Automatic panel replacing and machining equipment

A technology for processing equipment and panels, which is applied in the field of panel automatic refueling processing equipment, can solve the problems of increasing the labor burden of operators, reducing the degree of automation of processing machines, and uneven allowance, so as to improve processing efficiency and processing quality, and improve processing. Efficiency and processing quality, the effect of the allowance is uniform and consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

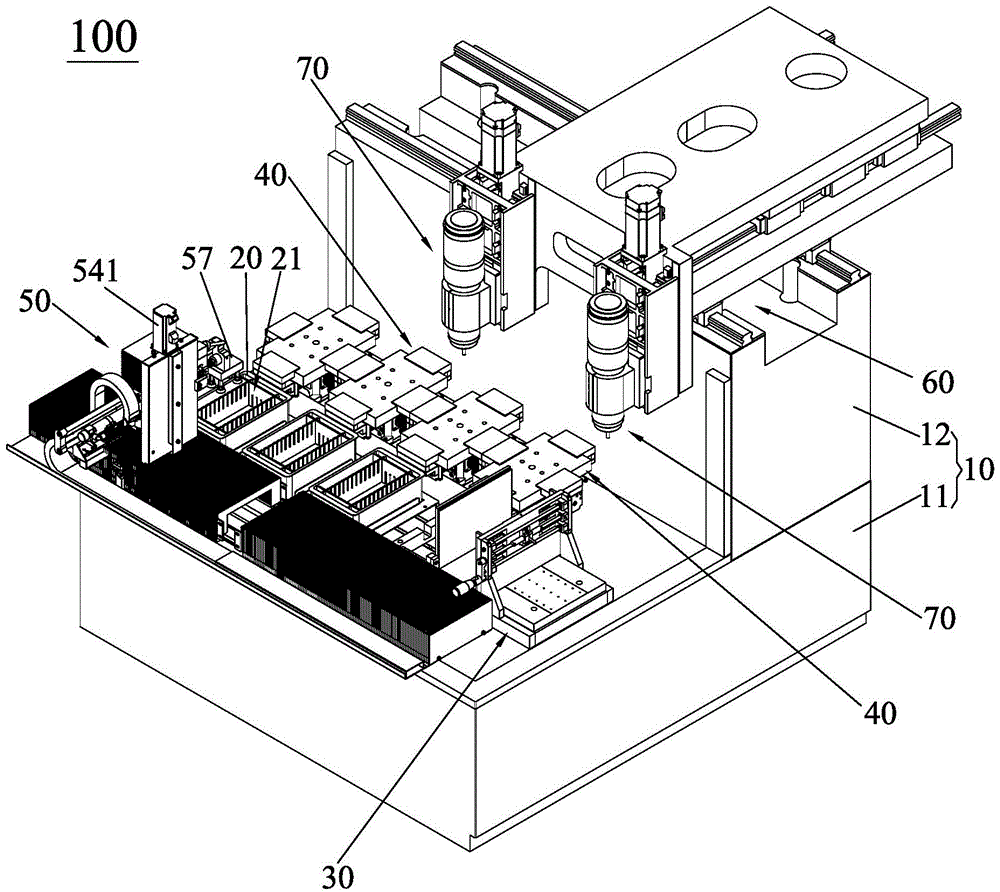

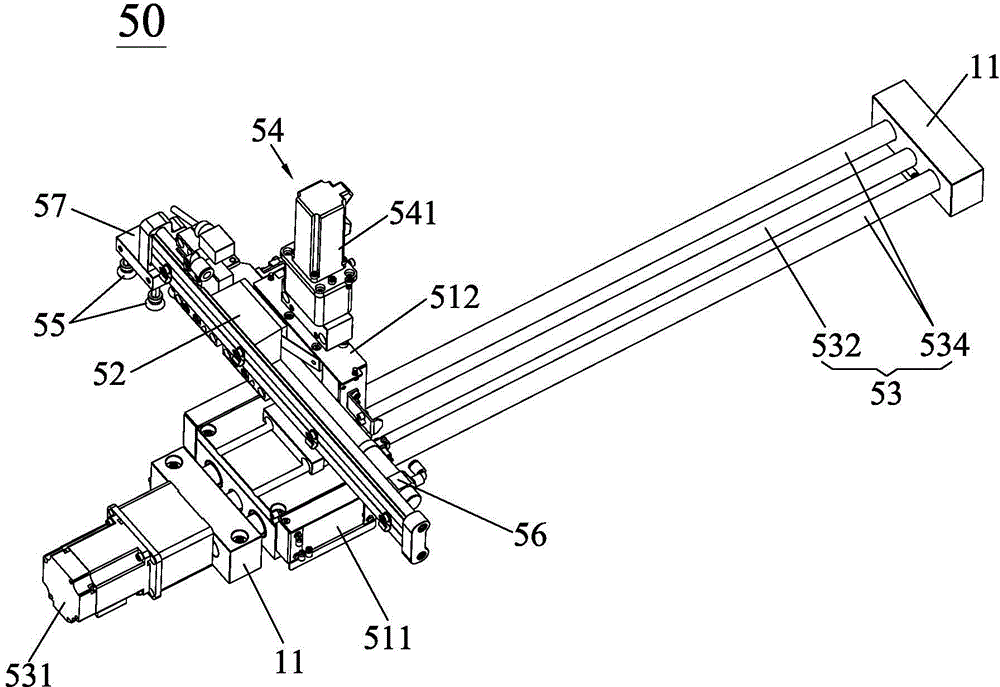

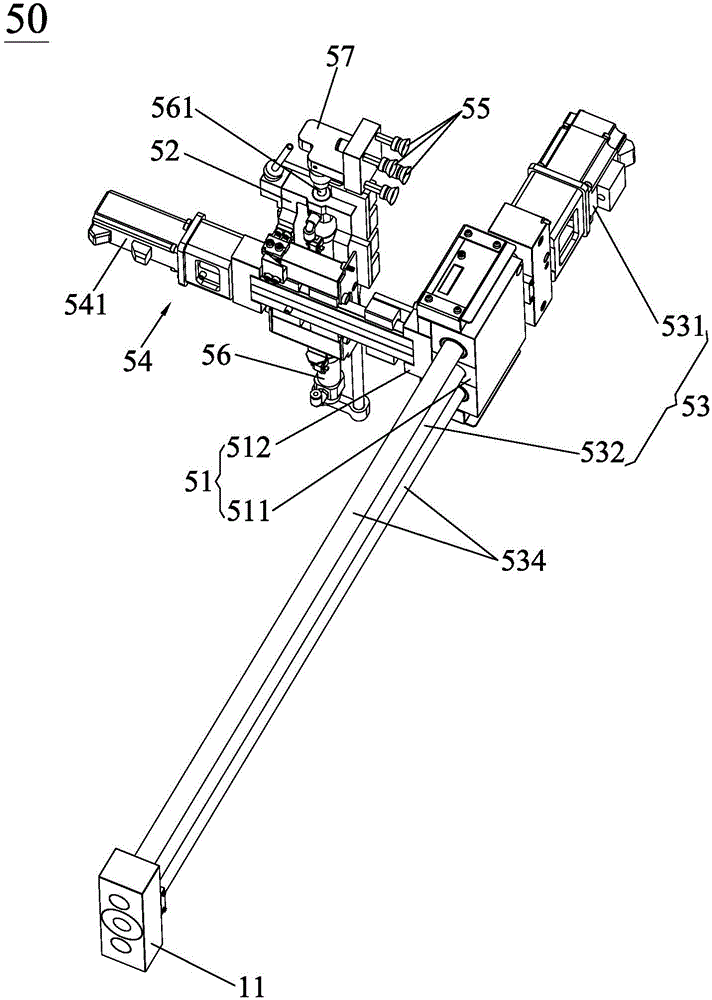

[0032] see figure 1 , the panel automatic refueling processing equipment 100 of the present invention is used for the purpose of automatically refueling and processing the panel 200 . Wherein, the panel automatic refueling processing equipment 100 of the present invention includes a frame 10 , a material box 20 , a piece-by-piece conveying mechanism 30 , a four-sided centering fixture 40 , a transfer mechanism 50 and a machine head 70 . The frame 10 includes a horizontal base frame 11 and an upright frame 12 installed on the horizontal base frame 11, so that the upright frame 12 stands on the horizontal base frame 11 to provide the required movement space for the assembly and operation of the machine head 70. The material box 20 is installed on the horizontal mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com