Forging process for large shaft parts

A shaft part, large-scale technology, applied in the field of forging technology of nuclear power rotors, can solve the problems of limited space of hydraulic press, lack of heating effect, large size of forgings, etc., to solve equipment overload, strengthen heating effect, and uniform allowance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Taking the production of 1100MW nuclear power rotor as an example, the forging process of the present invention will be described in detail in conjunction with the accompanying drawings.

[0036] step 1)

[0037] Firstly, the steel ingot ingot with a weight of 550t is wrapped around the steel ingot body with a single traveling plate chain, so as to press out the jaws from the riser of the steel ingot;

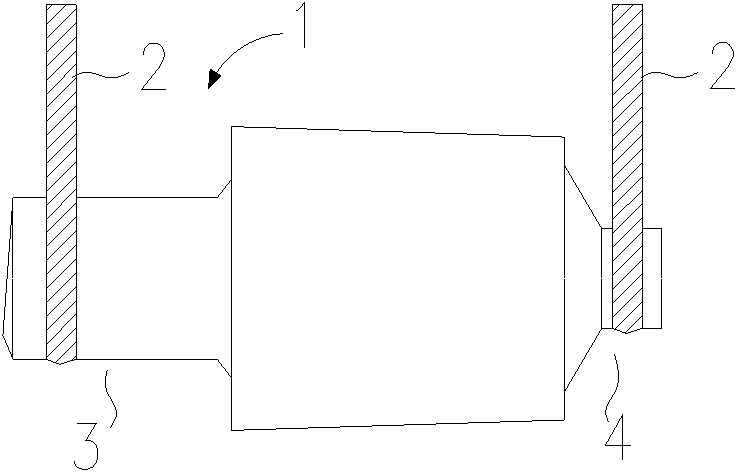

[0038] Then, if figure 1 As shown in the figure, two traveling cranes respectively pass the respective plate chains 2 to enclose the ingot tail 4 and the jaw 3 pressed out from the riser, and use the WHF method to pull out the steel ingot 1 into a flat square 5;

[0039] Finally, a new jaw is extruded at the ingot body near the ingot tail 4, and the old jaw 3 is cut off.

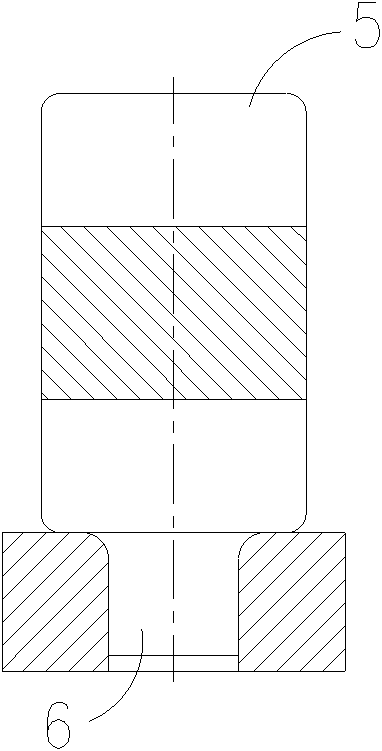

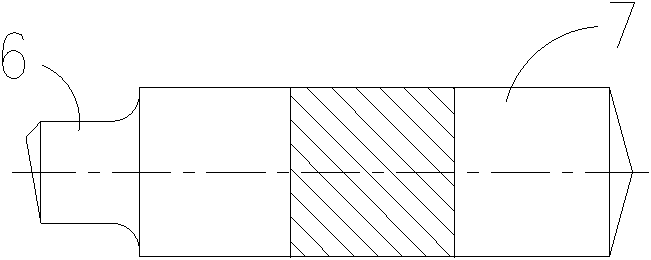

[0040] like Figure 2 to Figure 4 As shown, when implementing steps 2) to 4), new jaws 6 are used.

[0041] step 2)

[0042] like figure 2 As shown, the vertical upsetting is carried out to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com