A method for testing adhesive bonding properties of sheet substrates

A technology of adhesive properties and adhesives, applied in the direction of measuring devices, analyzing materials, and adopting mechanical devices, can solve problems such as waste, difficult operation, and increased test costs, and achieve the effect of reducing difficulty and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

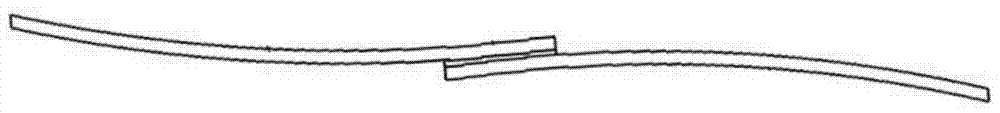

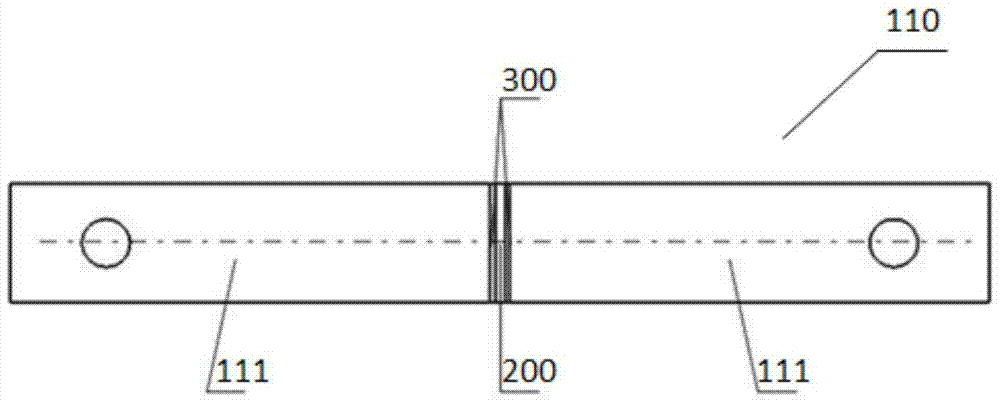

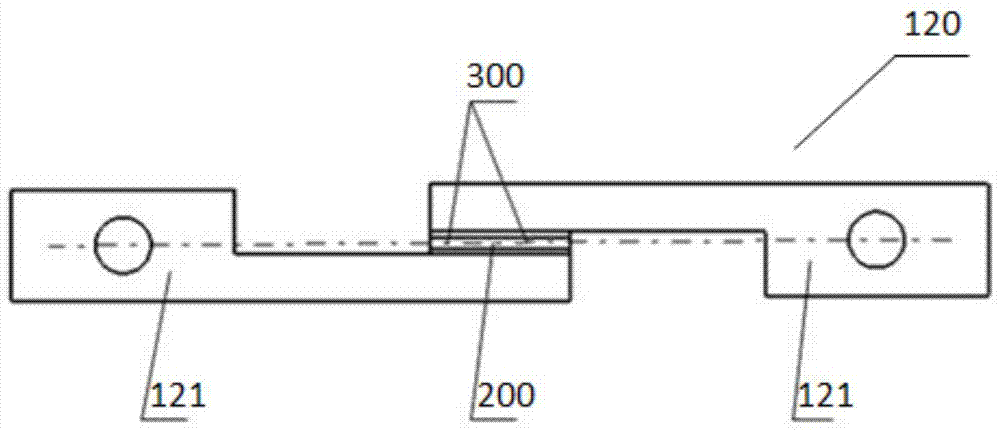

[0061] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, taking a certain vehicle adhesive as an example, the present invention provides an adhesive bonding performance testing device for sheet-like substrates, which includes: a sheet for testing the bonding performance of the adhesive Shape base material 200, the aluminum alloy loading block 101 that is used for bonding and fixing the sheet base material 200 to be tested to form the test assembly 100, and the tensile test assembly loading assembly 400; the test assembly 100 includes a pure tensile test assembly 110, a pure Shear test assembly 120 and tensile-shear combination test assembly 130; Tensile test assembly loading assembly 400 includes upper testing machine loading connector 411, lower tensile test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com