Device for preventing elongated piston rod from bending deformation during medium and high frequency quenching

A technology for preventing bending deformation and high-frequency quenching, applied in the direction of quenching device, improving energy efficiency, improving process efficiency, etc. The performance is improved, the straightening process is omitted, and the effect of not easy to grind cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

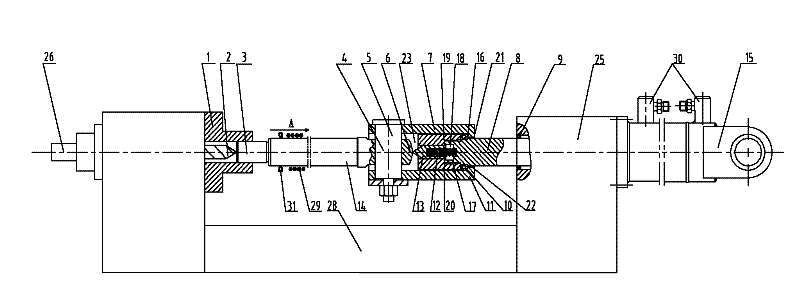

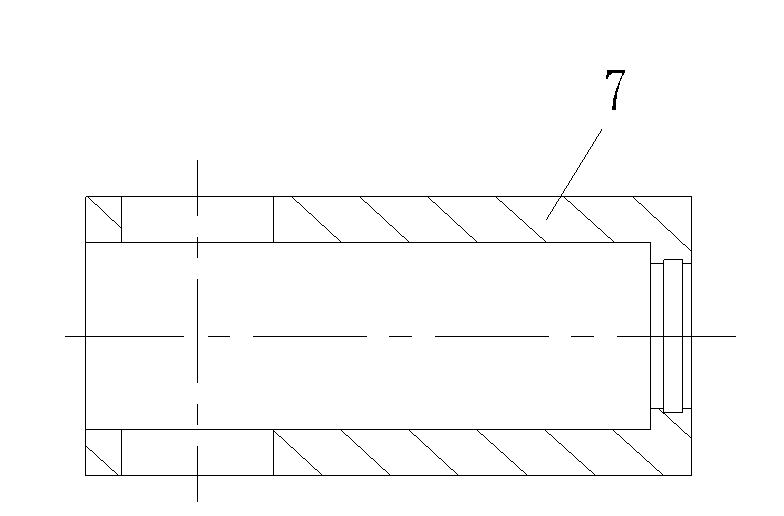

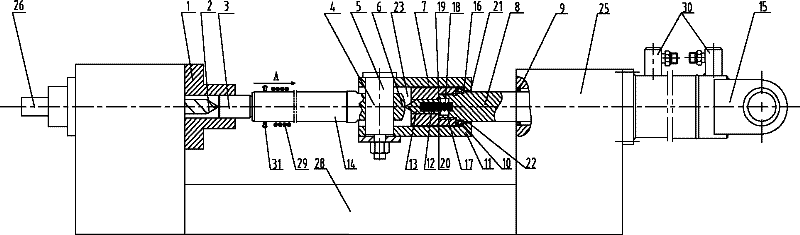

[0016] see figure 1 with 2 , the embodiment of the present invention is provided with machine tool 28, tailstock 25, insert body 7, axial thrust bearing 10, movable top 13, top lock nut 11, thrust spring 12, connecting bolt 4 and tension hydraulic cylinder 15; The insert body 7 is installed on the piston rod 8 of the stretching hydraulic cylinder 15, the leftward movement of the insert body 7 is limited at the right end of the axial thrust bearing 10, and the inner wall of the inner hole 23 of the insert body 7 and the axial thrust bearing 10 There is a gap between it and the top lock nut 11, the insert body 7 is connected with the quenched workpiece 14, the piston end 3 of the piston rod 8 is inserted into the three-jaw chuck 1 of the machine tool and offset against the top 2, and the piston rod 8 is also provided with There are connecting threads ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com