Machining method for nozzle steam channel

A processing method and steam channel technology, applied in the field of steam turbines, can solve the problems affecting machining efficiency, large deviation of nozzle steam channel pitch, reducing processing efficiency, etc., so as to ensure processing efficiency and processing quality, avoid large pitch deviation, Ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

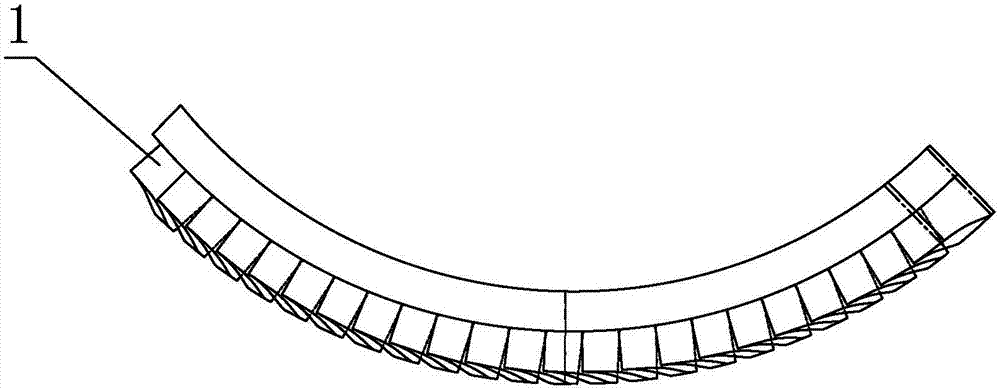

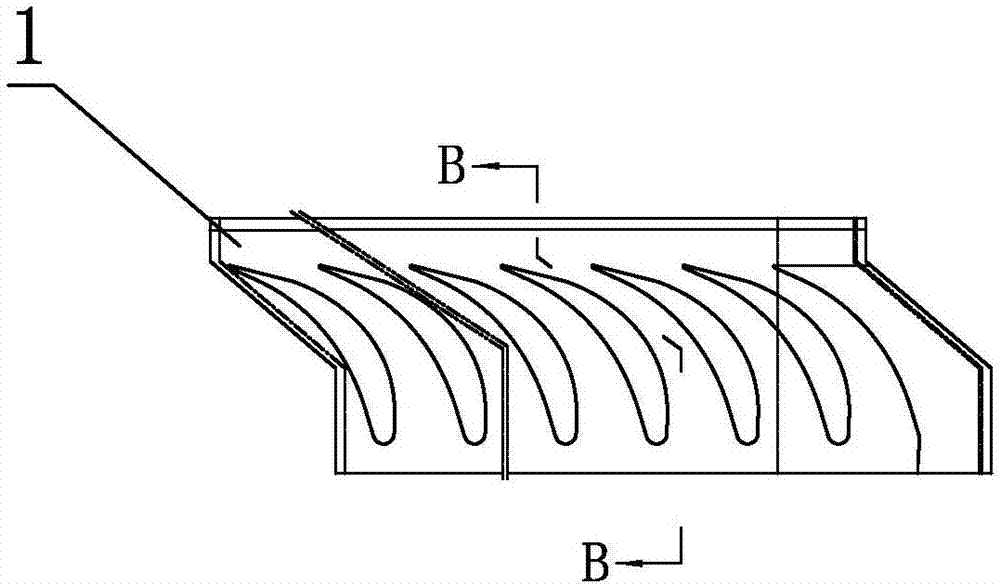

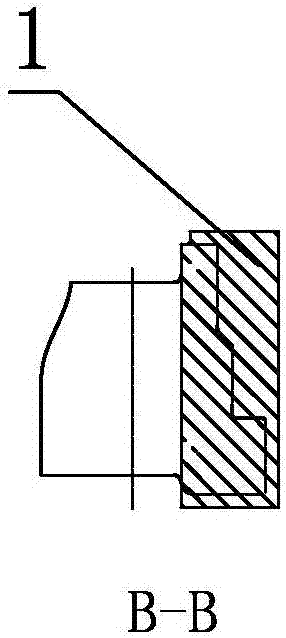

[0041] Specific implementation mode one: combine Figure 1 to Figure 9 Describe this embodiment, a method for processing a nozzle air passage in this embodiment, the method includes the following steps,

[0042] Step 1. Roughly machining the inlet and outlet sides of steam channel 1 of the nozzle:

[0043] According to the steam channel width, select the first milling cutter with a diameter of 10mm-14mm to roughly machine the inlet and outlet sides of the nozzle steam channel 1, the speed is 2000r / min-2500r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.01mm -0.02mm;

[0044] Step 2. Rough machining the middle part of the nozzle steam channel 1:

[0045] According to the width of the steam channel, the second milling cutter with a diameter of 6mm×R2mm-10mm×R2mm is used to roughly machine the middle part of the nozzle steam channel 1, the speed is 2000r / min-2500r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.01 mm-0.02mm;

[0046...

specific Embodiment approach 2

[0050] Specific implementation mode two: combination Figure 7To illustrate this embodiment, the rotation speed of the first milling cutter in Step 1 of this embodiment is 2250r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.01mm. With this arrangement, the first milling cutter is used to roughly machine the inlet and outlet sides of the nozzle steam channel 1, which avoids the existence of a hardened layer on the rear surface of the traditional EDM nozzle steam channel, makes the margin after rough machining more uniform, and effectively improves the The processing efficiency is not limited by the tool, and there will be no interference, which ensures the processing quality. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0051] Specific implementation mode three: combination Figure 8 To illustrate this embodiment, the rotation speed of the second milling cutter in step 2 of this embodiment is 2500r / min, the cutting depth is 1mm, and the cutting amount per blade is 0.02mm. In this way, the middle part of the nozzle steam channel 1 is roughly machined with the second milling cutter, which avoids the hardened layer on the rear surface of the traditional EDM nozzle steam channel, makes the margin after rough machining more uniform, and effectively improves the processing efficiency. It is not limited by the tool, and there will be no interference, which ensures the processing quality. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com