Patents

Literature

44results about How to "Uniform balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for removing re-melting layers on inner walls of air film holes of blades

InactiveCN102335789AImprove cooling effectExtended service lifeElectrolysis componentsElectrochemical machining apparatusTemperature controlControl system

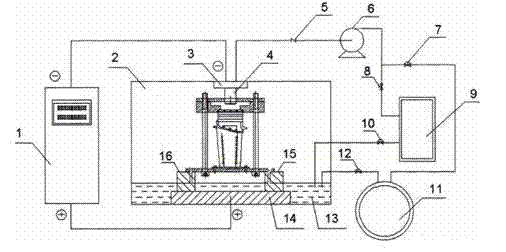

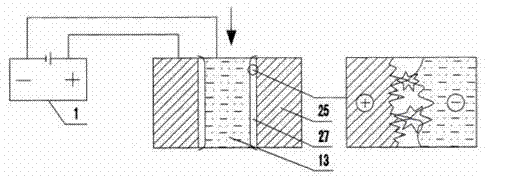

The invention provides a device and method for removing re-melting layers on inner walls of air film holes of blades. In the invention, the re-melting layers on the inner walls of the air film holes of the blades are uniformly removed by adopting an electrolyte-plasma machining technology. The device is characterized by comprising a direct-current (DC) power supply, a control system, a temperature control system, a filter system and a hydraulic system. The invention has the beneficial effects that the inner walls of the air film holes of the blades are processed with high-pressure internal flushing electrolyte in a non-immersion manner so as to effectively remove the re-melting layers of micro-holes; the device and method provided by the invention are convenient for implementation, achieve the effects of uniform allowance, no re-melting layer residue and high dimensional precision, have high operating efficiency improved by dozens of times as compared with an abrasive flow method, greatly enhance the air film cooling effect and prolong the service life of the blades.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

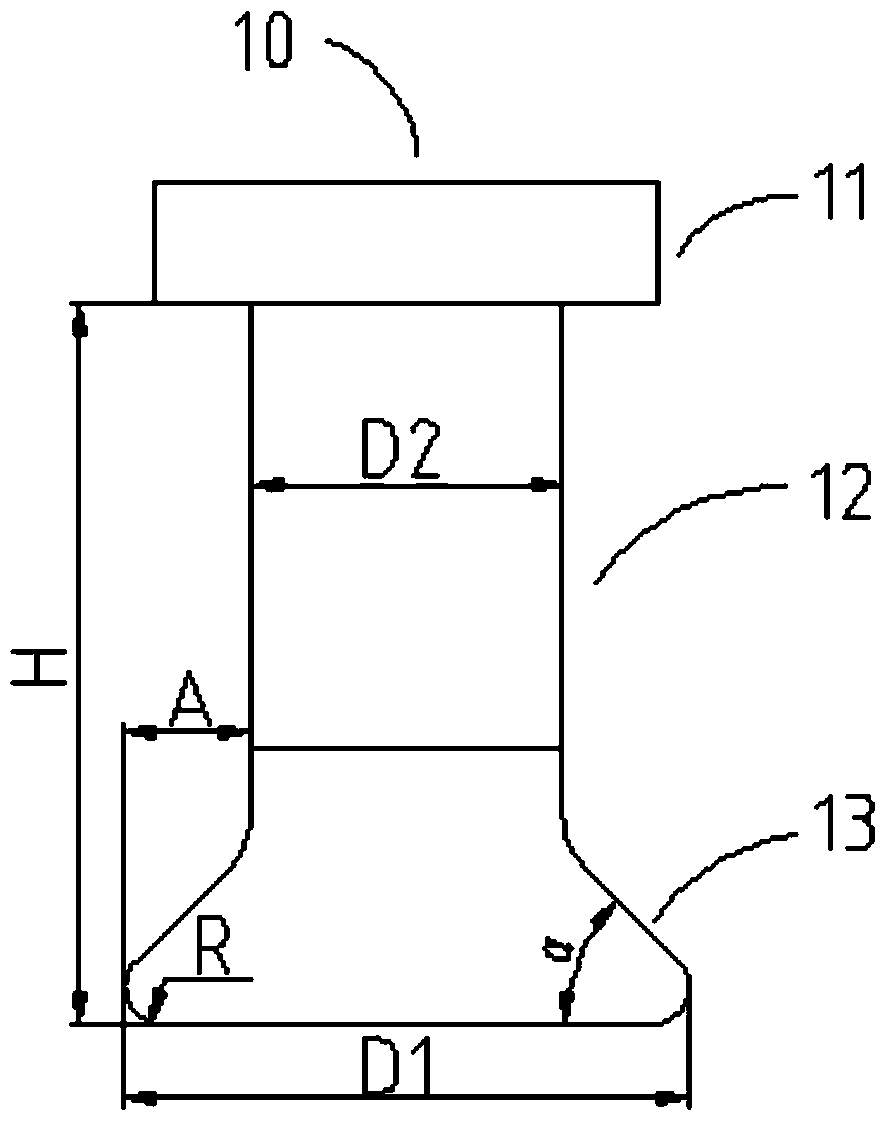

Profiling forging method of large cylinder forge piece provided with internal and external steps

The invention discloses a profiling forging method of a large cylinder forge piece provided with internal and external steps. According to the profiling forging method of the large cylinder forge piece provided with the internal and external steps, raw material consumption and machining allowance can be reduced under the premise that internal quality is guaranteed. The profiling forging method comprises steps as follows: A, tongs hold is performed; B, rolling, drawing and blanking are performed; C, upsetting and punching are performed; D, a common mandrel is subjected to pre-reaming until a step saddle can penetrate into a forging stock; E, step saddle pre-drawing is adopted to enable an inner hole of the forging stock to form the step, an outer contour of the forging stock forms a step cylinder shape, and meanwhile, the length of the forging stock meets the technical processing size; F, the step saddle and a step reaming anvil are adopted for hole reaming forming. With the adoption of the profiling forging method, natural streamline of metal can be prevented from being cut off, so that fibers of the forge piece are continuous, and improvement of synthesized mechanical properties of the forge piece is facilitated.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Polishing equipment for head of wrench

InactiveCN101966678AHave a tense effectPlay a limiting effectBelt grinding machinesDrive wheelWrench

The invention relates to polishing equipment for the head of a wrench, comprising a rack, a transmission device arranged on the rack and a fixing device arranged in front of the transmission device, wherein the transmission device comprises two groups of transmission mechanisms and two groups of guide mechanisms which are symmetrically arranged along the central line of the rack; each transmission mechanism comprises a driving wheel, a tensioning wheel, a fixed wheel and a sanding belt; guide plates of the two groups of guide mechanisms are positioned at the inner side of the tensioning wheel and can move simultaneously and oppositely; the fixed device comprises a clamp bracket and a vertical supporting frame sliding relative to the clamp bracket; and the vertical supporting frame is provided with a clamping push rod sliding relative to the vertical supporting frame, a clamping swinging arm, a positioning pin and a pressing plate. As the two groups of transmission mechanisms and the two groups of guide mechanisms are adopted to be symmetrically arranged on the rack and the adjustable fixed device fixes the movable wrench, the sanding belts of the two groups of transmission mechanisms are respectively contacted with two side surfaces of the head of the movable wrench under the driving of the guide plates. Therefore, the polishing equipment polishes the two side surfaces of the movable wrench simultaneously, and has the advantages of simple operation and high processing efficiency.

Owner:NINGBO SANTONG MACHINERY

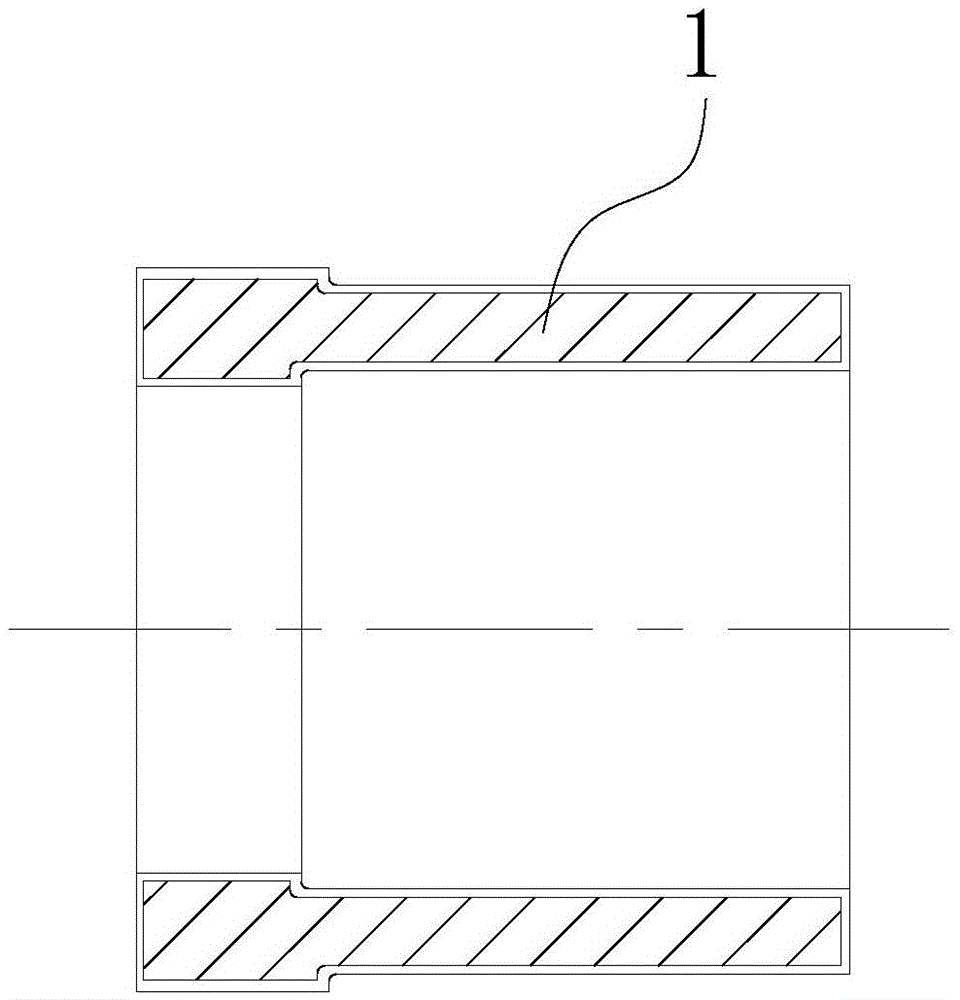

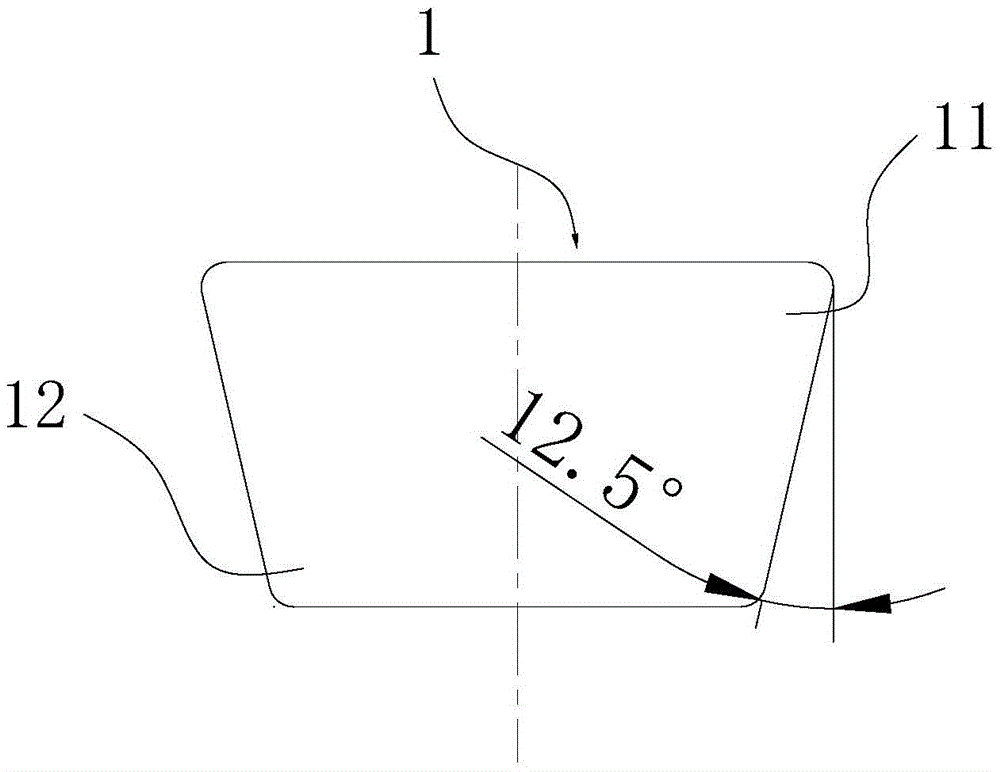

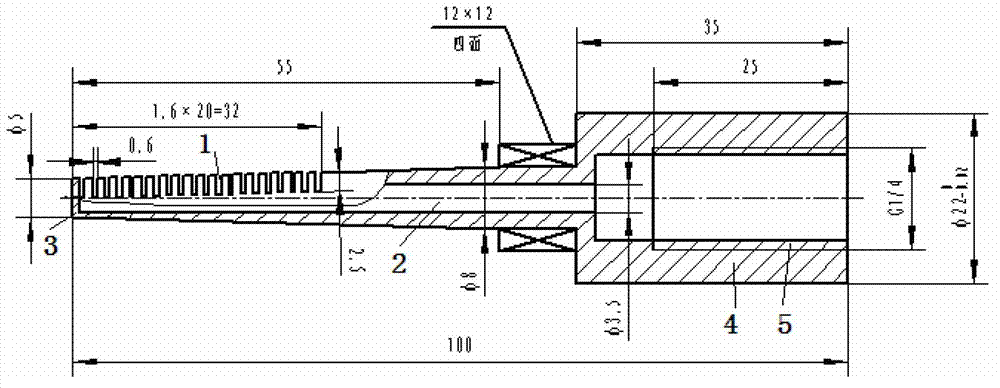

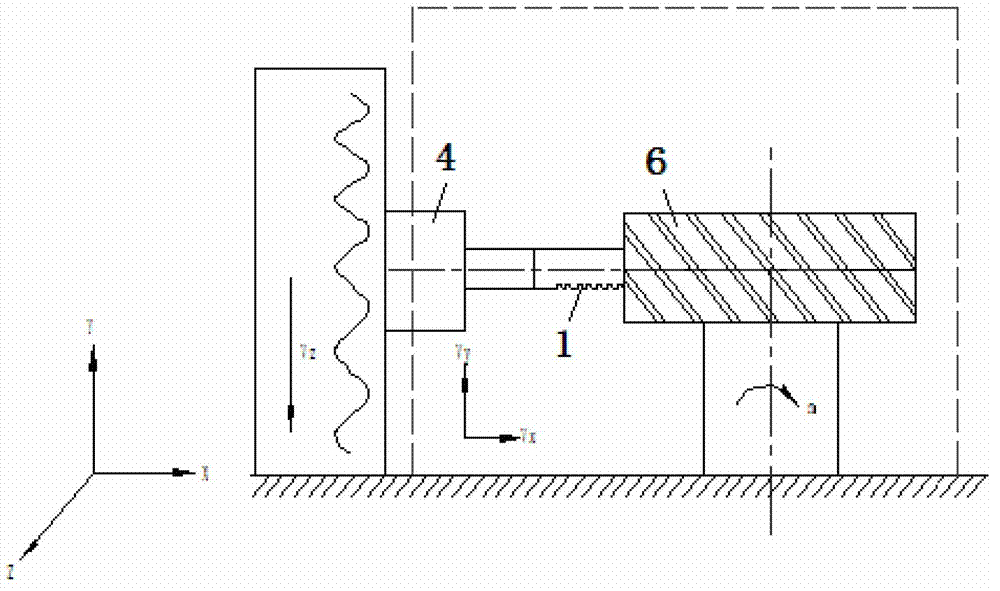

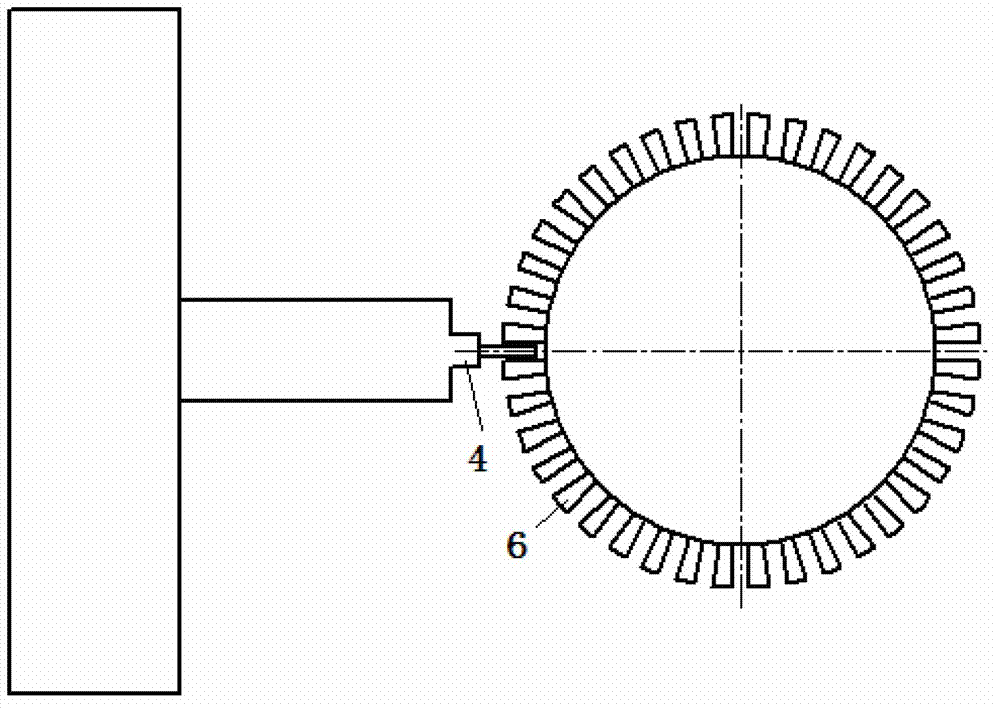

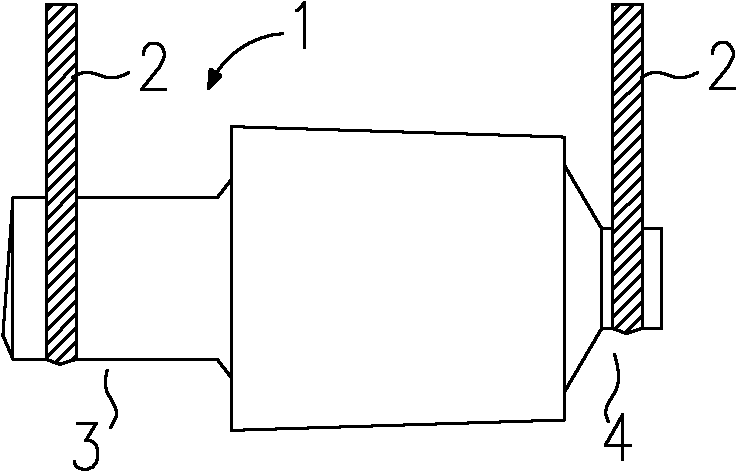

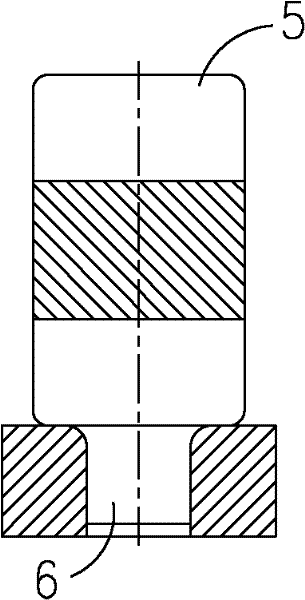

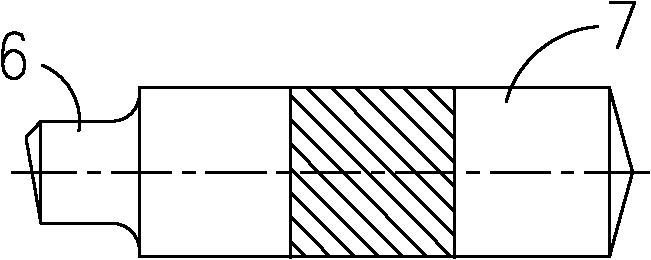

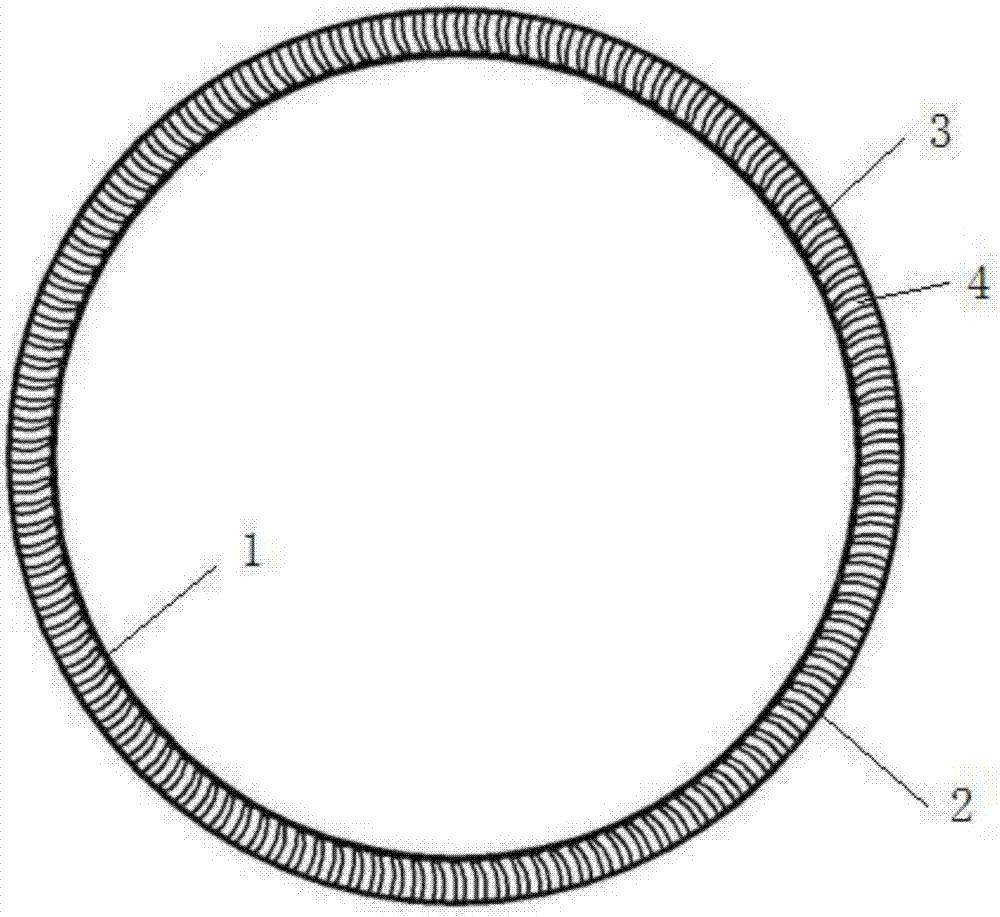

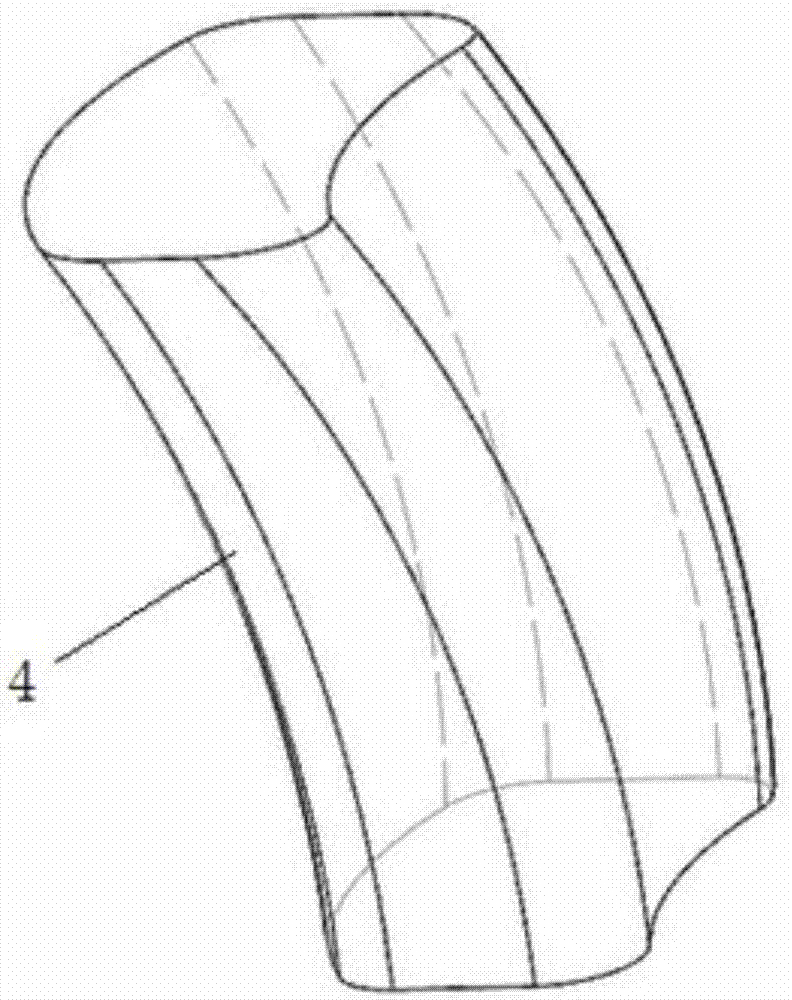

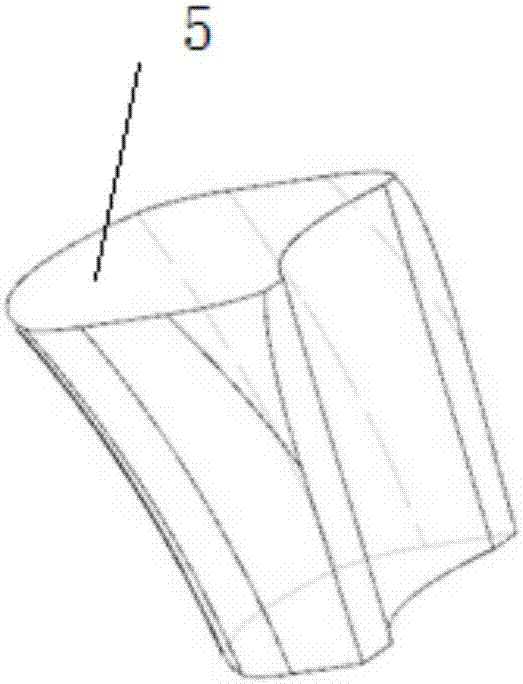

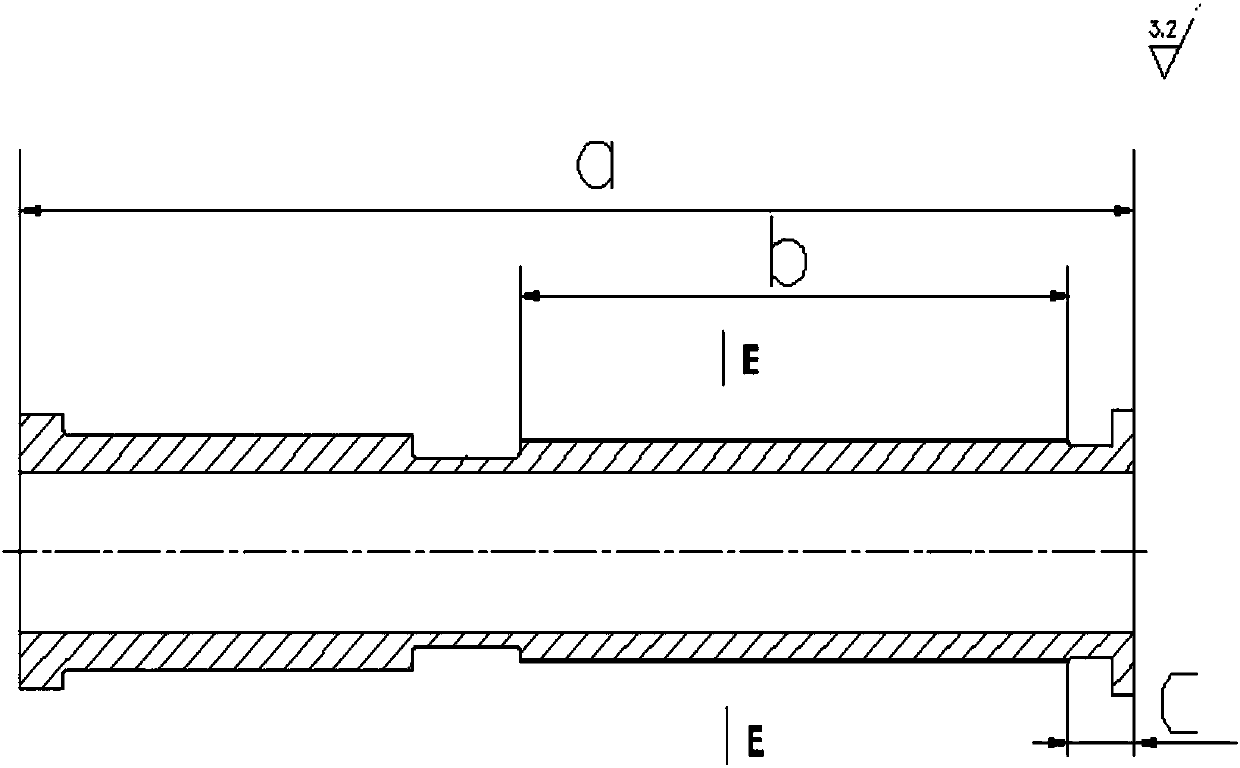

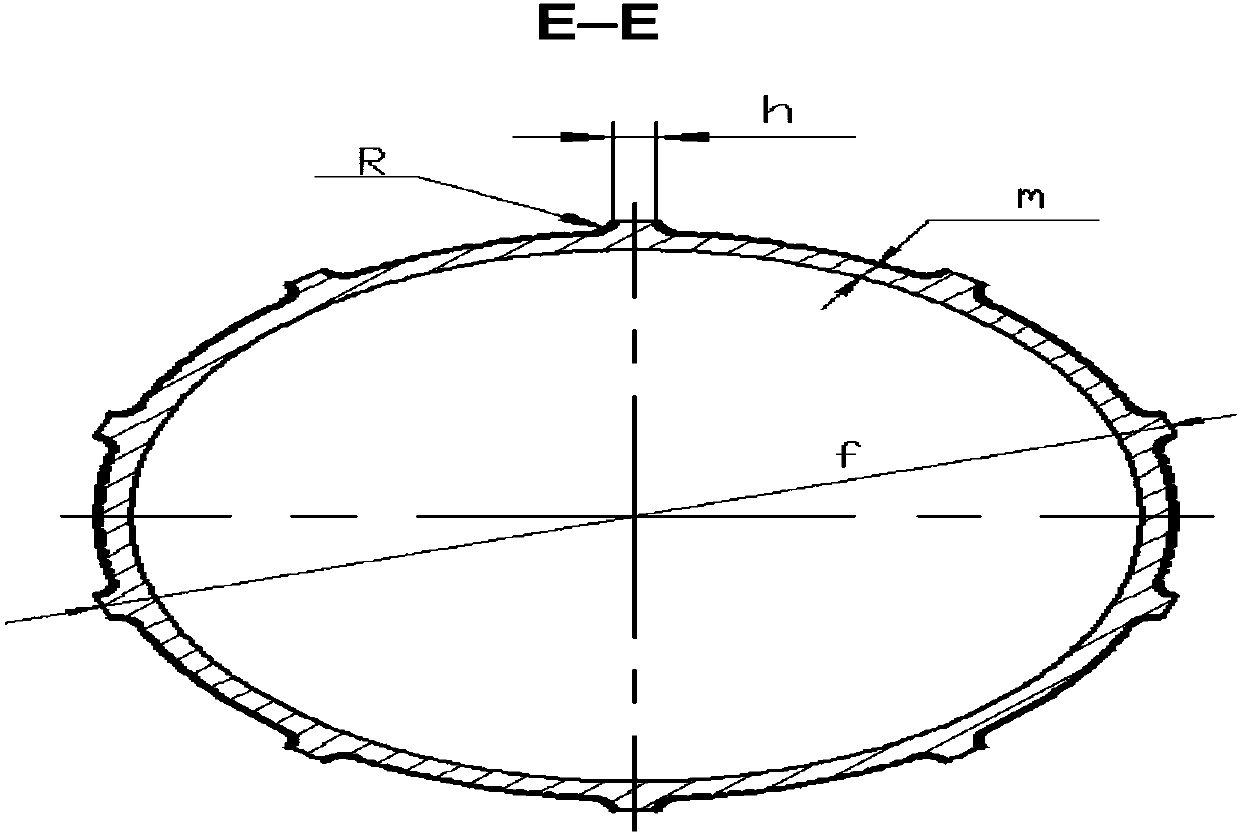

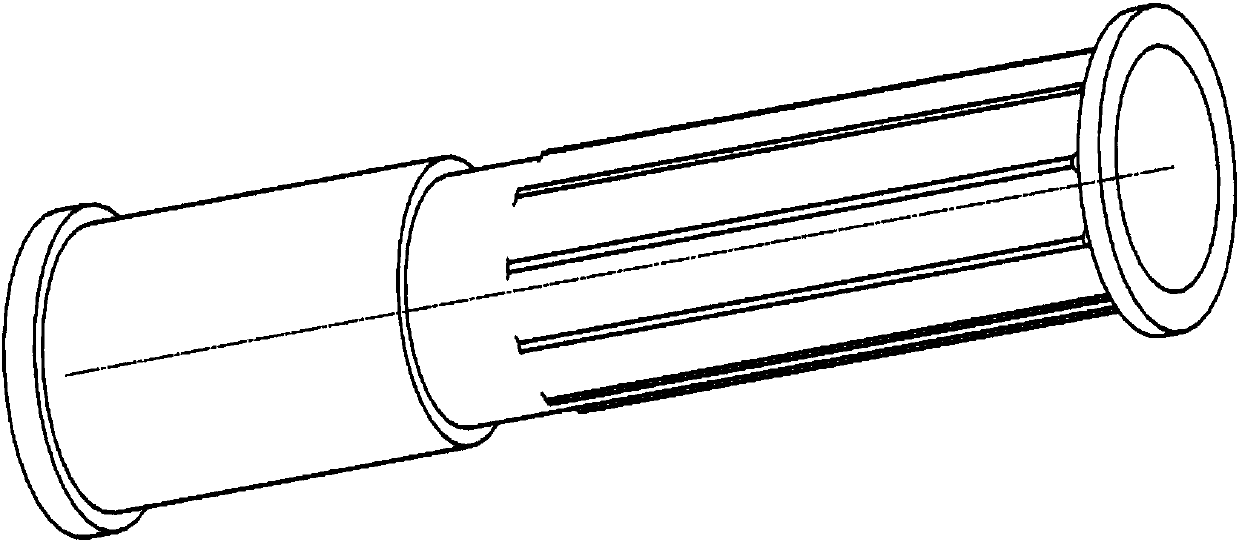

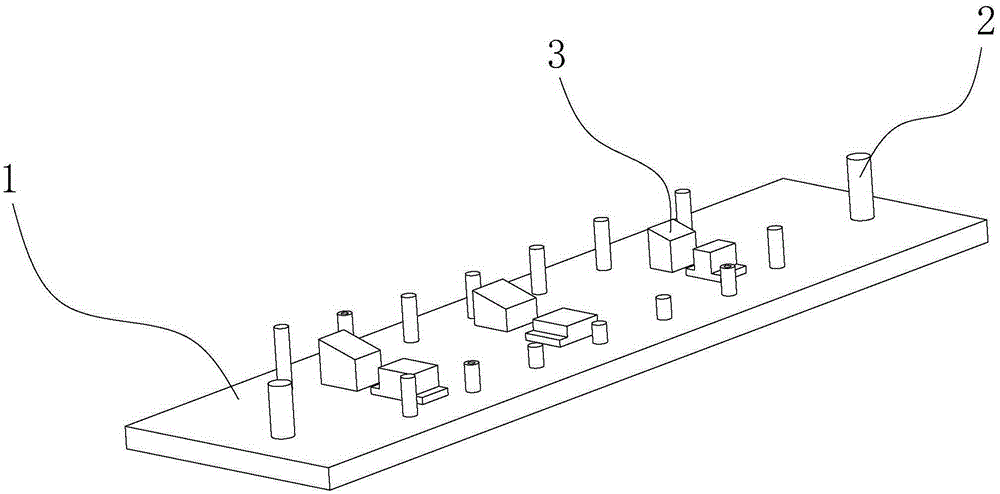

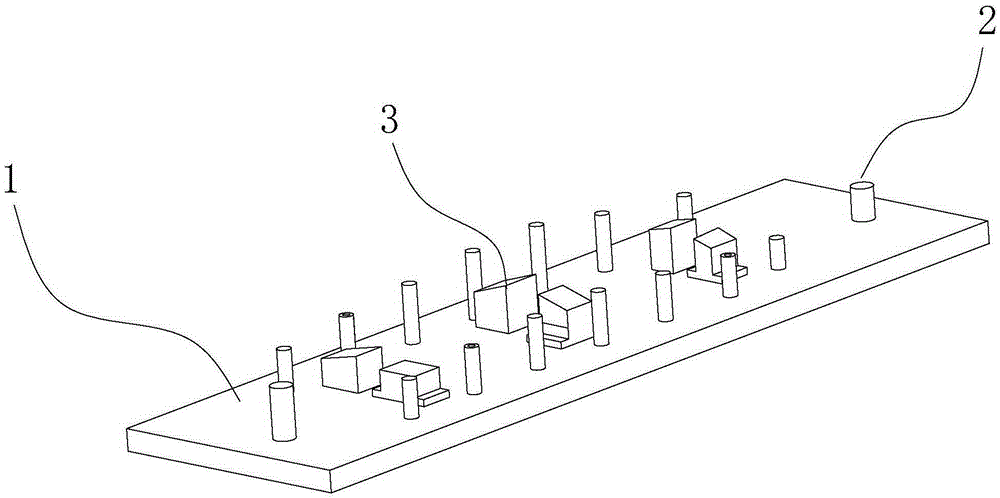

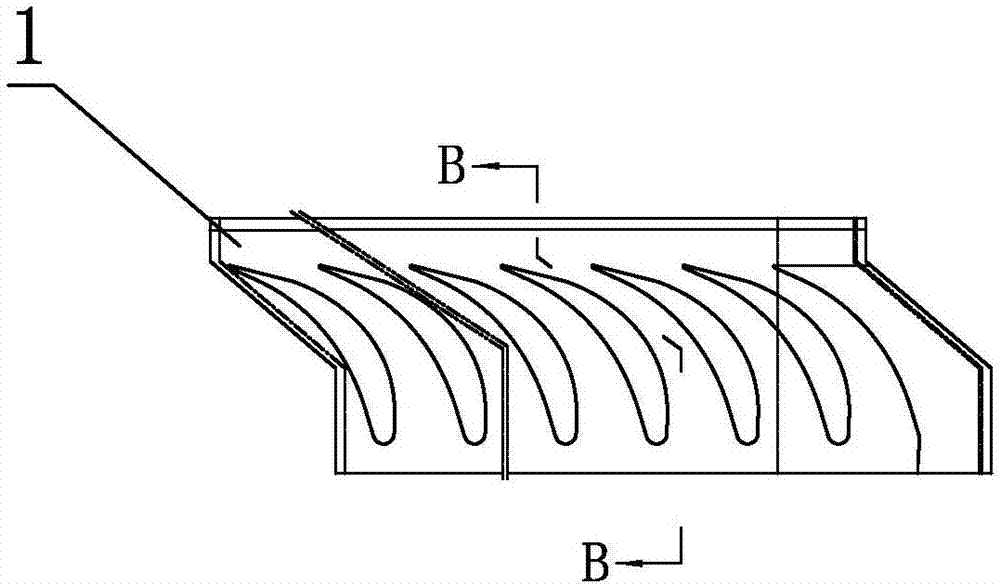

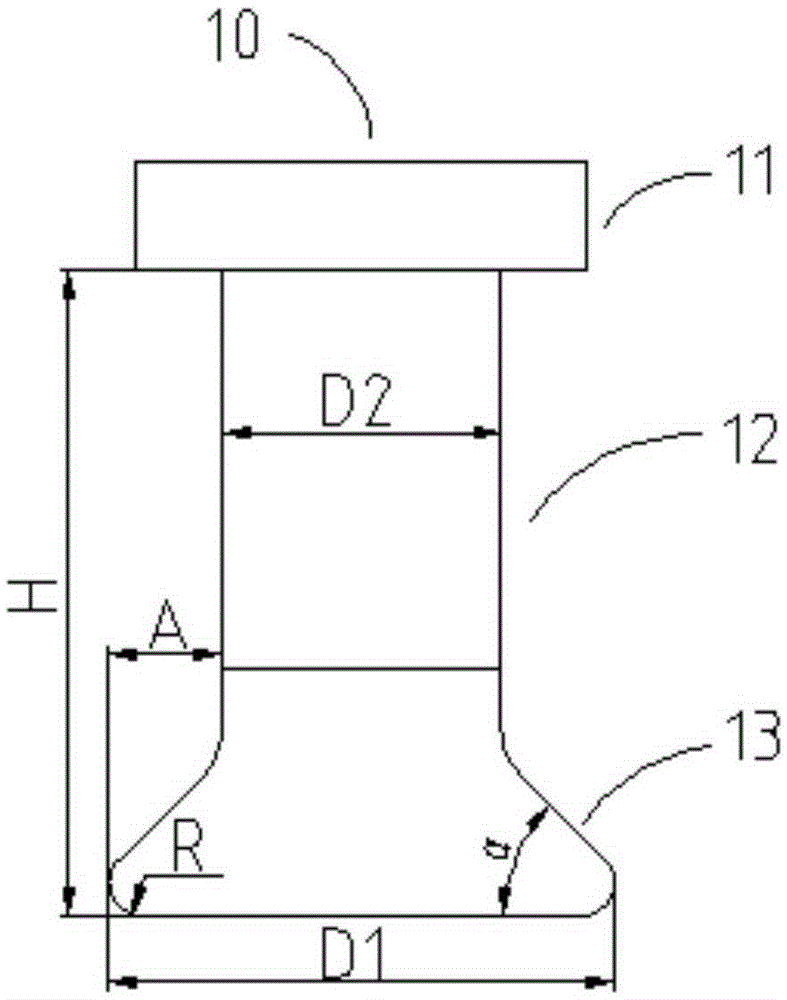

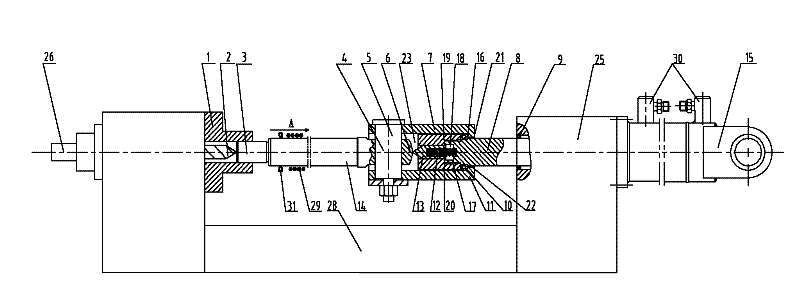

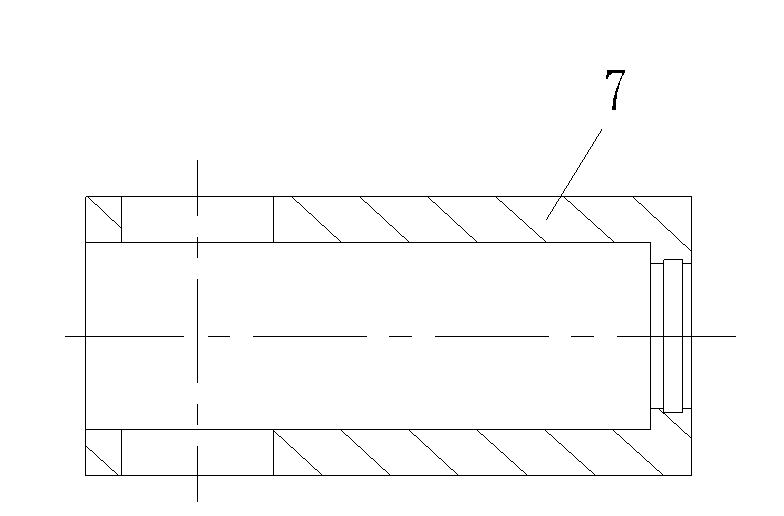

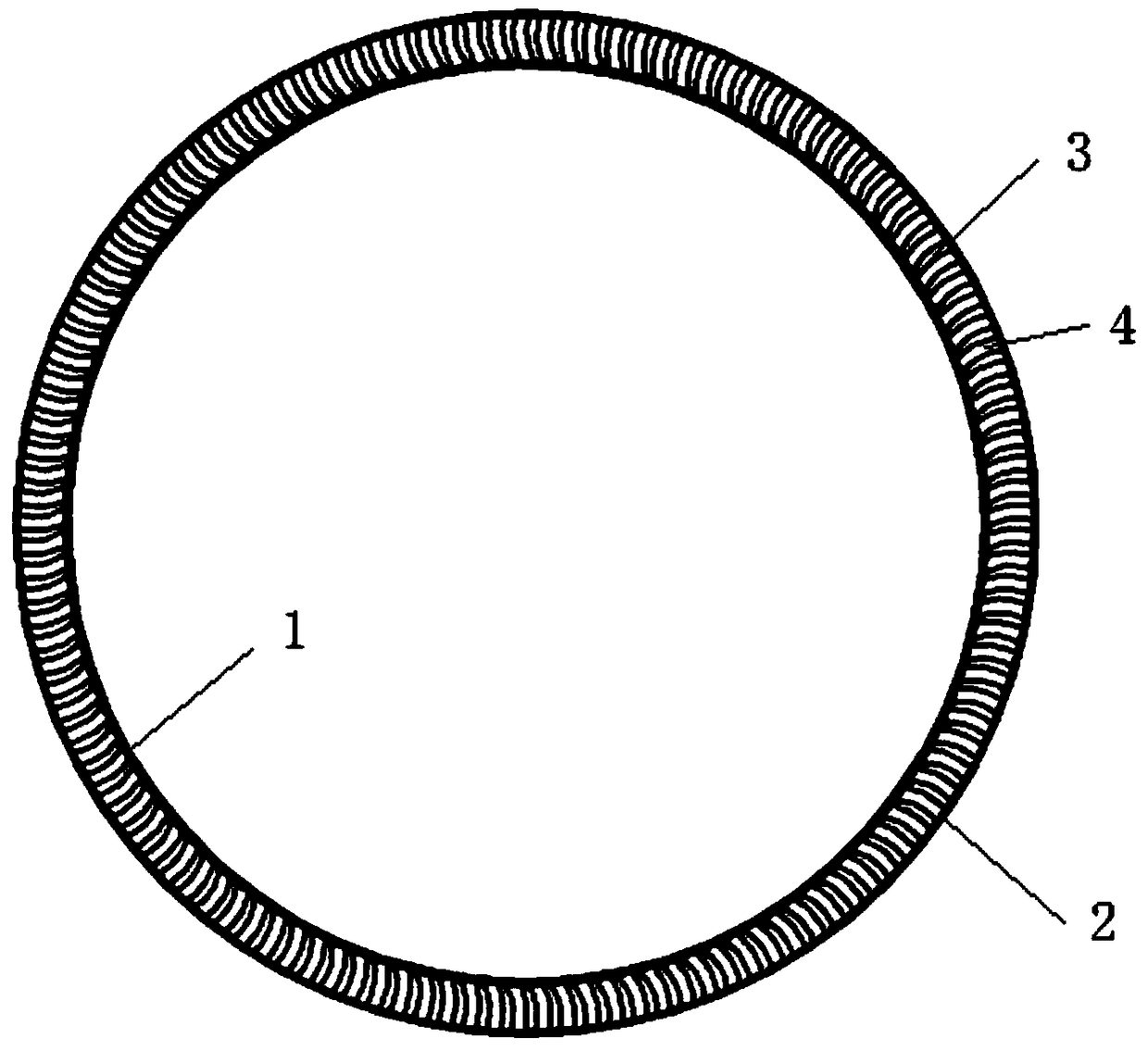

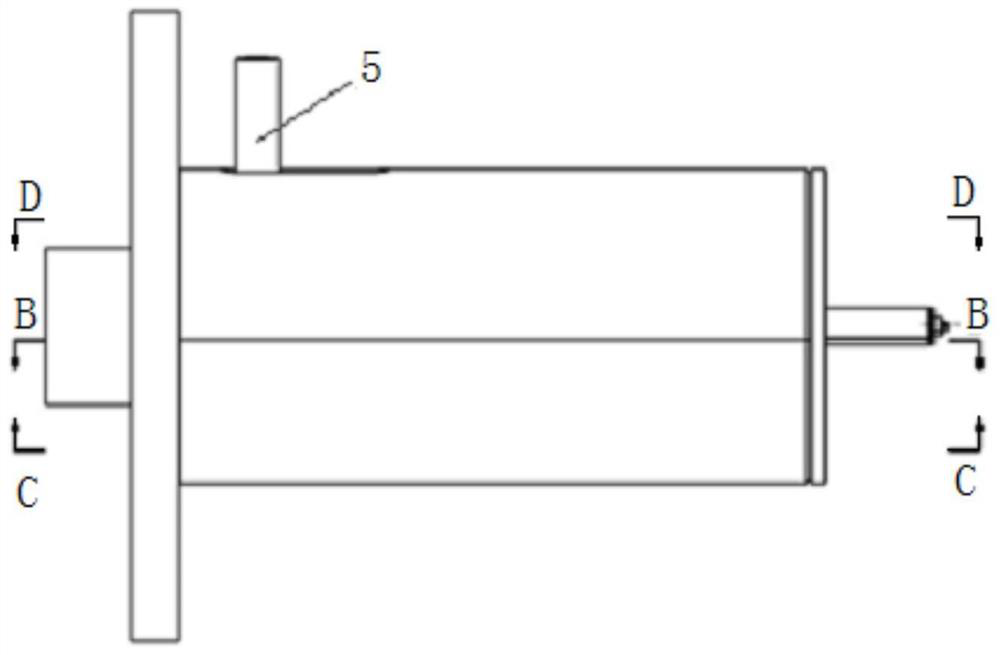

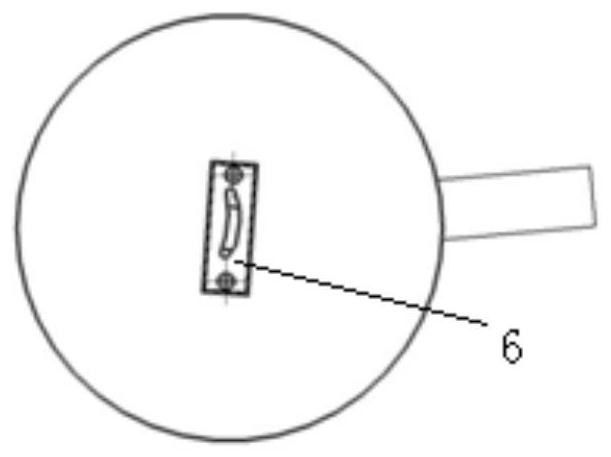

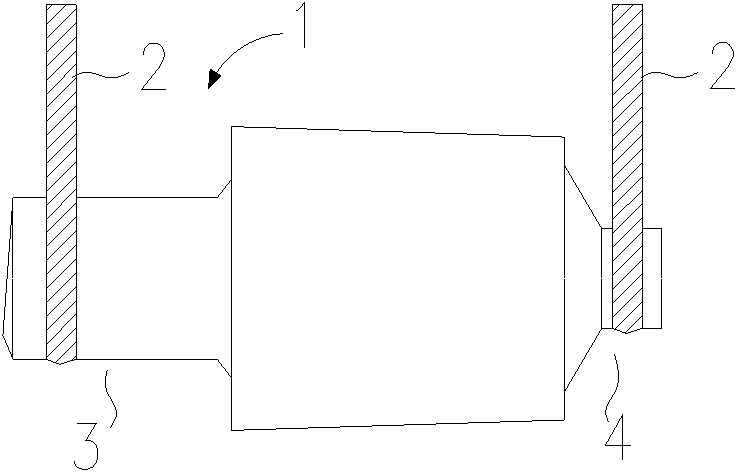

Electrode and machining method for electrolytic grooving of blisks

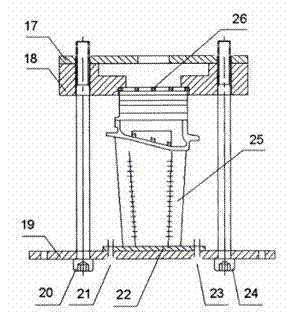

ActiveCN102873416AHigh precisionUniform balanceMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

An electrode for electrolytic grooving of blisks is integrally of a hollow finger-shaped structure. An electrolyte channel is arranged inside the electrode, narrow grooves (1) with the widths of 0.6mm are circumferentially arranged at intervals of 1mm and are positioned at locations distanced from the upper edge of an outer profile close to a finger end of the electrode by 1 / 3-1 / 2, an electrolyte delivery pipeline (2) is disposed inside the electrode, a plugging structure (3) is arranged at the finger end so that the electrolyte delivery pipeline (2) is of a blind hole structure, and electrolyte only can flow out from the narrow grooves (1). A machining method for electrolytic grooving of the blisks includes that the electrode for electrolytic grooving of the blisks is used as a special tool, and an anode of a workpiece is dissolved in the electrolyte under the action of an electric field, so that the purpose of performing dimension machining for the workpiece is achieved; and the pressure of the electrolyte ranges from 4MPa to 6MPa, and the allowance reserved on a profile of a blisk body is 3.5mm. The electrode and the machining method have the advantages that the allowance reserved during electrolytic machining is uniform, high precision of repetition can be realized easily, a good flow field is obtained during electrolytic machining, and machining efficiency is high.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Forging process for nuclear power rotor and other large shaft parts

ActiveCN102172766AIncrease the number of pulling tripsIncrease the effect of forging through compactionEngine componentsNuclear powerIngot

The invention discloses a forging process for nuclear power rotor and other large shaft parts, which can be used for effectively solving the forging problem of a high-grade rotor with a super large specification. The process specifically comprises the following steps of: (1) drawing out a steel ingot to form a flat square by using a WHF (Wide die Heavy blow Forging) method; (2) performing erecting and upsetting on the flat square; (3) drawing out the upset steel billet to the flat square again by using the WHF method; and (4) compacting the four sides and the center of the flat square, wherein the 'flat square' specifically means a cuboid-shaped steel billet. In accordance with the result of flaw detection (UT(Ultrasonic Test) and MT (Magnetic particle Test)), no flaw (phi is above 0.6), for which recording is required, is found in a 1100MW rotor piece manufactured by using 550t steel billets, and the quality is superior; based on the dimension of a workpiece, all the dimensions of various parts of a forge piece can meet the processing requirement, and the forging allowance is uniform; the control state of forging grain size is deduced from a UT state subsequent to thermal treatment after forging, the desired effect is completely achieved, and no phenomenon of coarse crystal or mixed crystal happens.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

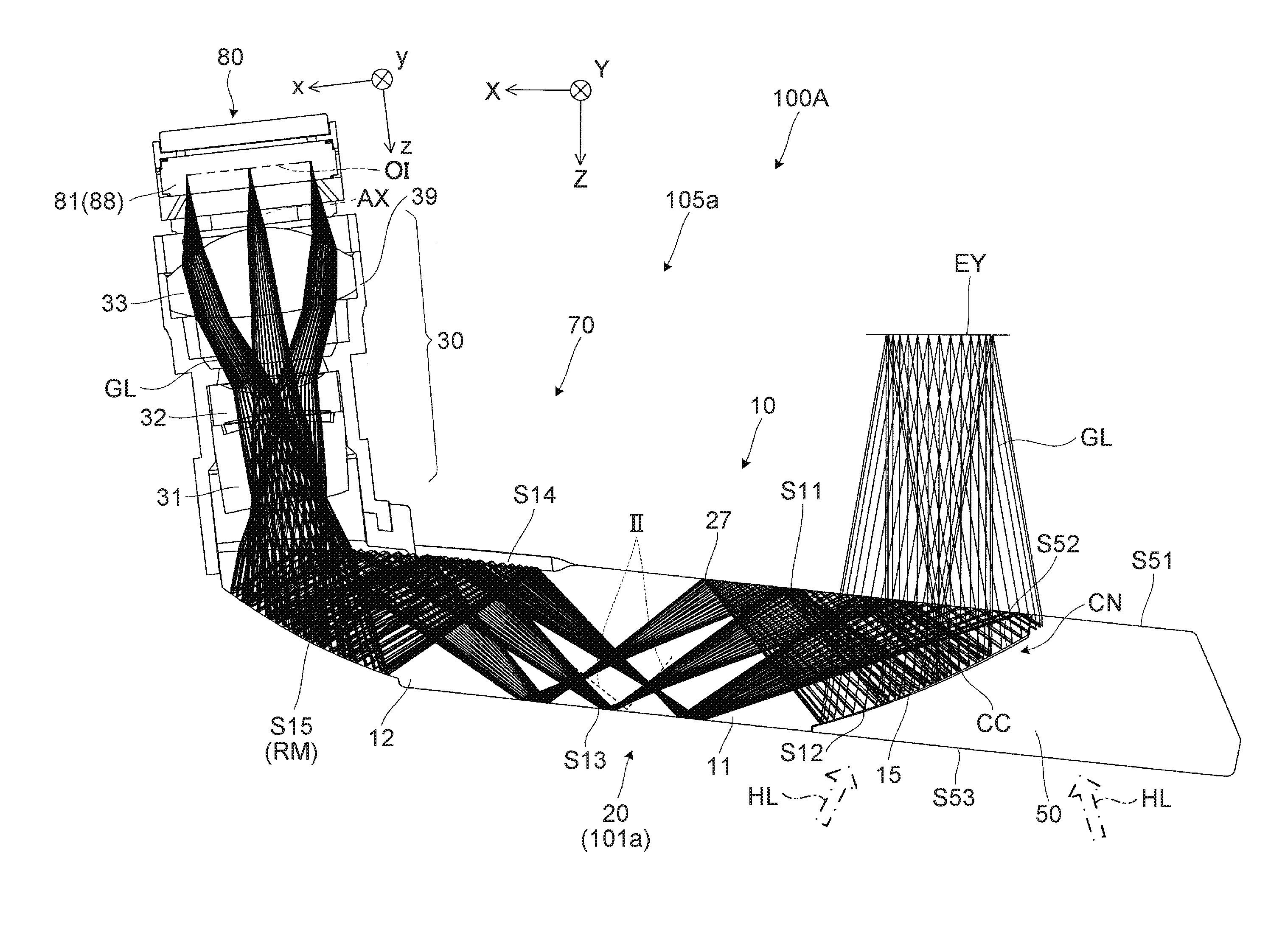

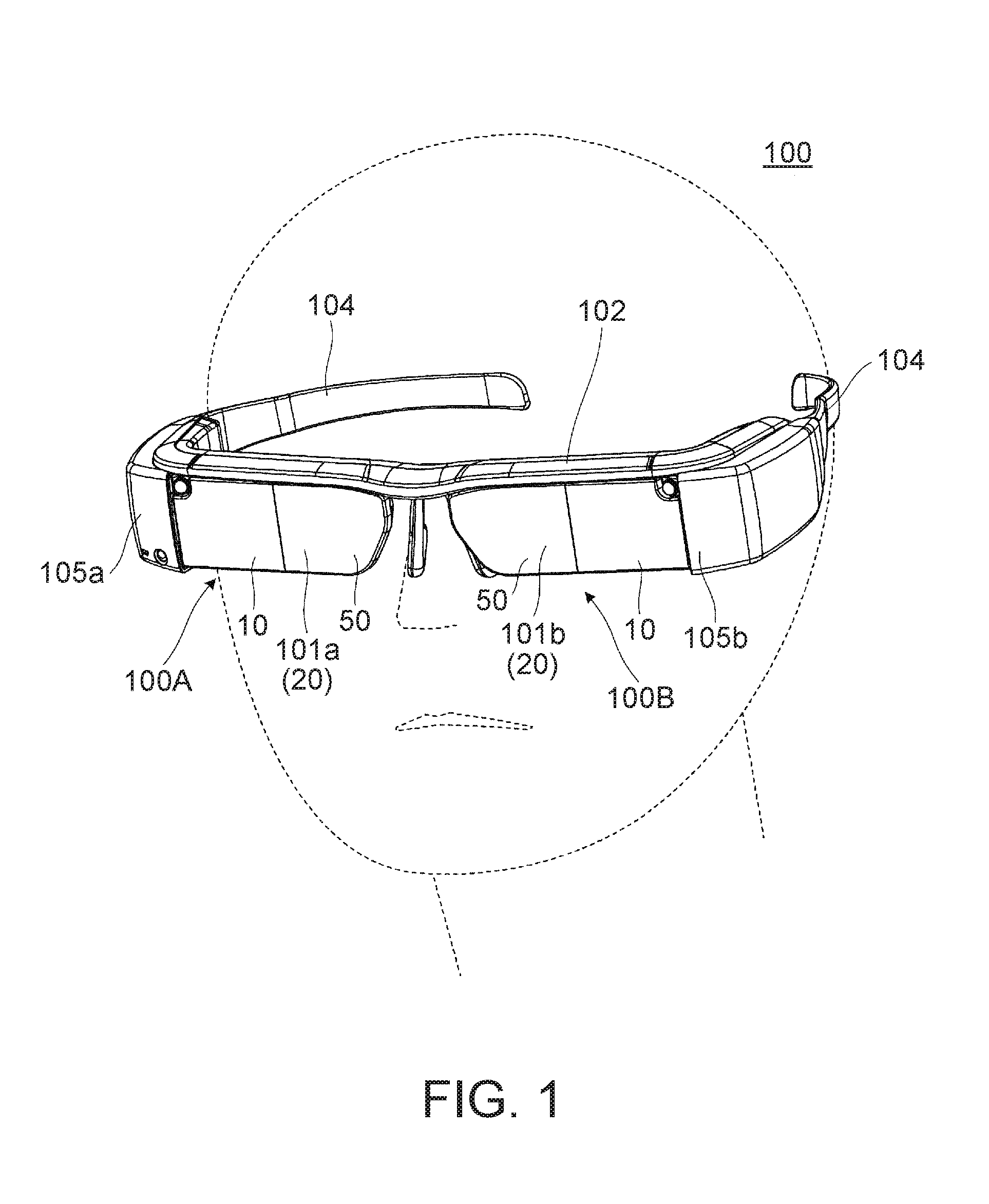

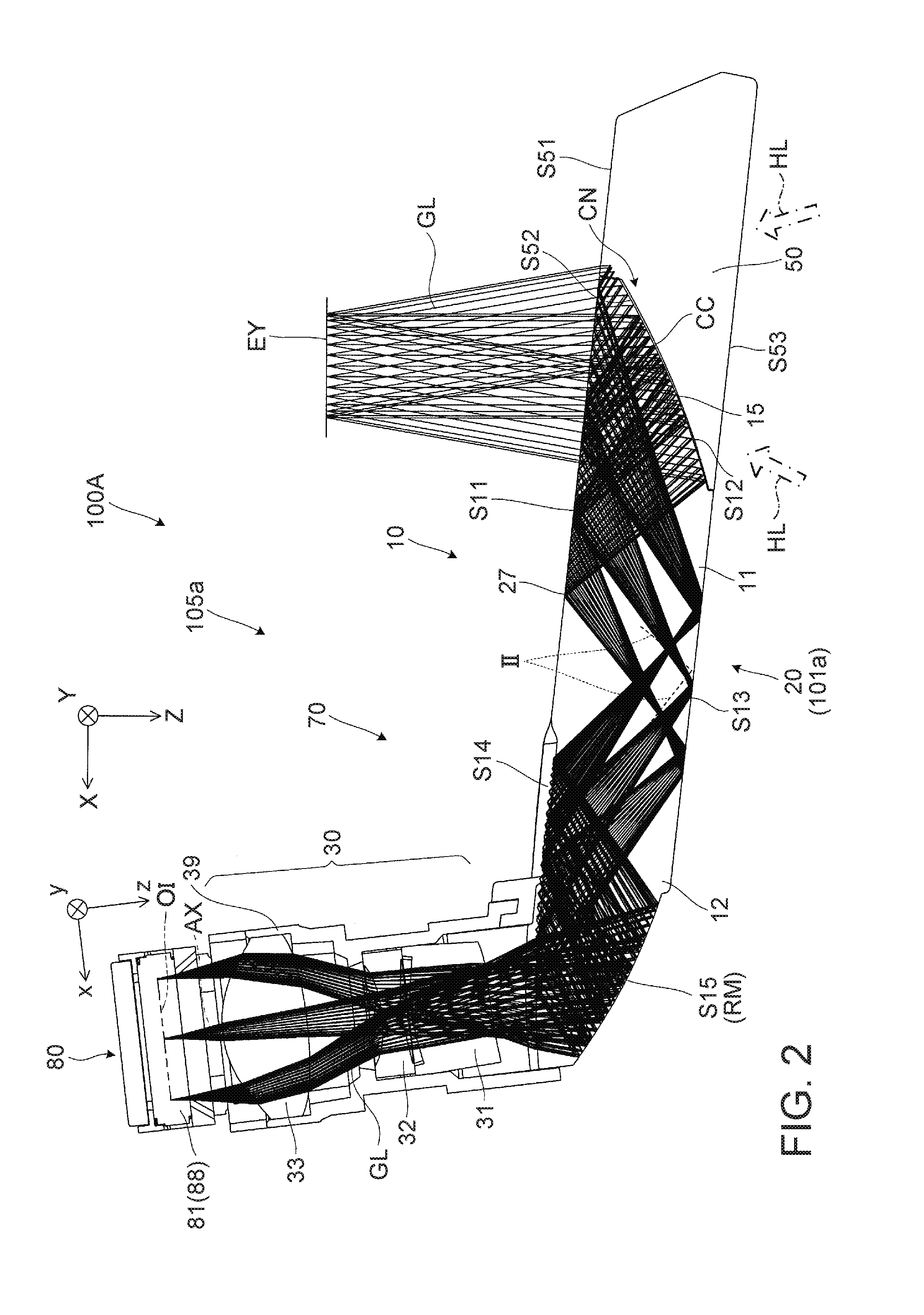

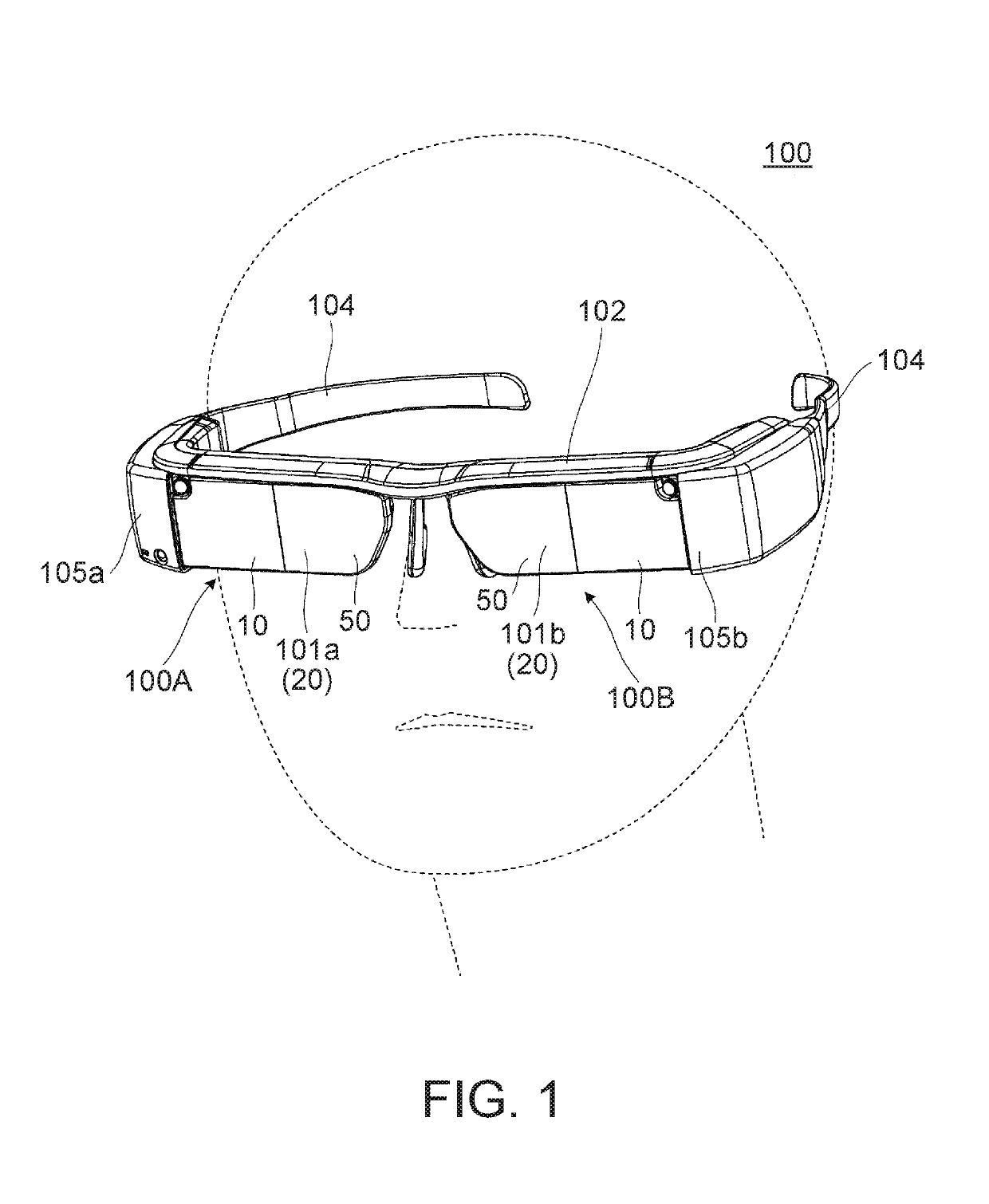

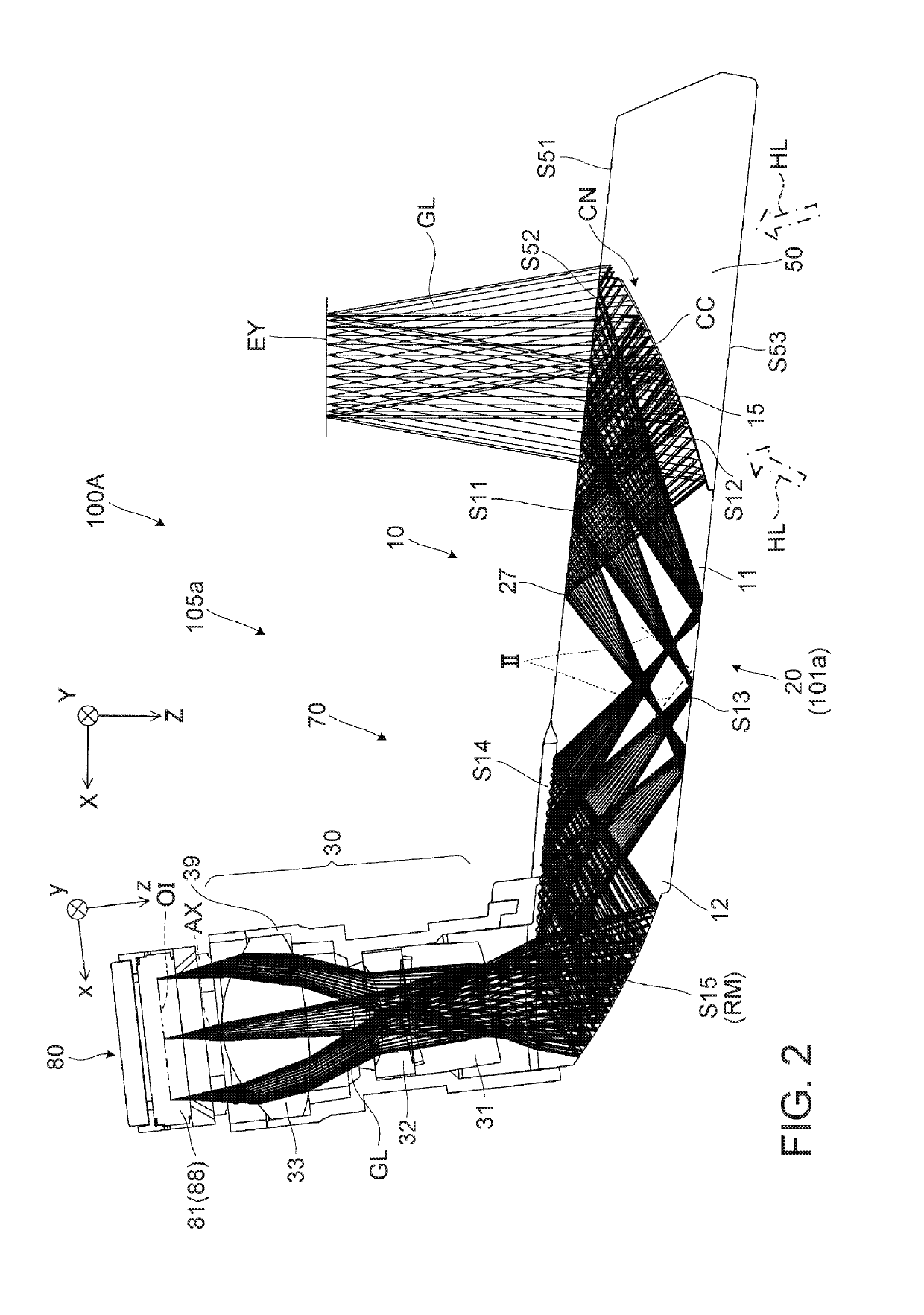

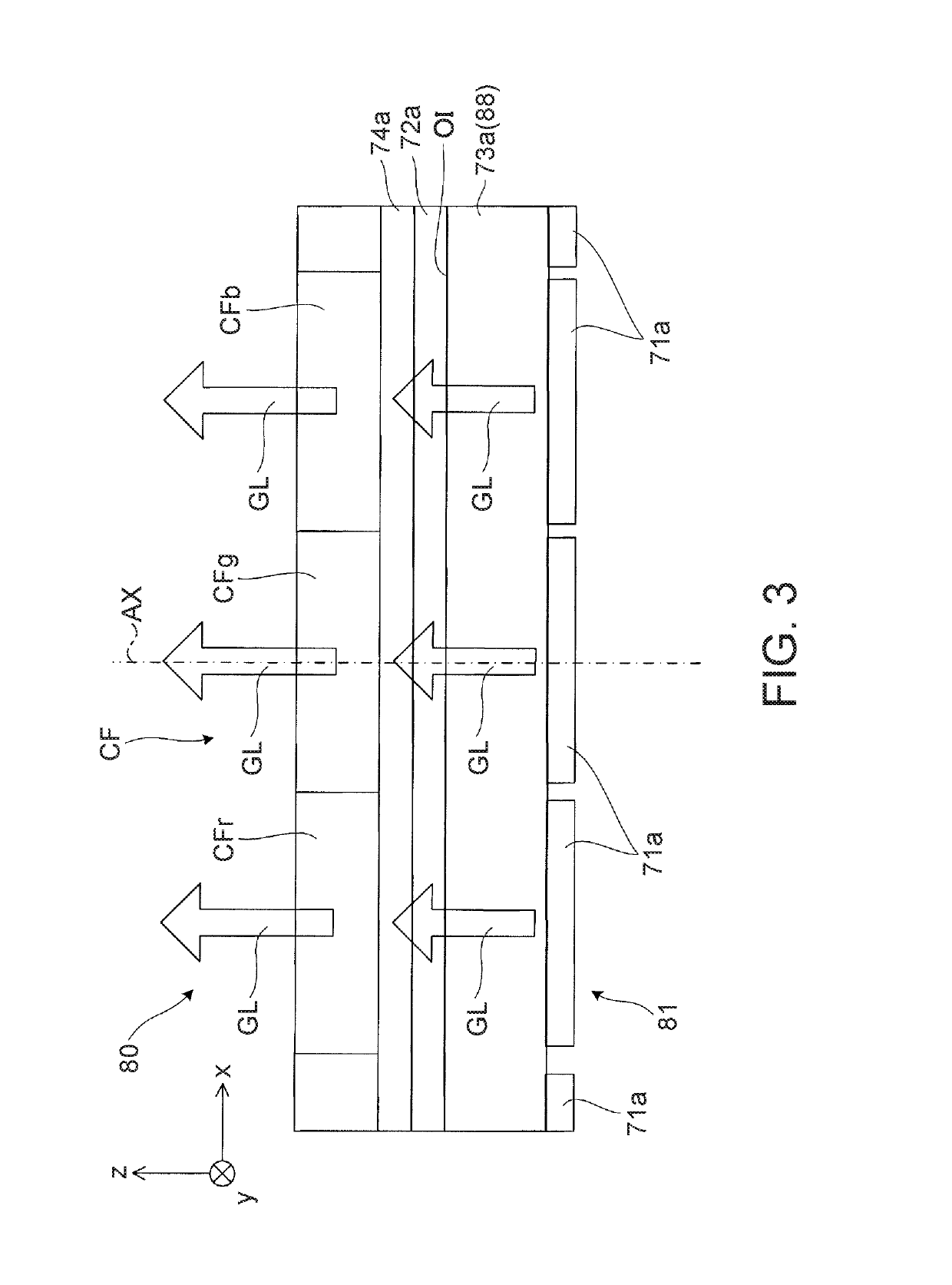

Virtual image display apparatus

ActiveUS20160282623A1OptimizationUniform balanceMechanical apparatusLight guides for lighting systemsLength waveContrast ratio

In an image generation unit, a light emitting part is formed using a self-emitting OLED device, and thereby, high-contrast images can be formed and the life of the light emitting part and the life of the virtual image display apparatus are extended. Even when the light emitted in the light emitting part has deviation in color balance, a half-mirror layer that has light transmissivity and realizes see-through vision is a reflection film having wavelength dependence, and thereby, a uniform color balance of image lights is achieved and images in good conditions are visually recognized.

Owner:SEIKO EPSON CORP

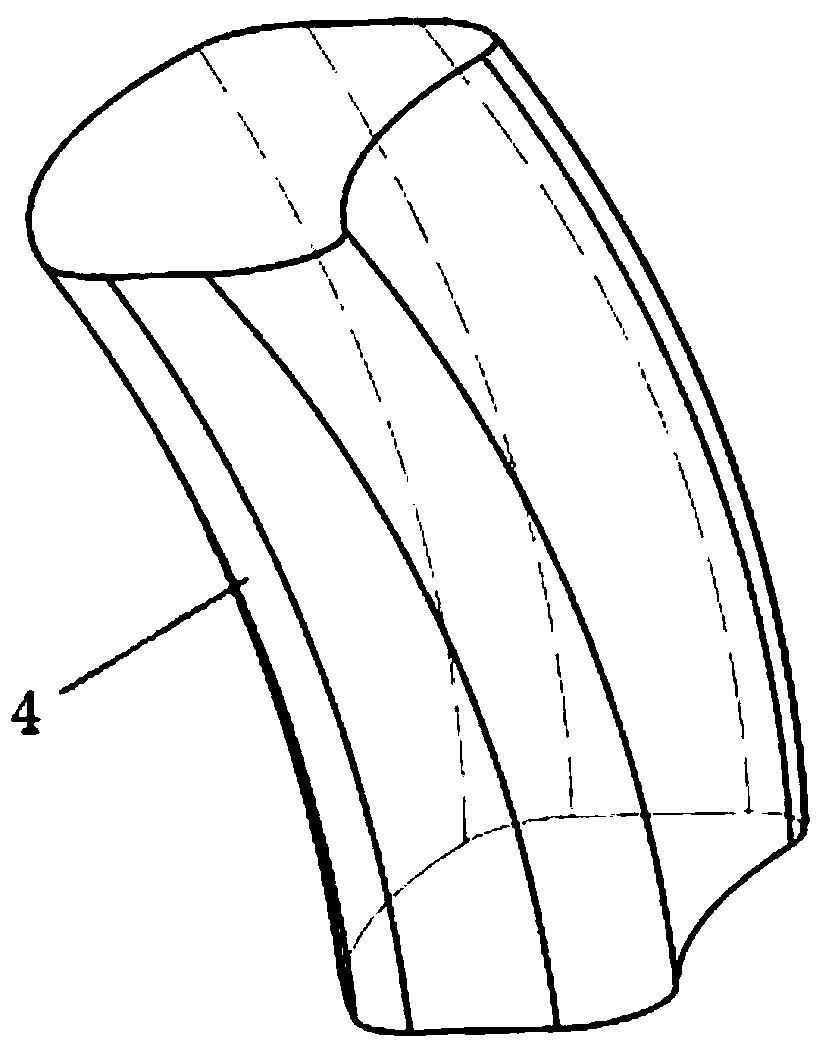

Fitting method of blade surface data

InactiveCN103577635AReduce duplicationReduce computing timeSpecial data processing applicationsEngineeringSolid surface

The invention discloses a fitting method of blade surface data. The method comprises the steps of the fixing of centers and radiuses of intake and exhaust sides, the fixing of arcs in polynomial fitting blade body surface and blade surface, and the fixing of the maximum thickness value of the blade body surface. According to the method,The repeated computing amount and the computing time of designers are greatly reduced, the computation of the blade surface data is enabled to be accomplished in seconds, the whole bade development time is shortened by one third, the data accuracy and the jig design accuracy of blade surfaces are improved, the precision forging technology is improved, and the requirements of modern digital machining equipment are met. Blades machined through the fitting method is smooth in solid surfaces, the phenomenon of back which usually occurs in traditional blade bodies manually adjusted can not occur, the blade body profile line of a blade forge piece designed on the basis of the surface is smooth, a final die cavity is not required to be repeatedly repaired, and the forming quality of the blade forge piece is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

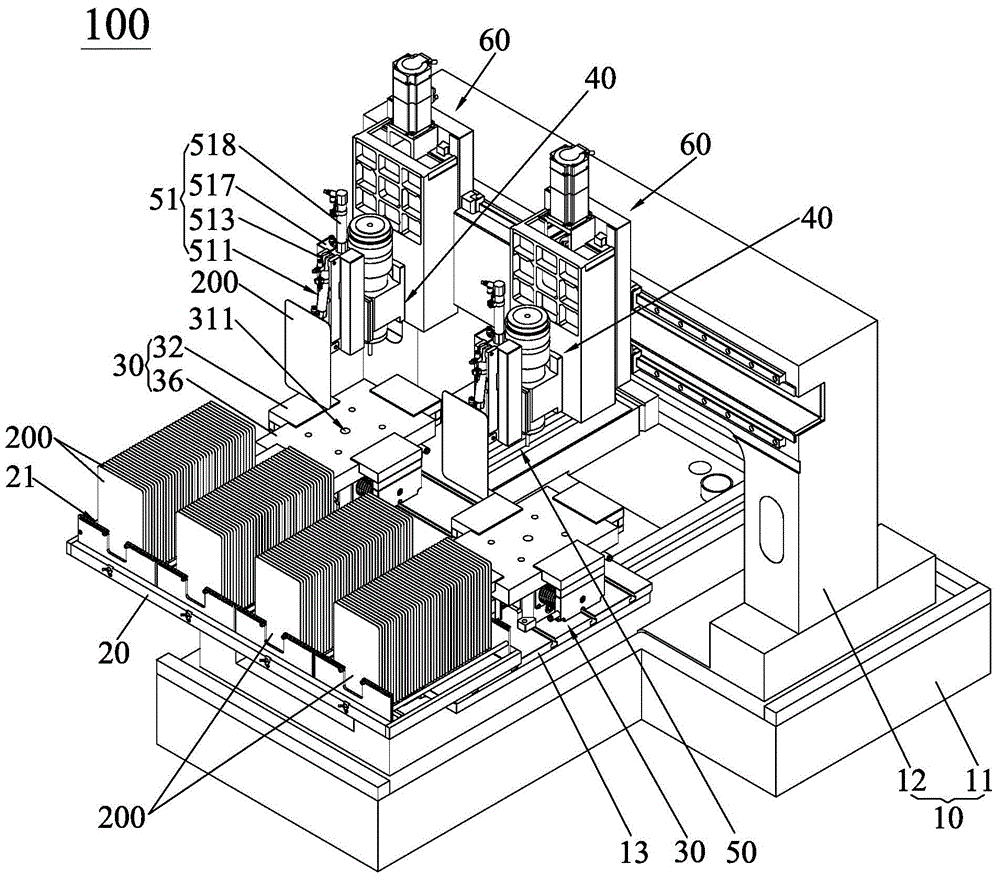

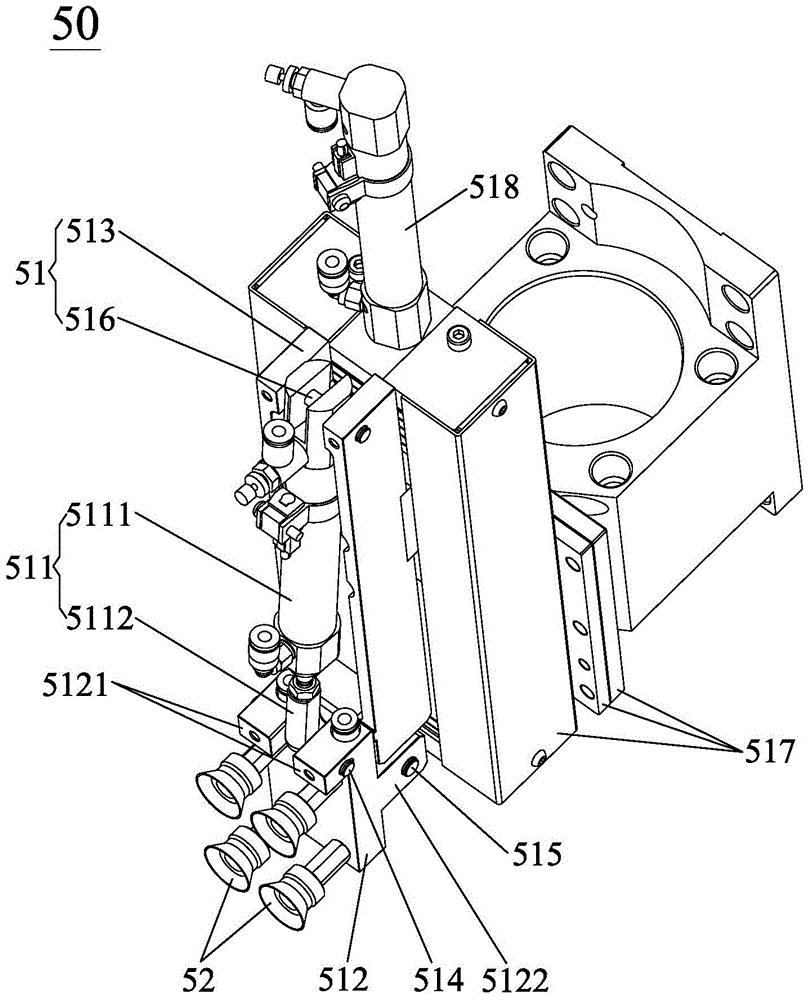

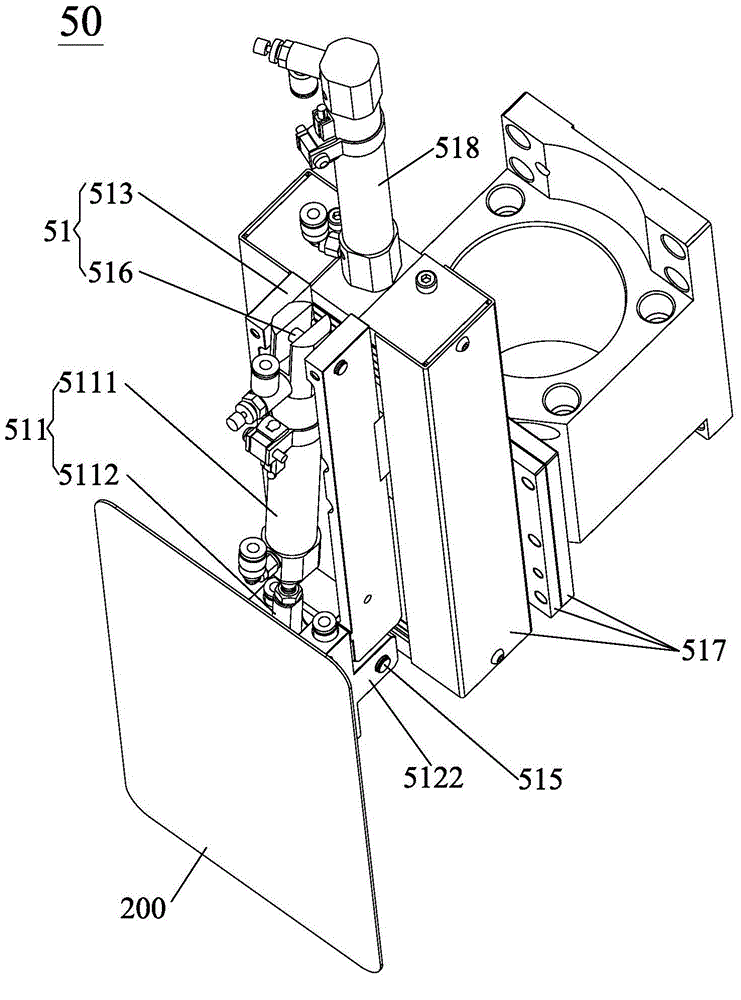

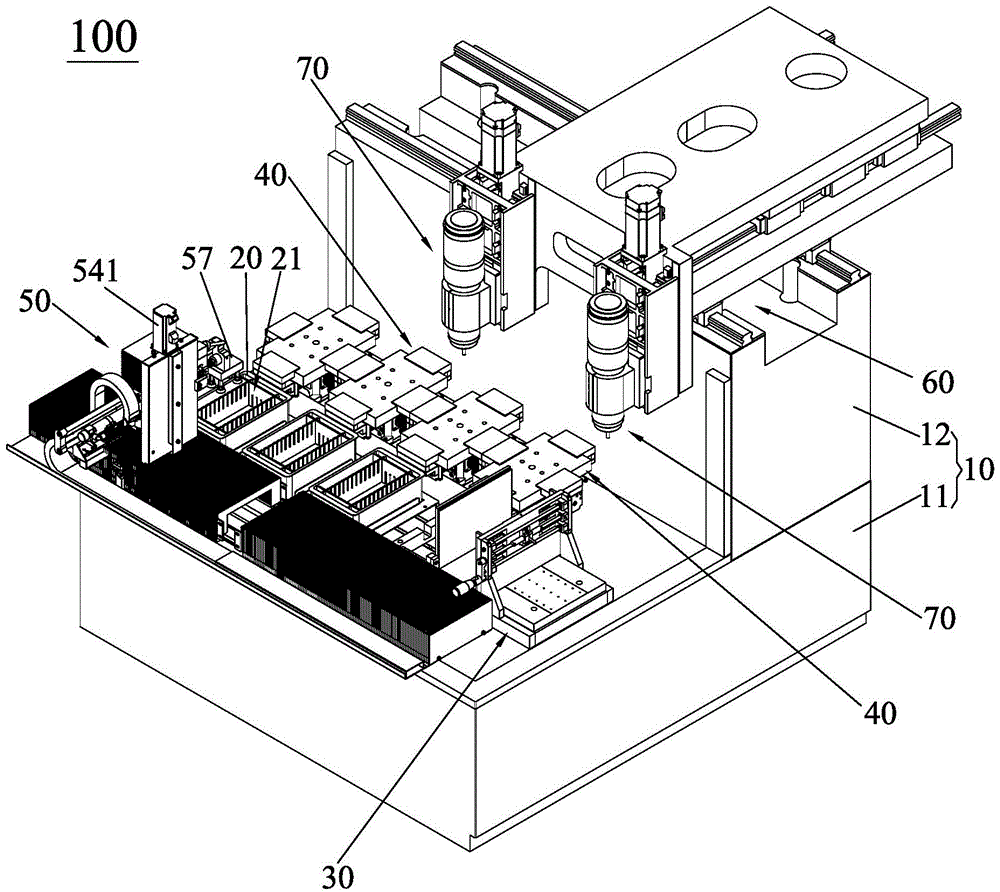

Automatic panel replacing and machining machine

The invention discloses an automatic panel replacing and machining machine which comprises a rack, a material box, four-face halving clamps, machine heads and turnover mechanisms. The rack comprises a horizontal seat frame and a vertical frame, and a sliding work platform is assembled on the horizontal seat frame. The material box is arranged at the front end of the work platform and provided with stacking sorting cavities. The four-face halving clamps are assembled on the work platform and at the rear end of the material box, each four-face halving clamp comprises an absorption structure, four halving blocks and a four-face drive assembly, and a containing cavity is defined by the four halving blocks of each four-face halving clamp together. The machine heads are assembled on the vertical frame and above the positions corresponding to the four-face halving clamps, and the machine heads slide in the vertical direction and left-right direction of the horizontal seat frame. The turnover mechanisms are arranged on the machine heads and comprise turnover drive assemblies and vacuum nozzles right opposite to a panel on the material box, the turnover drive assemblies drive the vacuum nozzles to turn over so that the panel between the material box and the containing cavities can be transferred through the vacuum nozzles, and the aim of automatic panel replacing and machining is achieved.

Owner:江西衡源智能装备股份有限公司

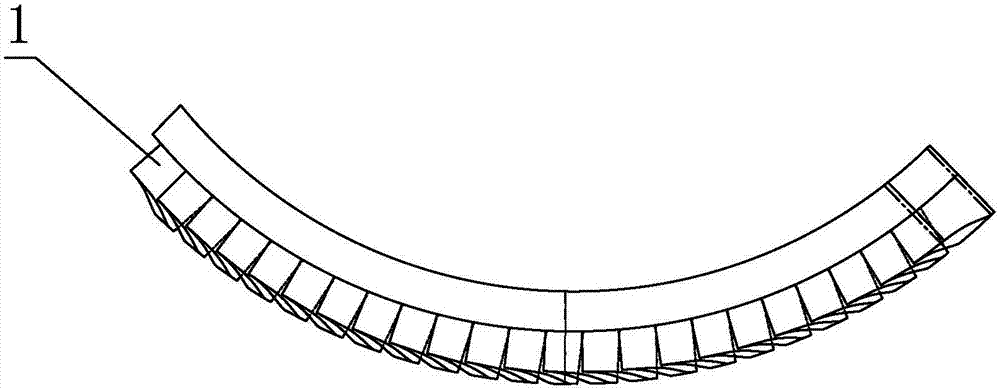

Milling grooving machining method for high-temperature alloy integral blade ring and blade part

The invention belongs to the field of machining, and particularly relates to a milling grooving machining method for a high-temperature alloy integral blade ring and blade part. The method comprises the machining steps of air inlet end pre-drilling, cavity milling of a blade back at the air inlet end, cavity milling of a blade basin at the air inlet end, milling of an air inlet end flow channel and back chipping, exhaust end pre-drilling, cavity milling of a blade basin at the exhaust end, cavity milling of a blade back at the exhaust end, and milling of an exhaust end flow channel and back chipping. The milling grooving machining method for the high-temperature alloy integral blade ring and blade part, the milling modes of driving a fixed shaft through multiple vectors for layering and sectional connecting are adopted, and a common end milling cutter is applied to realize rough grooving machining of uniform allowance.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Processing method of titanium alloy TA15 thin-wall long boss

ActiveCN107717030AReduce distortionReduced milling distortionWorkpiecesMilling equipment detailsNumerical controlMachining deformation

The invention relates to the technical field of machining, in particular to a processing method of a titanium alloy TA15 thin-wall long boss. The processing method particularly comprises the followingsteps: removing the margin of a middle arm, removing the margin of the right side of the boss, removing the margin of the left side of the boss, finish-milling the middle arc, finish-milling the right side of the boss and finish-milling the left side of the boss. The processing method is mainly applied to milling of an axial long boss of the new generation aero-engine titanium alloy TA15 material, the adverse effects of machining deformation of thin part structure wall and long axial size in the processing process of thin-wall guide pipe parts are avoided, the technical bottlenecks of programming of milling processing numerical control program and determination of milling processing process parameters are overcome, and the shape and the size precision requirements of the titanium alloy TA15 material thin-wall long boss parts are guaranteed effectively.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

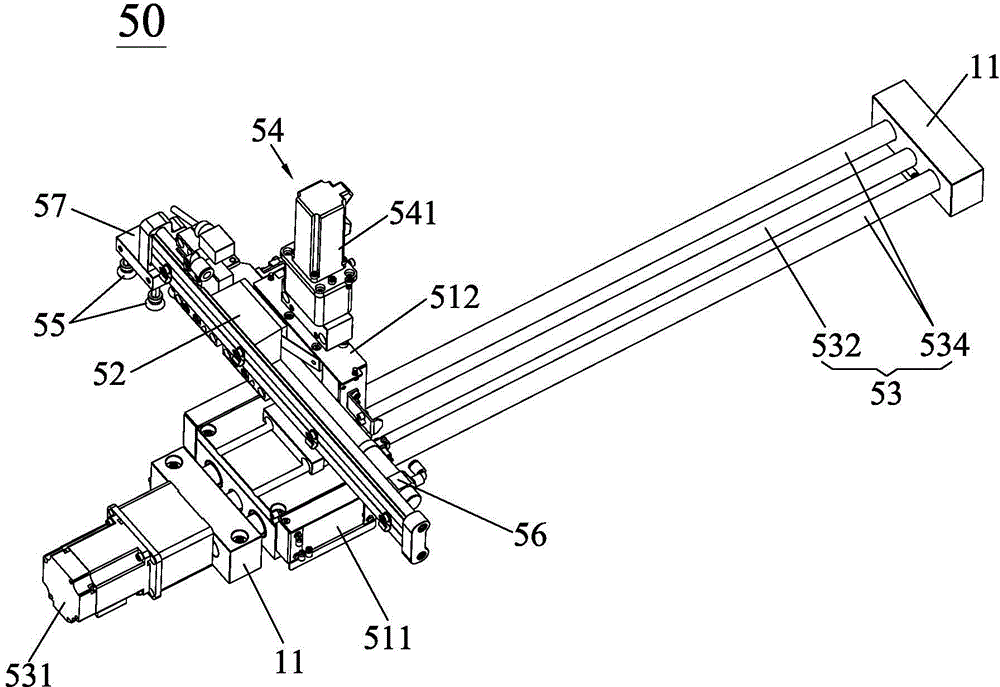

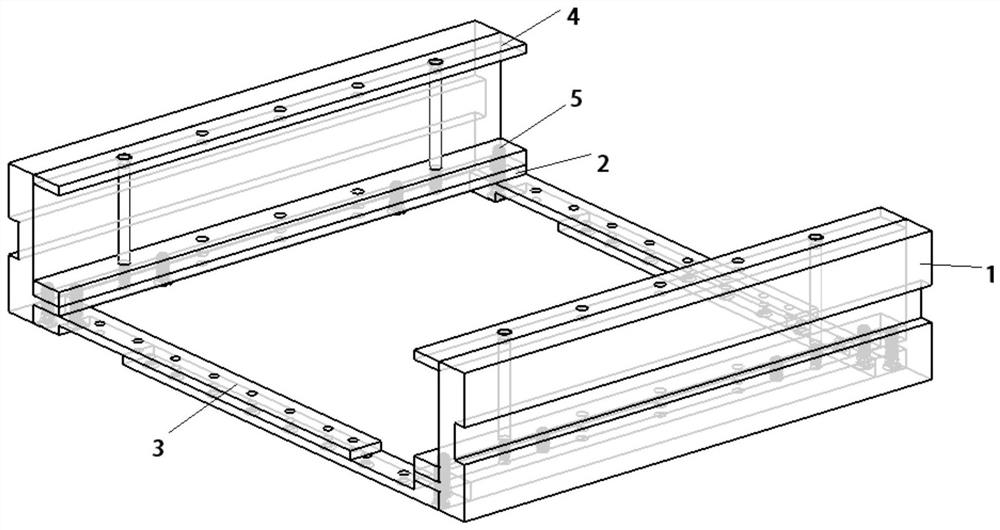

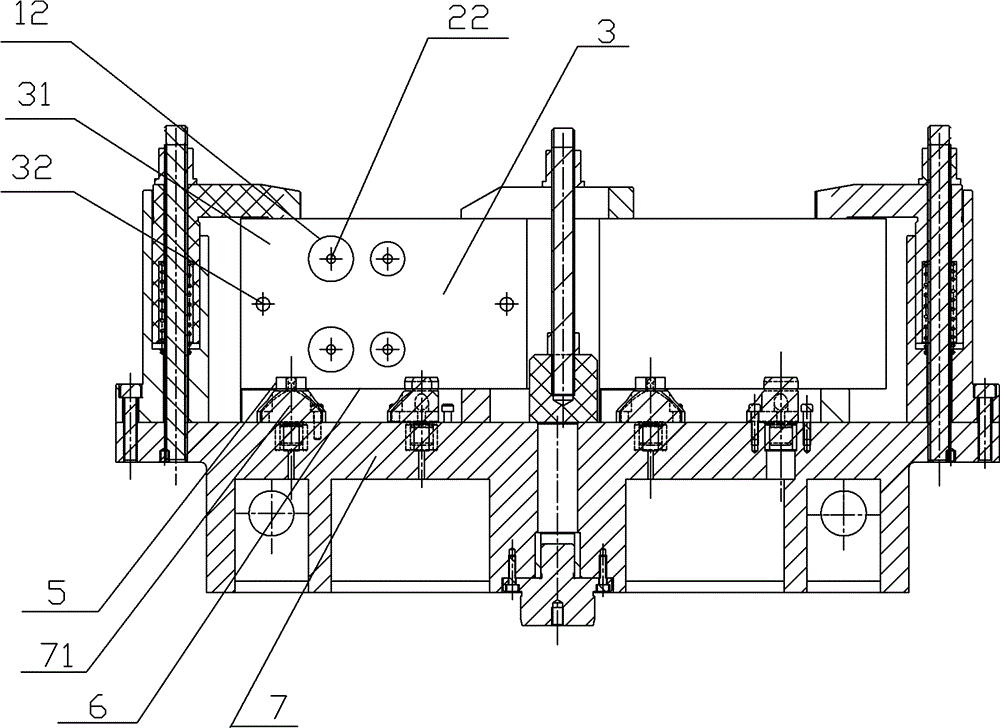

Automatic panel replacing and machining equipment

ActiveCN104607990AUniform balanceAvoid problemsWorking accessoriesMetal working apparatusTransfer mechanismMachining

The invention discloses automatic panel replacing and machining equipment which comprises a rack, material boxes, four-face halving clamps, machine heads, a sheet-by-sheet conveying mechanism and a transfer mechanism. The rack comprises a horizontal seat frame and a vertical frame. The material boxes are arranged on the horizontal seat frame and provided with stacking sorting cavities. The sheet-by-sheet conveying mechanism is arranged on the horizontal seat frame and arranged adjacent to the material boxes, and is provided with a stacking cavity and a pushing assembly. The four-face halving clamps are assembled on the horizontal seat frame and arranged adjacent to the material boxes, so that a panel is halved and clamped. The transfer mechanism is responsible for conveying the panel conveyed by the pushing assembly to the four-face halving clamps, and responsible for conveying the panel at the four-face halving clamps into the stacking sorting cavities in the material boxes. The machine heads are suspended above the positions corresponding to the four-face halving clamps, the machine heads slide in the vertical direction, the left-right direction and the front-back direction of the horizontal seat frame to machine the panel halved and clamped by the four-face halving clamps, and the aim of automatic panel replacing and machining is achieved.

Owner:江西衡源智能装备股份有限公司

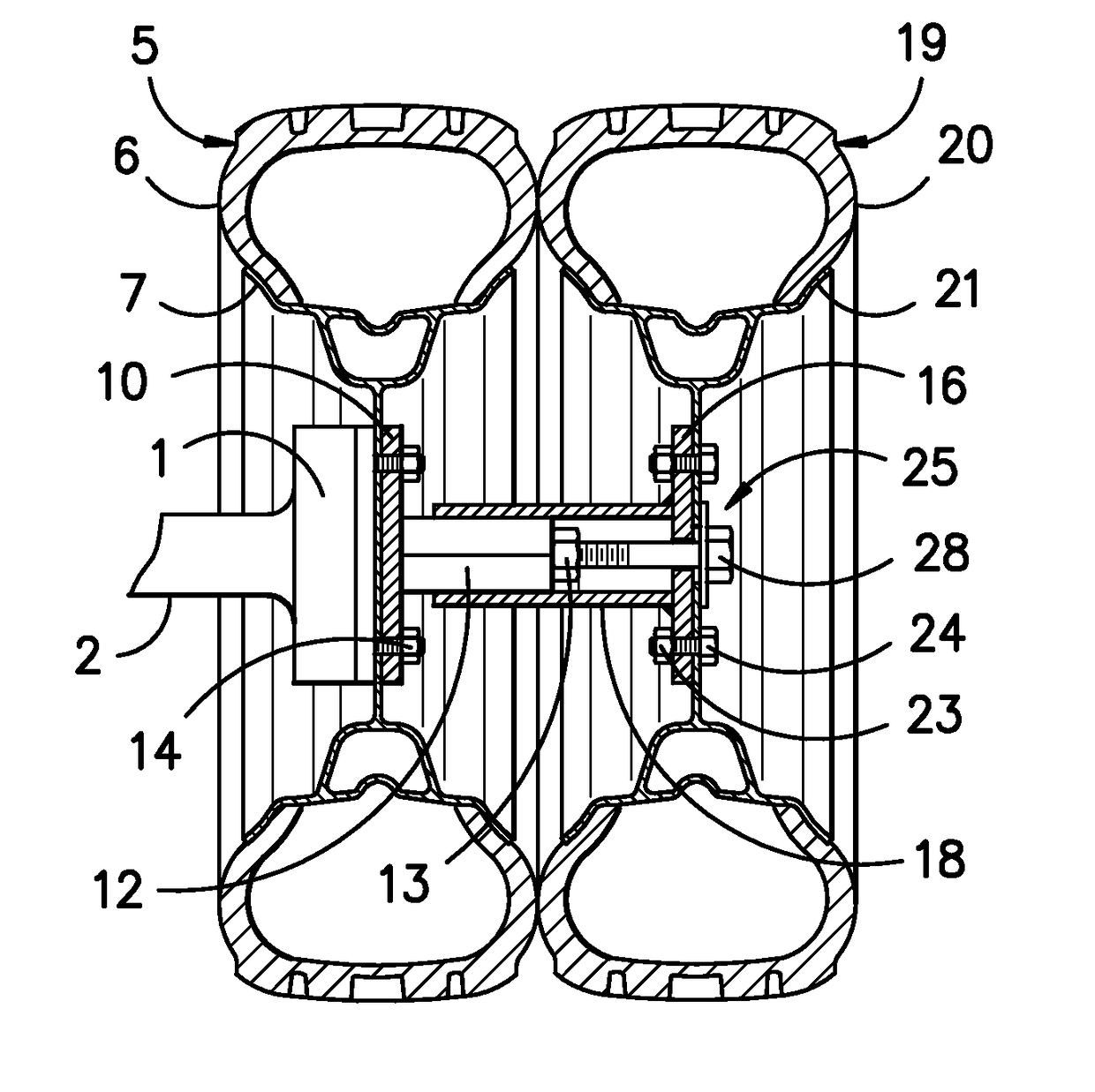

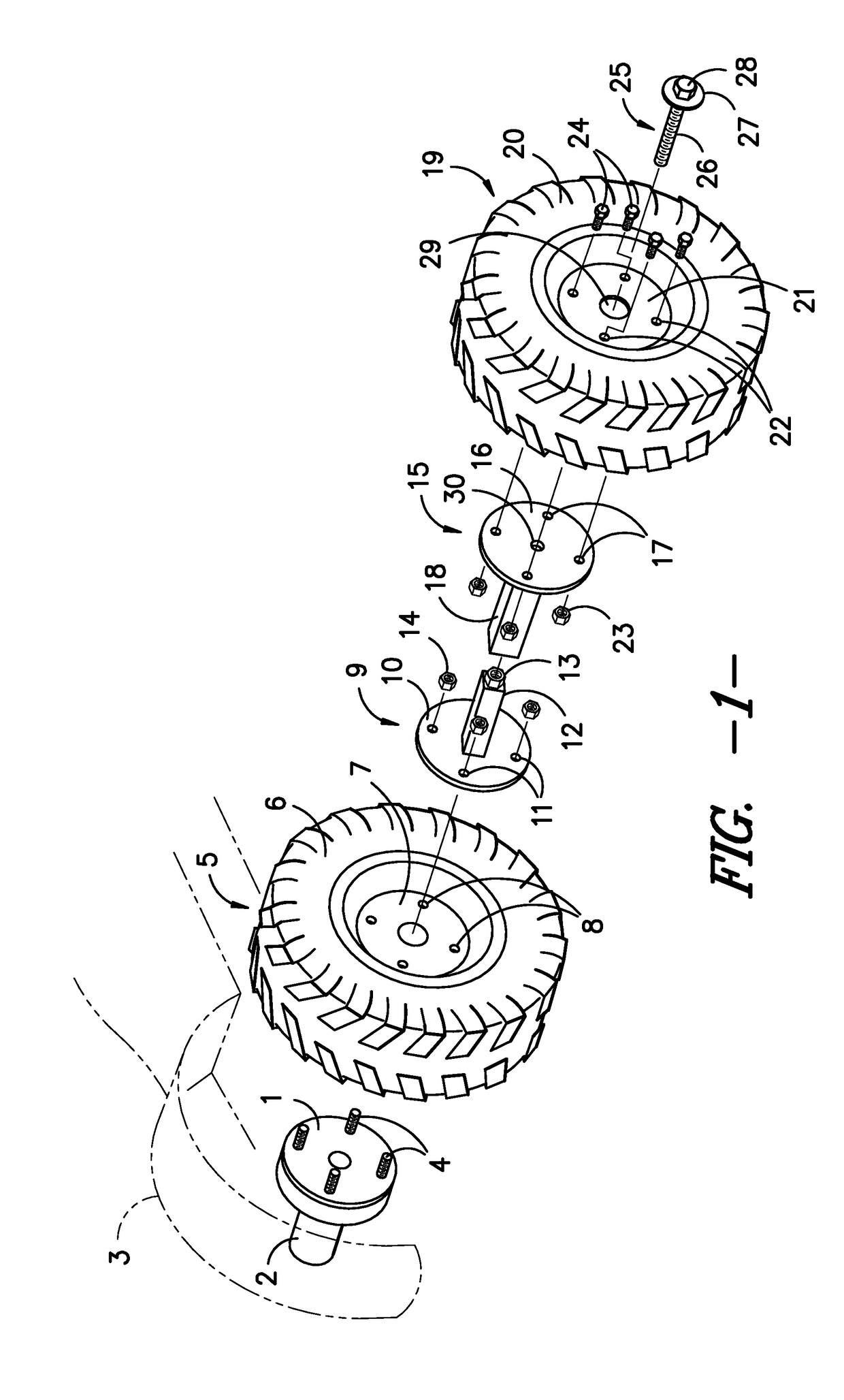

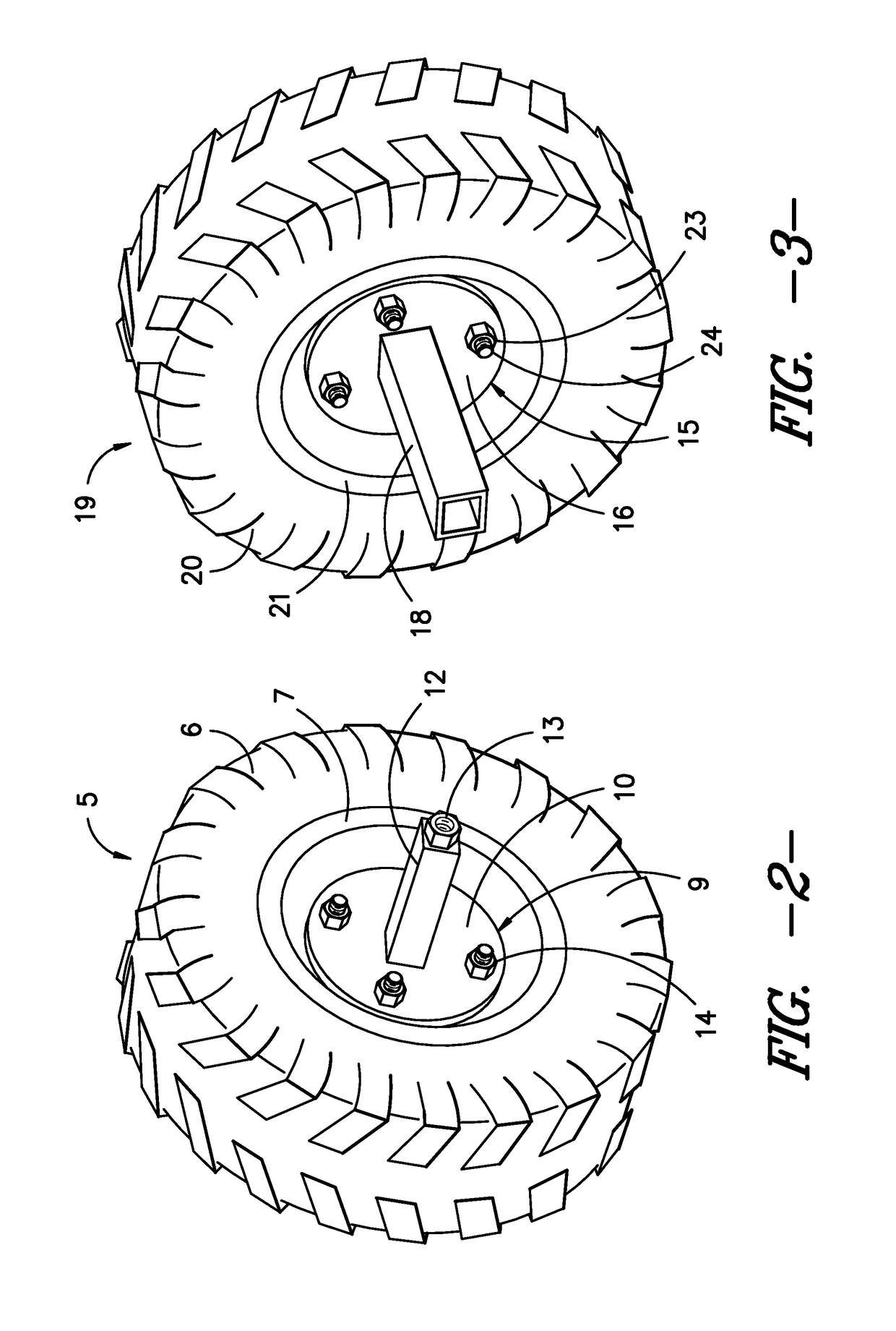

Adapter for dual-wheel vehicle

ActiveUS9616706B2Uniform balanceUniform performanceTrucksMultiple wheel assemblyDrive shaftEngineering

A kit for a dual wheel assembly for a vehicle is provided having a drive shaft adapter with an outwardly projecting extension attachable to an inner wheel by a flange and a drive shaft coupler having an outwardly projecting receiver attachable to an outer wheel with a flange, whereby drive shaft extension and receiver are telescopically engageable over a range of distances, which allows the inner wheel and outer wheel to be mounted with the tires abutting or the tires spaced apart by incorporating a spacer element into the assembly.

Owner:BENOIT JR WAYNE J

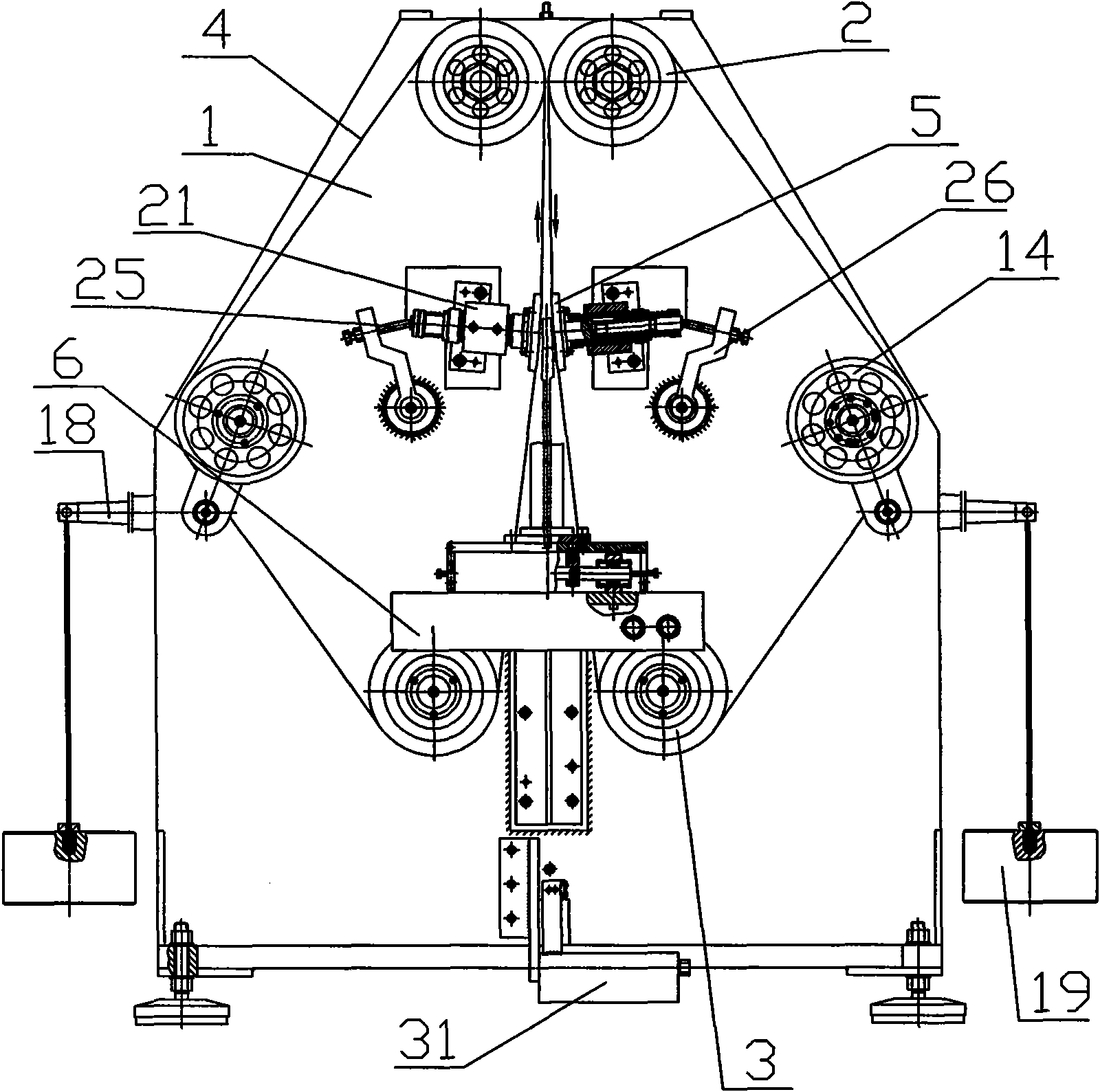

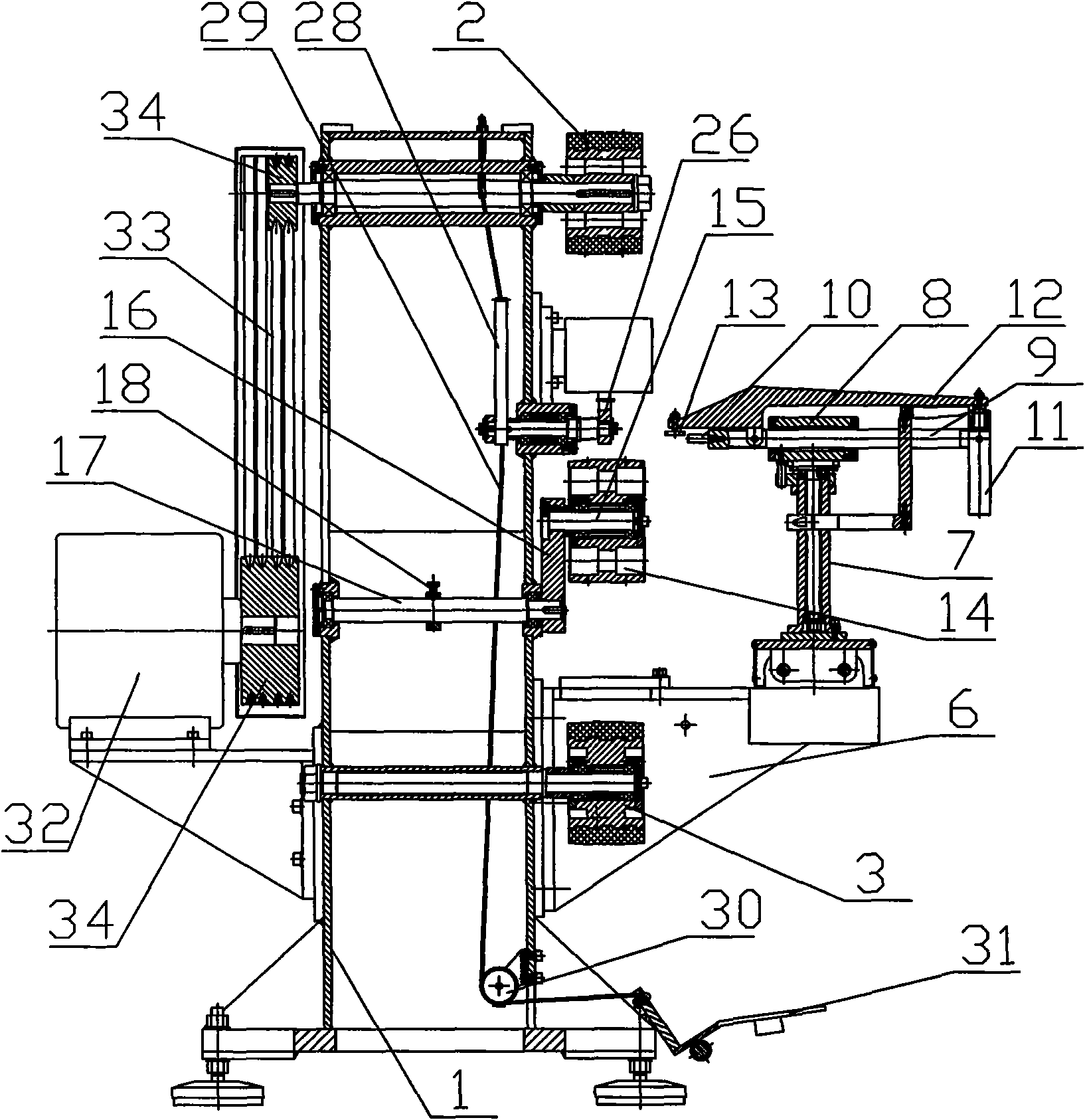

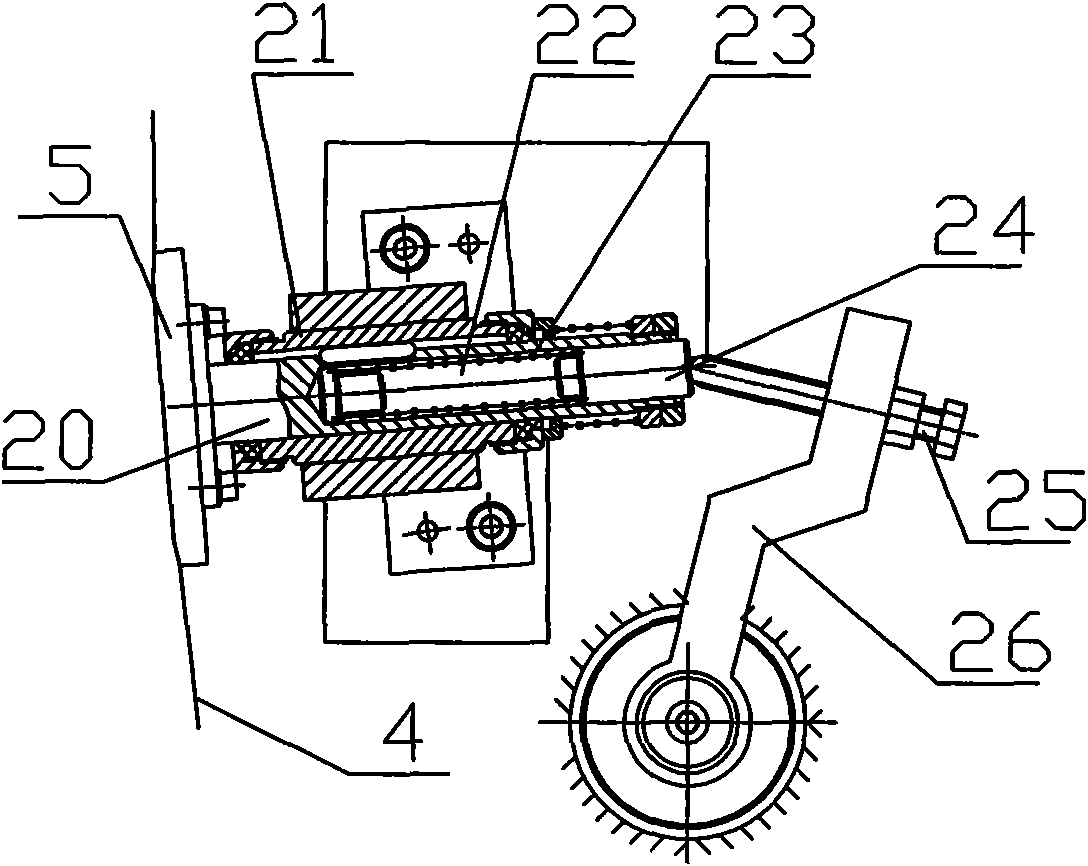

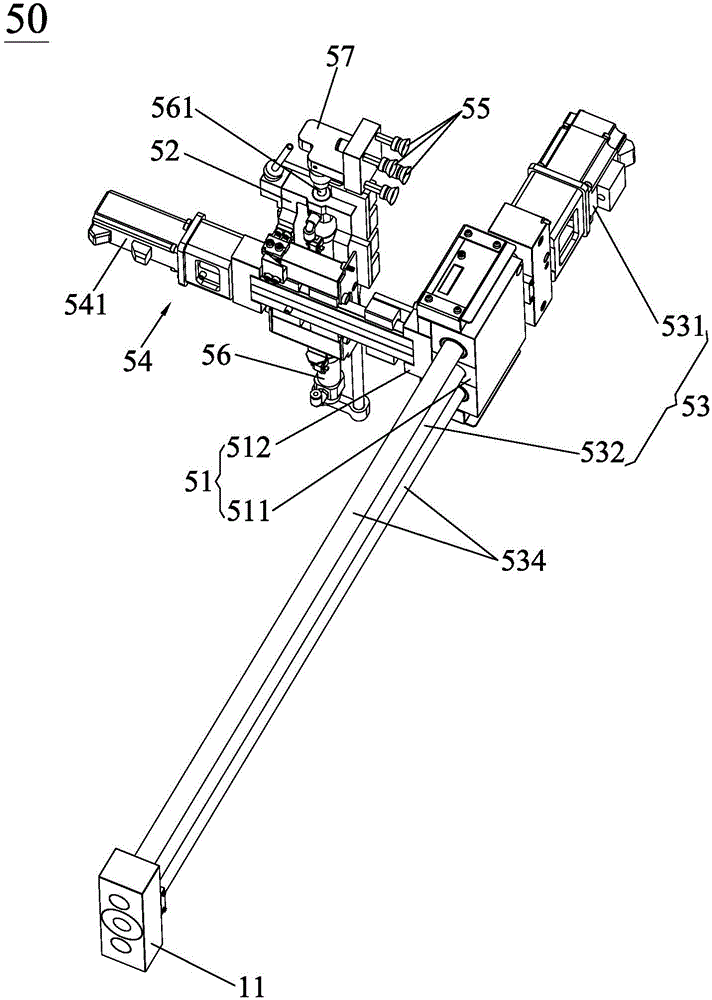

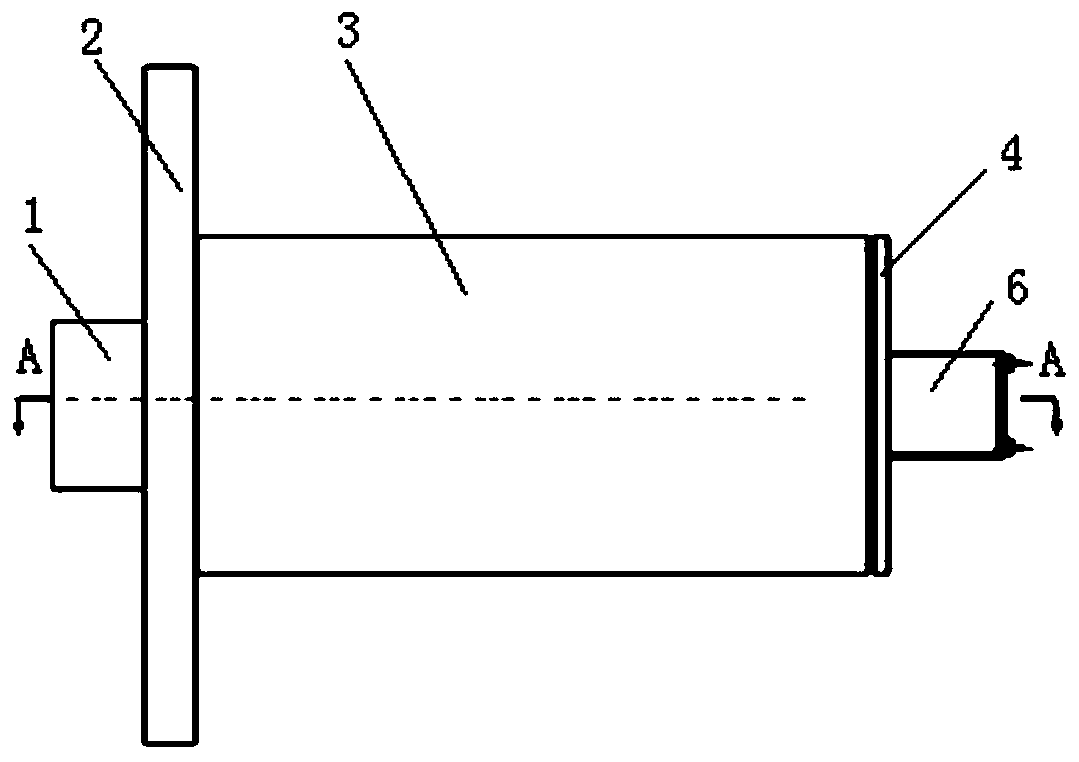

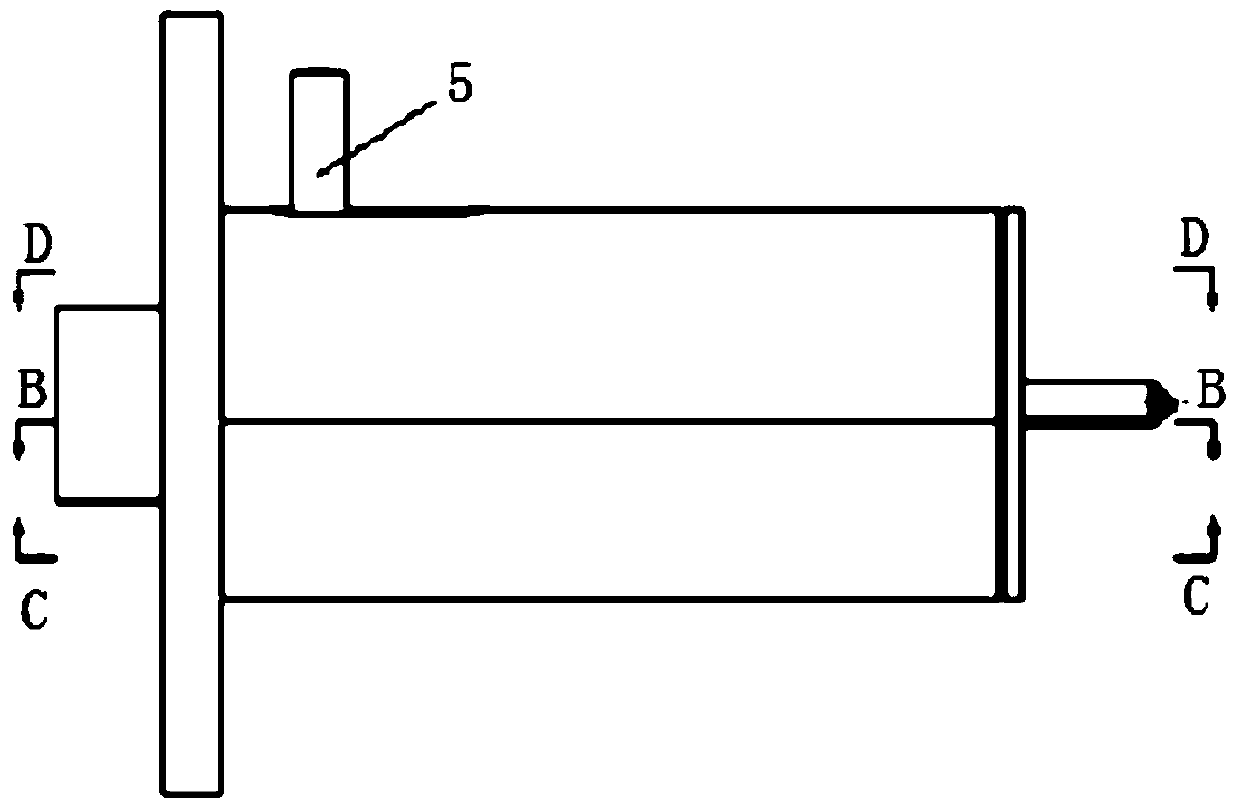

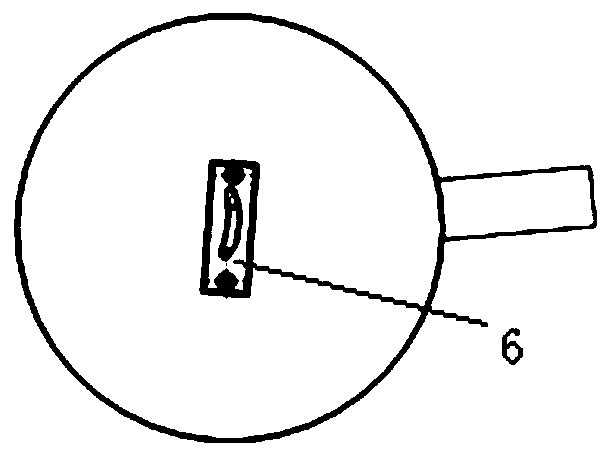

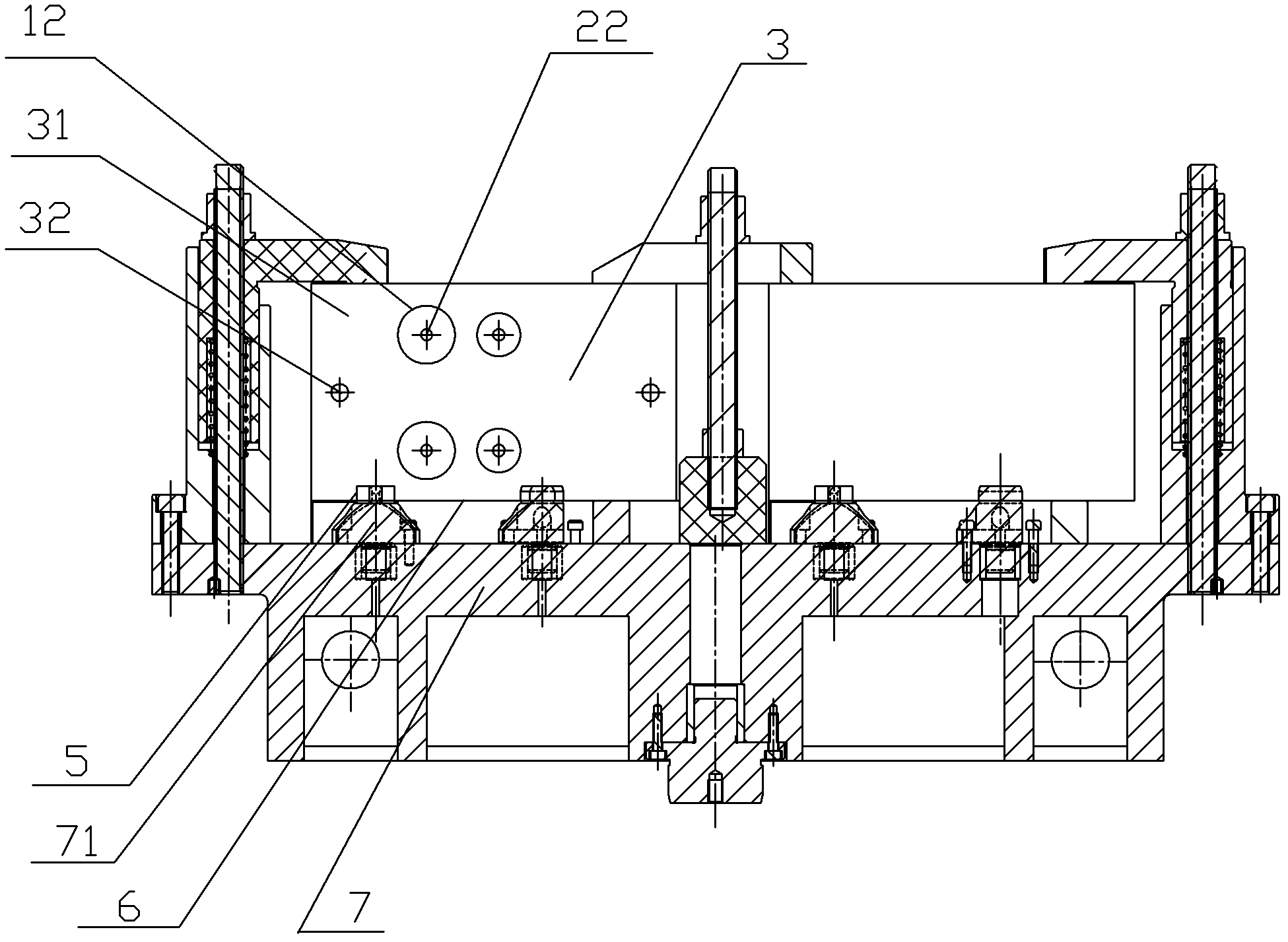

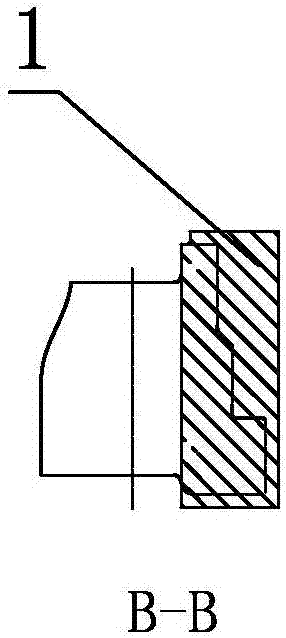

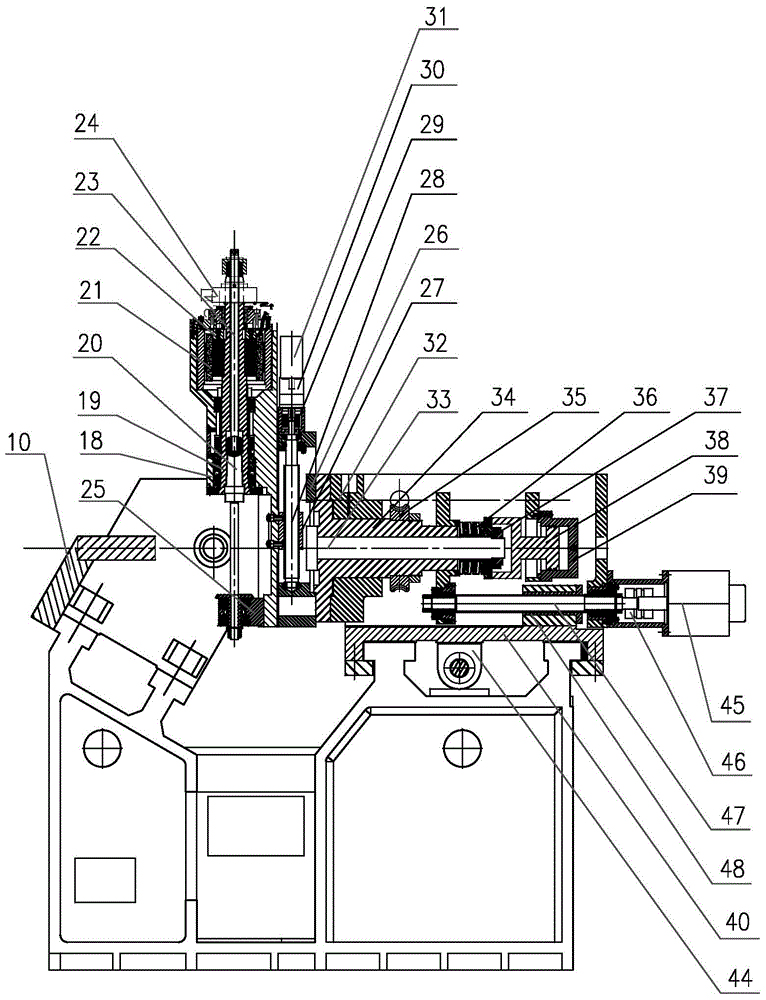

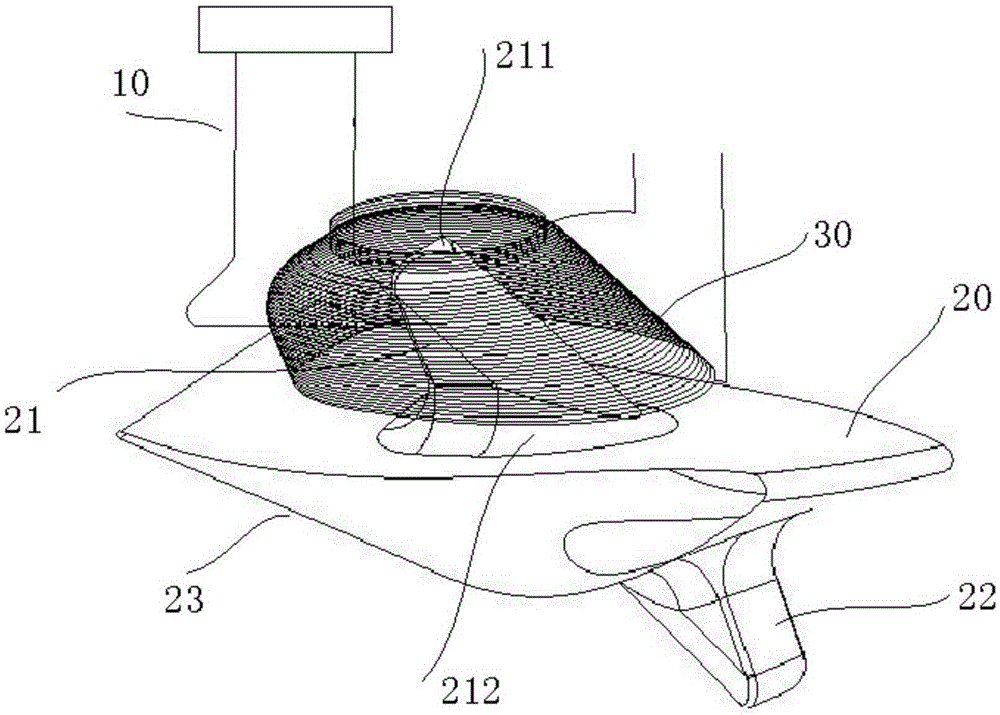

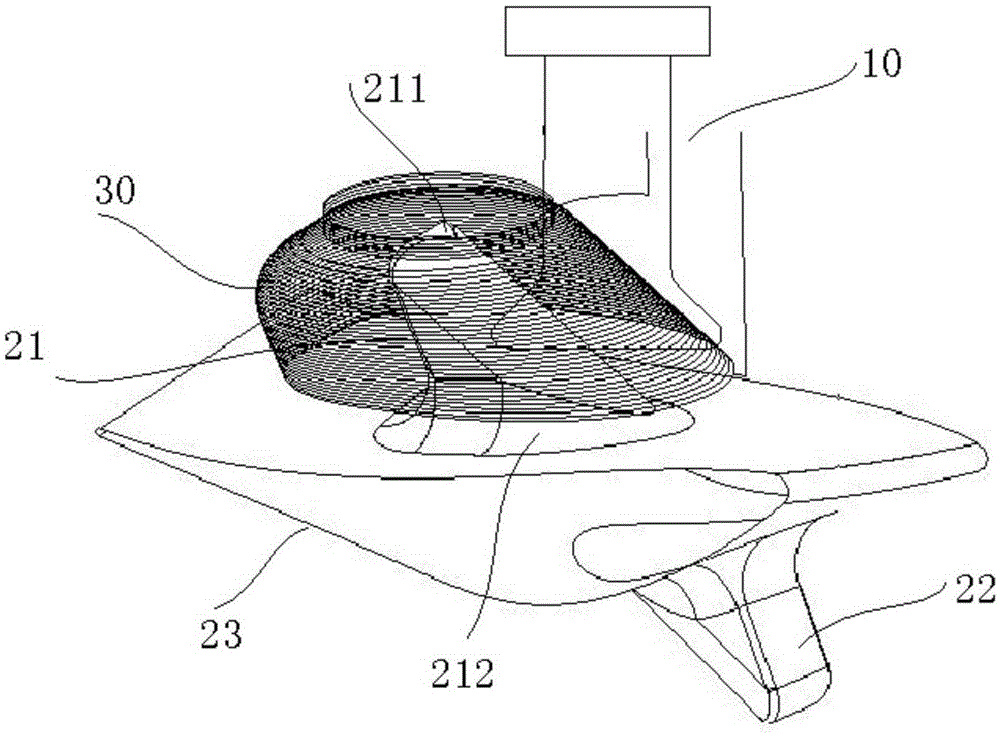

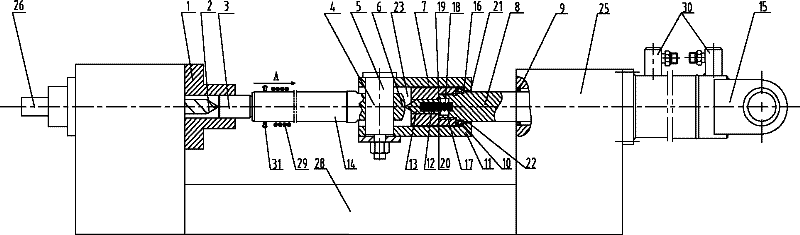

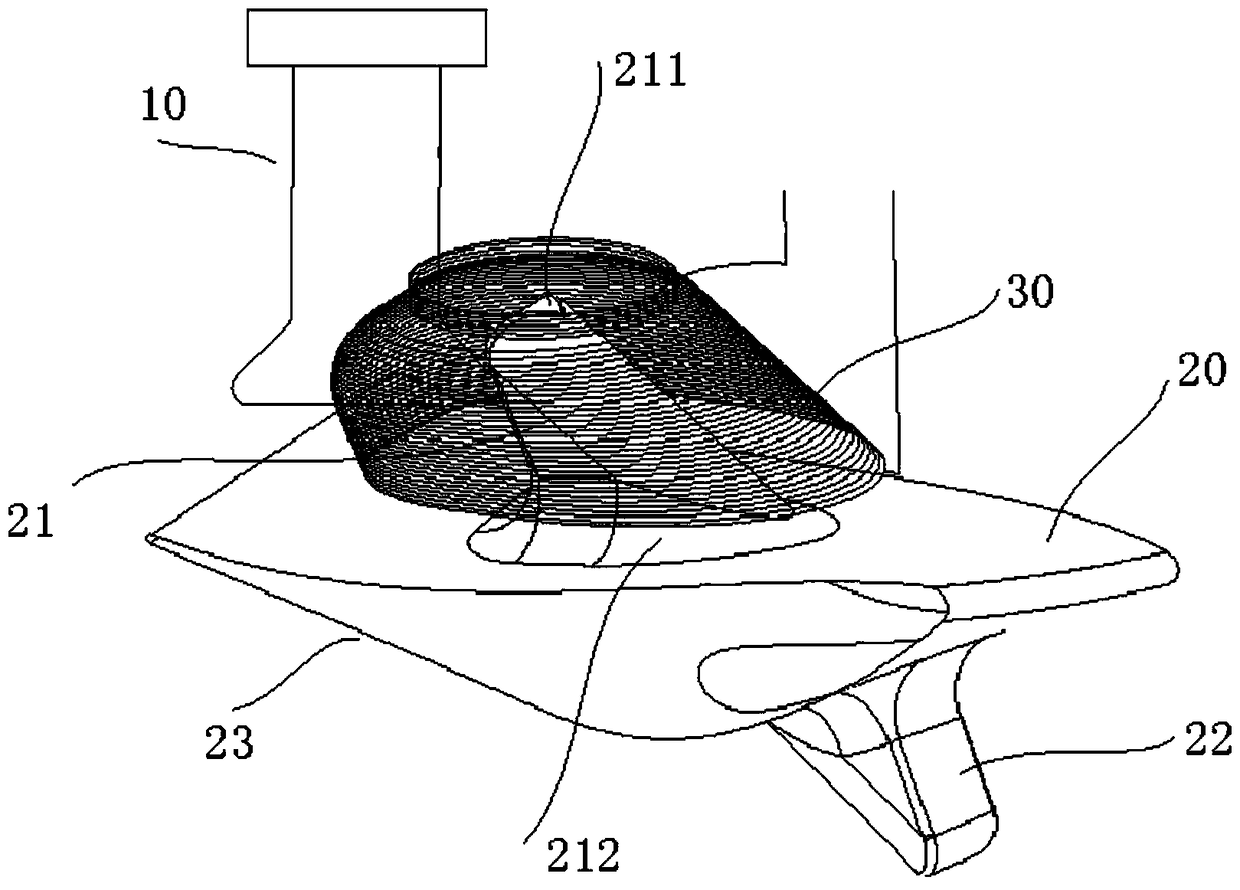

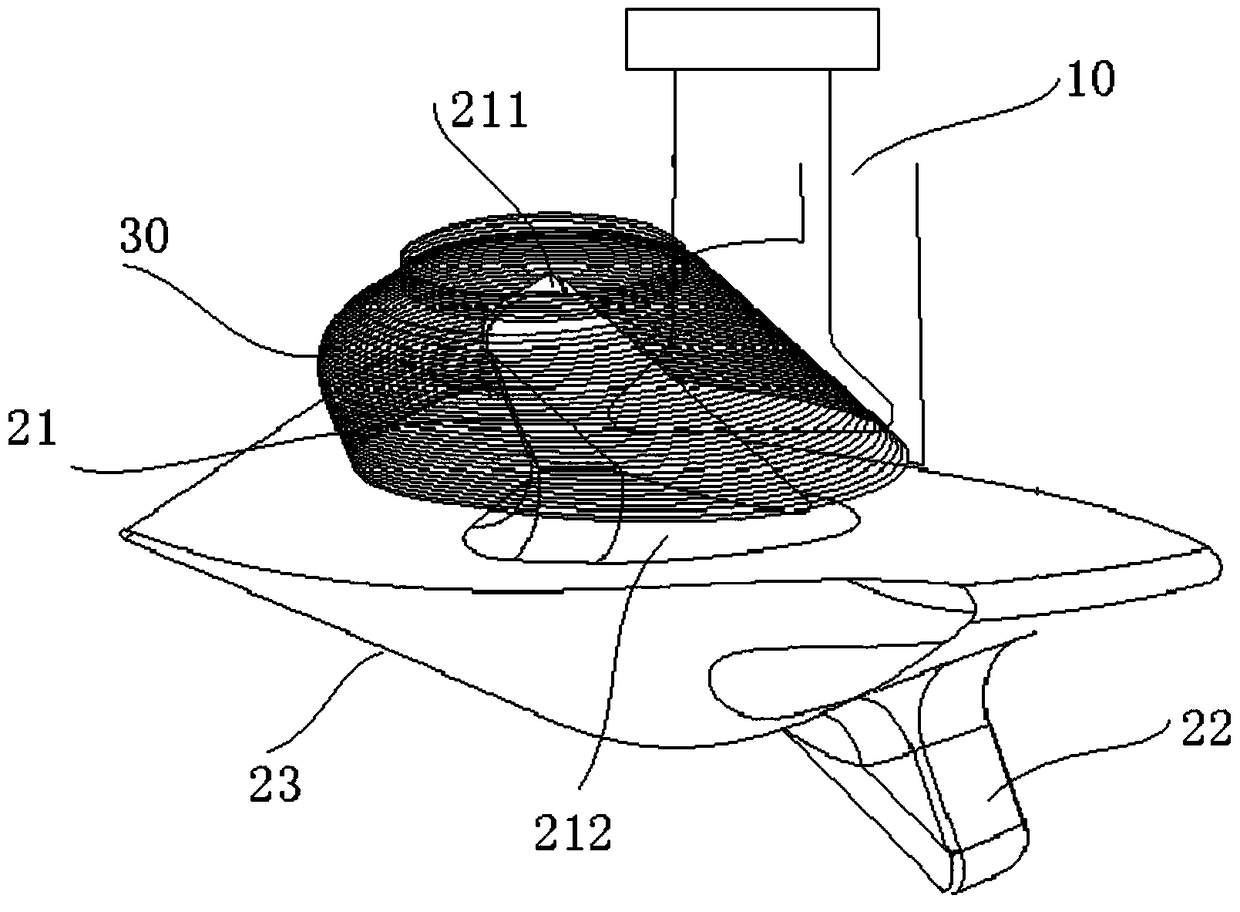

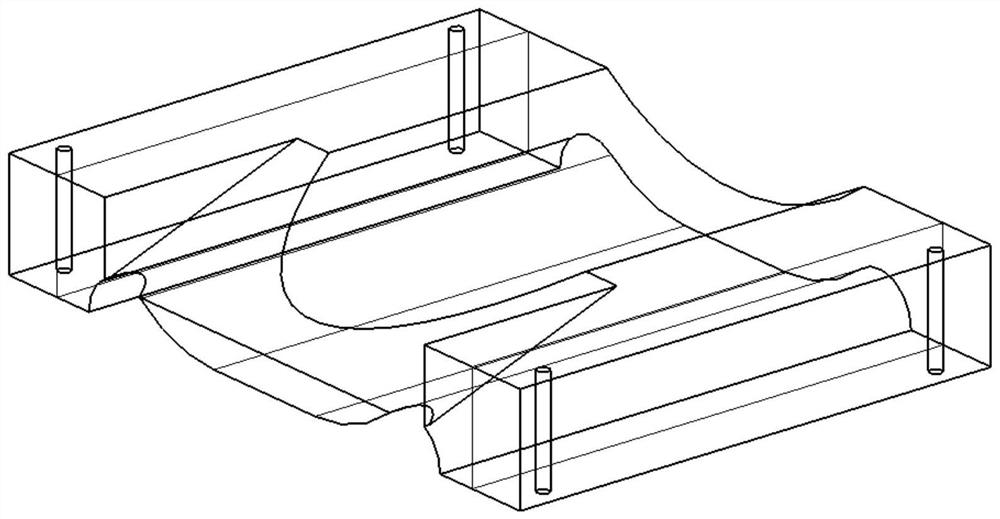

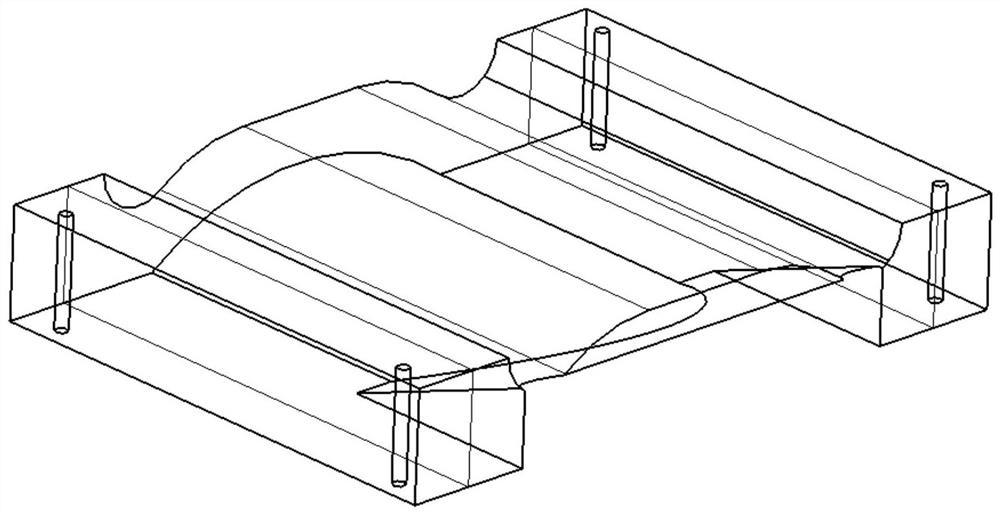

Blisk electrolytic forming rotary open type tool and electrolytic forming method

ActiveCN110977065AReduce processing R&D requirementsUniform balanceElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentEngineering

The invention discloses a blisk electrolytic forming rotary open type tool and an electrolytic forming method. The blisk electrolytic forming rotary open type tool comprises a sleeve assembly, a sleeve cover plate, an electrolyte water inlet pipe, an electrolyte water port, a power connection screw rod, a tool setting pin, an electrode plate, a shaft holder, a rotary connecting piece and a curve type sliding rail. A blisk electrolytic forming method comprises the following steps of step 1, installing a rotary open type tool on a machine tool open type shaft and a left cavity of a machine tool;step 2, determining initial machining original points of the machine tool open type shaft and X, Y and Z axes of a workbench of a horizontal electrolytic machine tool; step 3, inputting machining parameters through a control panel of the horizontal electrolytic machine tool; step 4, processing a single blade in a blisk; and step 5, after a single blade of the blisk is opened, adjusting an angularposition of the blisk through a blisk indexing tool, and processing a next blade till that machining is completed. The tool is used for carrying out rotary opening machining on a variable-curved-surface blade of the blisk, and the machined blade is uniform in allowance and high in precision.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

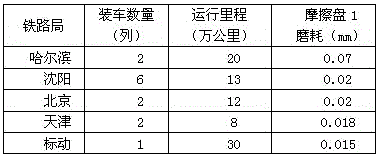

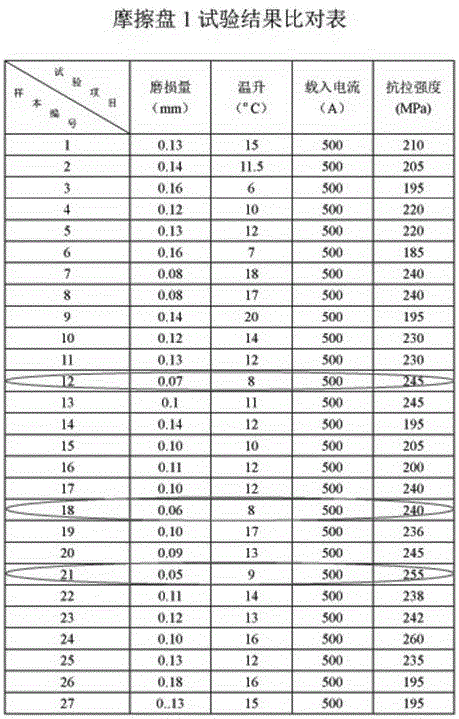

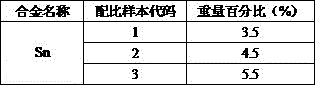

Friction disc for high-speed rail and preparation method of friction disc

InactiveCN106399747AThe result data is idealLiquid metal is better filledFoundry mouldsFoundry coresSand castingLiquid metal

The invention relates to a friction disc for a high-speed rail and a preparation method of the friction disc. The friction disc comprises the following components including, by weight, 3.5-5.5% of Sn, 4.0-6.0% of Zn, 1.0-3.0% of Ni, 1.5-3.5% of Pb, 0.2-0.4% of Be and the balance Cu. A vacuum suction fired mold is adopted for casting, gas in a cavity is sucked away from tiny pores in a shell, the cavity is better filled with liquid metal, the phenomena of pores and insufficient pouring are prevented, the appearance and inherent quality of products are improved, and the machining yield is up to 98%. The requirements of the friction disc for the abrasion resistance and electrical conductivity are higher, common sand casting structures are loose, casting defects are prone to occurring, and meanwhile the hardness is low. Precise die forging manufacturing is adopted, the blank allowance is even, the texture is compact, the hardness can reach the drawing requirement, and tests show that the abrasion resistance reaches and exceeds the level of foreign similar products.

Owner:YANGZHOU YIFENG BRONZE PROD

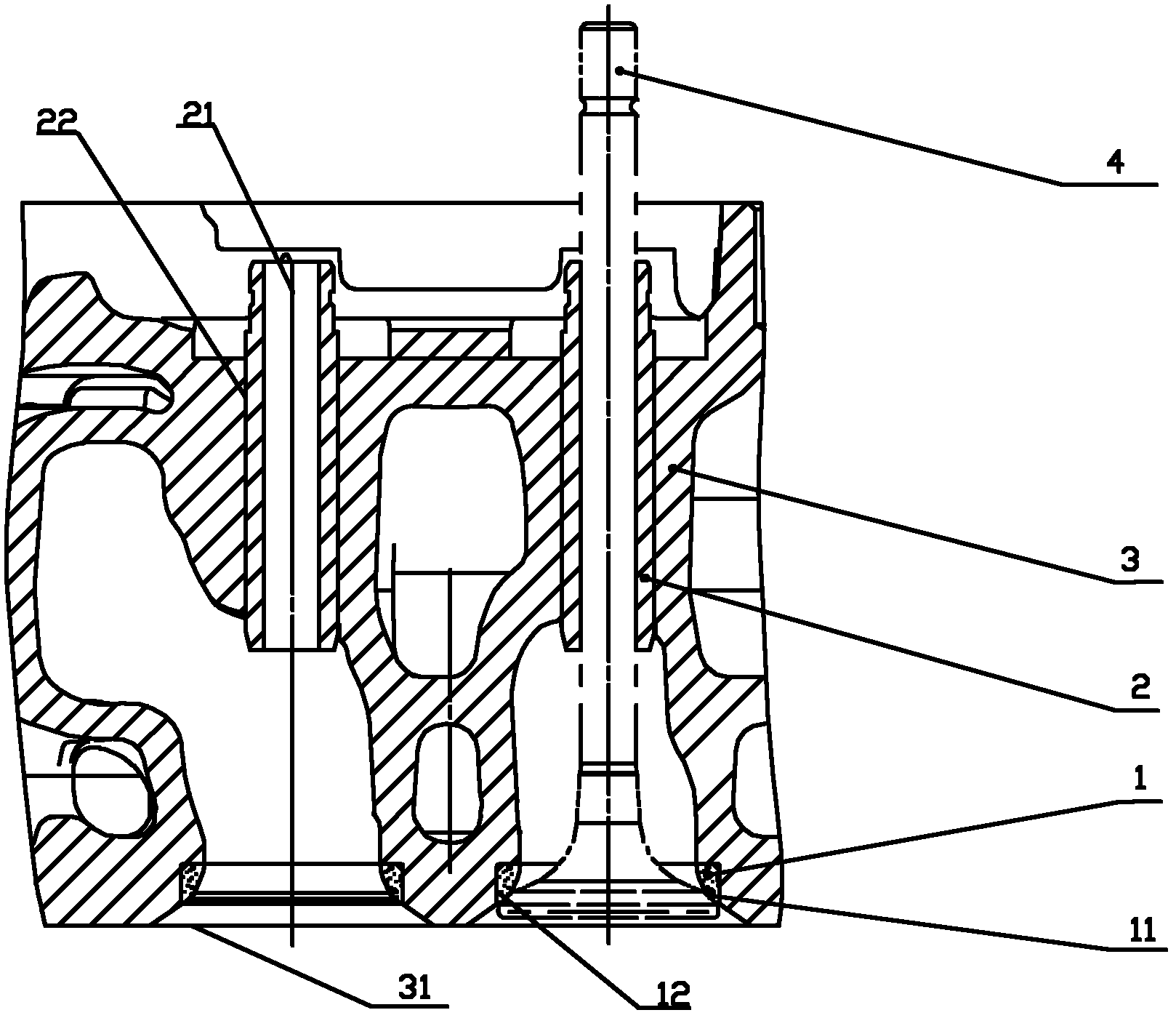

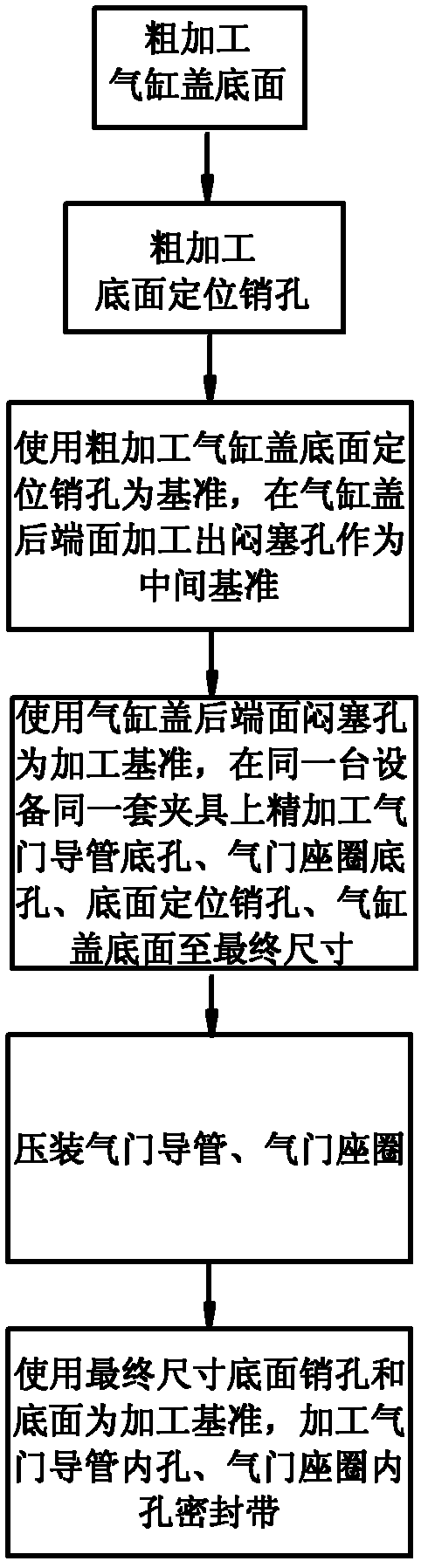

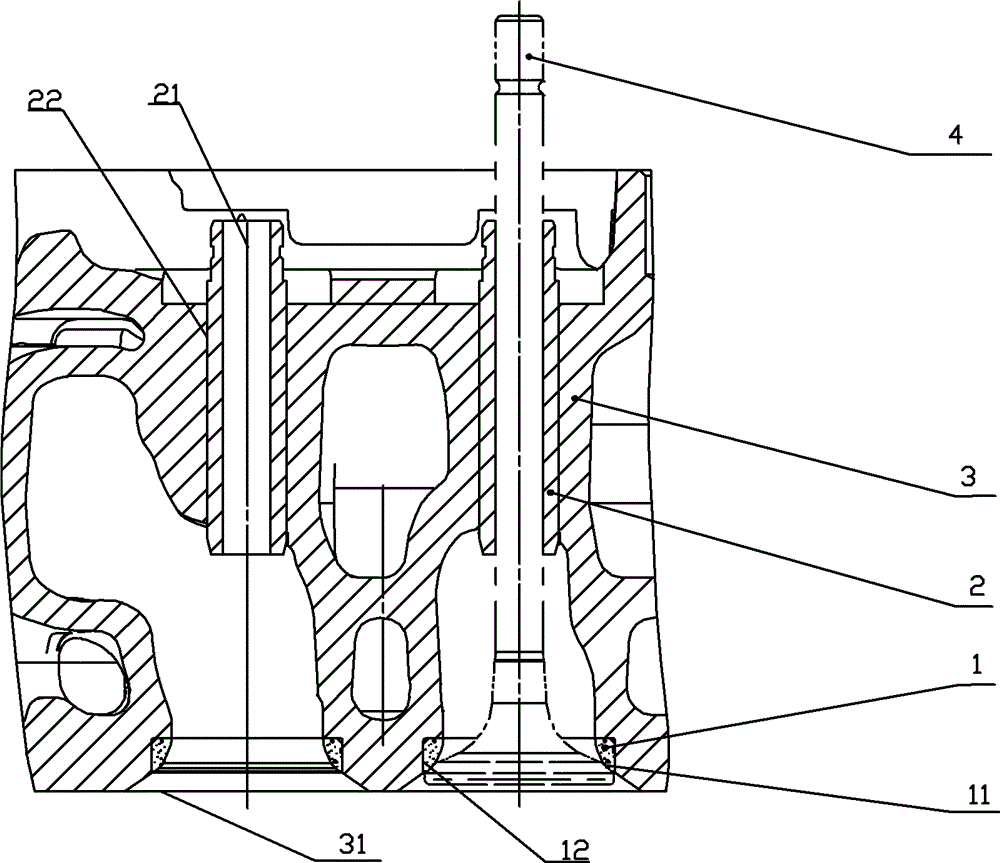

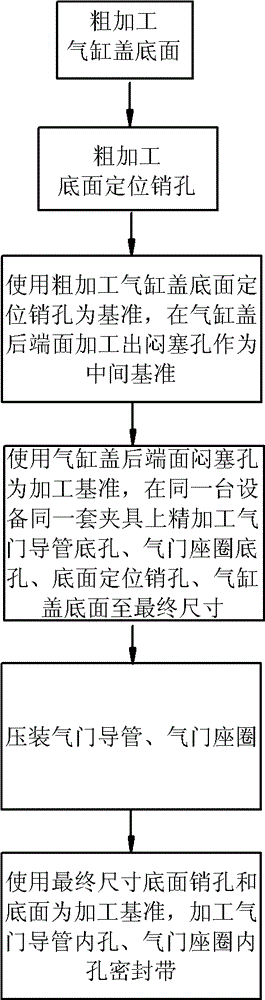

Machining method for sealing tape of valve seat ring of cylinder cover

ActiveCN102909525AThe processing allowance is uniformConcentricity satisfiesEngineeringProcess requirements

The invention discloses a machining method for a sealing tape of a valve seat ring of a cylinder cover. The method comprises the steps: firstly roughly machining the bottom surface of the cylinder cover; roughly machining a positioning pin hole on the bottom surface of the cylinder cover; taking the positioning pin hole roughly machined on the bottom surface as reference to machine a closed plug hole on the cylinder cover as middle reference; taking the closed plug hole as the machining reference to finely machine a valve guide pipe bottom hole, a valve seat ring bottom hole, a bottom-surface positioning pin hole and the bottom surface of the cylinder cover on the same set of fixture of the same equipment to the final sizes; pressing the valve guide pipe and the valve seat ring; and finally taking the bottom-surface positioning pin hole and the bottom surface of the cylinder cover as the machining reference to machine an inner hole of the valve guide pipe and the sealing tape of an inner hole of the valve seat ring. The bottom holes of the inner hole of the valve guide pipe and the sealing tape of the inner hole of the valve seat ring are machined at the same time by using the machining references, the allowance for continued machining is uniform, and the coaxiality of the sealing tape of the valve seat ring relative to the inner hole of the valve guide pipe meets the process requirements.

Owner:GUANGXI YUCHAI MASCH CO LTD

Method for machining thin web titanium alloy edge strip

ActiveCN105312645AGuaranteed thickness accuracyReduce distortionMilling equipment detailsMilling cutterTitanium alloy

The invention discloses a method for machining a thin web titanium alloy edge strip, wherein the method is convenient to operate and capable of eliminating part deformations. The method for machining the thin web titanium alloy edge strip comprises the following steps in order: rough machining, semi-finish machining and finish machining; in the process of rough machining, firstly, a hard alloy end mill is adopted for rough machining of a part at a large cutting depth, a low rotating speed and a low feed speed; and secondly, a clamped indexable milling cutter is adopted as a machining cutter for equal-height cutting machining at a small cutting depth in such a manner of fast feed. The method for machining the thin web titanium alloy edge strip is capable of quickly removing black allowance and improving the machining efficiency; besides, the allowance of each portion is uniform, which is favorable for programming during semi-finish machining of the part, and further, machining cutting can be more steady.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Machining method for nozzle steam channel

The invention relates to a method for processing nozzle steam channels, which relates to the field of steam turbines. The invention solves the problem that the existing nozzle steam channel adopts the electric discharge machining method, and there is a hardened layer on the surface after processing, which affects the machining efficiency. Efficiency affects product quality, and there is a problem that the rightmost steam channel cannot be processed due to the interference between the EDM electrode and the workpiece. The method of the present invention comprises the following steps: 1. Rough machining the inlet and outlet sides of the nozzle steam passage, the rotating speed is 2000r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.01mm; 2. Rough machining the nozzle steam passage In the middle part, the speed is 2500r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.02mm; 3. The leaf shape of the semi-finishing nozzle air passage, the speed is 3200r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.03mm; 4. Finishing the leaf shape of the nozzle steam channel, the speed is 3000r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.02mm. The invention is used for the processing of the nozzle steam channel.

Owner:HARBIN TURBINE

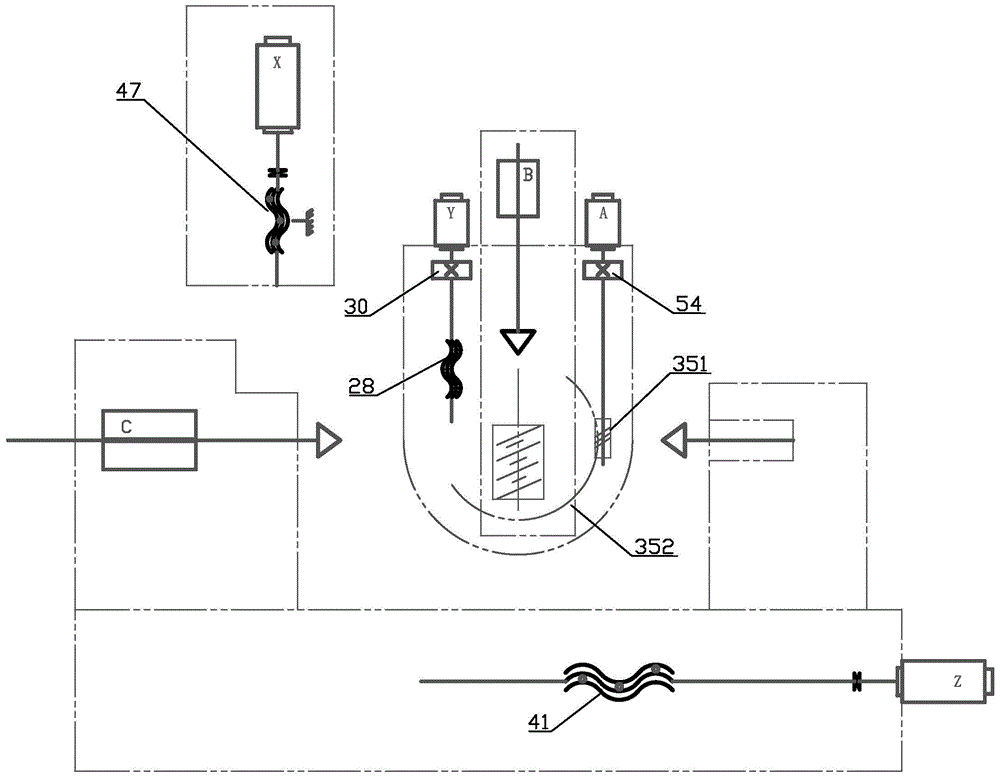

Direct-driven zero-drive complete-numerical-control spline shaft milling machine

InactiveCN104785830AImprove efficiencyIncrease productivityMeasurement/indication equipmentsFeeding apparatusStructural systemProcessing accuracy

Owner:ZHANGJIAGANG YITENG MACHINERY

Rough machining method for partspan shroud of turbine blade

The present invention discloses a rough machining method for a partspan shroud of a turbine blade. The method comprises the following steps: (1) selecting a cutter which has a radius difference between a cutter bit and a cutter bar equal or greater than the depth of the reversing shaded side of the partspan shroud to be machined; and (2) creating a numerical control machining procedure of the partspan shroud according to the features of the partspan shroud and the selected cutter, and by controlling the gesture of the cutter, machining the sharp curved surface of the partspan shroud and the adapter position of the partspan shroud and the root of the blade profile by a chamfer of the cutter, where the small position of the cutter bar of the cutter avoids the interference part of the shaded side of the partspan shroud. The method uses a cutter to finish the rough machining of the profile and the bottom of the partspan shroud, makes margin for finish machining, and improves the machining quality. It does not need to replace the cutter and does not need supplemental machining. The ineffective cutting time (except feeding and relieving) is short. The load of the machine tool is uniform, and the cutting process is smooth. Therefore, the machining efficiency is greatly improved, and the difficulty and bottleneck of the shroud machining is efficiently overcome.

Owner:DONGFANG TURBINE CO LTD

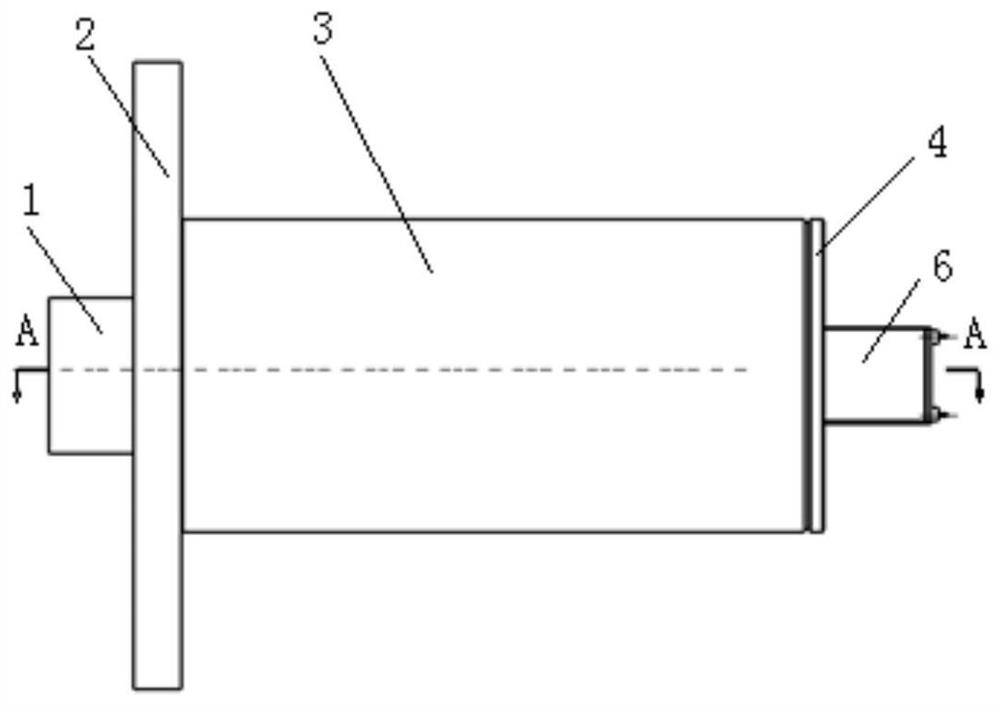

Device for preventing elongated piston rod from bending deformation during medium and high frequency quenching

InactiveCN102071294BImprove mechanical propertiesEliminate straightening processFurnace typesIncreasing energy efficiencyHydraulic cylinderThrust bearing

The invention discloses a device for preventing an elongated piston rod from bending deformation during medium and high frequency quenching, and relates to a metal part surface thermal treatment device. The device is provided with a plug body, an axial thrust bearing, a movable tip, a tip locking nut, a thrust spring, a connecting bolt and a tensile hydraulic cylinder, wherein the plug body is arranged on the piston rod of the tensile hydraulic cylinder; leftward movement of the plug body is limited at the right end of the axial thrust bearing; a gap is reserved between the inner wall of an inner hole of the plug body and the axial thrust bearing as well as the tip locking nut; the plug body is connected with a workpiece to be quenched; the piston end of the piston rod is clamped in a three-claw chuck of a machine tool and is pressed against a tip; the piston rod is provided with connecting threads and steps; the thrust spring is arranged in a counter bore which is formed at the frontend of the piston rod of the tensile hydraulic cylinder; the movable tip is pressed against the end part of the connecting bolt; the tensile hydraulic cylinder is fixed on a tail seat of the machine tool; and the center of an end face of the plug body is provided with a through hole in which a supporting ring is arranged. Through the device, the elongated piston rod can be prevented from bending deformation in the medium and high frequency quenching process.

Owner:福建省龙岩液压集团有限公司

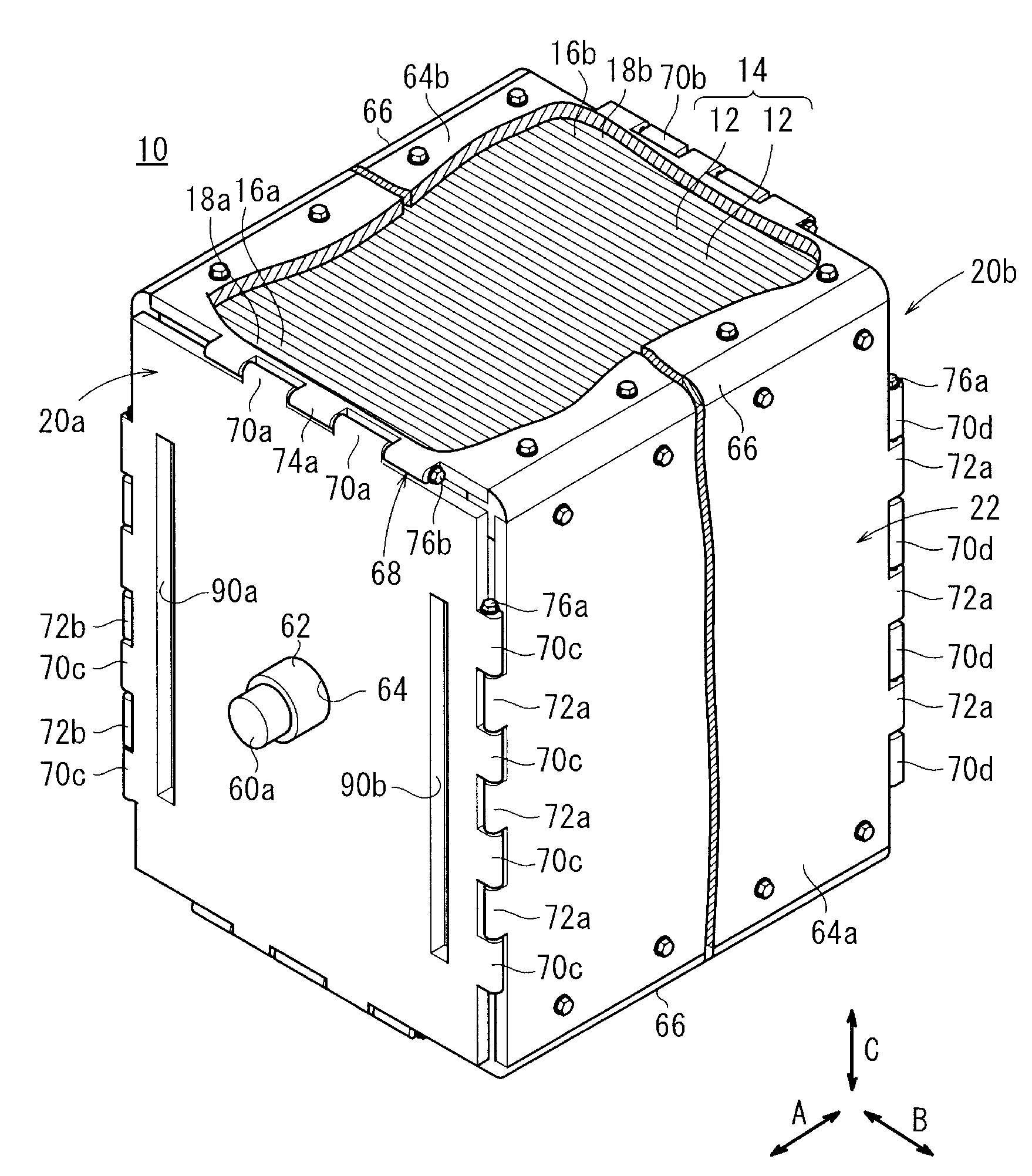

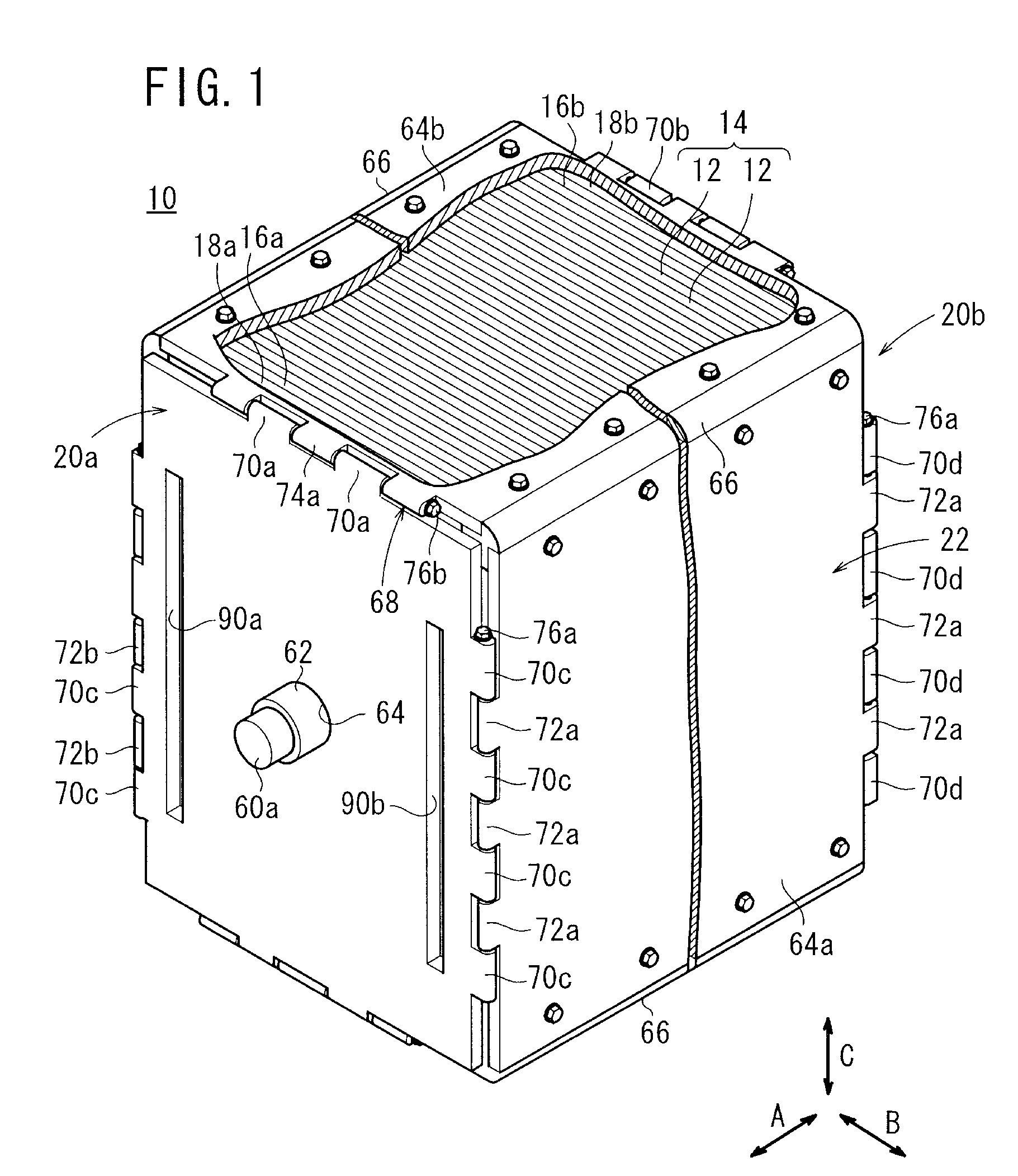

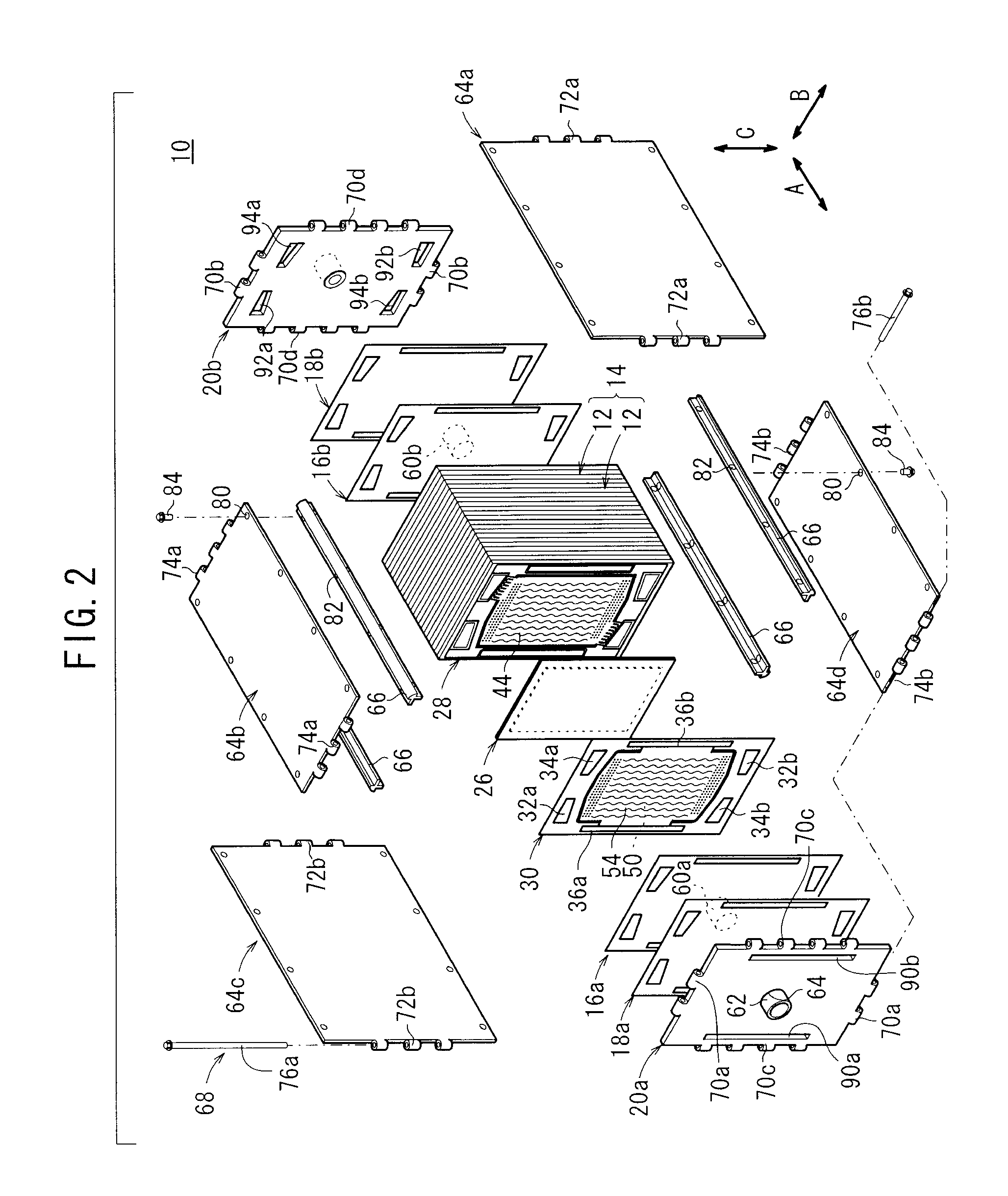

Fuel cell stack

ActiveUS20080233459A1Relieve pressureSimple and economical structureFuel cells groupingCell component detailsFuel cellsCoupling

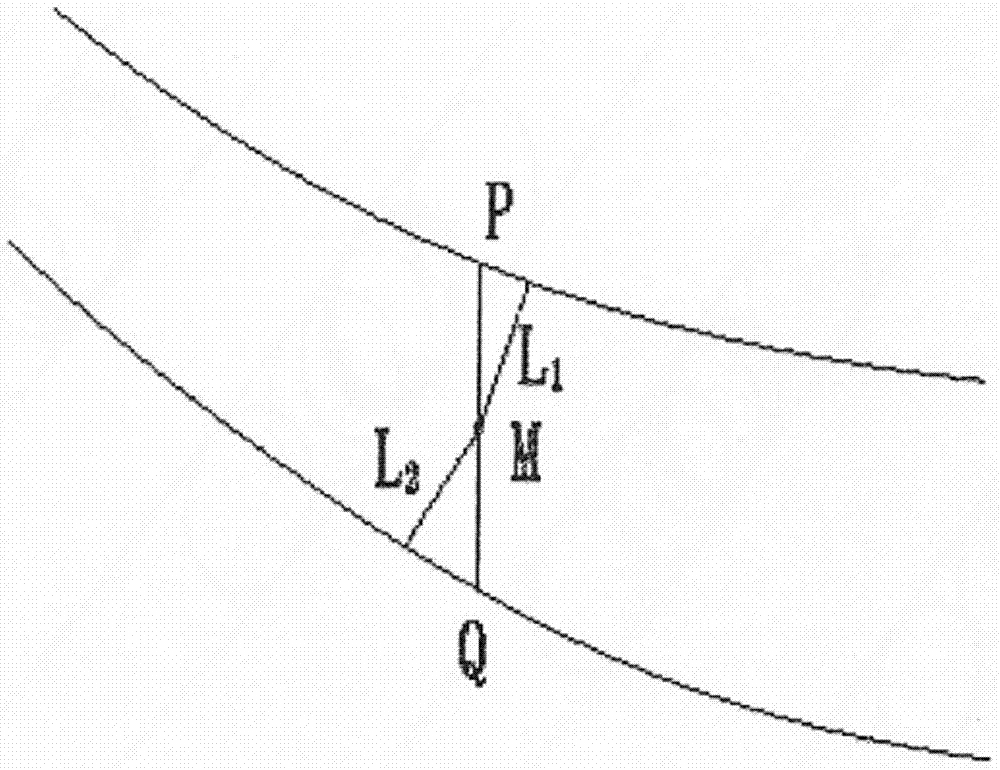

A casing includes end plates, side plates, and a hinge mechanism for coupling the end plates and the side plates. A power generation area is defined by the distance L1 and the distance L2. When first hinges and second hinges of the hinge mechanism are provided alternately, the first hinges and the second hinges are positioned within the distance L1. Preferably, the length of the shaft of a coupling pin is not more than the length L1. When the first hinges and the second hinges are provided alternately, the first hinges and the second hinges are positioned within the length L2. Preferably, the length of the shaft of a coupling pin is not more than the length L2.

Owner:HONDA MOTOR CO LTD

Method for producing b-eucryptite fine particles

ActiveUS20180001292A1Excellent crushabilityEnhance insulation propertyAluminium silicatesChemical/physical/physico-chemical processesColloidal silicaWater soluble

The β-eucryptite fine particle production method of the invention includes spraying, into an atmosphere at 50° C. to a temperature lower than 300° C., a solution containing a water-soluble lithium salt, a water-soluble aluminum salt, and colloidal silica, in such amounts that the mole proportions among lithium atoms, aluminum atoms, and silicon atoms (Li:Al:Si) are adjusted to 1:1:1, to thereby dry the solution, and, subsequently, firing the dried product in air at 600 to 1,300° C.

Owner:NISSAN CHEM IND LTD

Virtual image display apparatus

ActiveUS10481398B2Uniform balanceSolution to short lifeMechanical apparatusLight guides for lighting systemsLength waveContrast ratio

Owner:SEIKO EPSON CORP

A milling and slotting processing method for high-temperature alloy integral leaf ring blade parts

The invention belongs to the field of machining, and particularly relates to a milling grooving machining method for a high-temperature alloy integral blade ring and blade part. The method comprises the machining steps of air inlet end pre-drilling, cavity milling of a blade back at the air inlet end, cavity milling of a blade basin at the air inlet end, milling of an air inlet end flow channel and back chipping, exhaust end pre-drilling, cavity milling of a blade basin at the exhaust end, cavity milling of a blade back at the exhaust end, and milling of an exhaust end flow channel and back chipping. The milling grooving machining method for the high-temperature alloy integral blade ring and blade part, the milling modes of driving a fixed shaft through multiple vectors for layering and sectional connecting are adopted, and a common end milling cutter is applied to realize rough grooving machining of uniform allowance.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Rough Machining Method of Turbine Blade Damping Boss

Owner:DONGFANG TURBINE CO LTD

An integral blisk electrolytic forming rotary opening tool and electrolytic forming method

ActiveCN110977065BReduce processing R&D requirementsUniform balanceElectrochemical machining apparatusElectrical-based auxillary apparatusElectrolytic agentEngineering

An integral blisk electrolytic forming rotary opening tooling and electrolytic forming method, including a sleeve assembly, a sleeve cover plate, an electrolyte water inlet pipe, an electrolyte nozzle, an electric screw, a knife setting pin, an electrode piece, a shaft holder, A rotating connector and a curved sliding track; a method for electrolytic forming of an integral blisk, comprising the following steps: step 1, installing the rotating forming tooling on the forming shaft of the machine tool and the cavity on the left side of the machine tool; step 2, determining the opening of the machine tool The initial processing origin of the X, Y, and Z axes of the shape axis and the workbench of the horizontal electrolysis machine tool; step 3, input processing parameters through the control panel of the horizontal electrolysis machine tool; step 4, process a single blade in the overall blisk; step 5, After the single blade of the blisk is opened, the angular position of the blisk is adjusted through the blisk indexing tool, and the next blade is processed until the processing is completed. Utilizing the tooling of the invention to rotate and shape the variable-curved-surface blades of the integral blisk, the processed blades have uniform margins and high precision.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Machining method for PMI foam filling part

PendingCN113771116APracticalEasy clampingMilling equipment detailsMetal working apparatusStructural engineeringMachining process

The invention relates to the technical field of process heads, and provides a machining method of a PMI foam filling part. The machining method comprises the following steps of 1), clamping a blank piece by using a process head; 2), rough machining; 3), semi-finish machining; and 4), finish machining. The process head comprises two process head side baffles which are oppositely arranged, a length-adjustable connecting assembly is arranged between the two process head side baffles, the connecting assembly is used for adjusting the distance between the process head side baffles, each process head side baffle is provided with an adjustable clamping arm, each adjustable clamping arm comprises an upper strip-shaped pressing plate, a lower replacement base plate and an adjusting screw, the lower replacement base plates are fixed with the process head side baffles, and the upper strip-shaped pressing plates and the lower replacement base plates are in threaded connection with the upper ends and the lower ends of the adjusting screws. The problems that in the part machining process, due to irregular indentations, the datum plane of the part is uneven, due to the uneven datum plane, the molded surface and the mounting surface machined by the part are unqualified, and the machining efficiency and the machining qualification rate of PMI foam are affected are solved.

Owner:成都凯迪精工科技有限责任公司

Processing method of cylinder head valve seat ring sealing tape

The invention discloses a machining method for a sealing tape of a valve seat ring of a cylinder cover. The method comprises the steps: firstly roughly machining the bottom surface of the cylinder cover; roughly machining a positioning pin hole on the bottom surface of the cylinder cover; taking the positioning pin hole roughly machined on the bottom surface as reference to machine a closed plug hole on the cylinder cover as middle reference; taking the closed plug hole as the machining reference to finely machine a valve guide pipe bottom hole, a valve seat ring bottom hole, a bottom-surface positioning pin hole and the bottom surface of the cylinder cover on the same set of fixture of the same equipment to the final sizes; pressing the valve guide pipe and the valve seat ring; and finally taking the bottom-surface positioning pin hole and the bottom surface of the cylinder cover as the machining reference to machine an inner hole of the valve guide pipe and the sealing tape of an inner hole of the valve seat ring. The bottom holes of the inner hole of the valve guide pipe and the sealing tape of the inner hole of the valve seat ring are machined at the same time by using the machining references, the allowance for continued machining is uniform, and the coaxiality of the sealing tape of the valve seat ring relative to the inner hole of the valve guide pipe meets the process requirements.

Owner:GUANGXI YUCHAI MASCH CO LTD

Forging process for large shaft parts

ActiveCN102172766BIncrease the number of pulling tripsIncrease the effect of forging through compactionEngine componentsNuclear powerIngot

The invention discloses a forging process for nuclear power rotor and other large shaft parts, which can be used for effectively solving the forging problem of a high-grade rotor with a super large specification. The process specifically comprises the following steps of: (1) drawing out a steel ingot to form a flat square by using a WHF (Wide die Heavy blow Forging) method; (2) performing erecting and upsetting on the flat square; (3) drawing out the upset steel billet to the flat square again by using the WHF method; and (4) compacting the four sides and the center of the flat square, wherein the 'flat square' specifically means a cuboid-shaped steel billet. In accordance with the result of flaw detection (UT(Ultrasonic Test) and MT (Magnetic particle Test)), no flaw (phi is above 0.6), for which recording is required, is found in a 1100MW rotor piece manufactured by using 550t steel billets, and the quality is superior; based on the dimension of a workpiece, all the dimensions of various parts of a forge piece can meet the processing requirement, and the forging allowance is uniform; the control state of forging grain size is deduced from a UT state subsequent to thermal treatment after forging, the desired effect is completely achieved, and no phenomenon of coarse crystal or mixed crystal happens.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

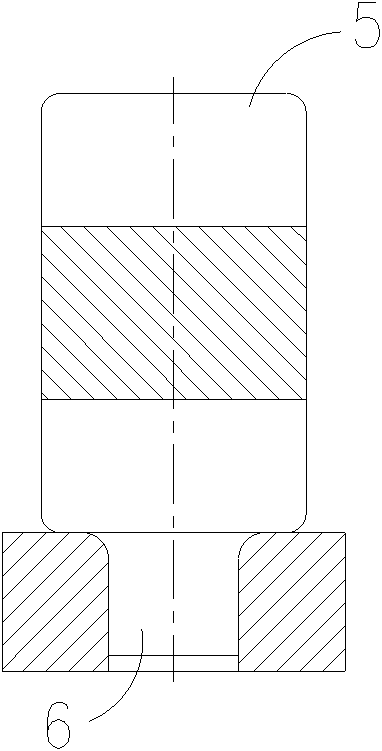

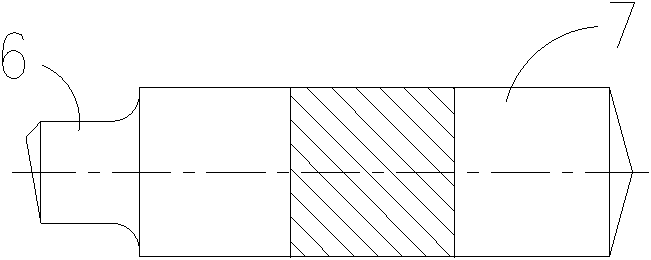

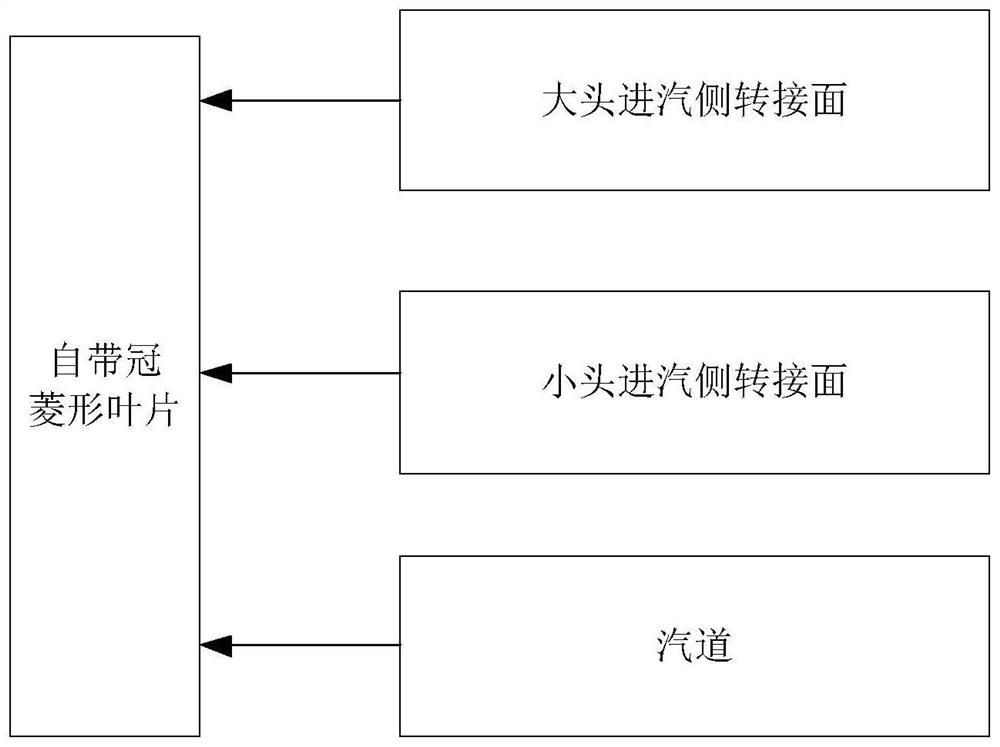

Numerical control machining method for diamond blade with crown

PendingCN114226817AImprove processing efficiencyImprove machining accuracyMilling equipment detailsNumerical controlStructural engineering

The invention discloses a numerical control machining method for a rhombic blade with a crown, belongs to the technical field of machining and manufacturing of steam turbines, and aims to solve the problems of low machining efficiency and low machining precision of an existing machining operation method for the rhombic blade with the crown. The method comprises the following steps of: processing a large-head steam inlet side adapter surface: positioning in a steam outlet side and a back radial direction, enabling a steam inlet side to face upwards, and milling a fixed outline of the large-head steam inlet side adapter surface; the inner radial faces of the blades are positioned downwards, the allowance of 5 mm height is removed from the back radial positions of the large-head steam inlet side and the small-head steam inlet side, and then fixed contour milling is conducted on the small-head steam inlet side adapting face; the two ends of the steam passage are locally milled through a small ball head cutter, and the middle of the steam passage is completely milled. The method is used for carrying out numerical control machining on the diamond blade with the crown.

Owner:HARBIN TURBINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com