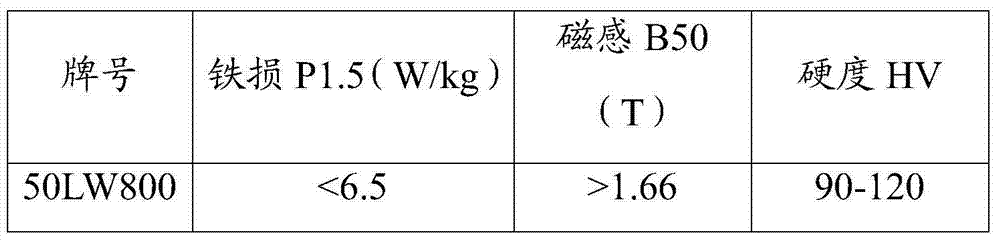

Semi-processed non-oriented silicon steel and manufacturing method thereof

A technology of oriented silicon steel and a manufacturing method, which is applied to non-oriented semi-process silicon steel (50LW800) and its manufacturing field, can solve the problems of low operation efficiency, unreasonable matching, waste of electricity, etc., and achieve the effect of ensuring thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

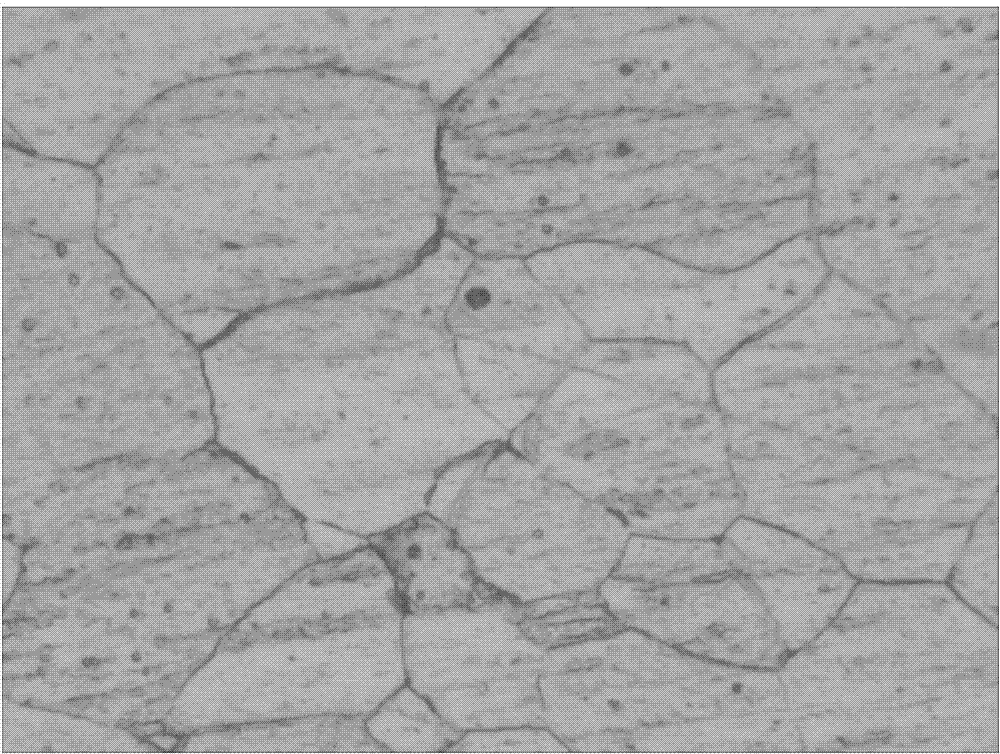

Image

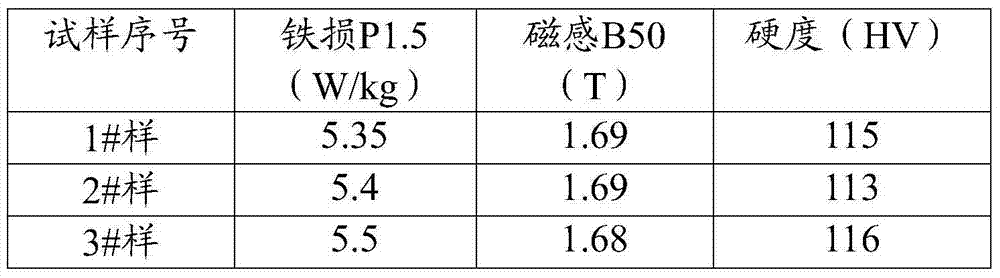

Examples

Embodiment 1

[0062] (1) Hot rolling:

[0063] See the table below for the ingredients of hot-rolled raw materials, all in the table are mass percentages:

[0064] serial number C(%) Si (%) Mn (%) P(%) S(%) Al(%) 1 0.003 0.35 0.28 0.032 0.004 0.065

[0065] 2 0.003 0.4 0.3 0.035 0.003 0.07 3 0.003 0.38 0.29 0.03 0.004 0.075

[0066] The balance is Fe and trace unavoidable impurities;

[0067] The finishing temperature of hot rolling is 850±20℃, and the coiling temperature of finishing rolling is 630±20℃;

[0068] (2) pickling

[0069] Hot-rolled steel coils are pickled by a push-pull shallow-trough turbulent-flow pickling unit, using hydrochloric acid pickling, the concentration is controlled between 7% and 17% (w / w), and the surface oxide scale is removed.

[0070] (3) cold rolling

[0071] After pickling, the steel coil is rolled by a double-stand reversible rolling mill, and the rolls of the rolling mill are finely ground ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com