An integral blisk electrolytic forming rotary opening tool and electrolytic forming method

A technology of integral blisks and tooling, which is applied in the direction of electric processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problems of occupying the production capacity of precision electrolysis equipment, increasing the requirements of electrolysis machine tools, and increasing the cost of rough slotting processing, etc., to achieve improvement R&D efficiency, ensuring full-section profiling accuracy, and shortening the R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

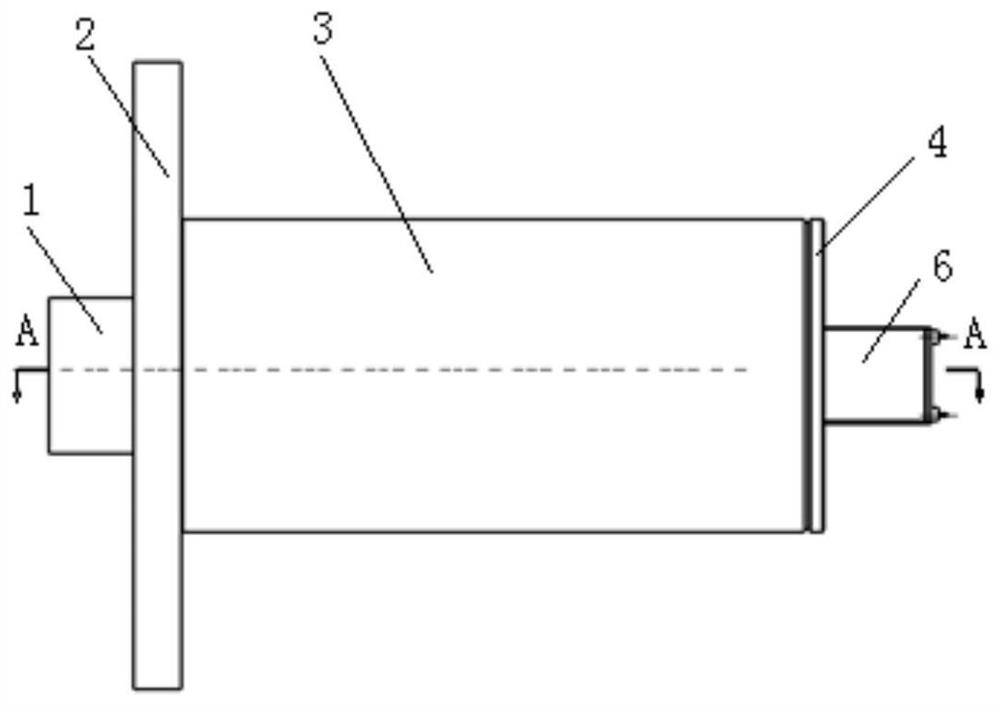

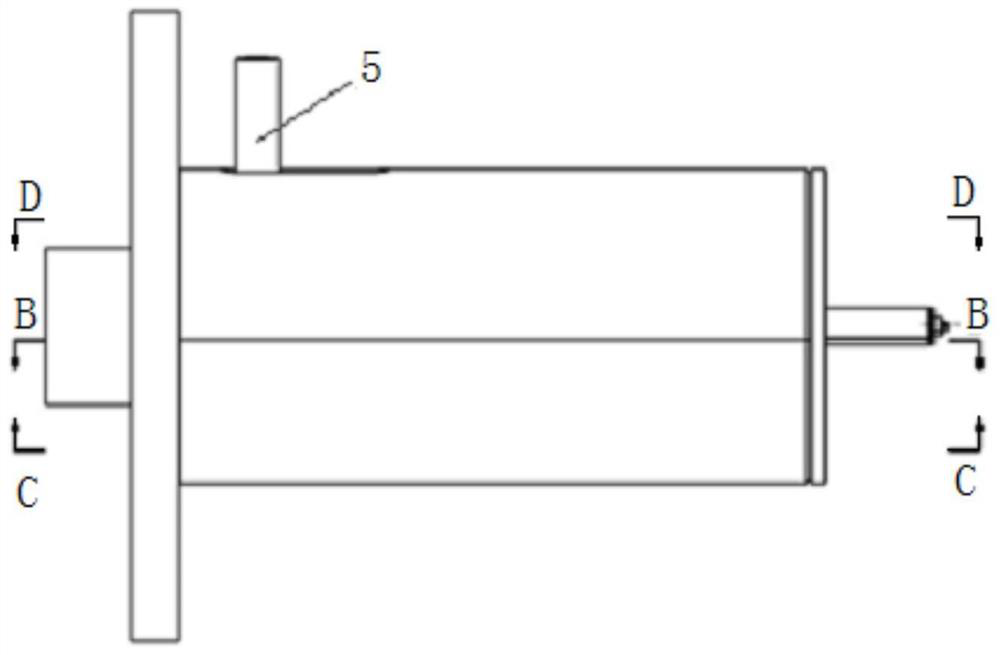

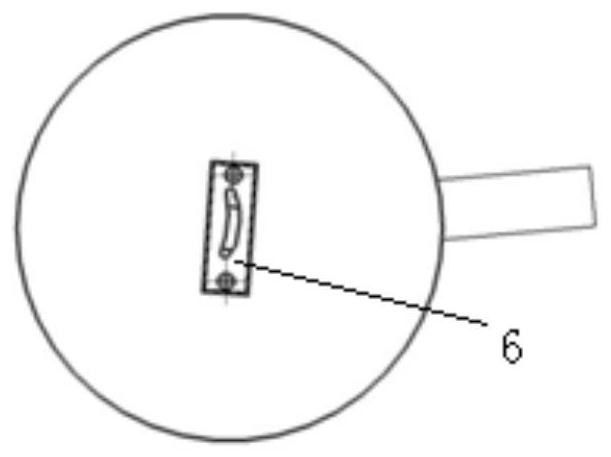

[0033] Such as Figure 1 to Figure 8 As shown, an integral blisk electrolytic forming rotary opening tooling includes a sleeve assembly 3, and one end of the sleeve assembly 3 is connected to the cavity 2 on the left side of the machine tool through pins and screws, and inside the cavity 2 on the left side of the machine tool The coaxial sleeve has a machine tool opening shaft 1, and the machine tool opening shaft 1 extends to the inner cavity of the sleeve assembly 3. The inner cavity of the sleeve assembly 3 is coaxially equipped with a shaft holder 10, and one end of the shaft holder 10 is connected to the machine tool. The inner hole of the open shaft 1 is matched, and the other end of the shaft holder 10 is provided with a curved sliding track 12 arranged symmetrically with respect to the axis. The trajectory is determined by the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com