Friction disk and preparation method thereof

A friction disc and sample making technology, which is applied in the field of high-speed rail components, can solve problems such as cost increase, achieve the effects of preventing air holes and insufficient pouring, uniform blank margin, and improving appearance and internal quality

Inactive Publication Date: 2017-04-19

扬州丰泽轨道交通科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] As a modern means of transportation, high-speed rail has brought great changes to people's travel with its high-speed and fast way. Because of the high-speed characteristics of high-speed rail, higher requirements are placed on the materials of various components. Therefore, the existing Many high-speed rail components rely on imports, resulting in a substantial increase in cost, which has greatly restricted the development of my country's high-speed rail. The friction disc is the most obvious example, so it needs to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028]

[0029]

[0030]

[0031]

[0032]

[0033]

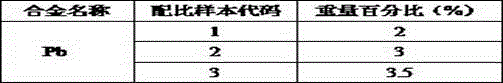

[0034] Note: Zn balance.

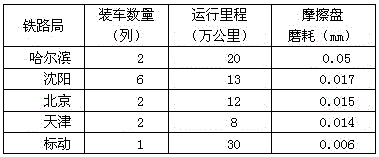

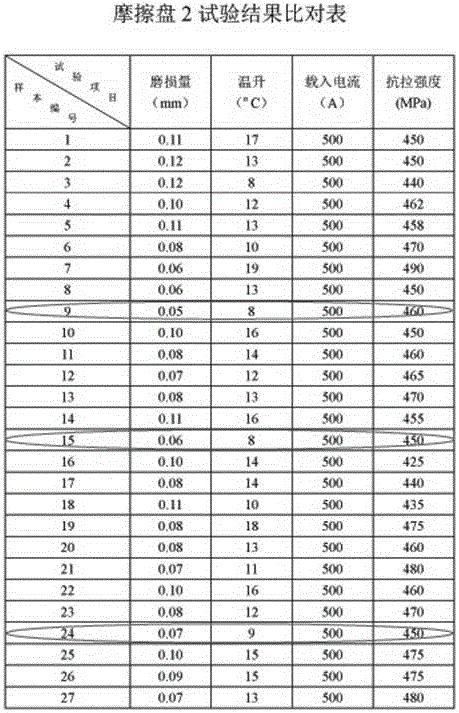

[0035] Carry out the test according to the above ratio, and the numbers are as follows.

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a friction disk and a preparation method thereof. The friction disk comprises, by weight, 56%-60% of Cu, 0.5%-2.0% of Al, 1.0%-2.0% of Sn, 2%-3.5% of Pb, 0.04%-0.06% of Be, 0.1%-0.4% of P and the balance Zn. According to the friction disk and the preparation method thereof, vacuum suction investment casting is adopted, gas in a cavity can be sucked away through tiny pores in a shell so that liquid metal can be better filled into the cavity, the phenomena of air pores and short run are prevented, the product appearance and inner quality are improved, and the machining rate of finished products reaches 98%. The requirements for abrasion resistance and electrical conductivity by the friction disk are high, the common sand casting structure is loose, casting defects can be caused easily and meanwhile the hardness is relatively low. By means of the friction disk and the preparation method thereof, precision die forging manufacture is adopted, so that the blank allowance is uniform, and the texture is compact; and the hardness can also meet the drawing requirement, and the abrasion resistance reaches and exceeds the level of similar products overseas through experiments.

Description

technical field [0001] The invention relates to a friction disc and a preparation method thereof, belonging to the technical field of high-speed rail components. Background technique [0002] As a modern means of transportation, high-speed rail has brought great changes to people's travel with its high-speed and fast way. Because of the high-speed characteristics of high-speed rail, higher requirements are placed on the materials of various components. Therefore, the existing Many high-speed rail components rely on imports, resulting in a substantial increase in cost, which has greatly restricted the development of my country's high-speed rail. The friction disc is the most obvious example, so it needs to be improved. Contents of the invention [0003] The purpose of the present invention is to provide a high-speed rail friction disc with reasonable proportion and excellent performance and its preparation method. [0004] The technical scheme that the present invention ado...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C9/04B22C9/04B22C9/22

CPCB22C9/04B22C9/22C22C9/04

Inventor 何叶锋戴光泽赵君文

Owner 扬州丰泽轨道交通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com