Friction disc for high-speed rail and preparation method of friction disc

A friction disc and sample making technology, applied in the field of high-speed rail parts, can solve problems such as cost increase, and achieve the effects of preventing pores and insufficient pouring, improving appearance and internal quality, and uniform blank allowance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]

[0028]

[0029]

[0030]

[0031]

[0032]

[0033] Note: Cu balance.

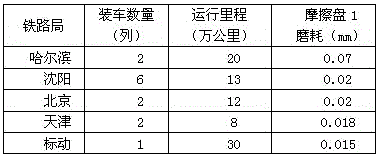

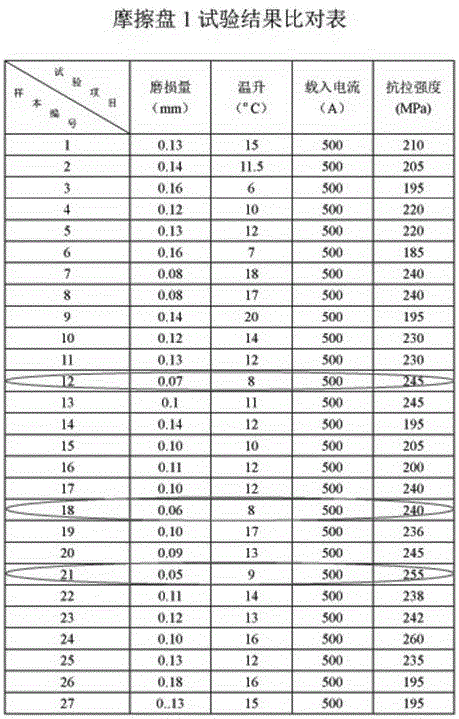

[0034] Carry out the test according to the above ratio, and the numbers are as follows.

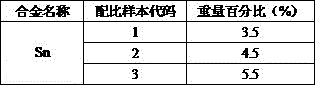

[0035] Sample No sn Zn Ni Pb be P 1 1 1 1 1 1 1 2 1 1 1 1 2 2 3 1 1 1 1 3 3 4 1 2 2 2 1 1 5 1 2 2 2 2 2 6 1 2 2 2 3 3 7 1 3 3 3 1 1 8 1 3 3 3 2 2 9 1 3 3 3 3 3 10 2 1 2 3 1 2 11 2 1 2 3 2 3 12 2 1 2 3 3 1 13 2 2 3 1 1 2 14 2 2 3 1 2 3 15 2 2 3 1 3 1 16 2 3 1 2 1 2 17 2 3 1 2 2 3 18 2 3 1 2 3 1 19 3 1 3 2 1 3 20 3 1 3 2 2 1 21 3 1 3 2 3 2 22 3 2 1 3 1 3 23 3 2 1 3 2 1 24 3 2 1 3 3 2 25 3 3 2 1 1 3 26 3 3 2 1 2 1 27 3 3 2 1 3 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com