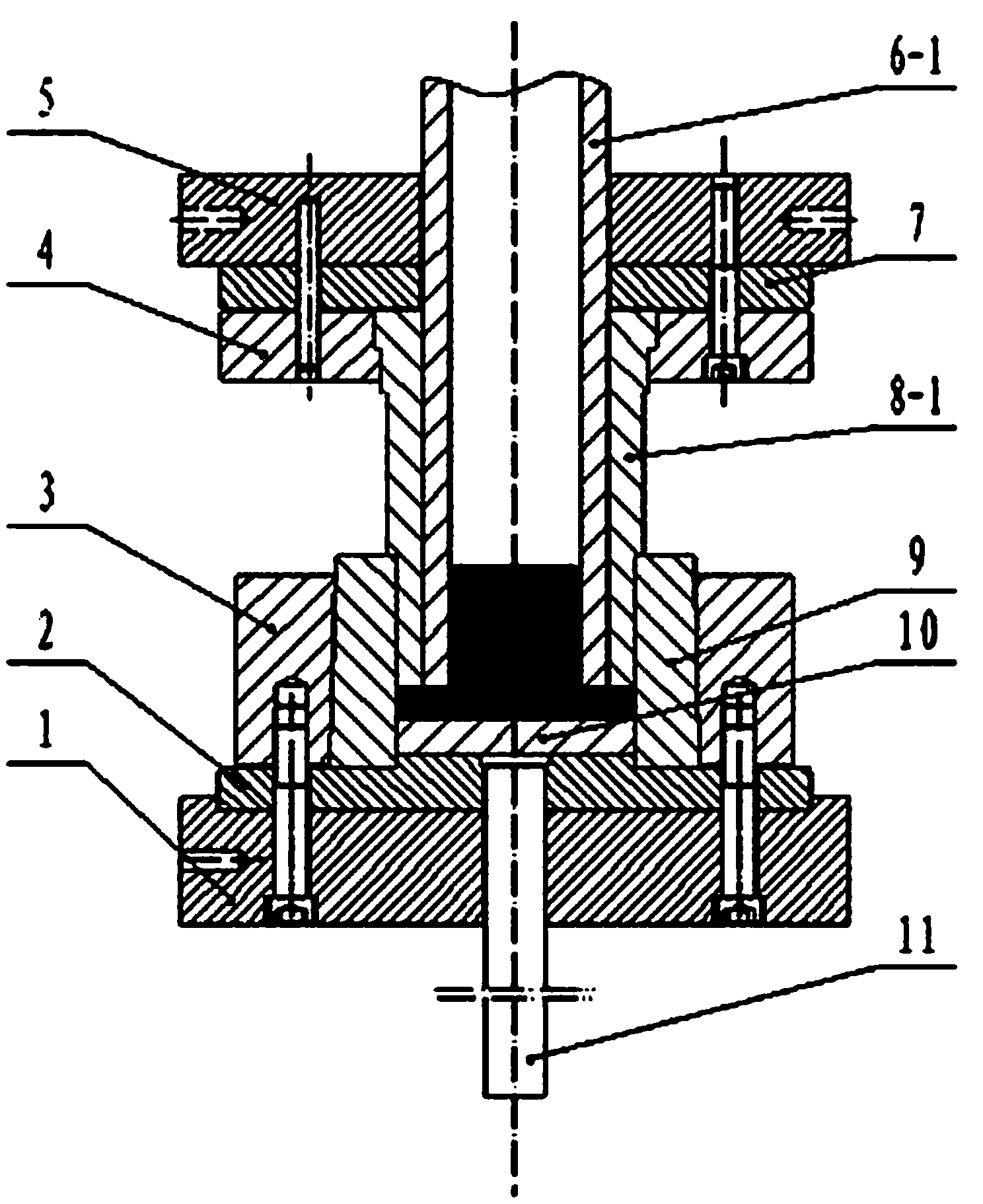

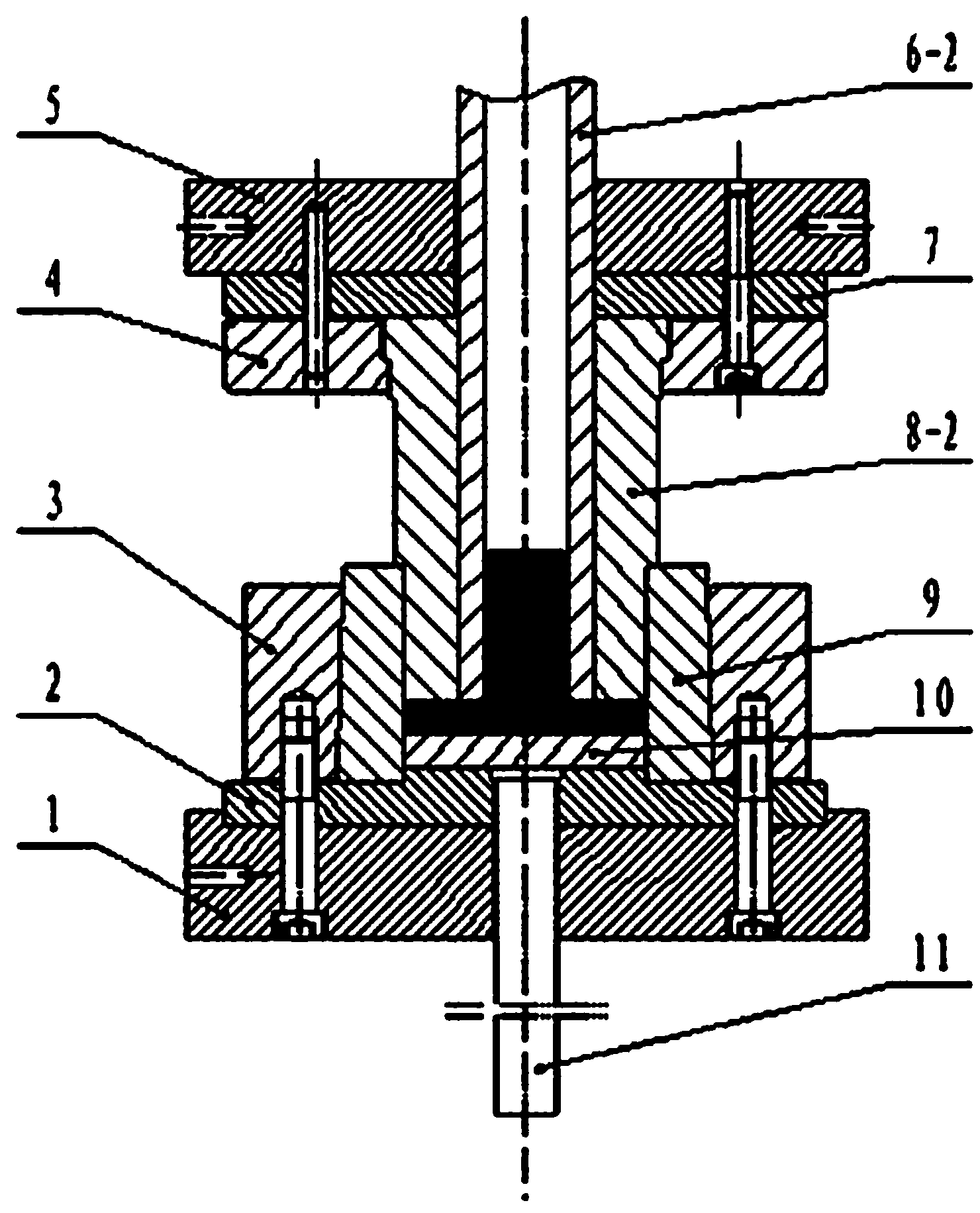

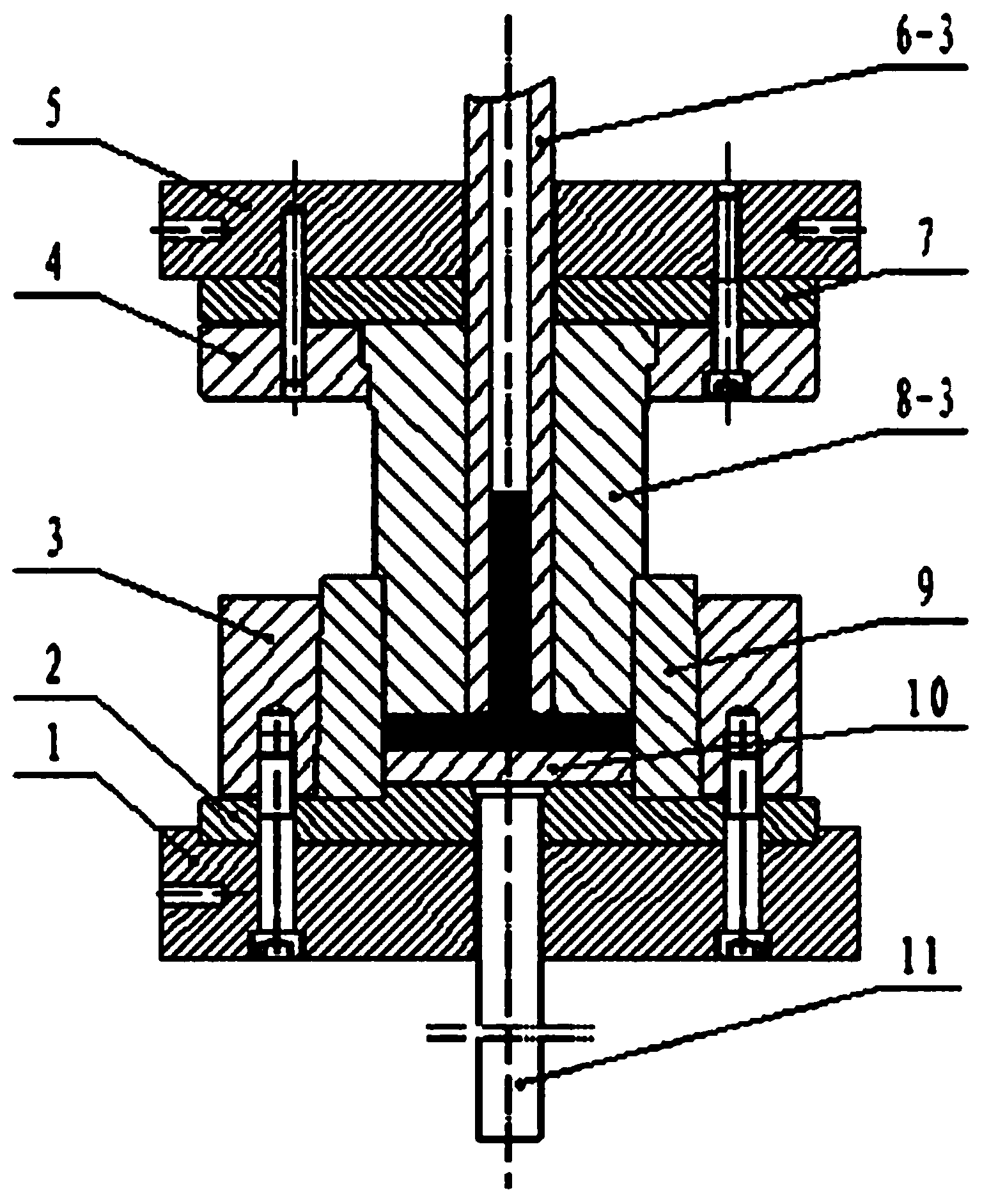

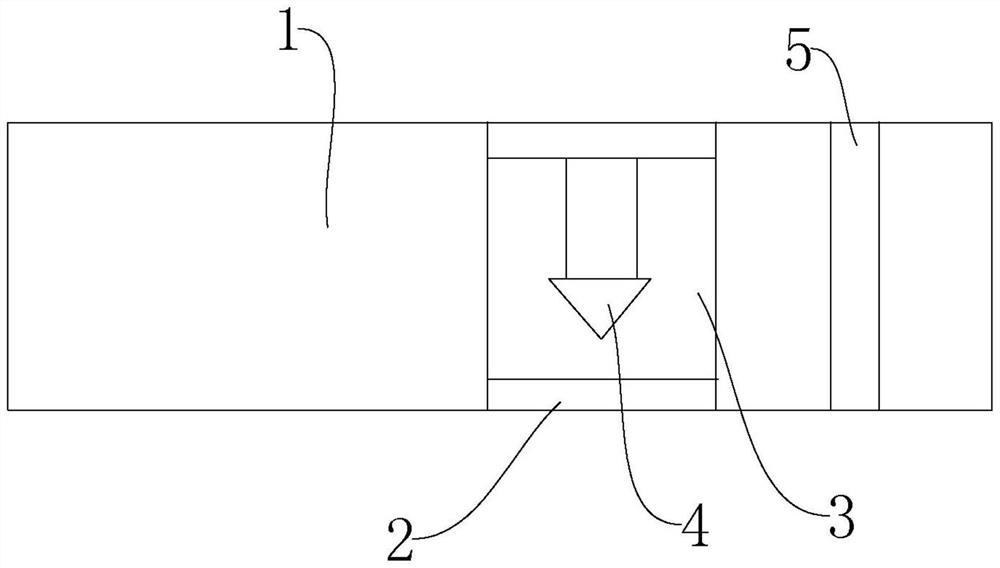

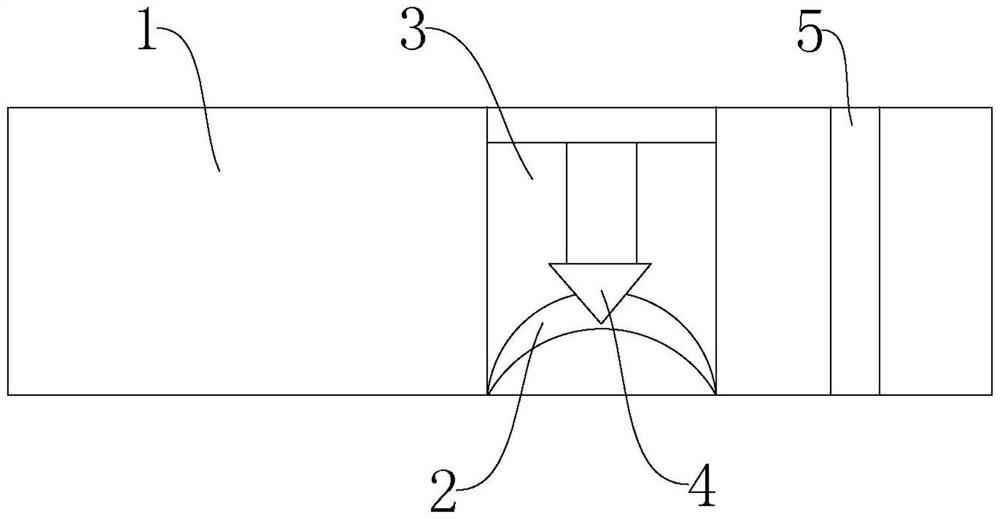

Extrusion moulding method for shaft parts with flanges, and special extrusion mould

ActiveCN103551410ASingle extrusion area is smallReduce investmentExtrusion diesEngineeringMachine press

The invention relates to an extrusion moulding method for shaft parts with flanges, and a special extrusion mould. The adopted extrusion moulding method comprises the following steps: 1, placing a blank material in a female die, wherein the extrusion moulding mould comprises an external male die with a center hole extending along the axial direction, an internal male die is arranged in the center hole of the external male die in a penetrating manner, the hole wall of the center hole of the external male die is matched with the peripheral wall of the internal male die in a guiding sliding manner, a corresponding power output shaft of a press drives the external male die to extrude the blank material and downwards moves to reach the thickness of the flange of the required part; 2, ejecting the external male die to be kept stable on the blank material, wherein the press and a power output shaft which is in transmission connection with the corresponding internal male die drive the internal male die to downwards extrude the blank material, and the required part is formed through extrusion; and 3, completing the extrusion, wherein the press drives the external male die and the internal male die to return to eject the formed part. According to the extrusion moulding method, by adopting sequential extrusion moulding, the one-time extrusion area is small, the extrusion force required by one-time extrusion is small, the input of equipment is reduced by adopting the equipment with small tonnage, and the production cost is lowered.

Owner:HENAN UNIV OF SCI & TECH

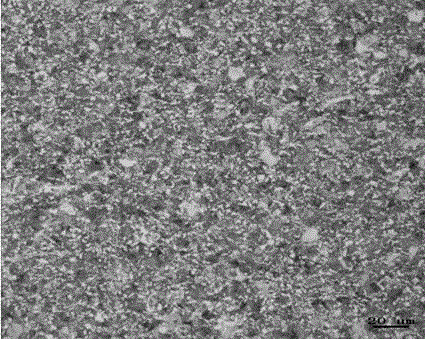

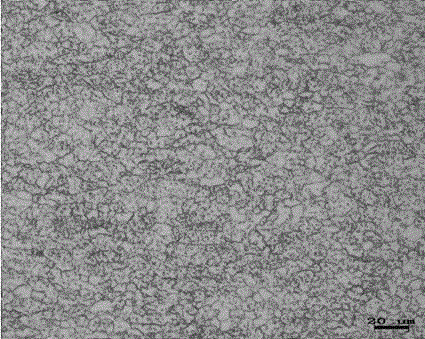

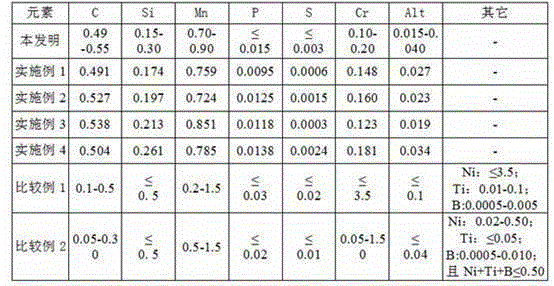

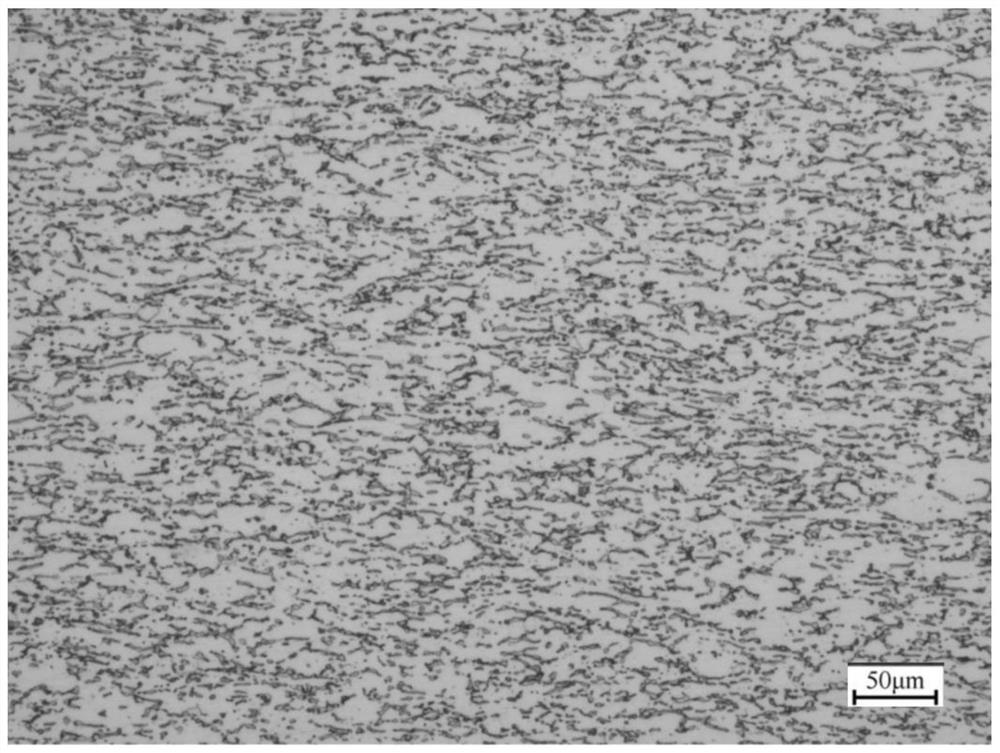

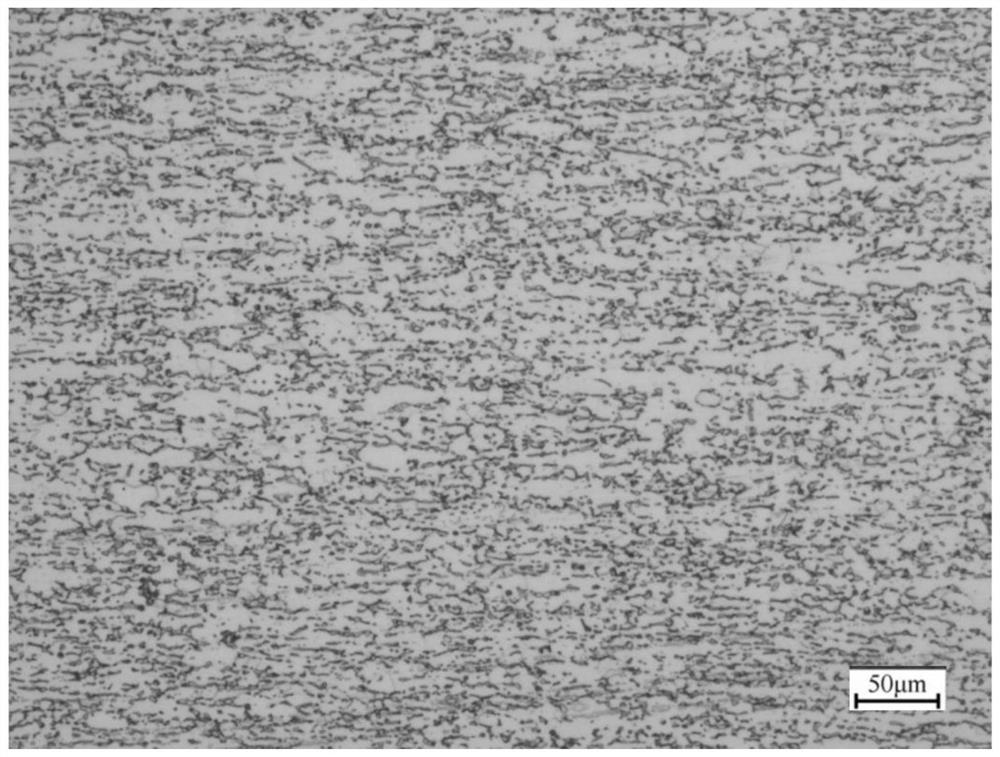

Cold-rolling strip steel used for automobile flywheel processed by precision stamping and manufacture method thereof

ActiveCN106256918ASmall range of performance fluctuationsHigh strengthCompound (substance)Strip steel

The invention relates to a cold-rolling strip steel used for an automobile flywheel processed by precision stamping and a manufacture method thereof, which solves the technical problems that the manufacture cost of the cold-rolling strip steel used for precision stamping is high, the high strength and toughness of the cold-rolling strip steel are not matched, and the precision stamping moulding cannot be satisfied. The cold-rolling strip steel comprises the following chemical components by mass percentage: 0.49-0.54% of C, 0.15-0.30% of Si, 0.70-0.90% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.10-0.20% of Cr, 0.015-0.040% of Alt, and the balance of iron and unavoidable impurity. The structure is composed of block ferrite, granular pearlite and a few of sheet-shaped pearlite, the yield strength of the cold-rolling strip steel is 410-460 MPa, and the percentage elongation after fracture A50 is 25-33%. The cold-rolling strip steel is used for fine blanking of the automobile flywheels.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Steel strip for household electric appliance panel and production method thereof

ActiveCN103194670AGuaranteed plasticityGuaranteed thickness accuracyFurnace typesHeat treatment furnacesChemical compositionHardness

The invention provides a steel strip for deep drawing of a household electric appliance panel film. The steel strip comprises the following chemical components by mass percent: 0.01 percent<=C<=0.03 percent; zero percent<Si<=0.02 percent; 0.1 percent<=Mn<=0.25 percent; zero percent<P<=0.02 percent; zero percent<S<=0.025 percent; 0.02 percent<=Al<=0.05 percent; and the balance of Fe. The high-hardness steel strip for a household electric appliance panel totally meets the quality requirements for strength, hardness and elongation of refrigerator panel steel based on many tests and trial use, is popular among clients, and has popularization application value and broad prospect as the cold rolled strips for household appliances have a very broad development prospect.

Owner:浙江龙盛薄板有限公司

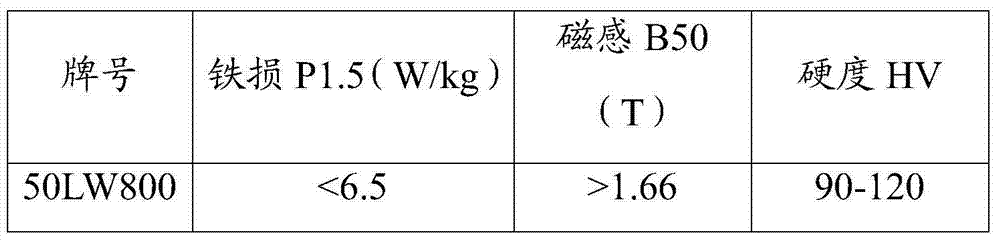

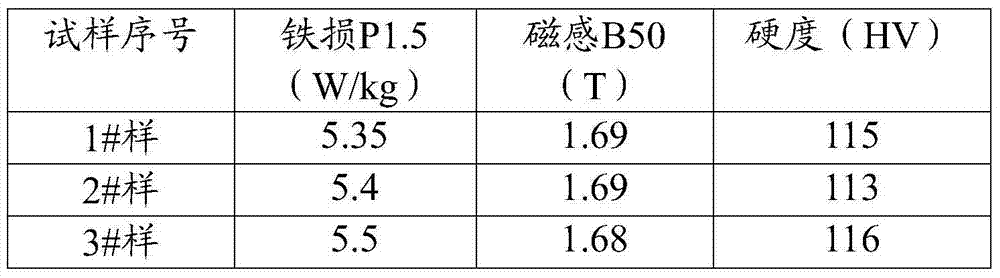

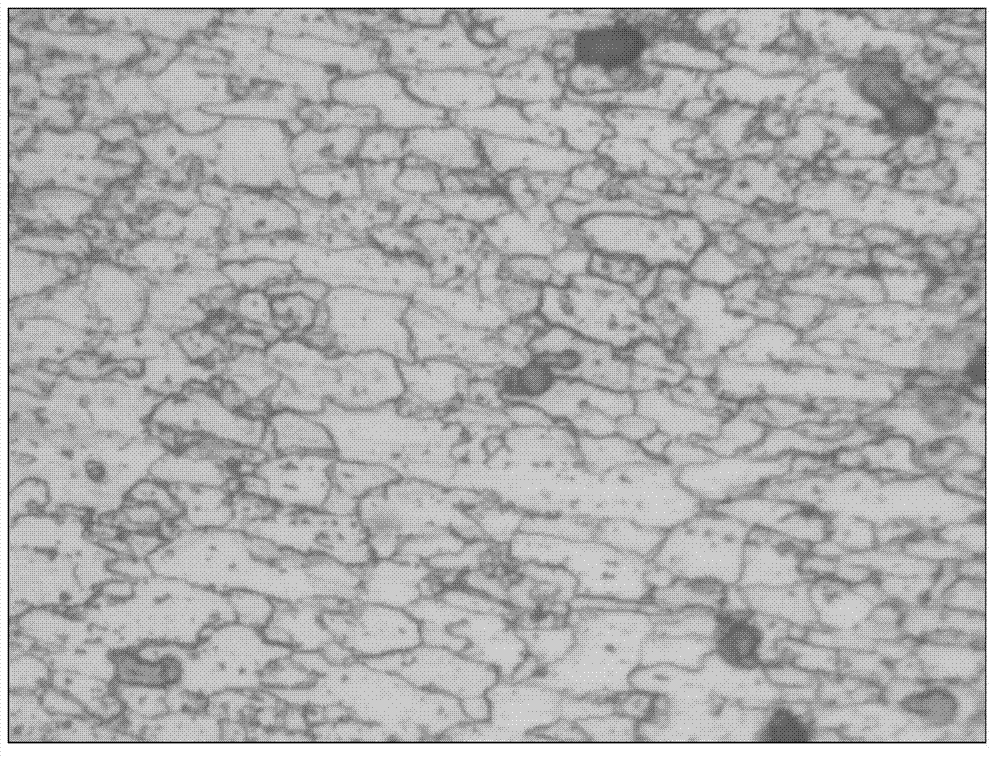

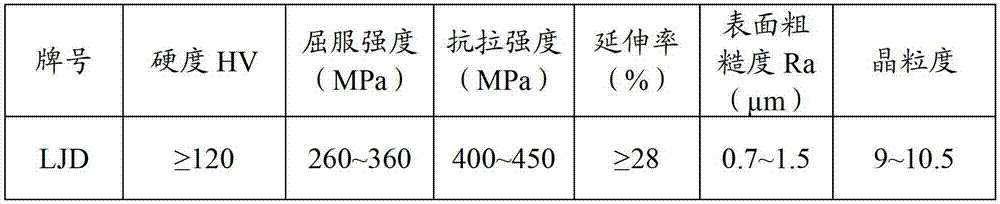

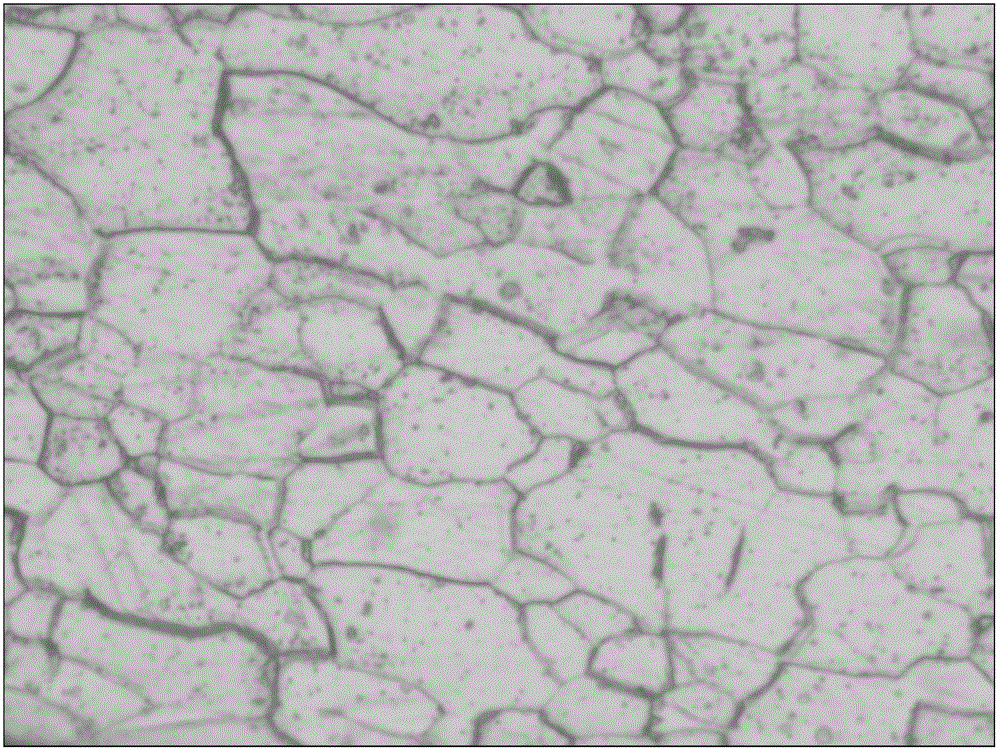

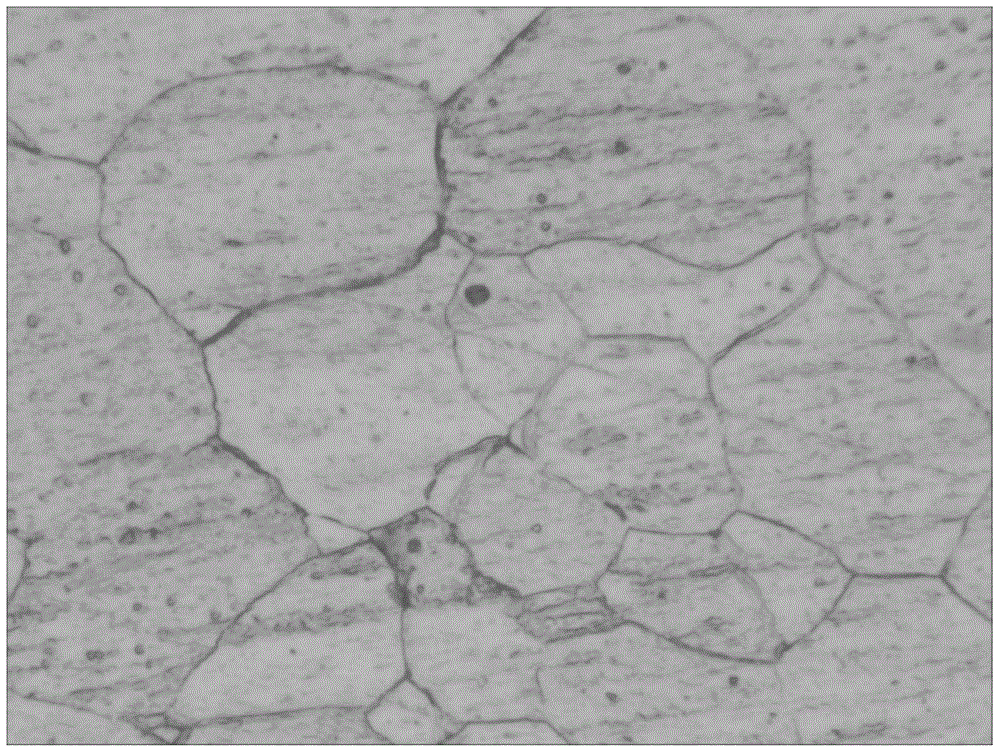

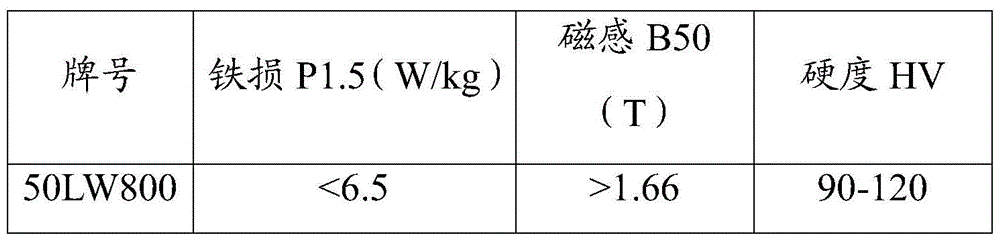

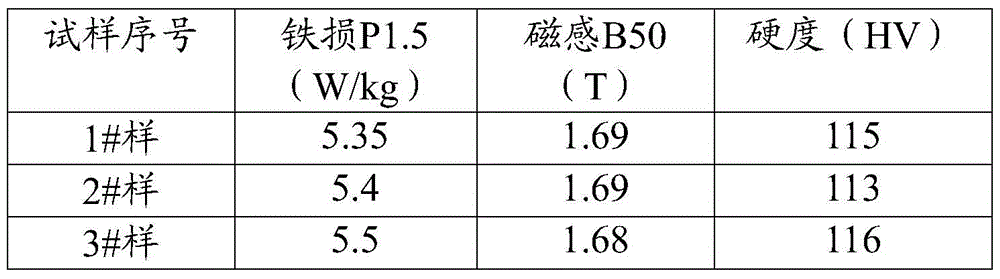

Semi-processed non-oriented silicon steel and manufacturing method thereof

ActiveCN104195426AGuaranteed plasticityGuaranteed surface finishChemical compositionSurface roughness

The invention provides semi-processed non-oriented silicon steel. The silicon steel comprises following chemical components by mass: not more than 0.005% and not less than 0 of C, not more than 0.8% and not less than 0.15% of Si, not more than 0.4% and not less than 0.2% of Mn, more than 0.02% and less than 0.1% of P, more than 0% and less than 0.01% of S and not more than 0.1% and not less than 0.03% of Al, with the balance being Fe. The thickness of the silicon steel is 0.35-0.65 mm, the width is 1000-1250 mm, and the surface roughness Ra is 0.4-1.0 [mu]m. Through a plurality of tests and trials, the silicon steel fully meets quality requirements on iron loss and magnetic induction for motors. After secondary annealing and blueing, the performance can be improved by two levels. The silicon steel is favored by users at present. As the development prospect of the motor industry is wide, the silicon steel is high in popularization and application value and has a wide prospect.

Owner:浙江龙盛薄板有限公司

High-hardness steel belt for home appliances and manufacturing method

InactiveCN103205629AGuaranteed thickness accuracyGuaranteed cleanlinessFurnace typesHeat treatment furnacesChemical compositionHome appliance

The invention provides a high-hardness steel belt for home appliances. The chemical component of the high-hardness steel belt includes, by mass, 0.06%<=C<=0.13%, 0.03%<=Si<=0.25%, 0.2%<=Mn<=0.4%, 0%<P<0.025%, 0%<S<0.025%, 0.01%<=Al<=0.05%, and the balance of Fe. After many tests and tries, the high-hardness steel belt completely meets quality requirements for strength, hardness and elongation of high-hardness steel for side plates of refrigerators, is quite popular with customers, and has high popularization and application values and wide prospect since cold-rolled steel belts for home appliances are quite wide in development prospect.

Owner:浙江龙盛薄板有限公司

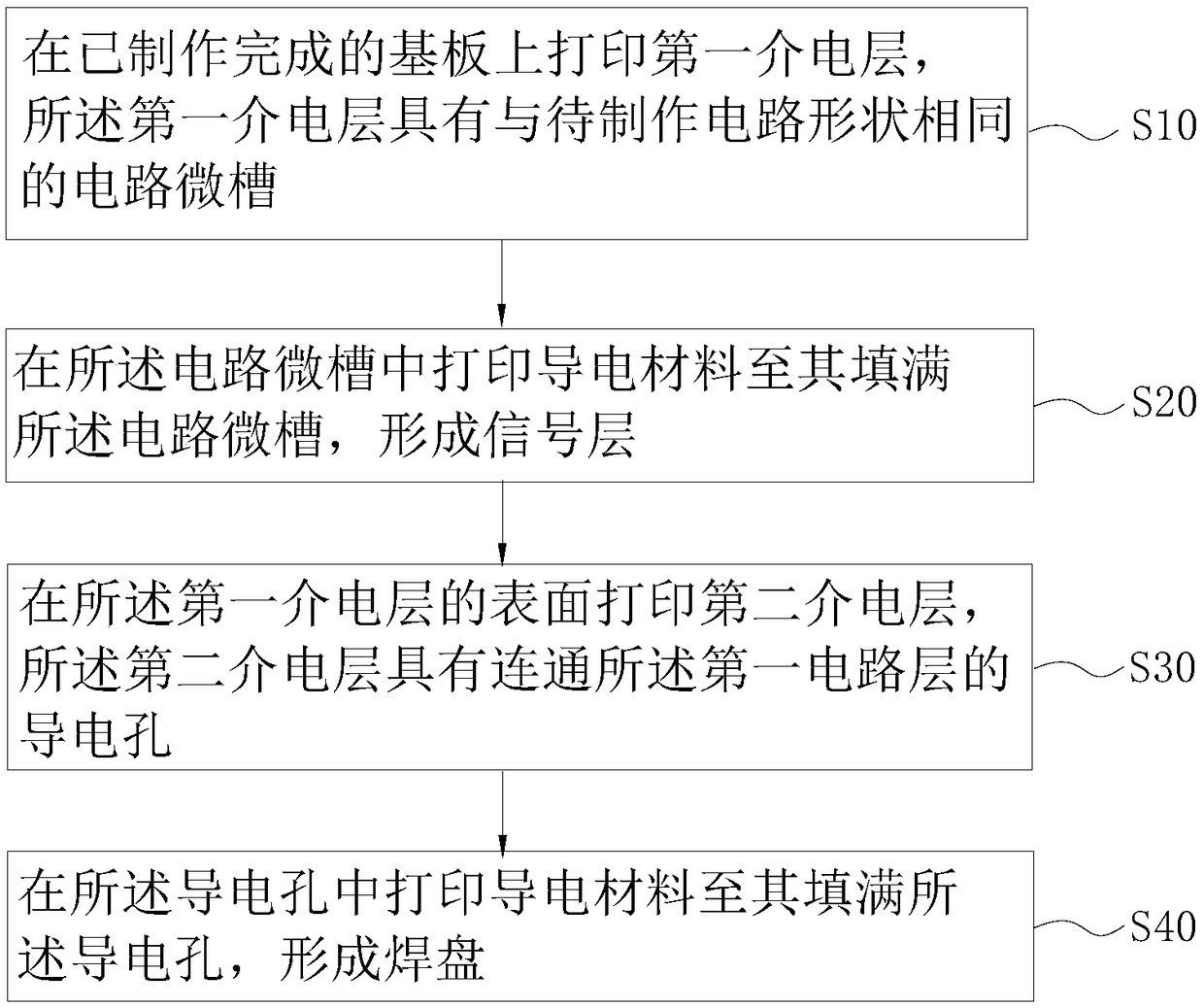

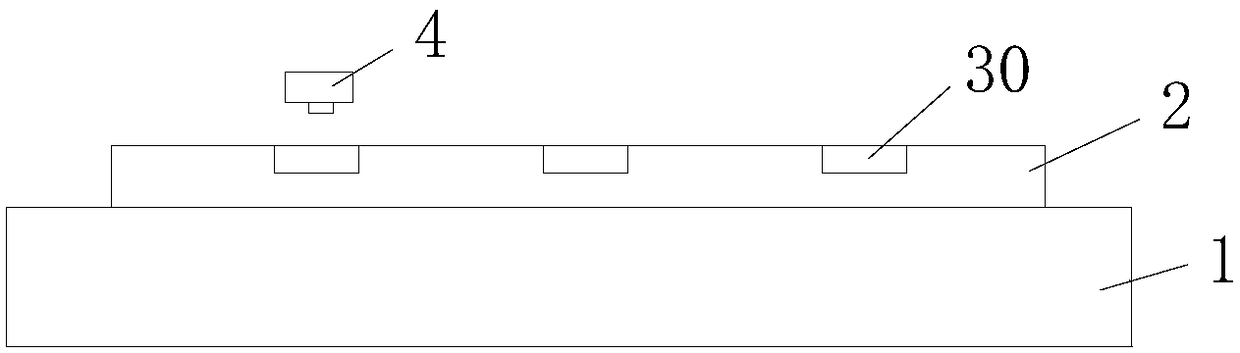

Method for manufacturing printed circuit board

InactiveCN109451674AIncrease profitPrevent splashConductive pattern formationMultilayer circuit manufactureConductive materialsEngineering

The invention provides a method for manufacturing a printed circuit board. The method comprises the following steps: printing a first dielectric layer on a fabricated substrate, wherein the first dielectric layer has a circuit micro slot in the same shape as the circuit to be fabricated; printing conducting material in the circuit micro slot until the circuit micro slot is filled to form a signallayer; printing a second dielectric layer on the surface of the first dielectric layer, wherein the second dielectric layer has a conducting hole communicated with the signal layer; and printing conducting material in the conducting hole until the conducting hole is filled to form a pad. The method for manufacturing a printed circuit board provided by the invention prints the first dielectric layer having the circuit micro slot on the substrate, and prints the conducting material in the circuit micro slot. The dielectric layers and signal layer are respectively manufactured by printing, with no need to manufacture a circuit board by adopting traditional processes such as exposure, development, etching and electroplating, which causes no environmental pollution.

Owner:SHENZHEN JINZHOU PRECISION TECH

Rolling method of wide-width thin-specification 6Mo super austenitic stainless steel plate

ActiveCN110756580AIncrease widthReduce the number of weldsTemperature control deviceMetal rolling stand detailsHeating timeSS - Stainless steel

The invention discloses a rolling method of a wide-width thin-specification 6Mo super austenitic stainless steel plate. The rolling method includes the following steps that a blank which has the thickness of 110-125 mm, the width of 1500 mm or above and the length of 2550-2620 mm is adopted; the steel blank is sent to a stepping type heating furnace, the ratio of the total heating time to the thickness of the steel blank is controlled to be 15-22 min / cm, the temperature of a uniform heating section is 1230-1270 DEG C, the time for the uniform heating section is at least 30 min, and the tappingtemperature is 1240-1260 DEG C; full transverse rolling is performed through 12+1 rounds, the reduction rate is increased from 17% in the first round to 30-40% in the fifth round and is then gradually reduced, the reduction rate in the eleventh round is 7-9%, the reduction rate of the twelfth round is 4-6%, and air cooling is performed after rolling; and the solid solution temperature is 1160 DEGC, heat preservation is performed for 20 min, and water cooling is performed. The width of this type of finished products can be increased from 2000 nm in the prior art to 2500 mm.

Owner:NANJING IRON & STEEL CO LTD

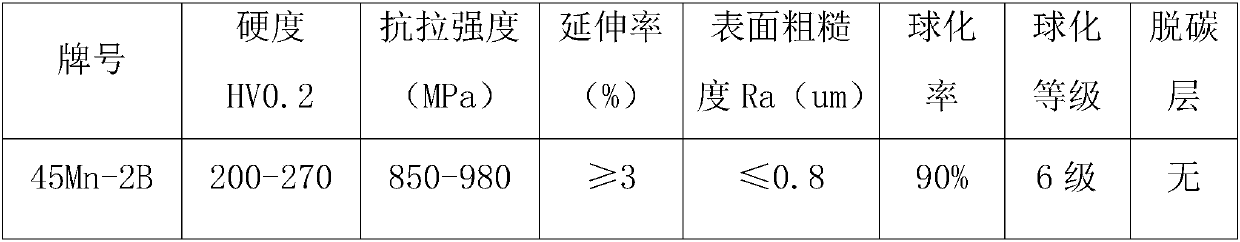

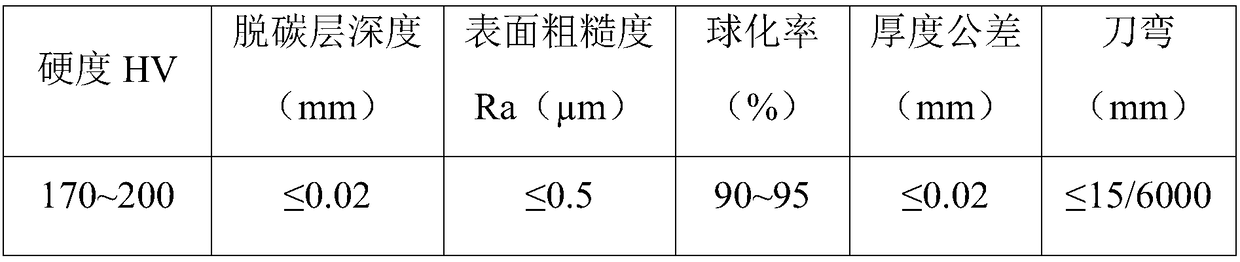

Wide steel strip for paper cutting blade and manufacturing method thereof

The invention provides a wide steel strip for a paper cutting blade. The wide steel strip is characterized in that the content of the chemical components of the steel comprises, by weight, 0.43%-0.47%of C, 0.17%-0.28% of Si, 0.7%-1.0% of Mn, 0-0.035% of P, 0-0.035% of S, 0.15%-0.3% of Cr, and the balance Fe; and the thickness of the wide steel strip 0.45-1.42mm, the width is 23-35 mm. According to the wide steel strip for the paper cutting blade, through repeated testing and trial, requirements of the steel for the paper cutting blade for the strength, the hardness, the size precision, the straightness and the quality requirement of the spheroidized structure can be completely met, and the wide steel strip has been favored by customers at present; and due to the fact that the developmentprospect of the cold-rolled wide steel strip for the paper cutting blade is very wide, the wide steel strip has great popularization and application values and is quite wide in prospect.

Owner:浙江龙盛薄板有限公司

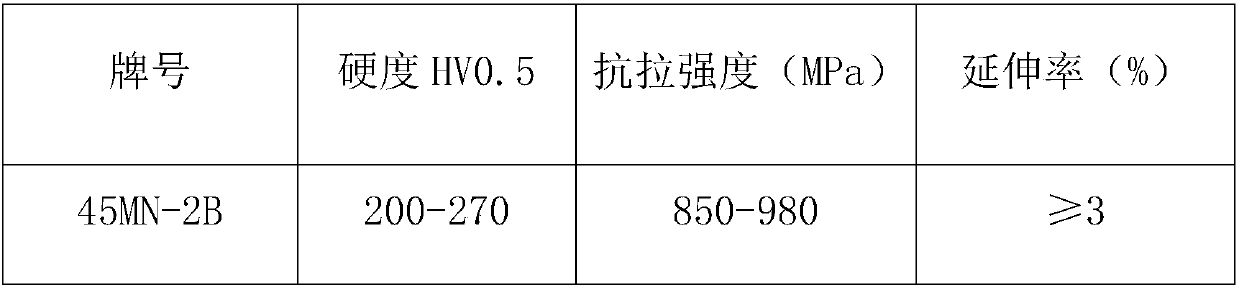

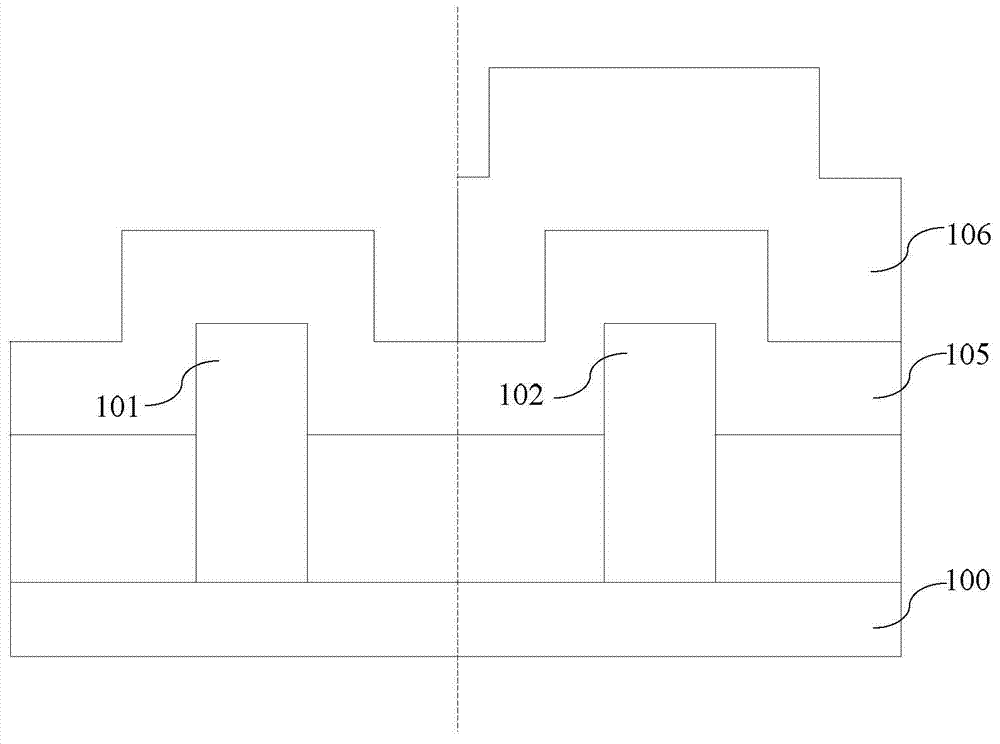

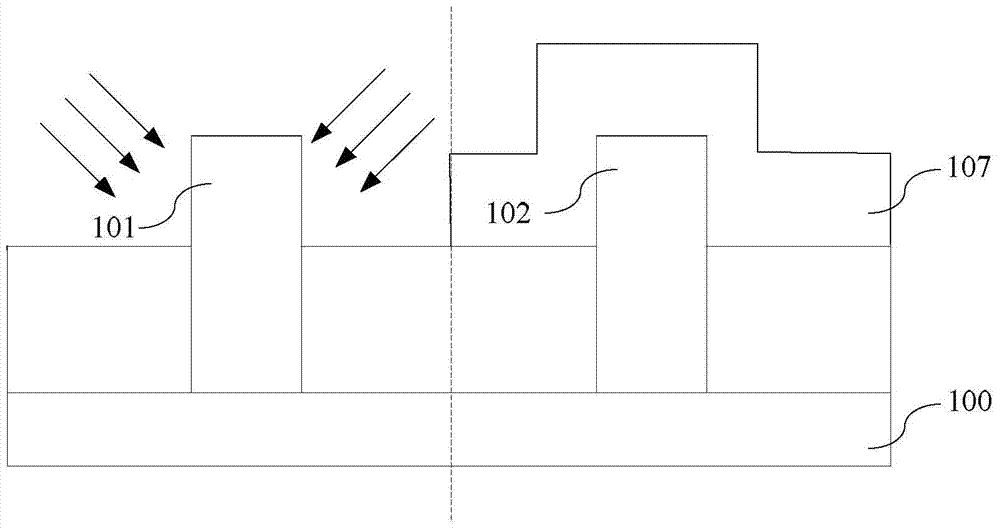

Forming method of fin type field effect transistor

ActiveCN104752221AComplete and precise removalGuaranteed thickness accuracySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringField-effect transistor

A forming method of a fin type field effect transistor comprises the following steps: forming adjacent first fin portion and second fin portion on a substrate; forming a grid electrode spanning the first fin portion and the second fin portion; sequentially forming a first protective layer, a first etching stop layer, a second protective layer and a second etching stop layer covering the grid electrode and the substrate from top to bottom; forming a patterned mask layer on the second etching stop layer, wherein the patterned mask layer covers the second etching stop layer of the second fin portion; removing the second etching stop layer on the first fin portion, then removing the patterned mask layer and the second protective layer on the first fin portion in a same technology; removing the first etching stop layer on the first fin portion by a first etching, then removing the first protective layer on the first fin portion by a second etching to expose the first fin portion; heating the substrate, injecting ions into the first fin portion on bilateral sides of the grid electrode to form a source electrode and a drain electrode; removing the first etching stop layer and the first protective layer covering the second fin portion. By the method of the fin type field effect transistor, the difficulty in manufacturing the transistor is reduced, and the performance of the transistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

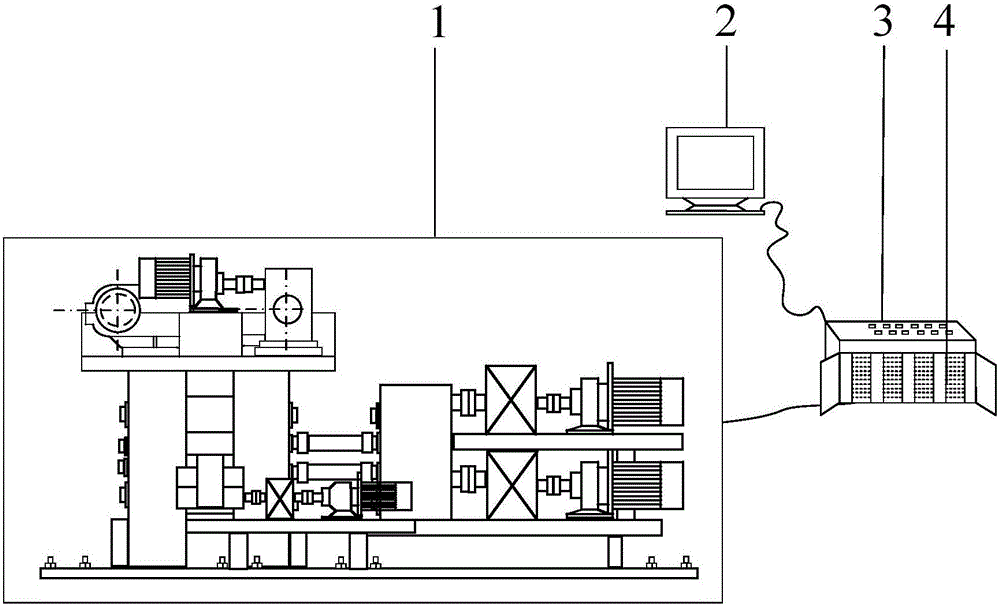

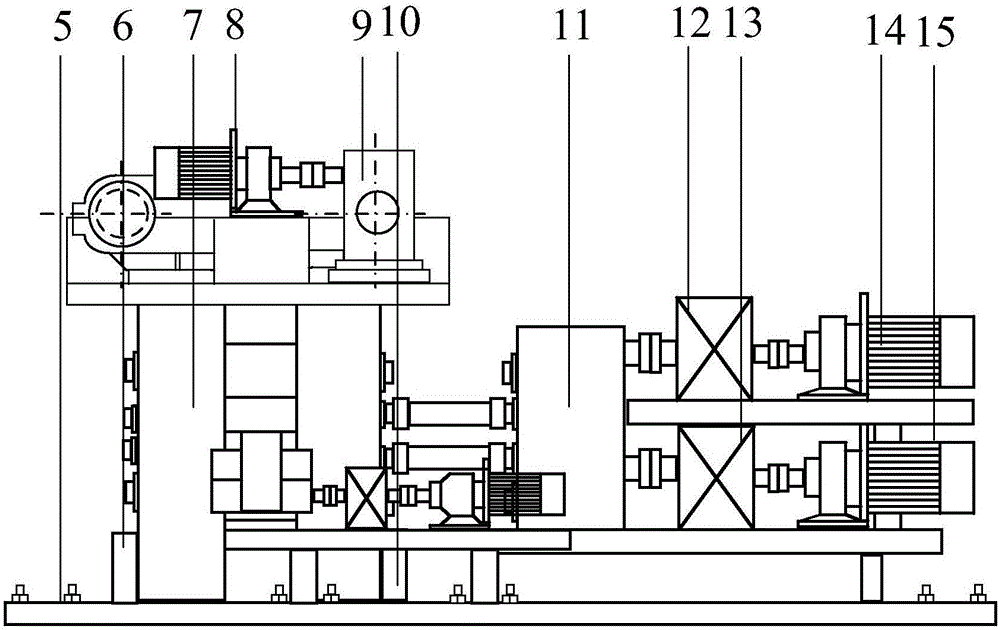

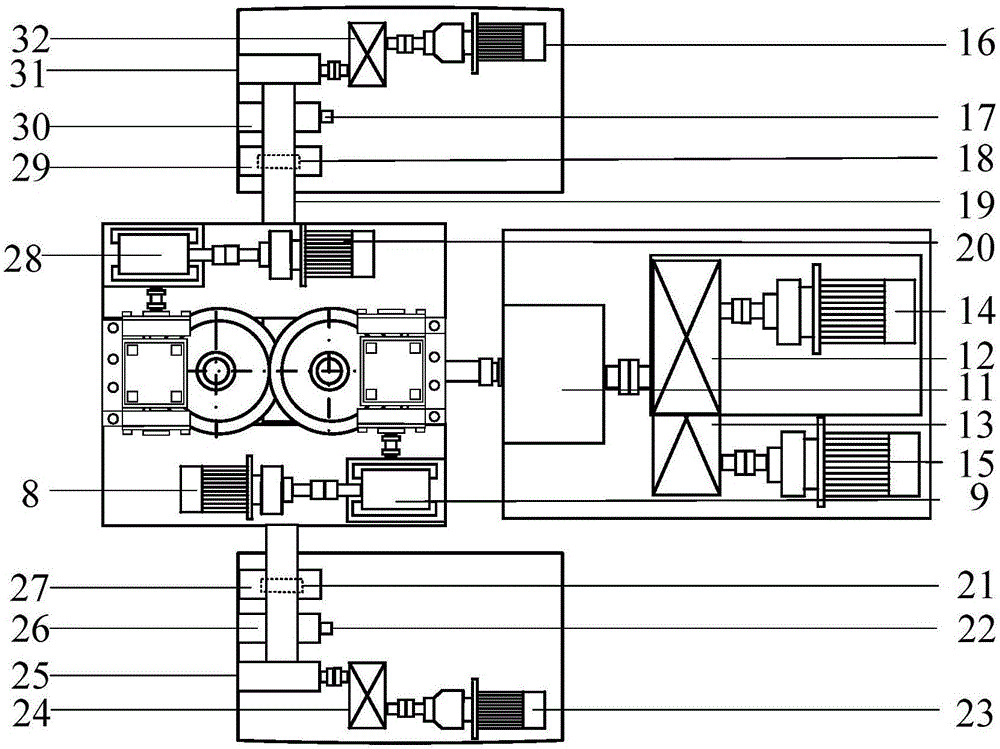

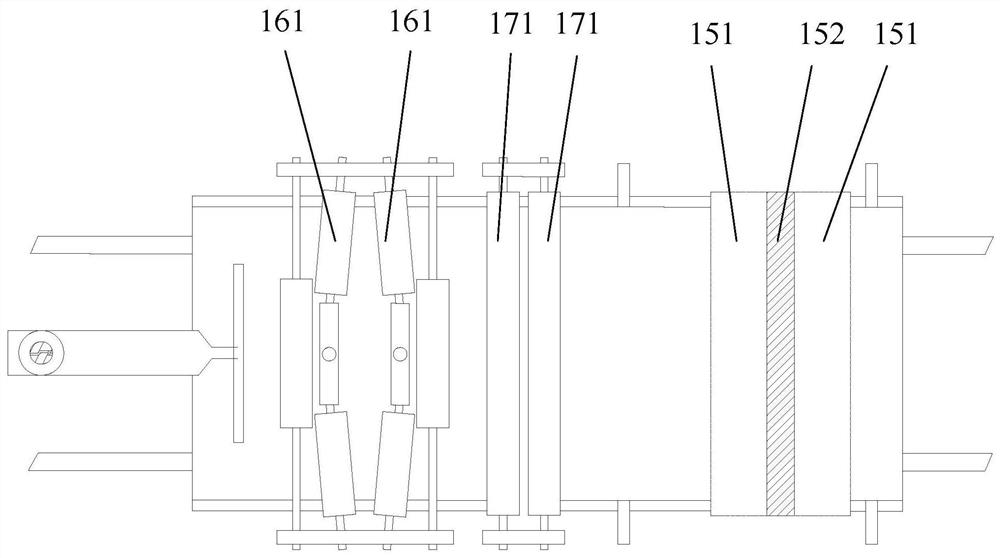

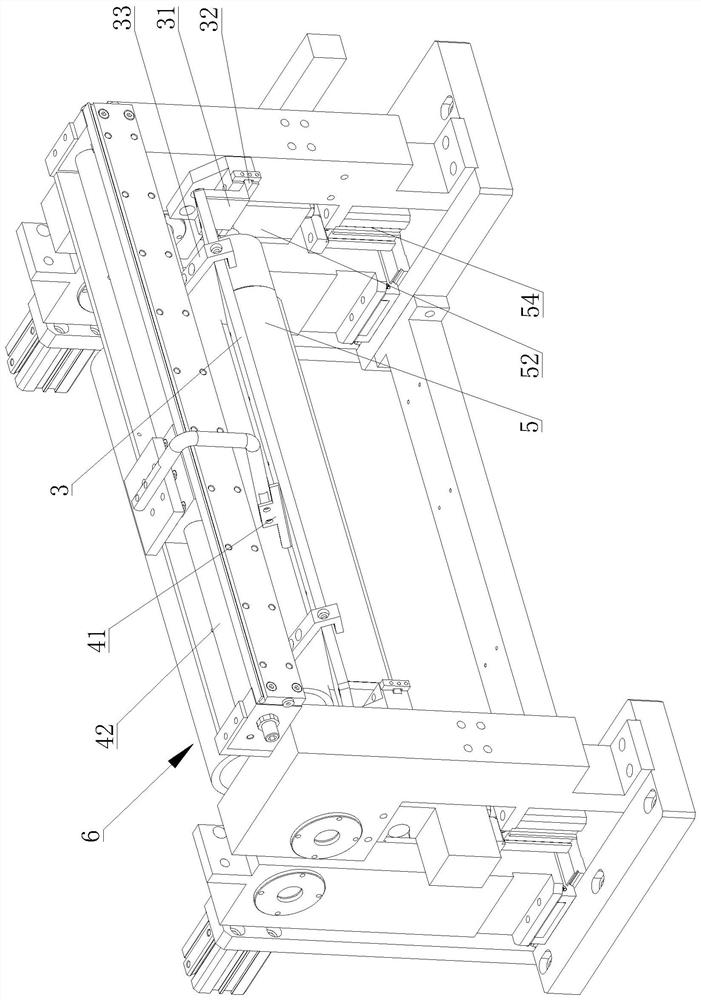

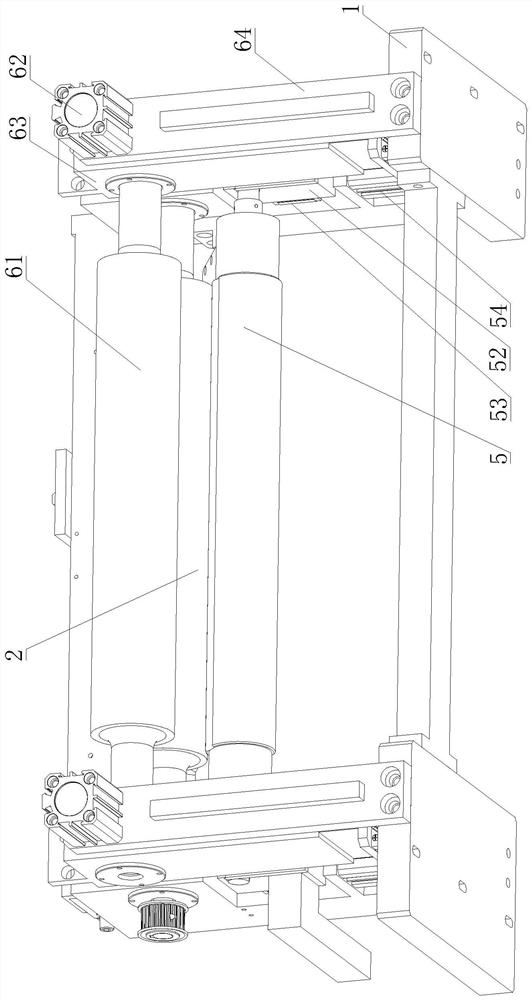

Metal ultra-thin strip rolling mill with selectable driving modes and rolling method thereof

ActiveCN106583452AIncrease stiffnessIncreased torsional strengthMetal rolling stand detailsMeasuring devicesControl systemEngineering

The invention provides a metal ultra-thin strip four-roller rolling mill with selectable driving modes and a rolling method thereof. The rolling mill comprises a rolling mill mechanical part and a control system, wherein two main driving motors, two main reduction gears and a compound gear box are positioned on the same side of a mill housing; the compound gear box is provided with four output shafts which are connected with an upper support roller and a lower support roller through universal spindles or connected with an upper work roller and a lower work roller through the universal spindles; and the upper driving part and the lower driving part of the compound gear box are independently controlled by the first main driving motor and the second main driving motor respectively and are mutually independent, and the reduction ratio of the upper driving part to the lower driving part is adjustable. The rolling method has a support roller driving mode and a work roller driving mode. When the rolling mill is used for asymmetrical rolling of ultra-thin strips, as asymmetrical rolling can break through the restriction from the minimum rollable thickness of synchronous rolling, the sheet rolling capacity is higher, the on-line adjustment range of the different speed ratio is broad, and the range of rollable raw materials can be effectively expanded.

Owner:NORTHEASTERN UNIV

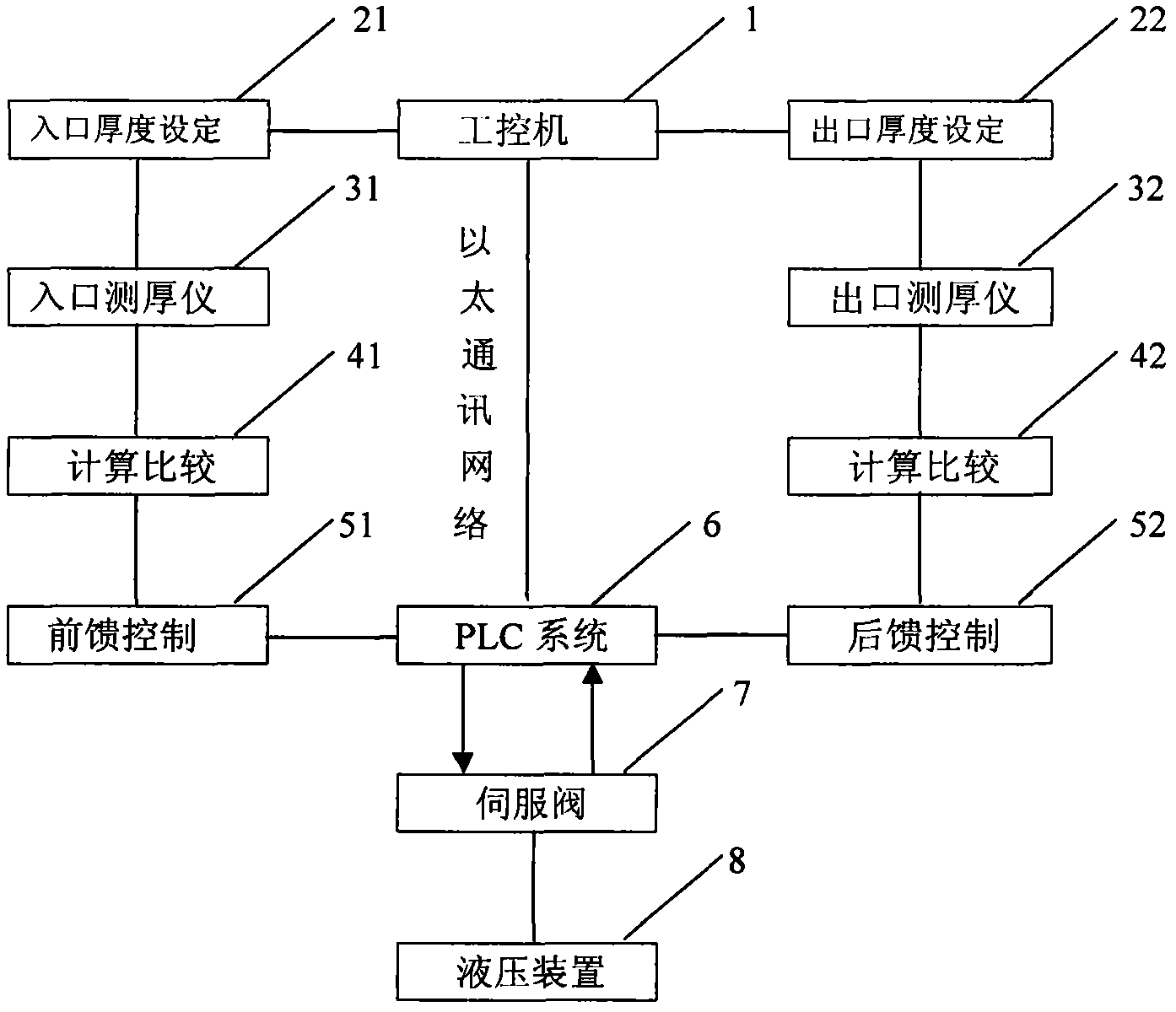

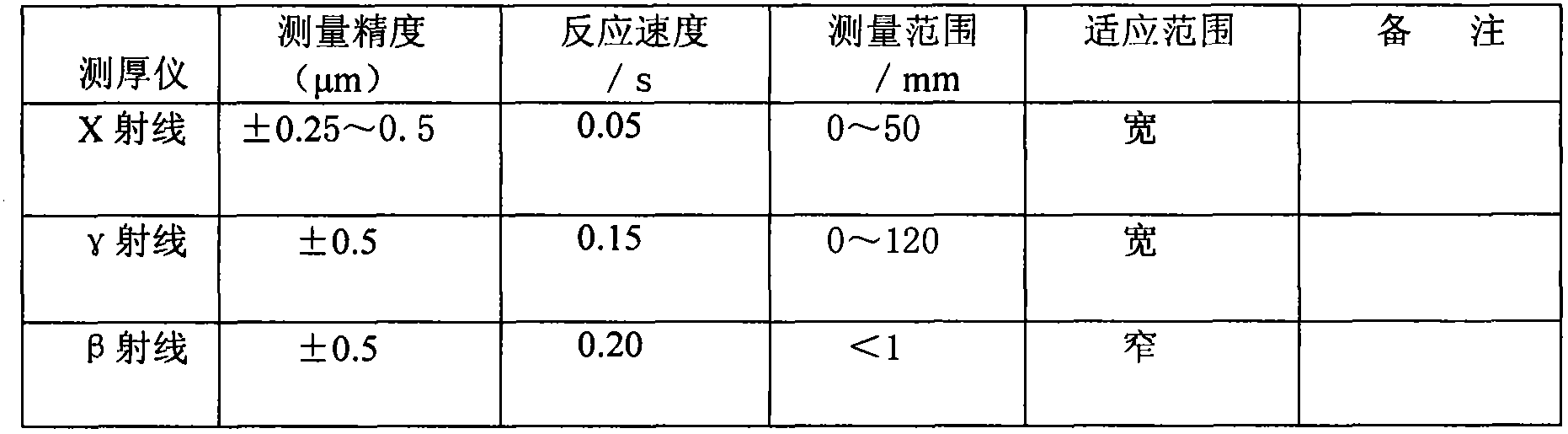

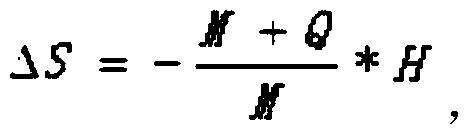

Thickness measuring method for cold rolling strips

InactiveCN103008365AGuaranteed thickness accuracyReasonable methodRoll mill control devicesMeasuring devicesProgrammable logic controllerEngineering

The invention discloses a thickness measuring method for cold rolling strips, which comprises an industrial control computer, inlet thickness setting, outlet goal setting, an inlet thickness meter, an outer thickness meter, inlet calculating and comparing, outlet calculating and comparing, feedforward control, feed backward control, a PLC (Programmable Logic Controller) system, a servo valve and a hydraulic device. The X-ray thickness measuring method without a radioactive source is adopted to input the inlet thickness setting and outlet thickness setting of strip steel through the human-computer interface of the industrial control computer, ensuring that the thickness precision of the cold rolling strips conforms to the quality requirement.

Owner:TIANJIN YIBO STEEL MAKING

Method for machining thin web titanium alloy edge strip

ActiveCN105312645AGuaranteed thickness accuracyReduce distortionMilling equipment detailsMilling cutterTitanium alloy

The invention discloses a method for machining a thin web titanium alloy edge strip, wherein the method is convenient to operate and capable of eliminating part deformations. The method for machining the thin web titanium alloy edge strip comprises the following steps in order: rough machining, semi-finish machining and finish machining; in the process of rough machining, firstly, a hard alloy end mill is adopted for rough machining of a part at a large cutting depth, a low rotating speed and a low feed speed; and secondly, a clamped indexable milling cutter is adopted as a machining cutter for equal-height cutting machining at a small cutting depth in such a manner of fast feed. The method for machining the thin web titanium alloy edge strip is capable of quickly removing black allowance and improving the machining efficiency; besides, the allowance of each portion is uniform, which is favorable for programming during semi-finish machining of the part, and further, machining cutting can be more steady.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Steel strip for home appliance panel and manufacturing method thereof

ActiveCN103194670BGuaranteed plasticityGuaranteed thickness accuracyFurnace typesHeat treatment furnacesChemical compositionHardness

The invention provides a steel strip for deep drawing of a household electric appliance panel film. The steel strip comprises the following chemical components by mass percent: 0.01 percent<=C<=0.03 percent; zero percent<Si<=0.02 percent; 0.1 percent<=Mn<=0.25 percent; zero percent<P<=0.02 percent; zero percent<S<=0.025 percent; 0.02 percent<=Al<=0.05 percent; and the balance of Fe. The high-hardness steel strip for a household electric appliance panel totally meets the quality requirements for strength, hardness and elongation of refrigerator panel steel based on many tests and trial use, is popular among clients, and has popularization application value and broad prospect as the cold rolled strips for household appliances have a very broad development prospect.

Owner:浙江龙盛薄板有限公司

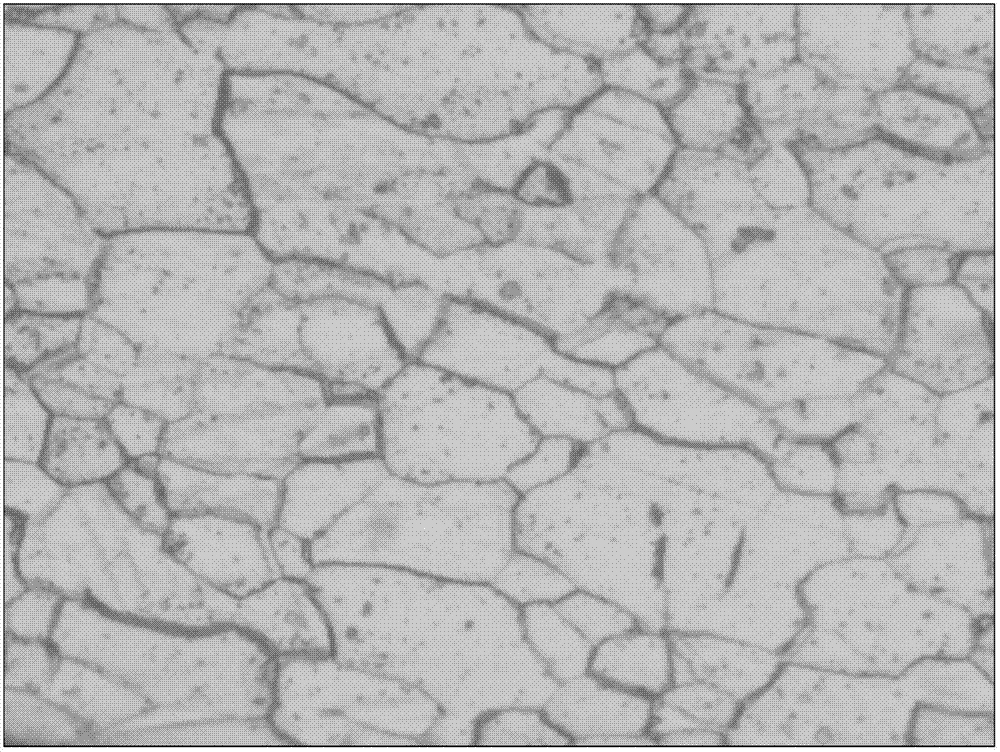

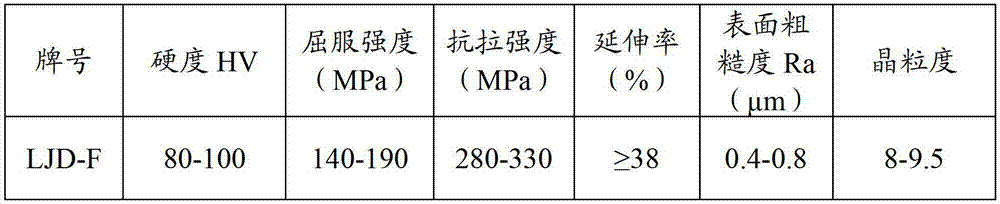

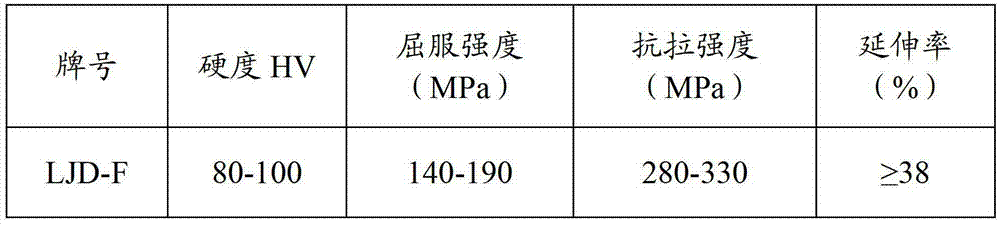

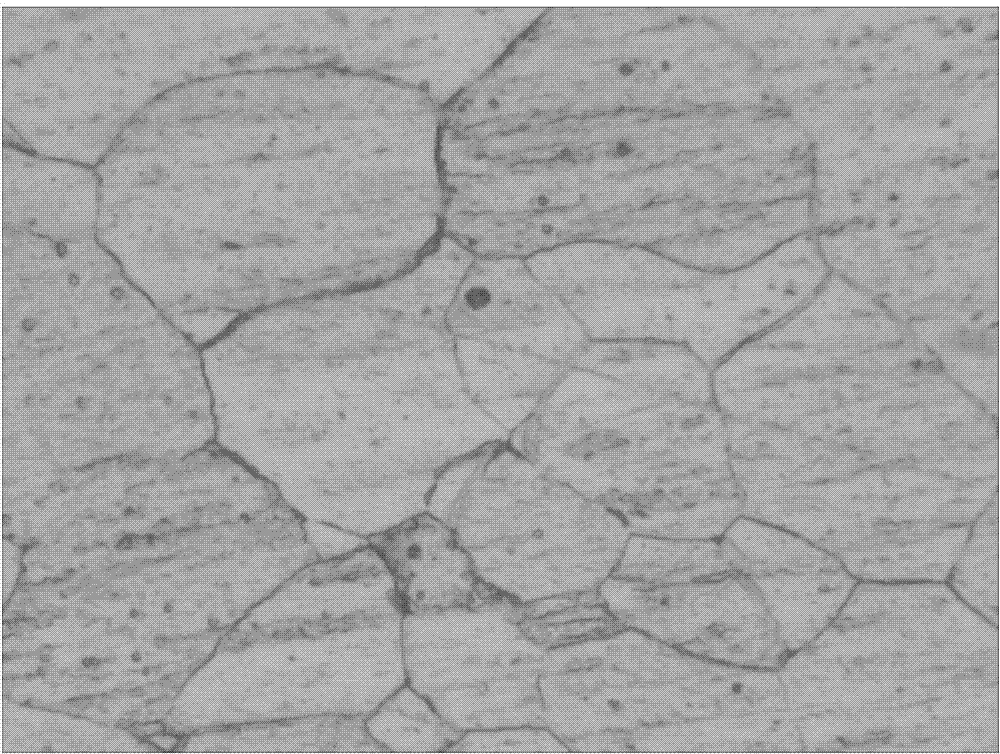

A semi-process non-oriented silicon steel and its manufacturing method

The invention provides semi-processed non-oriented silicon steel. The silicon steel comprises following chemical components by mass: not more than 0.005% and not less than 0 of C, not more than 0.8% and not less than 0.15% of Si, not more than 0.4% and not less than 0.2% of Mn, more than 0.02% and less than 0.1% of P, more than 0% and less than 0.01% of S and not more than 0.1% and not less than 0.03% of Al, with the balance being Fe. The thickness of the silicon steel is 0.35-0.65 mm, the width is 1000-1250 mm, and the surface roughness Ra is 0.4-1.0 [mu]m. Through a plurality of tests and trials, the silicon steel fully meets quality requirements on iron loss and magnetic induction for motors. After secondary annealing and blueing, the performance can be improved by two levels. The silicon steel is favored by users at present. As the development prospect of the motor industry is wide, the silicon steel is high in popularization and application value and has a wide prospect.

Owner:浙江龙盛薄板有限公司

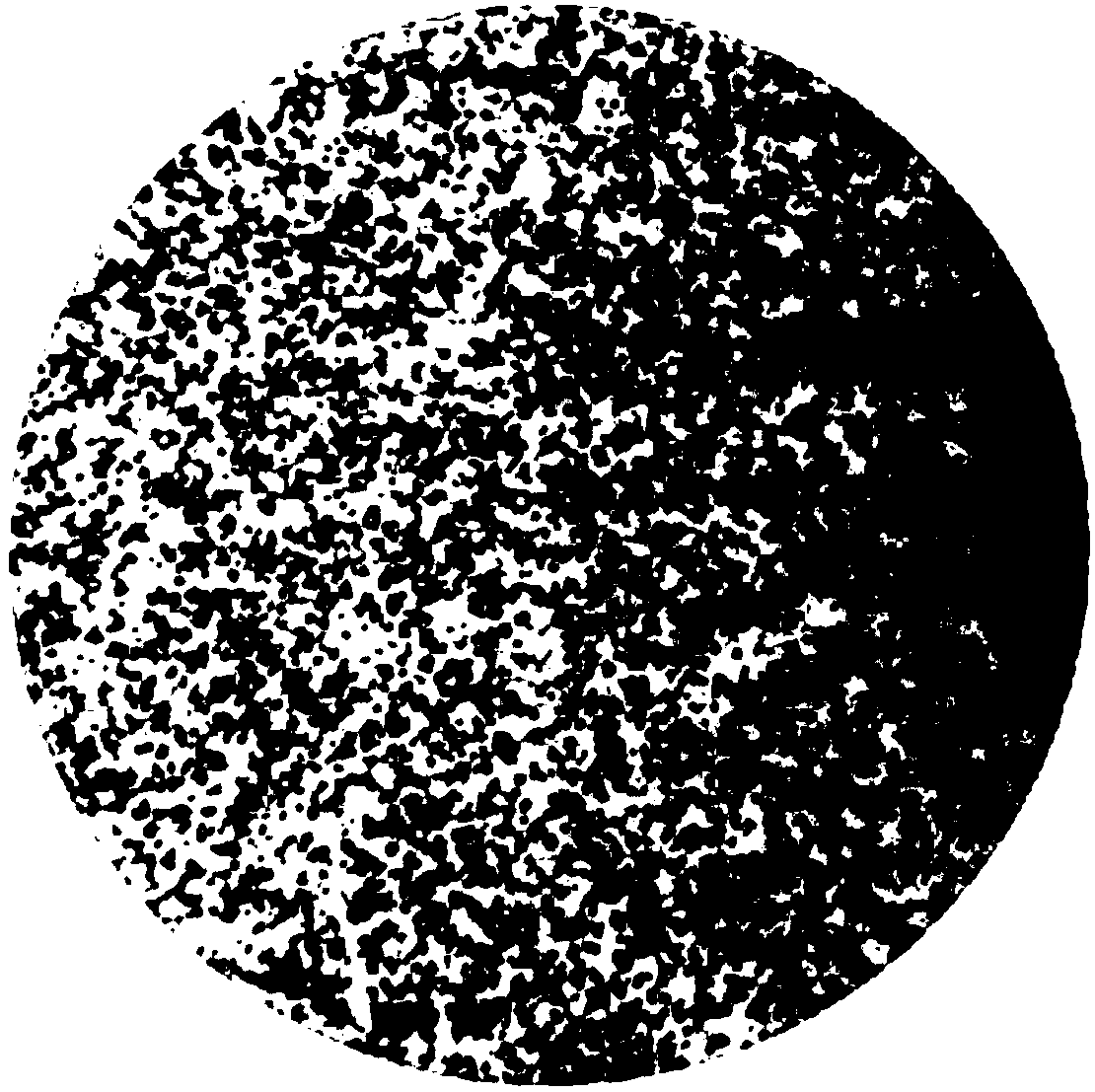

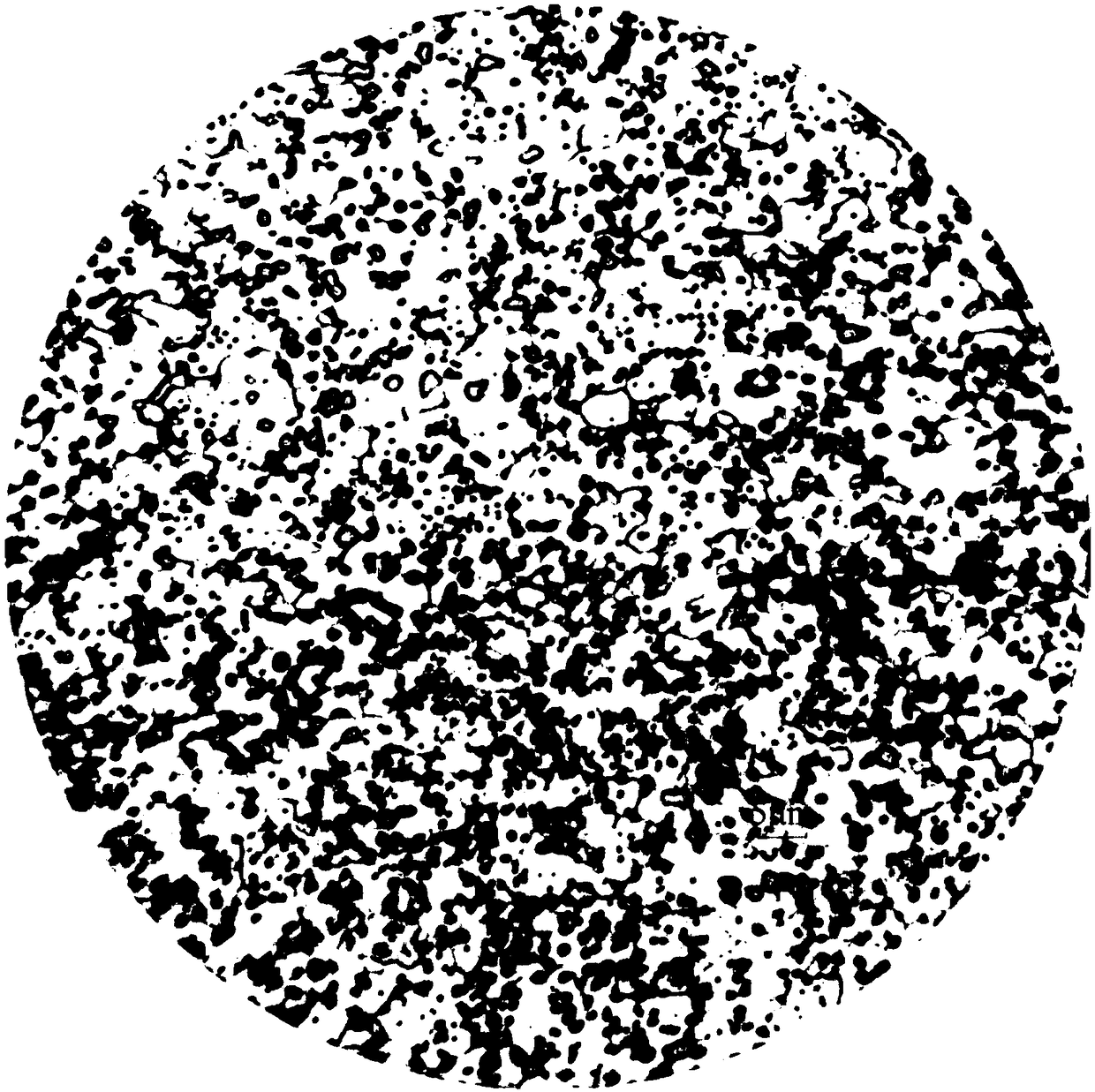

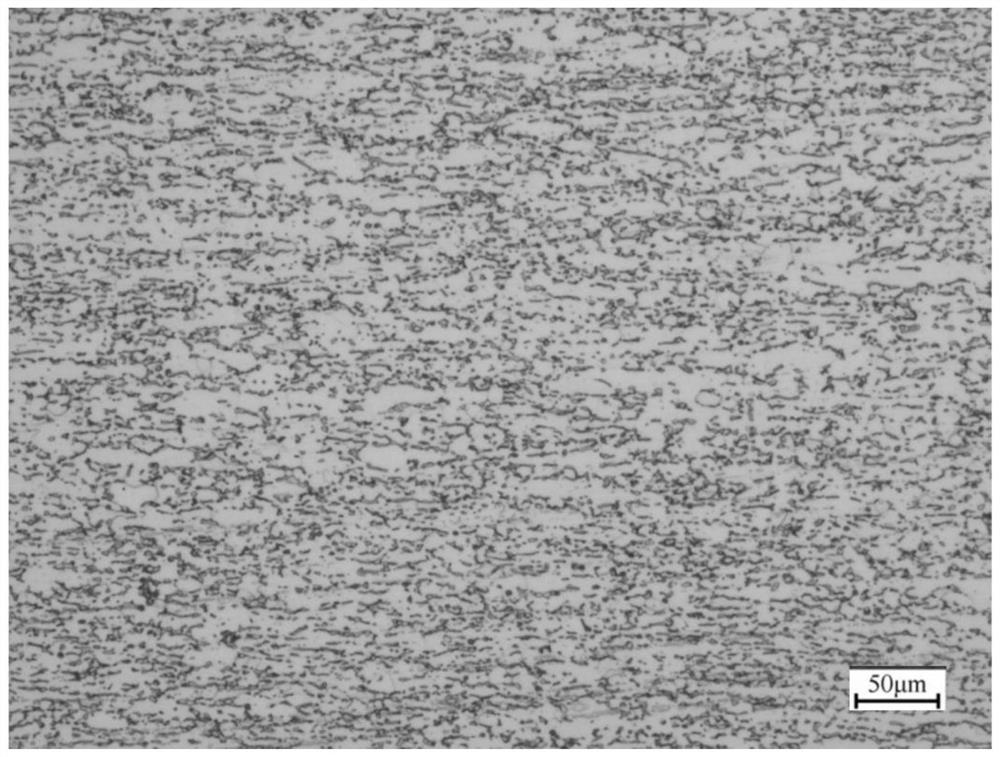

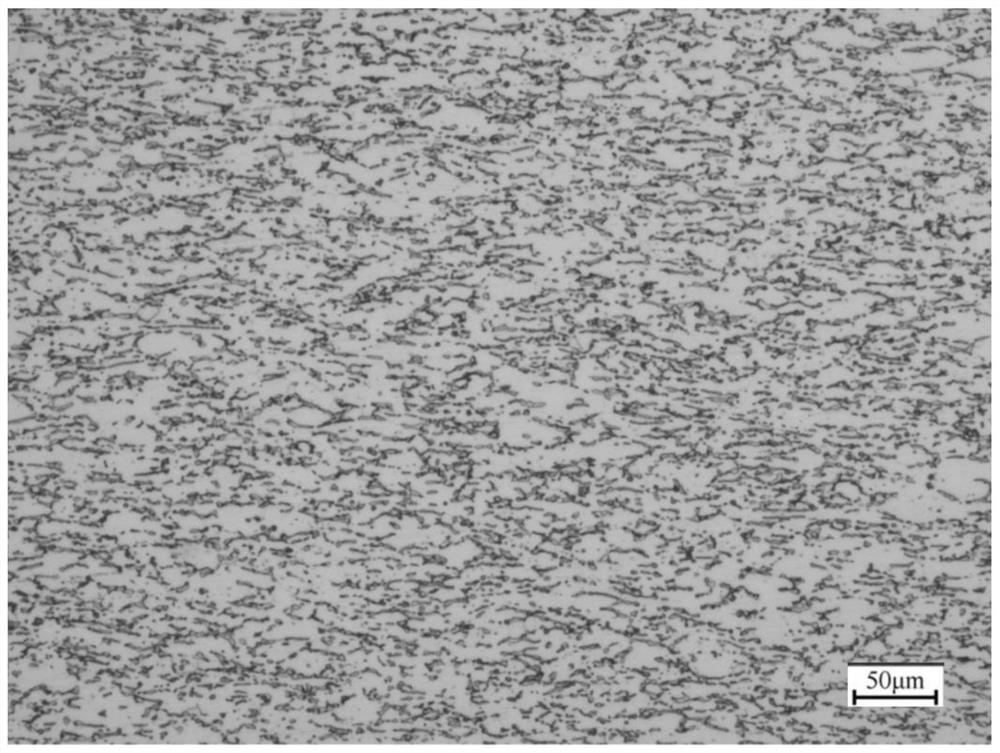

Cold-rolled steel strip for saw-chain cutter teeth and preparation method thereof

InactiveCN108929937ARefining raw material organizationEasy for cold rollingBell type furnacesHeat treatment furnacesChemical compositionSteel belt

The invention discloses a cold-rolled steel strip for saw-chain cutter teeth, wherein the cold-rolled steel strip comprises the following chemical composition by mass: 0.61%=<C=<0.72%; 0.15%=<Si=<0.30%; 0.30%=<Mn=<0.40%; 0.10%=<Cr=<0.20%; 0.90%=<Ni=<1.10%; 0%=<Mo=<0.02%; 0.03%=<Ni=<0.05%; 0%<P=<0.02%; 0%<S=<0.01%; and the balance Fe. A target product can be obtained from hot-rolled raw materials through hot rolling, cold rolling, annealing and cutting. The test result of the final product meets the target value of the customer demand and is 95% or more. The cold-rolled steel strip for a saw chain has broad development prospects and great promotion and application value.

Owner:浙江龙盛薄板有限公司

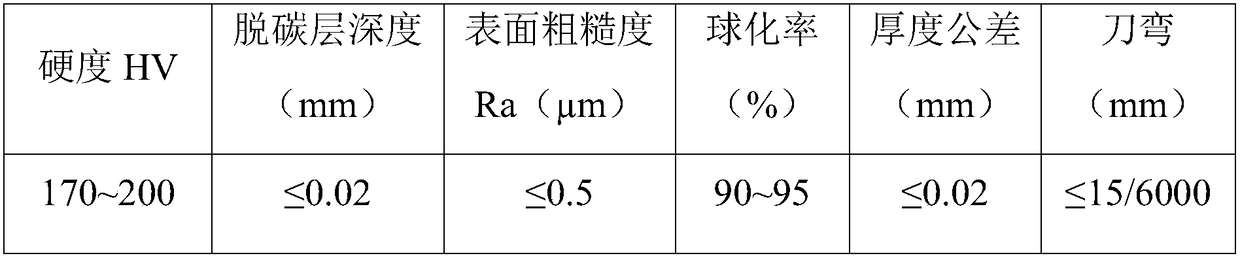

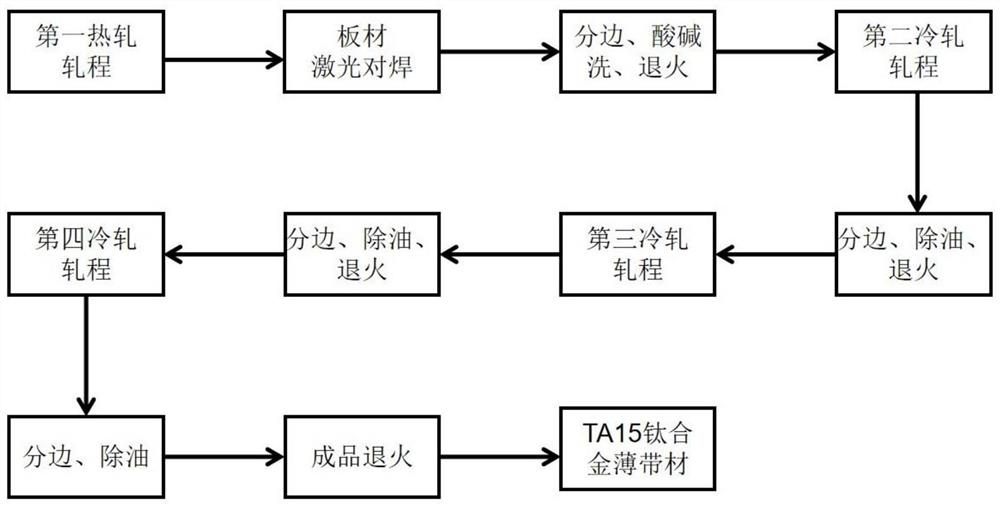

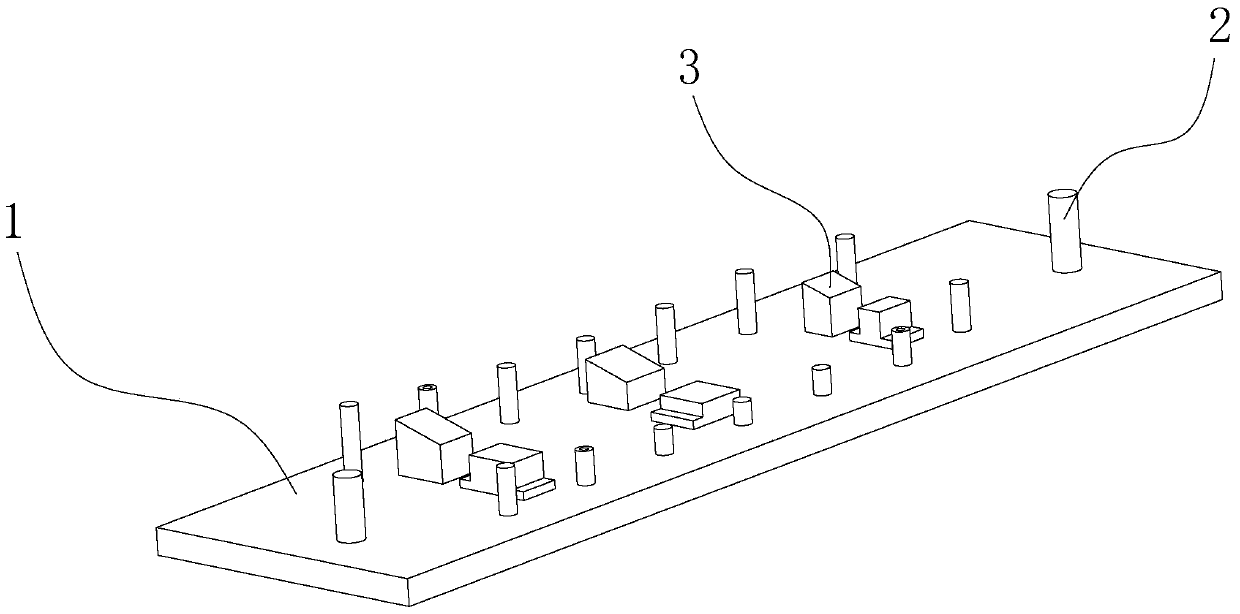

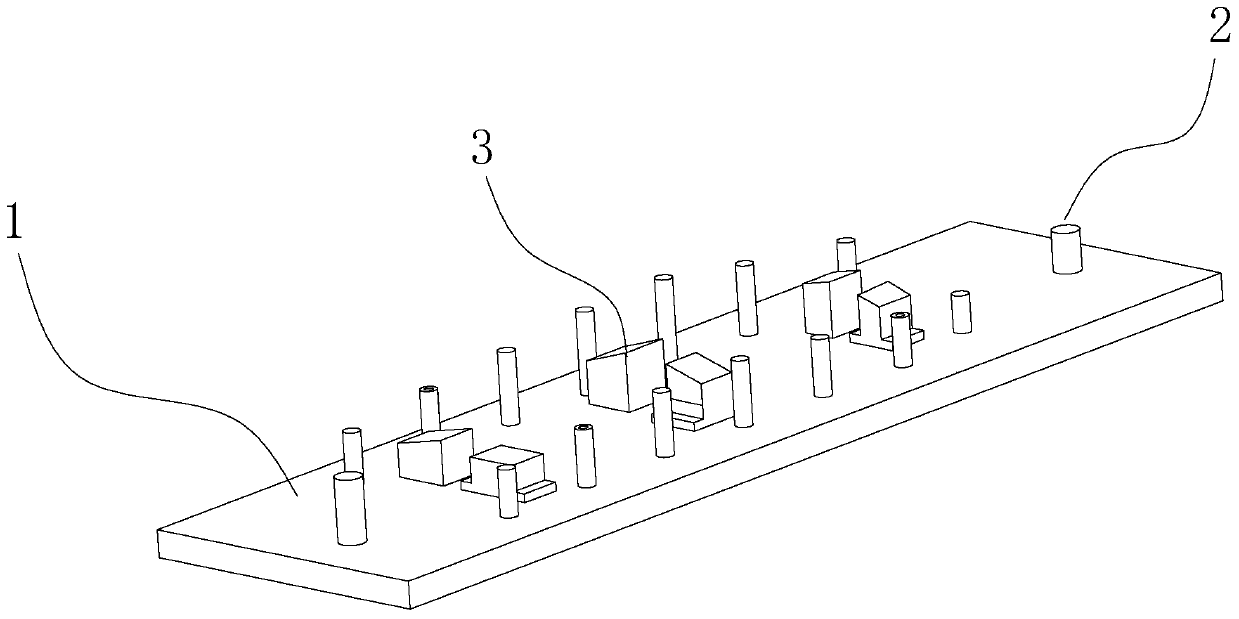

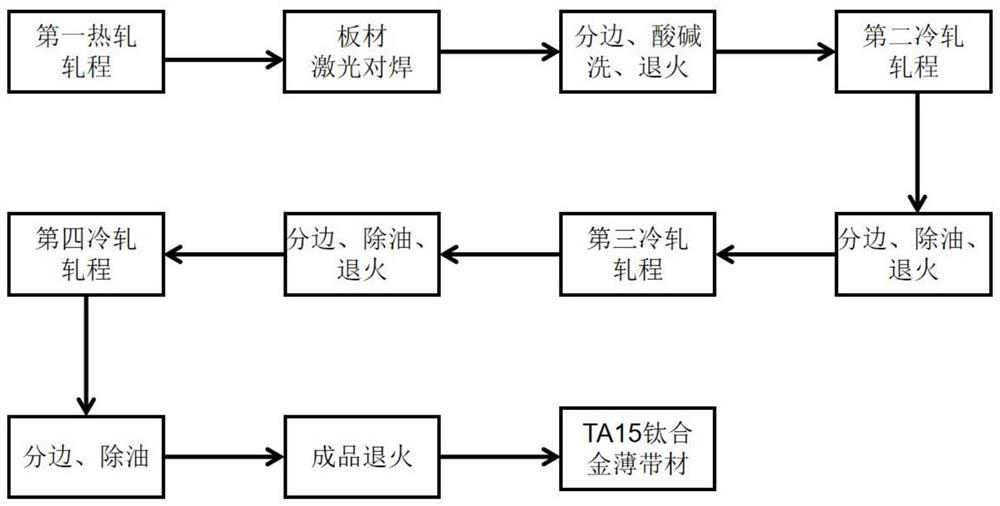

Preparation method for TA15 titanium alloy thin strip

ActiveCN113714286AGuaranteed thickness accuracyImprove rolling efficiencyFurnace typesRollsButt weldingTitanium alloy

The invention discloses a preparation method for a TA15 titanium alloy thin strip. The preparation method comprises the following steps of 1, carrying out single-strip reversible hot rolling in the first rolling process; 2, carrying out butt welding; 3, carrying out vacuum annealing heat treatment after acid-alkali washing and longitudinal shearing and splitting treatment; 4, carrying out reversible strip rolling in the second rolling process; 5, carrying out vacuum annealing heat treatment after cleaning and longitudinal shearing and splitting treatment; 6, carrying out reversible strip rolling in the third rolling process; 7, carrying out vacuum annealing heat treatment after cleaning and longitudinal shearing and splitting treatment; 8, carrying out reversible strip rolling in the fourth rolling process; 9, carrying out cleaning and longitudinal shearing and splitting treatment; and 10, carrying out annealing treatment so as to obtain the TA15 titanium alloy thin strip. According to the preparation method, a four-roller reversible hot rolling mill and a Sendzimir twenty-roller cold rolling mill are adopted, plate laser butt welding is combined, rolling of one hot rolling process and three cold rolling processes is carried out in sequence, and therefore the rolling efficiency is improved, the yield is increased, the cost is lowered, the number of the rolling processes is decreased, and the thickness precision of the TA15 titanium alloy thin strip with the thickness ranging from 0.3 mm to 0.6 mm is guaranteed.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Lithium ion battery cover with explosion-proof function

PendingCN112331967AGuaranteed thickness accuracyHigh precisionSecondary cellsCell lids/coversLithium electrodeStructural engineering

Owner:GUANG DONG VDL NEW ENERGY CO LTD

Lithium ion battery negative plate and preparation method thereof

InactiveCN112331814ASimple preparation processEasy to produceSecondary cellsElectrode collector coatingHigh energyFast charging

The invention relates to the field of battery negative plates, and discloses a lithium ion battery negative plate. The negative plate comprises a copper foil, a first graphite layer coated on one surface of the copper foil, a second graphite layer coated on the other surface of the copper foil, a first quick charge material layer coated on one surface of the first graphite layer back to the copperfoil, and a second fast charging material layer which is coated on one surface, back to the copper foil, of the second graphite layer. The invention also discloses a preparation method of the lithiumion battery negative plate. The technical problems that in the prior art, a battery negative plate is complex in manufacturing process, low in energy density and poor in fast charging performance consistency are solved; the negative plate provided by the invention has the advantage of convenience in manufacturing, is convenient for high-efficiency automatic production, and meets the high-qualityand high-efficiency production requirements of customers; besides, the consistency of the quick charging performance of the negative plate with the structural design is convenient to maintain, the negative plate can be ensured to strictly meet the quality index of the quick charging performance, and meanwhile, the negative plate adopting the coating structure has the advantage of high energy density.

Owner:GUANG DONG VDL NEW ENERGY CO LTD

Resin composition for forming dielectric layer of dielectric substrate for antenna and use thereof

ActiveCN103351578BSmall coefficient of thermal expansionLittle change in thicknessSynthetic resin layered productsMetal layered productsEpoxyDielectric substrate

The invention relates to a resin composition used for forming a dielectric layer of a dielectric substrate for an antenna. The resin composition comprises (A), epoxy resin containing a naphthalene nucleus or diphenyl structure, (B), any one of or a mixture of at least two of tri(4-hydroxyphenyl) methane type epoxy resin, o-cresol type novolac epoxy resin and phenol type novolac epoxy resin, (C), a resin fusion viscosity modifier, and (D), spherical ceramic powder after presintering treatment. With the adoption of the resin composition, the obtained dielectric substrate has a high dielectric constant, high peeling strength, a low thermal expansion coefficient and very good thickness consistency, and can meet a performance requirement of the high dielectric constant antenna substrate.

Owner:江苏生益特种材料有限公司

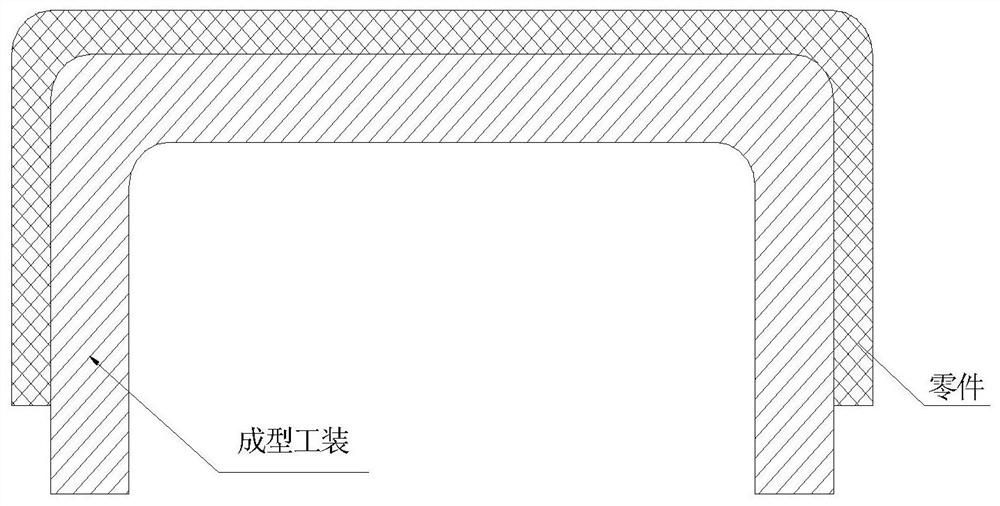

C-beam composite material forming tooling and composite material C-beam forming method

ActiveCN108688192BQuality assuranceGuaranteed thickness accuracyDomestic articlesShaped beamEngineering

Owner:深圳市泰格尔航天航空科技有限公司

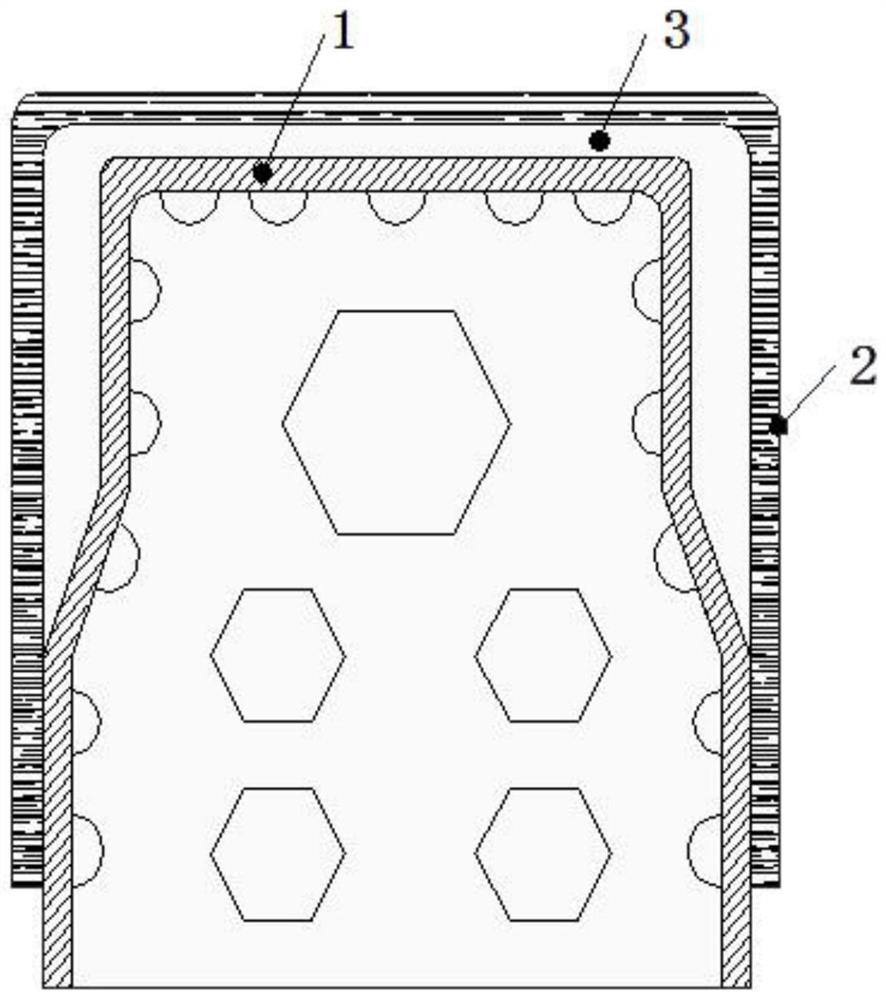

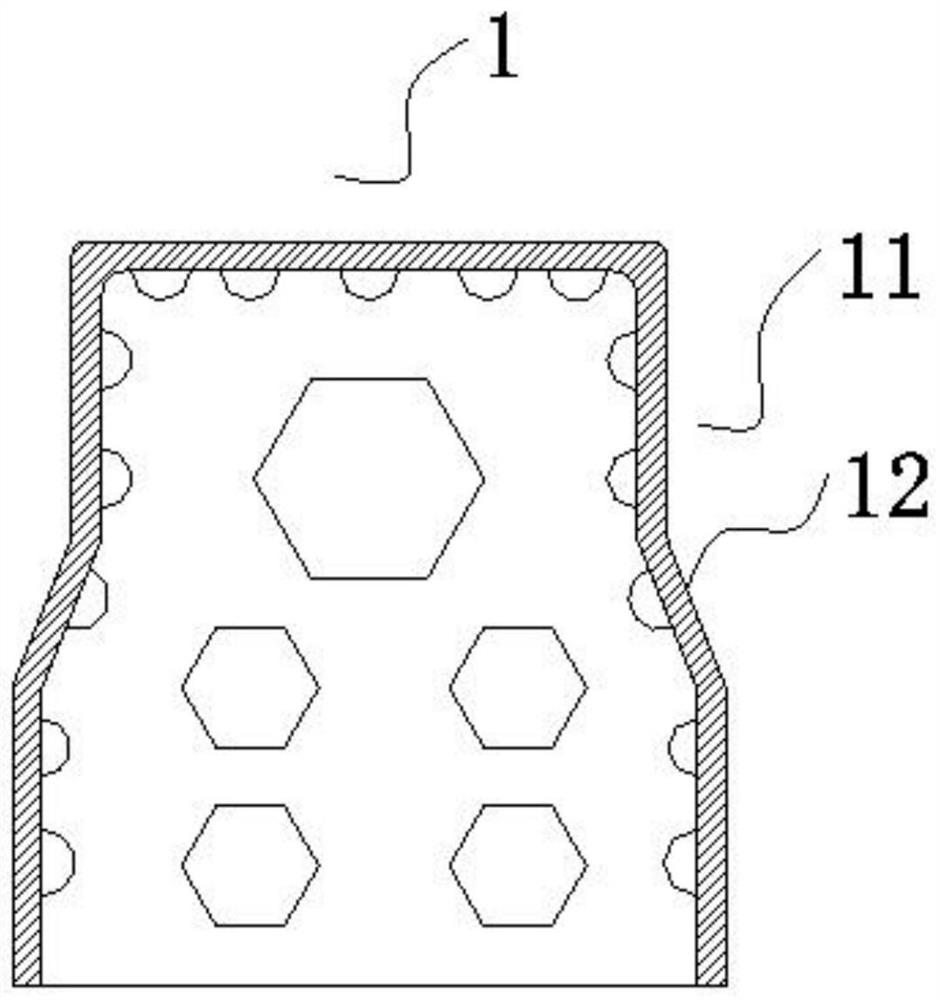

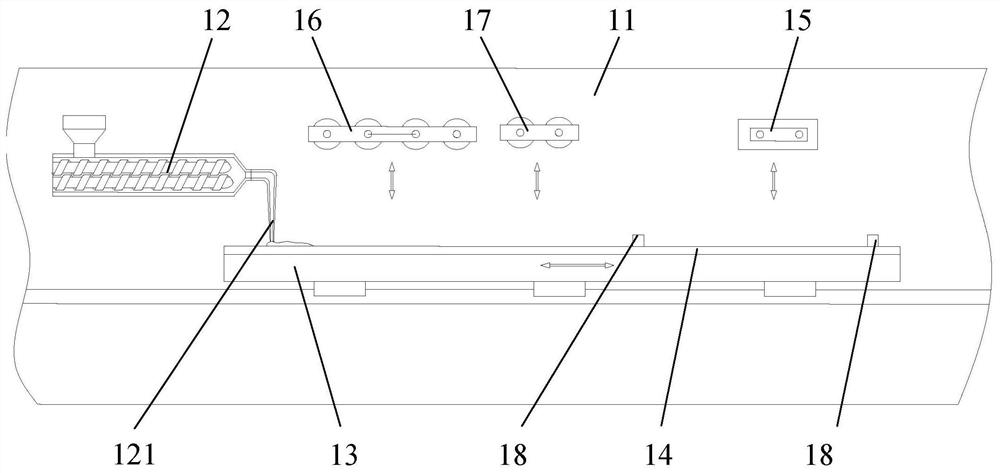

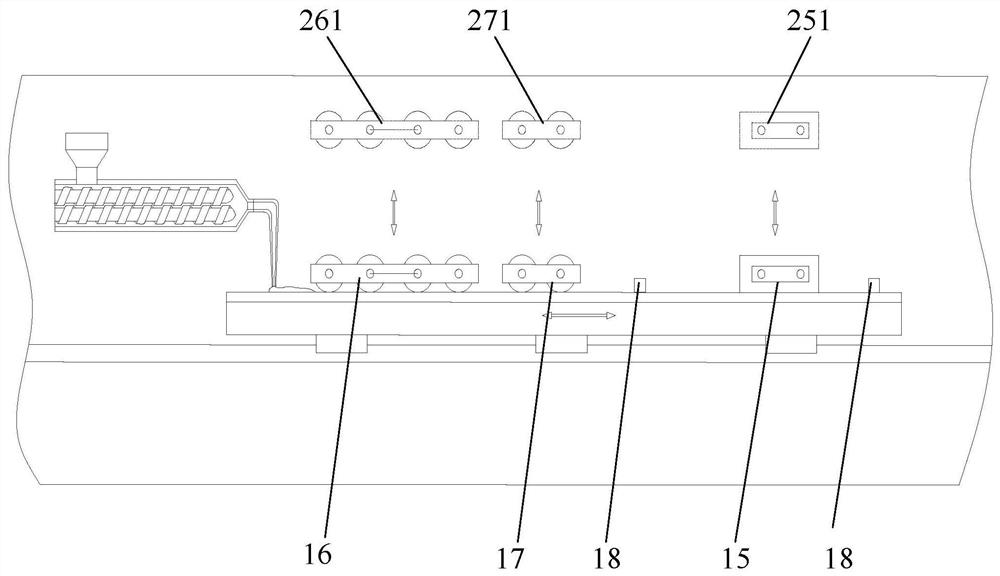

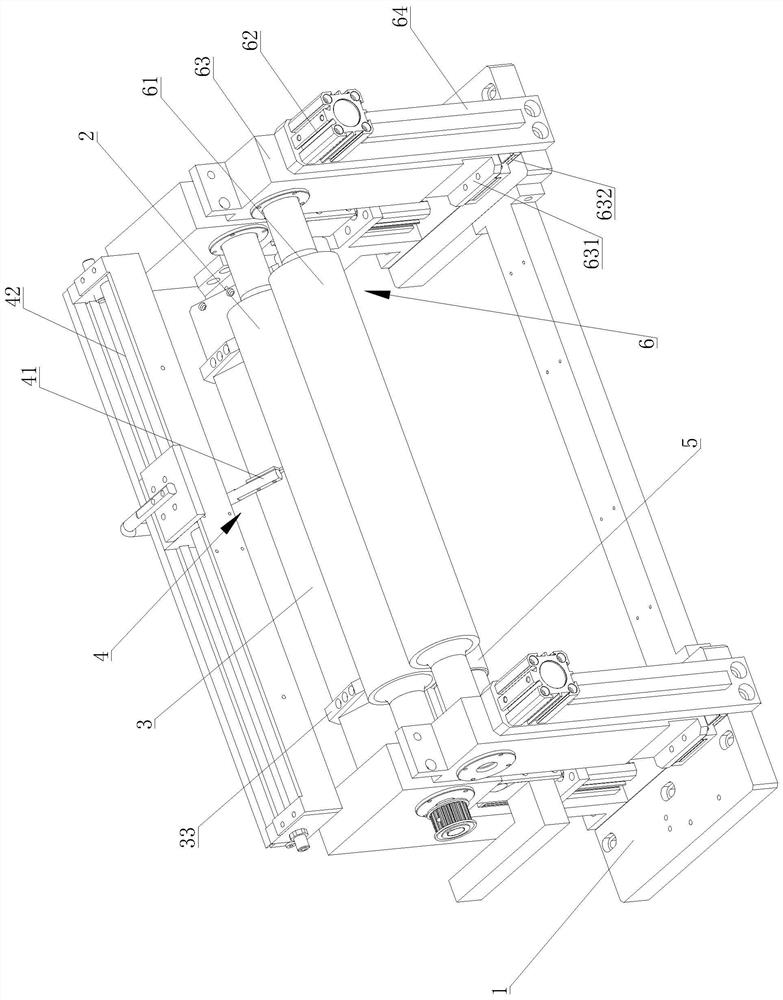

Medicinal film forming equipment, forming equipment control method and film forming method

ActiveCN113043564AGuaranteed thickness accuracyMeet the needs of precision moldingPharmaceutical industryControl system

The invention provides precise forming equipment and method for a large-area viscoelastic material film. The film forming equipment comprises a rack, a mixing extrusion device, a movable bed, a cushion block, a pressing plate, a rolling device and a control system. A thin film material is extruded onto the movable bed, the rolling device is controlled to uniformly distribute and pre-press the thin film material, and the pressing plate is controlled to move to the cushion block to uniformly press the thin film material to a preset thickness. According to the thin film forming equipment, the thin film forming equipment control method and the thin film forming method, the requirement for precise forming of a large-area viscous-elastic material thin film in the pharmaceutical industry can be met, the thin film can be rapidly and evenly formed, continuous production can be achieved on the premise that the thickness precision of the thin film is guaranteed, the labor intensity of operators is reduced, and the production efficiency is effectively improved.

Owner:江苏集萃新型药物制剂技术研究所有限公司

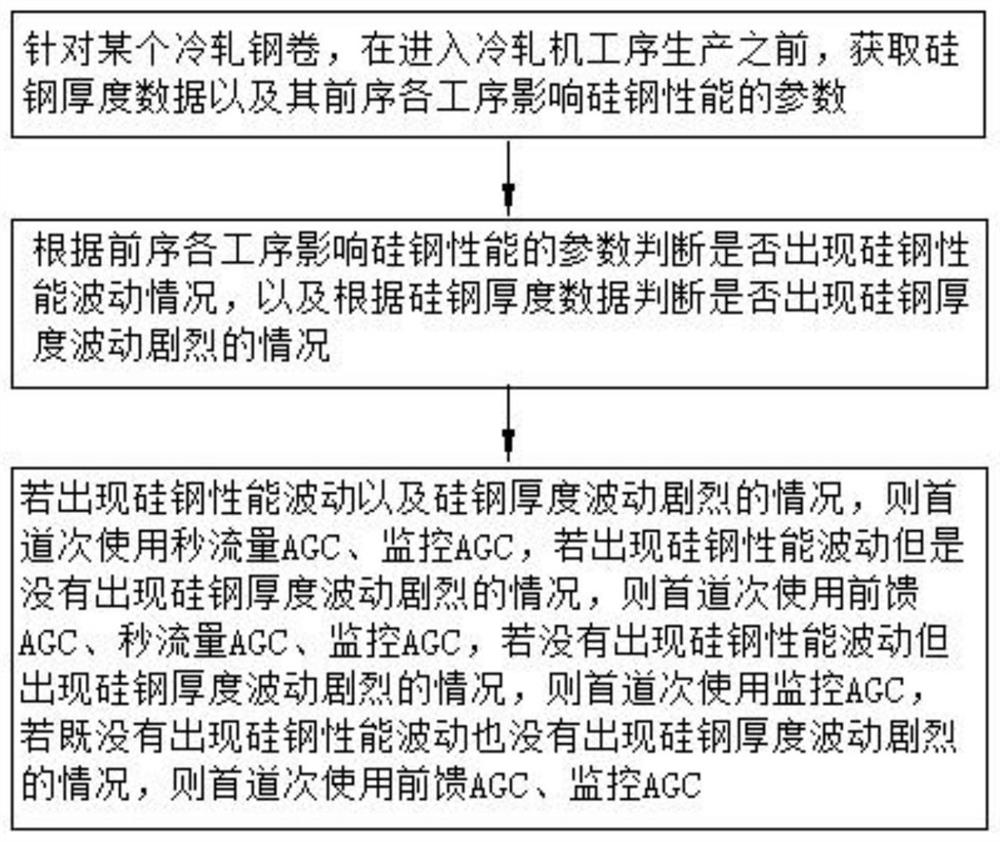

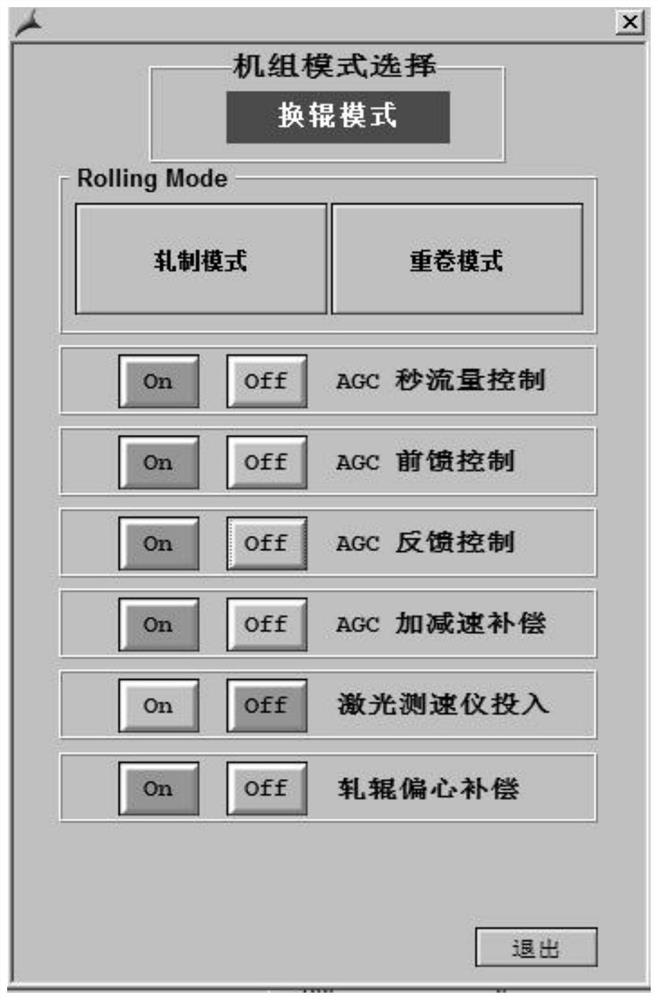

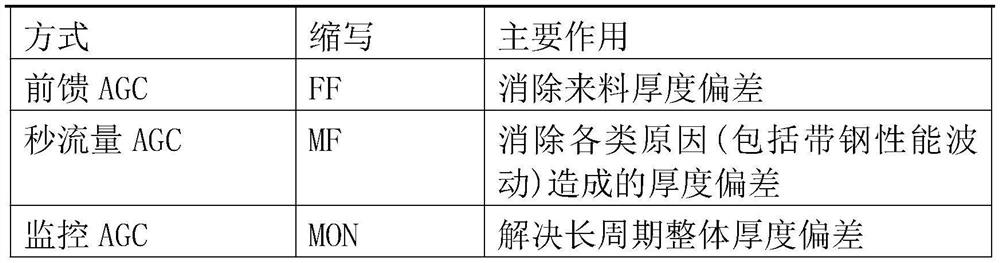

Cold-rolled silicon steel thickness control method and device based on full-process data

PendingCN114101338AGuaranteed thickness accuracyAvoid defectsRoll force/gap control deviceMetal rolling stand detailsManufacturing engineeringMaterials science

The invention relates to a cold-rolled silicon steel thickness control method and device based on full-process data, and the method comprises the steps: for a certain cold-rolled steel coil, monitoring AGC is used by default in the first pass, before the cold-rolled steel coil enters a cold-rolling mill process for production, the production process and quality data of the previous full process of the cold-rolled steel coil are obtained, pre-identification is carried out, and if the performance fluctuation of silicon steel is found, the cold-rolled steel coil is determined; if yes, the first pass additionally uses the second flow AGC; if it is found that the silicon steel thickness fluctuation is not violent, the feedforward AGC is additionally used for the first pass. According to the method, manual interference is not needed, the optimal AGC production mode can be automatically determined before production by adopting the rule, the thickness precision of a silicon steel product is ensured, and the defect of the silicon steel thickness index is avoided.

Owner:WISDRI ENG & RES INC LTD

A kind of rolling method of wide and thin gauge 6mo super austenitic stainless steel plate

ActiveCN110756580BIncrease widthReduce the number of weldsTemperature control deviceMetal rolling stand detailsHeating timeSS - Stainless steel

The invention discloses a rolling method of a wide-width thin-specification 6Mo super austenitic stainless steel plate. The rolling method includes the following steps that a blank which has the thickness of 110-125 mm, the width of 1500 mm or above and the length of 2550-2620 mm is adopted; the steel blank is sent to a stepping type heating furnace, the ratio of the total heating time to the thickness of the steel blank is controlled to be 15-22 min / cm, the temperature of a uniform heating section is 1230-1270 DEG C, the time for the uniform heating section is at least 30 min, and the tappingtemperature is 1240-1260 DEG C; full transverse rolling is performed through 12+1 rounds, the reduction rate is increased from 17% in the first round to 30-40% in the fifth round and is then gradually reduced, the reduction rate in the eleventh round is 7-9%, the reduction rate of the twelfth round is 4-6%, and air cooling is performed after rolling; and the solid solution temperature is 1160 DEGC, heat preservation is performed for 20 min, and water cooling is performed. The width of this type of finished products can be increased from 2000 nm in the prior art to 2500 mm.

Owner:NANJING IRON & STEEL CO LTD

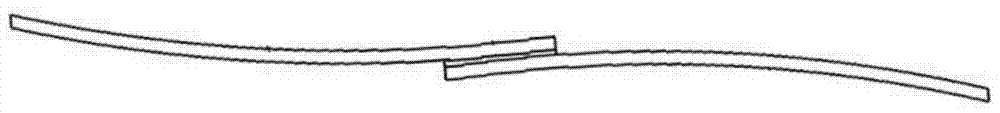

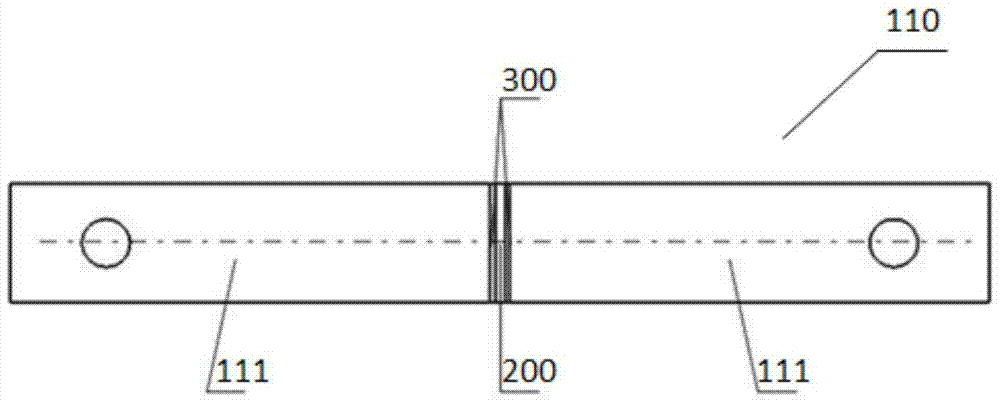

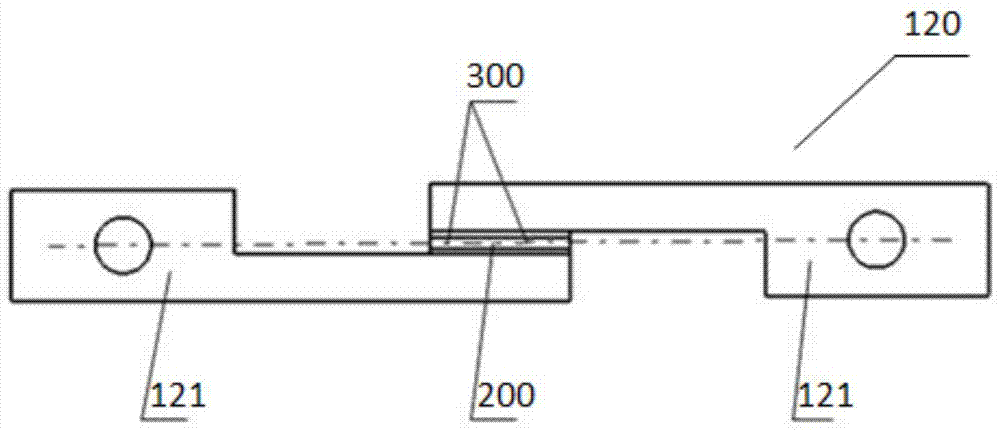

A method for testing adhesive bonding properties of sheet substrates

InactiveCN105067518BNo bending deformationTest and check adhesionUsing mechanical meansMaterial analysisEmpirical correctionEngineering

The invention discloses an adhesive bonding performance testing device for a sheet-shaped base material, which comprises: a sheet-shaped base material; a loading block, which is used to bond and fix the sheet-shaped base material to form a test assembly; The tensile test assembly loading assembly includes a testing machine loading connector, a test assembly connector and a connecting device; wherein, the connecting device, the test assembly connector and the testing machine loading connector are connected in sequence; the test assembly is connected to the test assembly connecting part through the connecting device Connected, the testing machine loads the connector and connects with the testing machine for tensile fracture failure test. The invention also discloses a method for testing the bonding performance of the adhesive used for sheet substrates and an empirical correction method. The invention has the advantages of simple structure, convenient operation, and can effectively test and evaluate the bonding performance of a certain adhesive with respect to sheet substrates, and can also conduct any test components based on tensile-shear combination. test features.

Owner:JILIN UNIV

Oil coating production device for large surface of lithium strip

PendingCN113926639ASimple structureCompact structureLiquid surface applicatorsCoatingsPhysical chemistryEngineering

The invention discloses an oil coating production device for a large surface of a lithium strip. The oil coating production device comprises a rack, an oil coating roller, an oil material plate assembly and a compression roller assembly, wherein the oil coating roller is mounted in the rack; the oil material plate assembly is obliquely mounted in the rack, an oil drainage panel is arranged on the upper surface of the oil material plate assembly, and the oil outlet end of the oil drainage panel is attached to the rear side of the oil coating roller; and the compression roller assembly is mounted in the rack, the pressure applying end of the compression roller assembly is located on the front side of the oil coating roller, and the pressure applying end of the compression roller assembly presses the lithium strip to the oil coating roller. The oil coating production device for the large surface of the lithium strip provided in the invention is simple in structure, achieves large-area oiling on one side of the lithium strip through the oil coating roller and the compression roller assembly, is uniform in oil coating, and is high in speed.

Owner:广东坤川实业有限公司

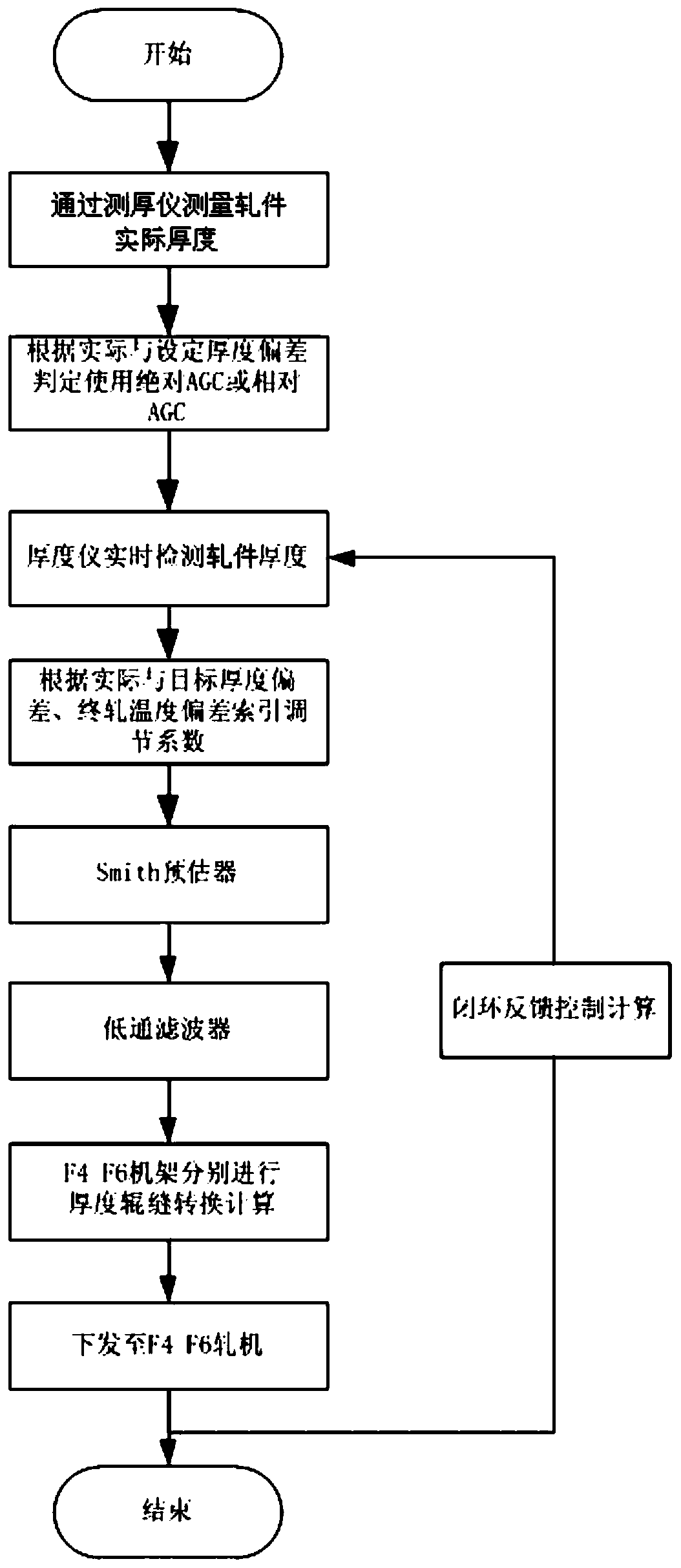

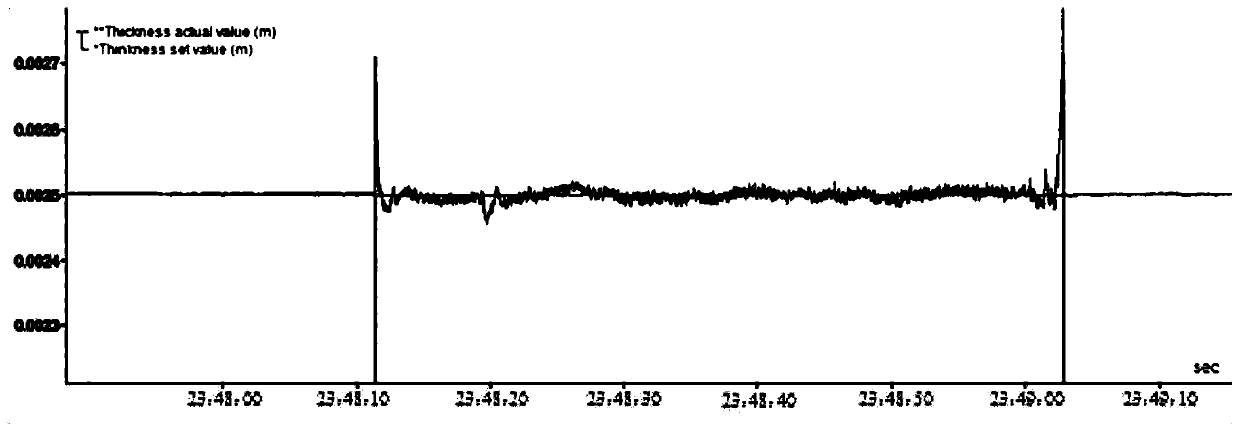

A variable step size monitoring AGC automatic control method for rolling piece thickness control

ActiveCN108453138BImproved Thickness ControlPrecise thickness controlRoll mill control devicesMetal rolling arrangementsAutomatic controlEngineering

The invention discloses a variable step size monitoring AGC automatic control method for rolled piece thickness control. Through the method, a thickness adjustment coefficient KM is automatically indexed according to the difference of a measured actual thickness and a target thickness; different temperature adjustment coefficients Kp are adopted according to the variation of a finished rolling actual temperature and a set temperature; the product of the thickness adjustment coefficient KM multiplied by the temperature adjustment coefficient Kp serves as a final adjustment coefficient K; the AGC adjustment step size of the final n racks of a roll train is adjusted according to the final adjustment coefficient K, the thickness of a rolled piece can be controlled accurately, and the qualifiedrate of the thickness within the tolerance range of + / - 30 microns can reach 100%. Over-adjustment and adjustment quantity insufficiency cannot occur.

Owner:BEIJING SHOUGANG CO LTD

Processing method of thin web titanium alloy flange

ActiveCN105312645BGuaranteed thickness accuracyReduce distortionMilling equipment detailsMilling cutterCarbide

The invention discloses a processing method for a thin web titanium alloy flange which is easy to operate and can eliminate deformation of parts. The processing method of the thin web titanium alloy flange includes the steps in turn: rough machining, semi-finishing, and finishing; in the process of rough machining, firstly, a hard alloy end mill is used, with a large depth of cut, low speed, Rough machining parts at low feed speed; then use machine clamp indexable milling cutter as the processing tool, and use shallow depth of cut and fast feed for contour cutting. The processing method of the thin web titanium alloy flange can quickly remove the blank allowance and improve the processing efficiency; and the allowance of each part is uniform, which is conducive to the programming of the semi-finishing part, and the machining and cutting are more stable.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

A kind of preparation method of ta15 titanium alloy thin strip

ActiveCN113714286BGuaranteed thickness accuracyImprove rolling efficiencyFurnace typesRollsButt weldingTitanium alloy

The invention discloses a preparation method of a TA15 titanium alloy thin strip. The method comprises: first, single-piece reversible hot rolling in the first rolling process; second, butt welding; third, after alkali pickling and slitting treatment Vacuum annealing heat treatment; 4. Reversible strip rolling in the second rolling process; 5. Vacuum annealing heat treatment after cleaning and slitting treatment; 6. Reversible strip rolling in the third rolling process; 7. Cleaning and slitting Slitting treatment followed by vacuum annealing heat treatment; eighth, the fourth rolling process reversible strip rolling; ninth, cleaning and slitting treatment; tenth, annealing treatment to obtain TA15 titanium alloy thin strip. The invention adopts a four-high reversible hot rolling mill and a Sendzimir twenty-high cold rolling mill, combined with laser butt welding of plates, and performs one hot rolling process and three cold rolling rolling processes in sequence, thereby improving the rolling efficiency. Improving the yield and reducing the cost reduces the number of rolling passes, and ensures the thickness accuracy of the TA15 titanium alloy thin strip with a thickness of 0.3mm to 0.6mm.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com