Method for machining thin web titanium alloy edge strip

A processing method, titanium alloy technology, applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems that it is difficult to ensure the thickness and dimension accuracy of the web, low processing efficiency, and large removal allowance, etc., to ensure the thickness dimension And precision, short manufacturing cycle, reduce the effect of knife and overcut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

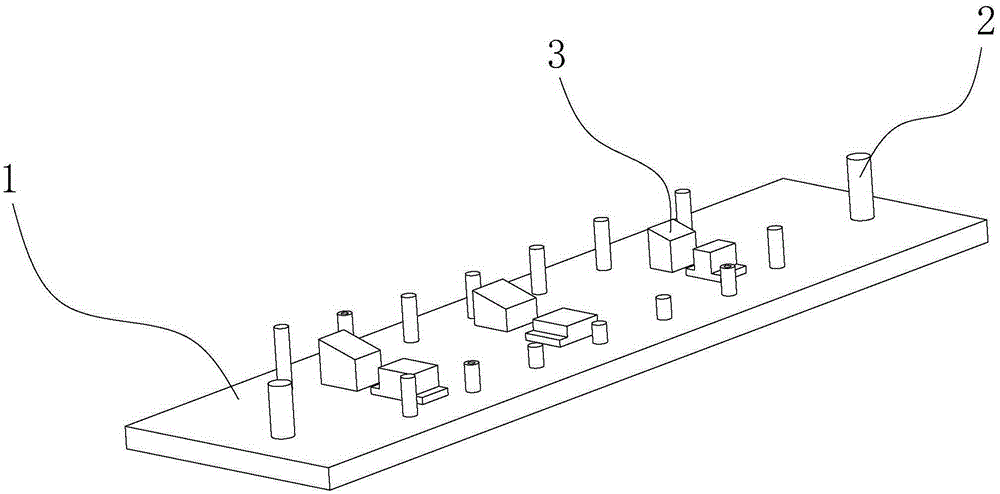

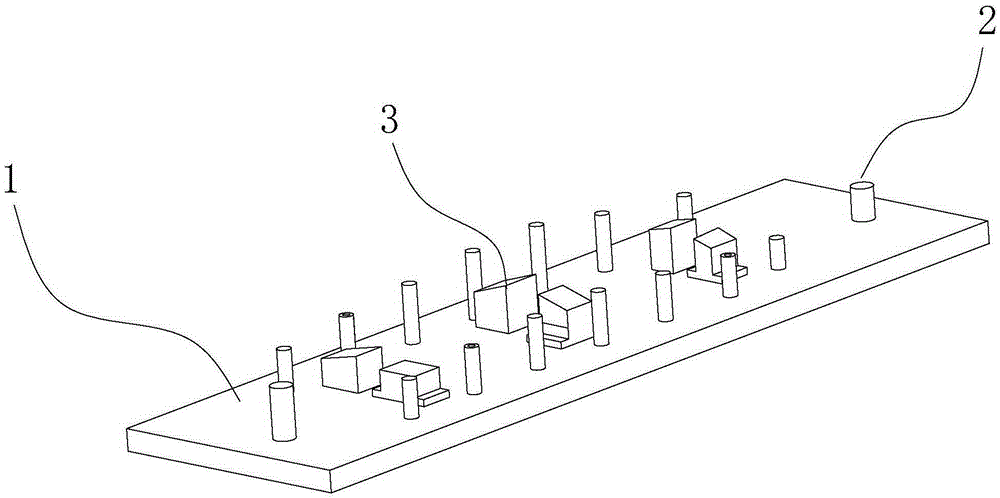

[0020] The fixture set used for roughing, semi-finishing and finishing the first side of the part includes such as figure 1 The shown fixtures for rough machining and semi-finishing of ribbed surfaces; and figure 2 Fixtures for rough machining, semi-finishing and finishing parts without ribs shown in the edge; figure 1 and 2 It can be seen that the tooling fixture includes a support plate 1 on which a parallel iron 3 and a support 2 matching the parts are arranged. The shim 3 plays the role of auxiliary support for the part. There are four shims 3 with threaded holes in the shim 3, which are respectively located on both sides of the width direction of the part 2. They are connected by screws to fix the part 2 and the tooling to prevent the Part movement caused by collision or excessive cutting force. The tooling is simple, the manufacturing period is short, and the use is convenient.

[0021] During the processing of parts:

[0022] For roughing use such as figure 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com