Patents

Literature

50results about How to "Uniform machining allowance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

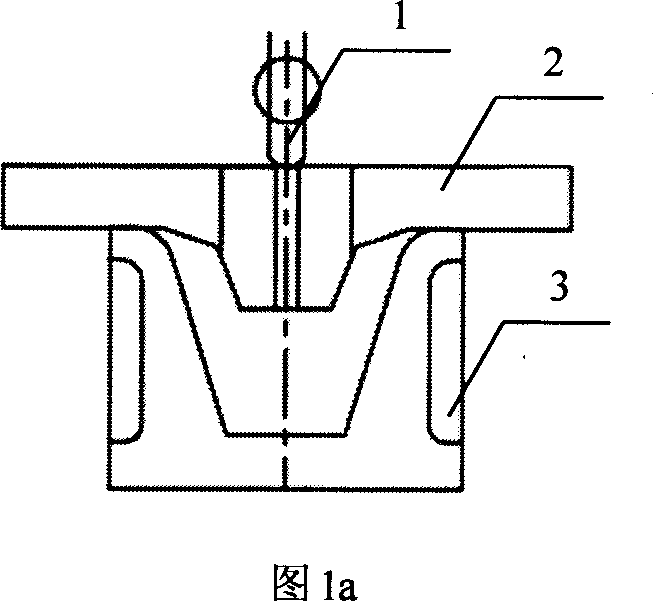

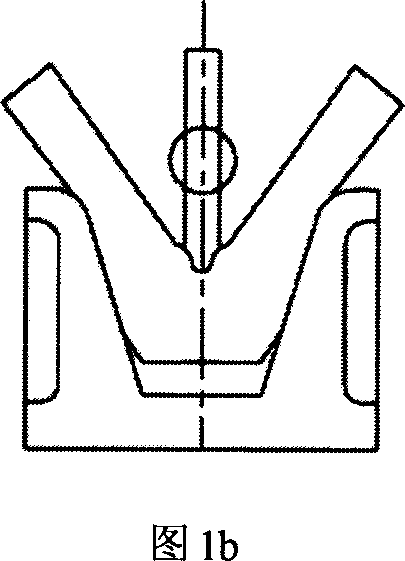

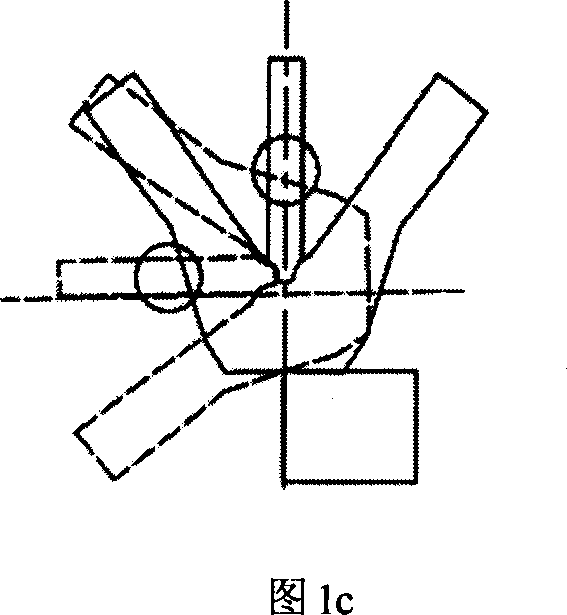

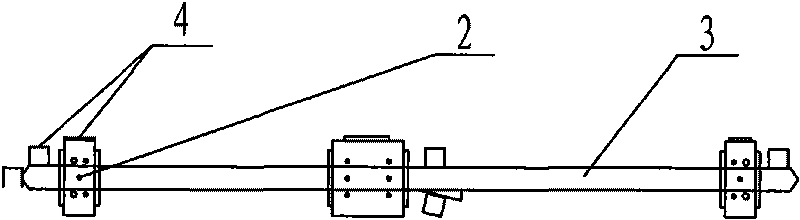

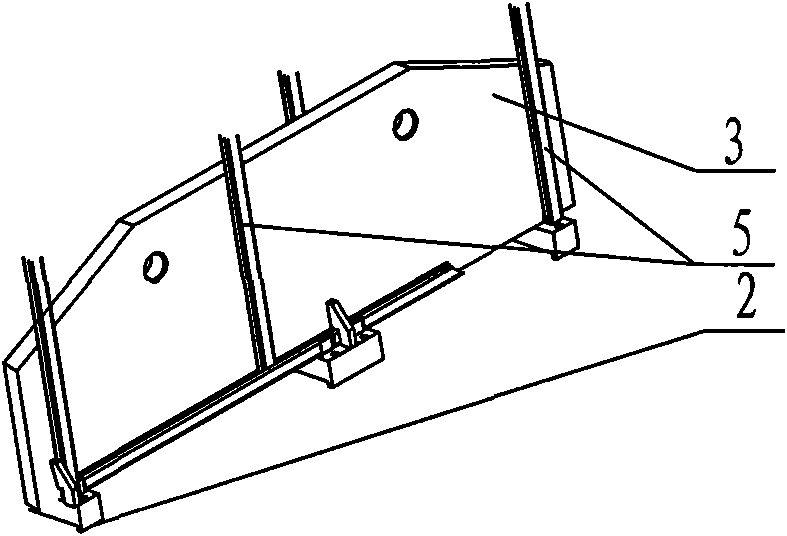

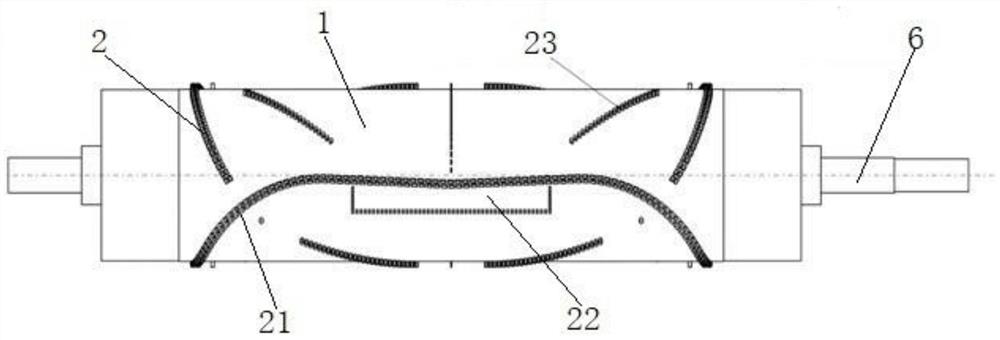

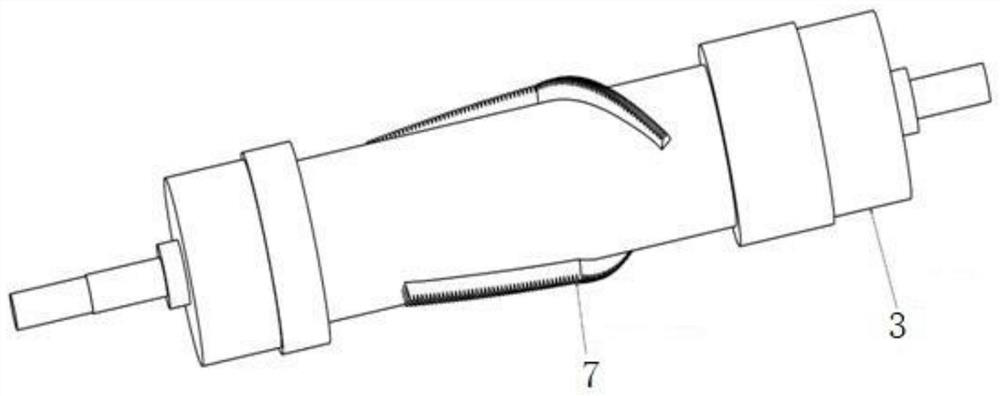

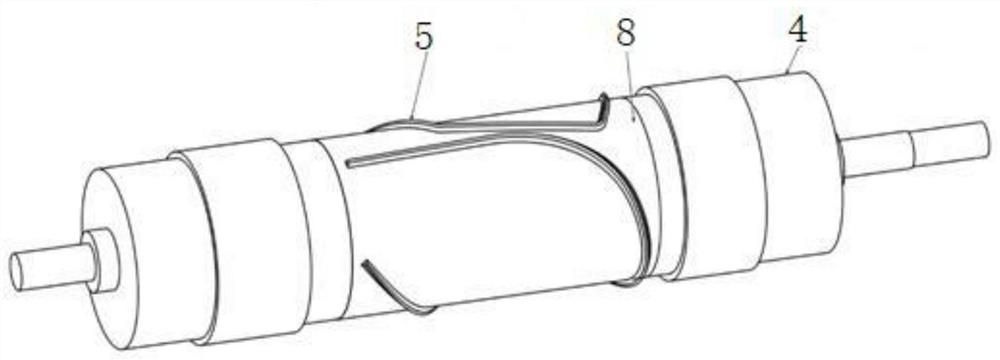

Equipment for bend-forging crank axle toggle of large ship and method for forging the same

ActiveCN1947886AUnder-forecastSimulation is accurateForging/hammering/pressing machinesEngine componentsMarine engineeringIngot

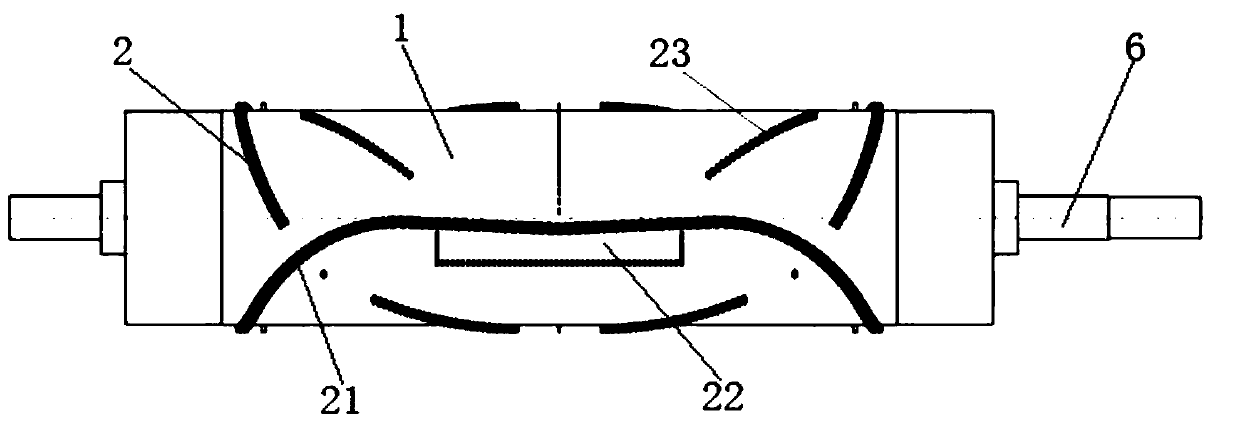

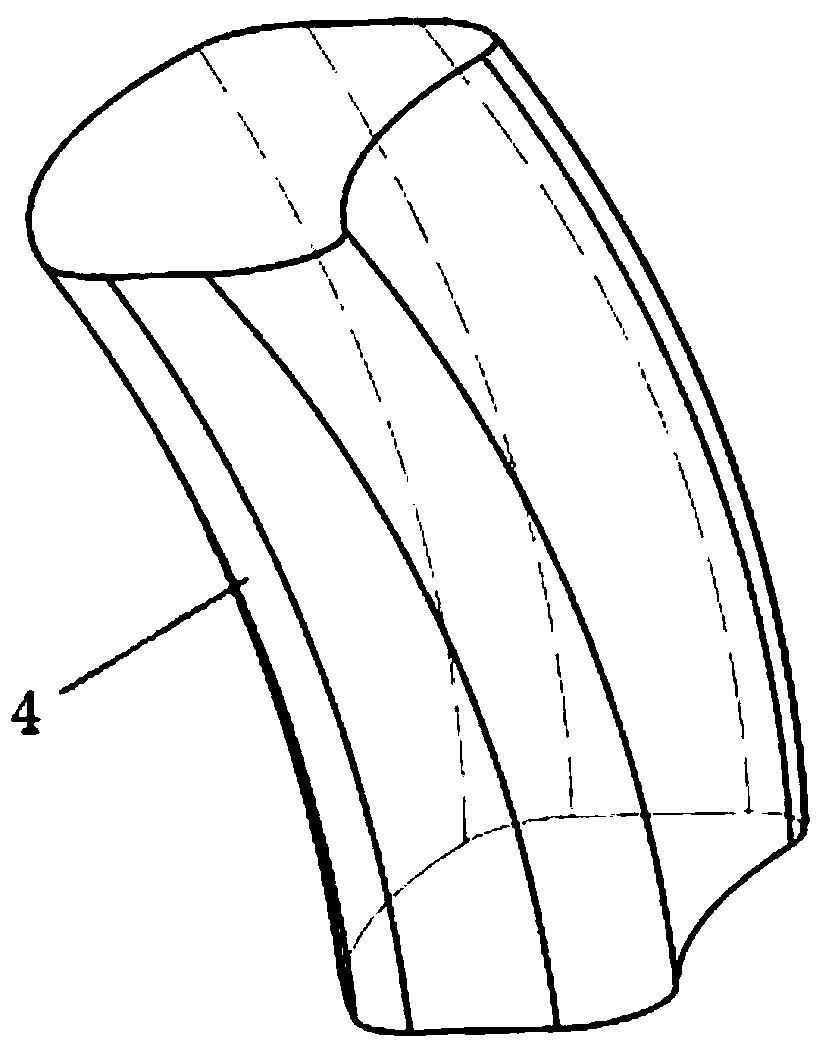

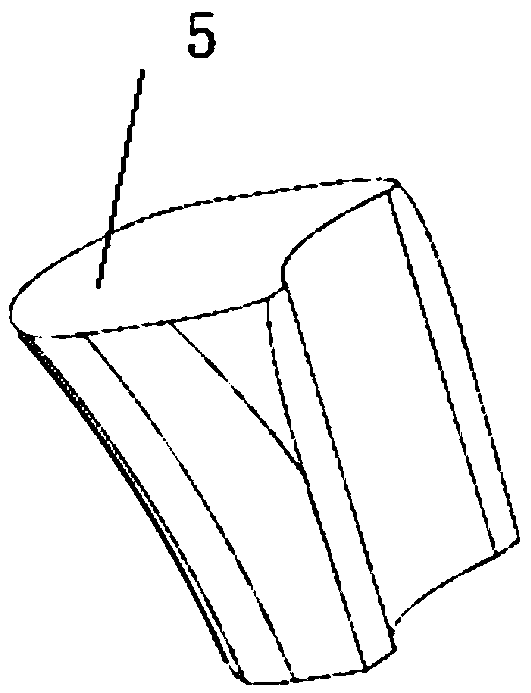

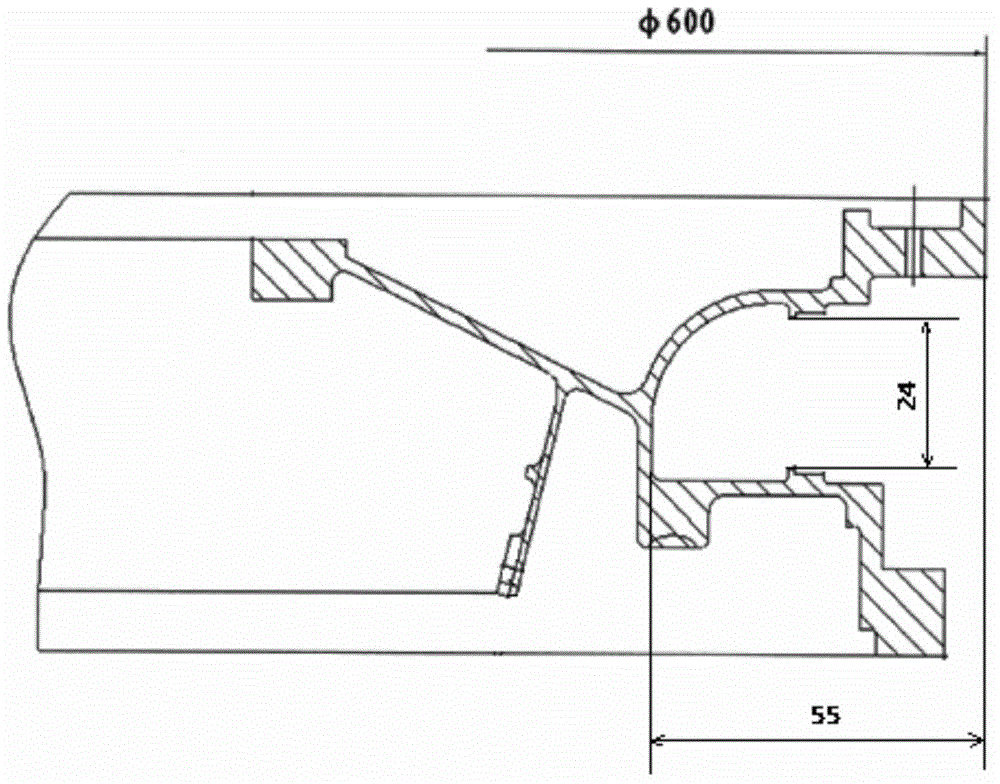

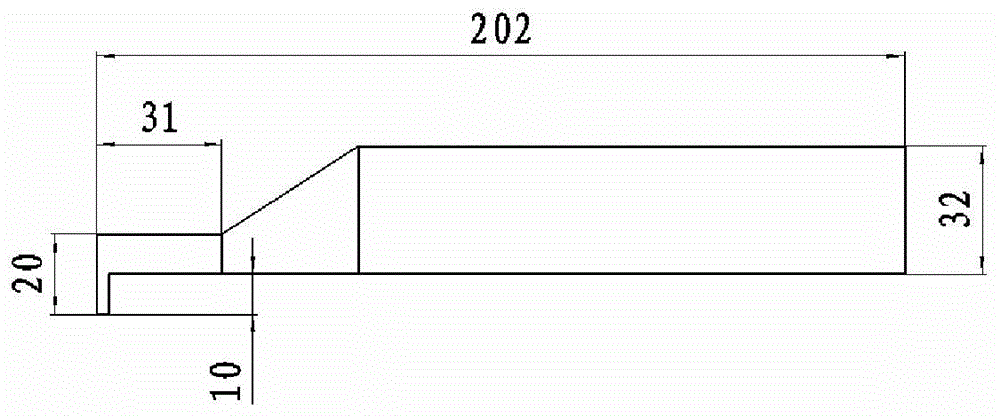

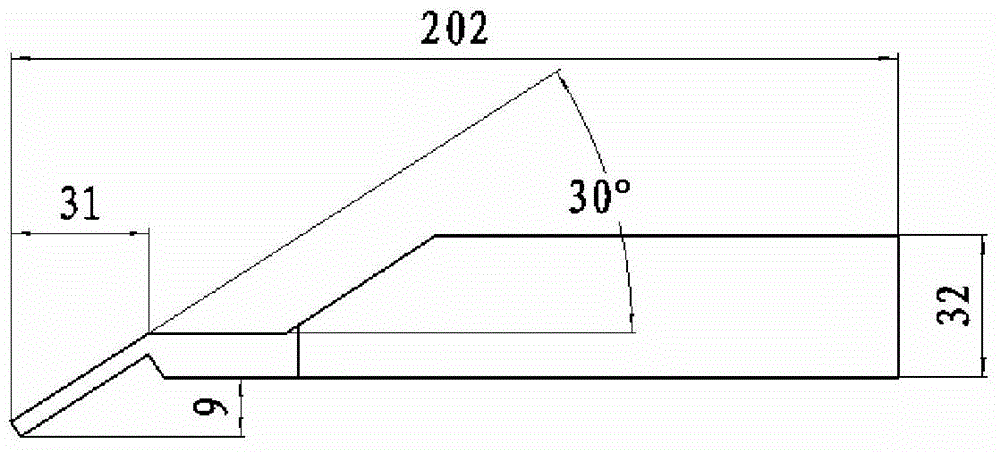

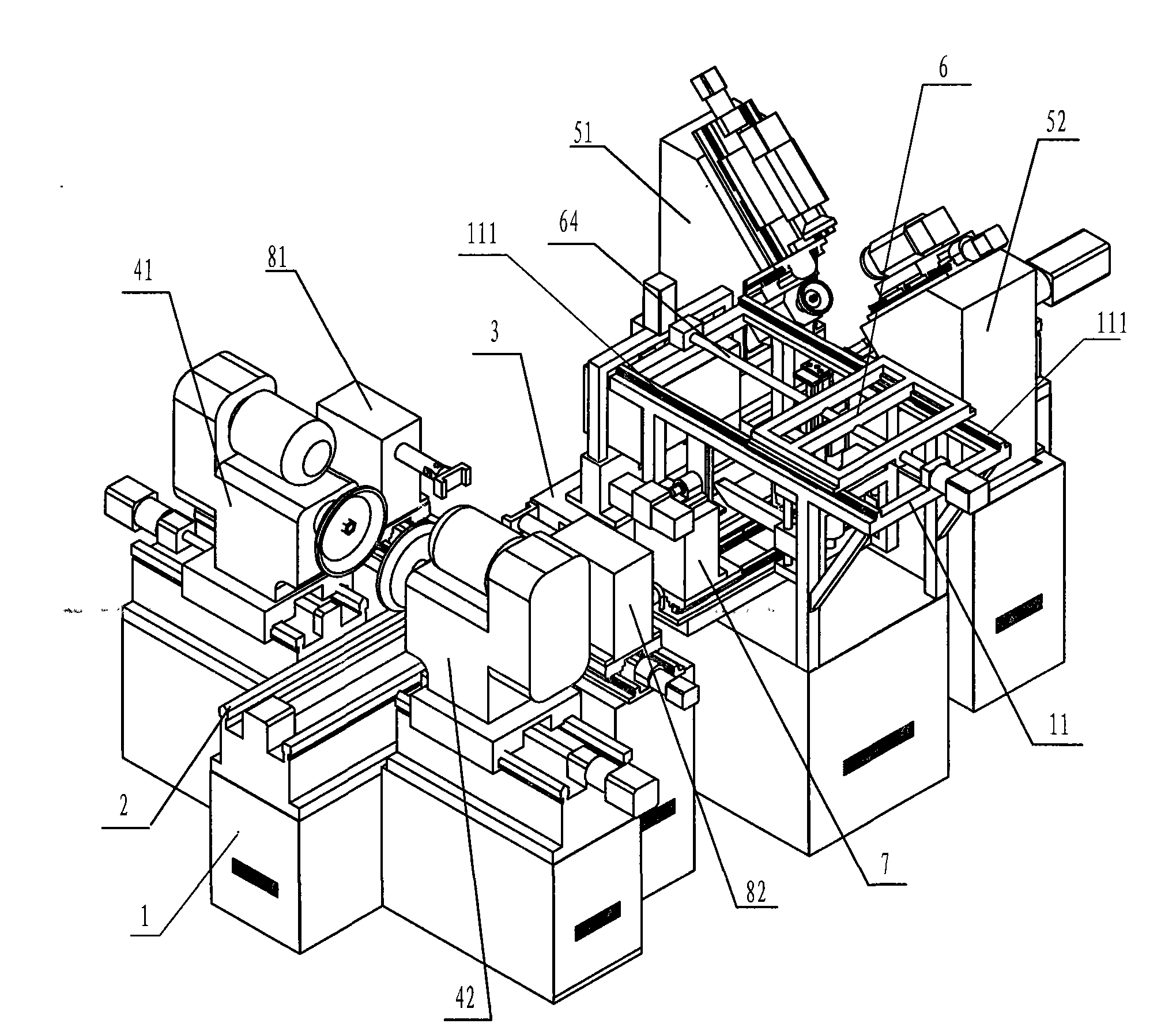

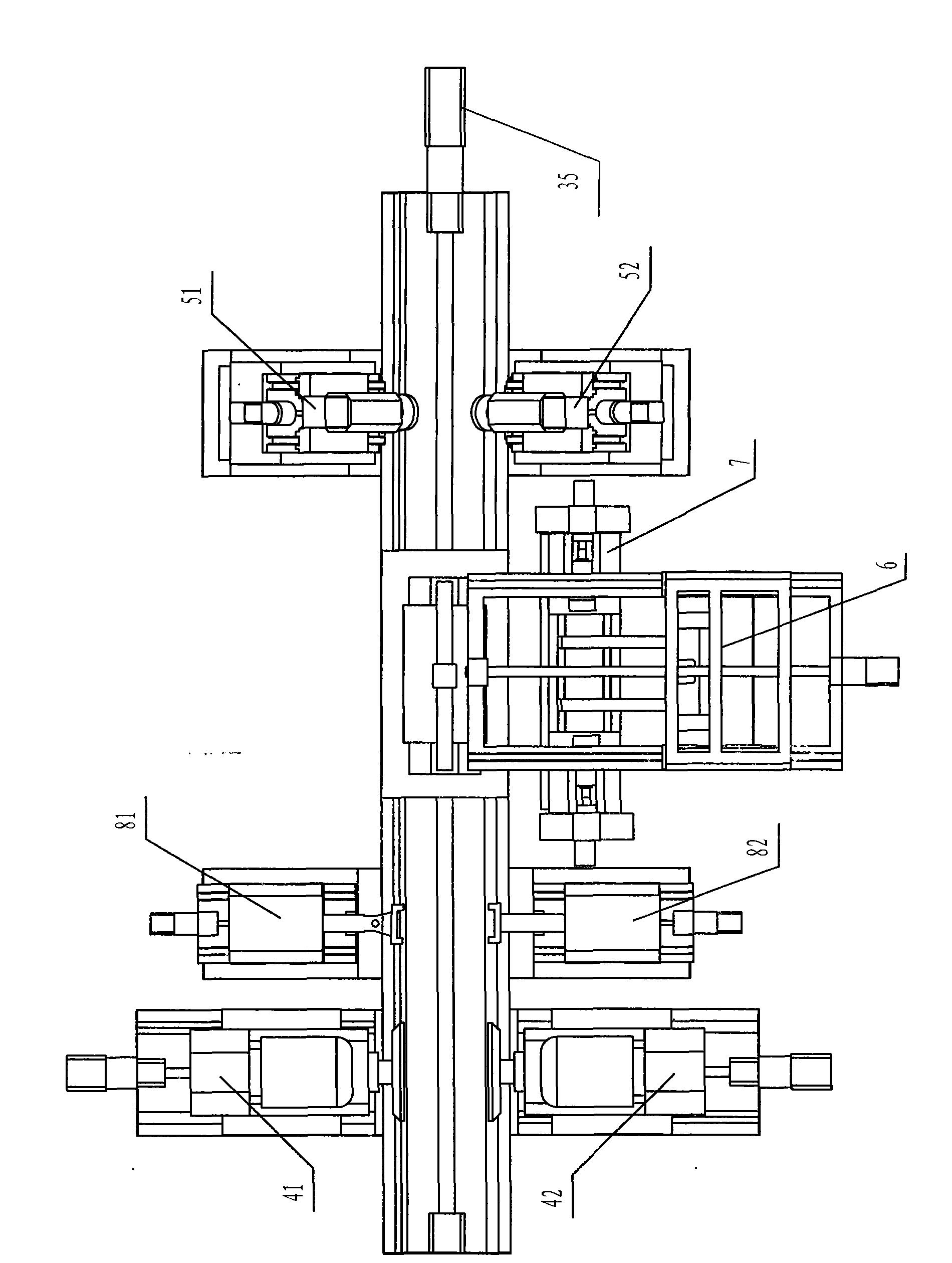

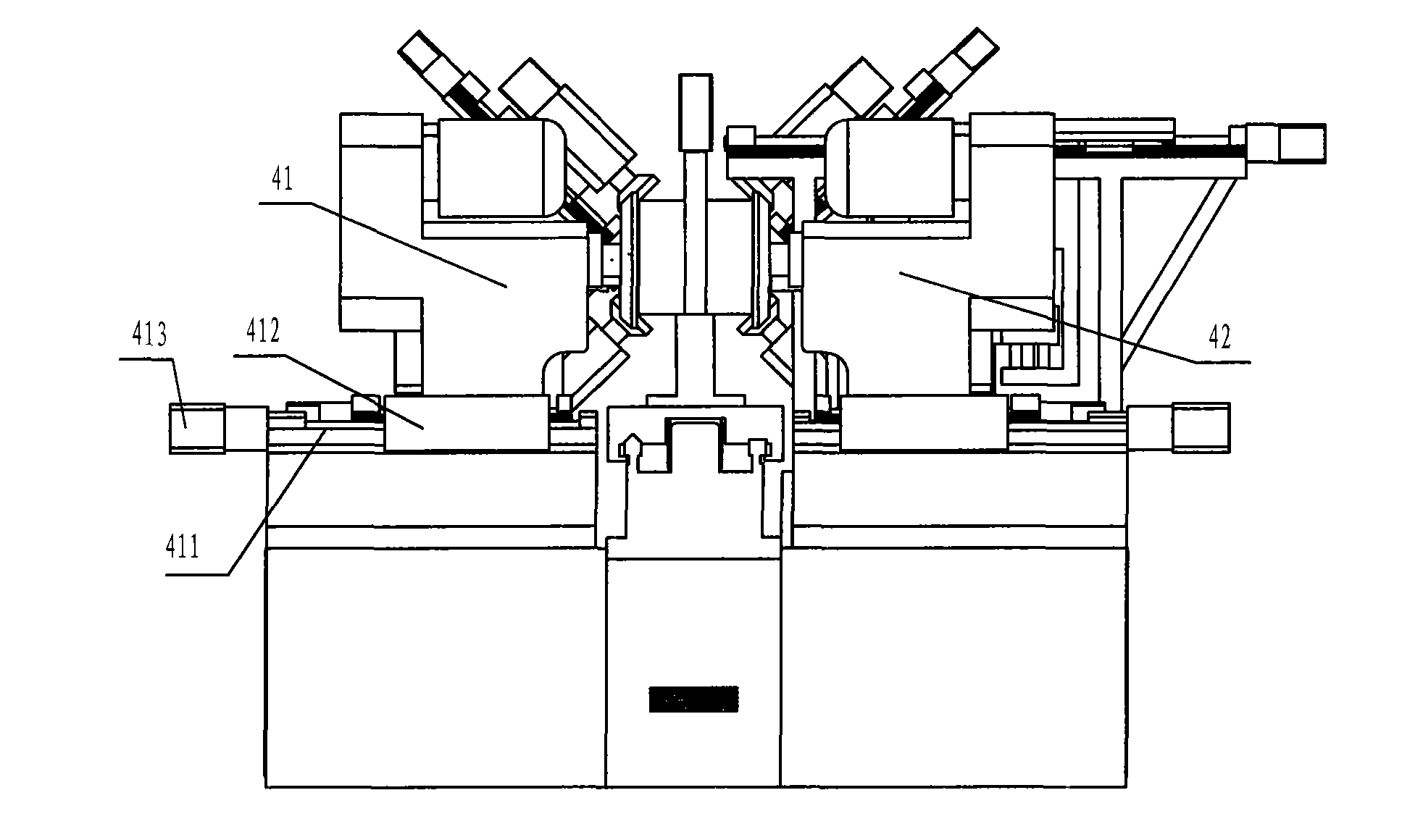

A bending-forging machine for manufacturing the large crankshaft or bellcrank used by ship is composed of upper die with lower arc end, bending lower die, upper and lower flat stocks, and insertion plate with lower arc end. Its forging method includes such steps as upsetting a steel ingot to become a flat square billet, drawing it to become a blank with shoulder, pressing V-shaped die on the middle of blank to form symmetric two V-shaped slots, bending by upper and lower dies, removing the upper and lower dies, inserting the insertion plate for finishing, trimming, and removing insertion plate.

Owner:SHANGHAI HEAVY MACHINERY PLANT +1

Processing method for controlling processing deformation of titanium-aluminum alloy thin-wall case

The invention relates to a processing method for controlling processing deformation of a titanium-aluminum alloy thin-wall case. The technical scheme of the processing method is as follows: the processing method comprises the steps as follows: a primary rough turning process, a primary heat treatment process, a secondary rough turning process, a secondary heat treatment process, a fine turning process, a third heat treatment process and a finish turning process. According to the processing method for controlling the processing deformation of the titanium-aluminum alloy thin-wall case, reasonable processing parameters are set, and an appropriate cutter is used, so that the processing deformation of the titanium-aluminum alloy thin-wall case is controlled, and the processing requirement is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

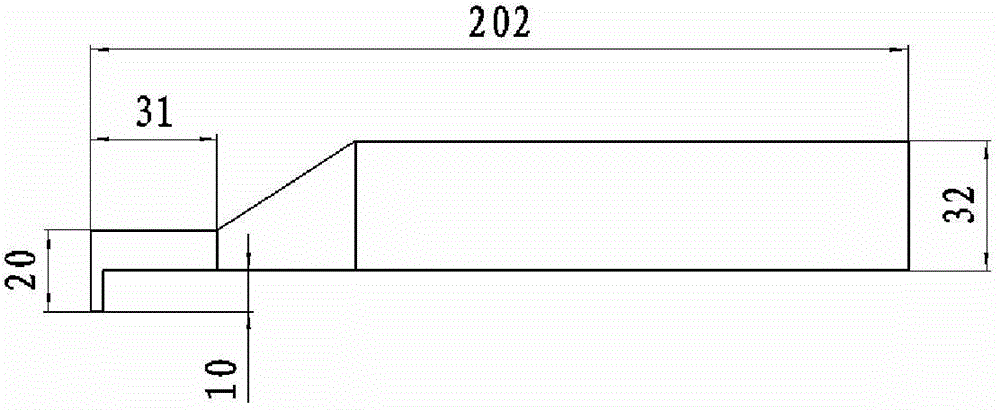

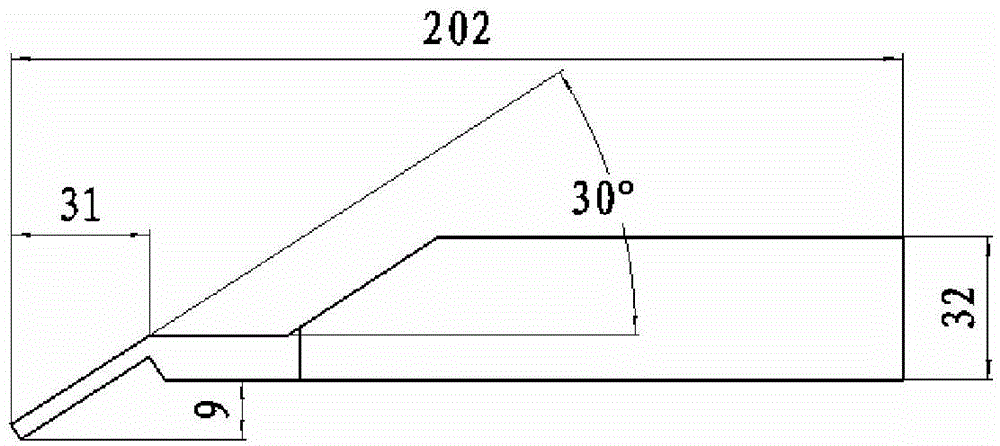

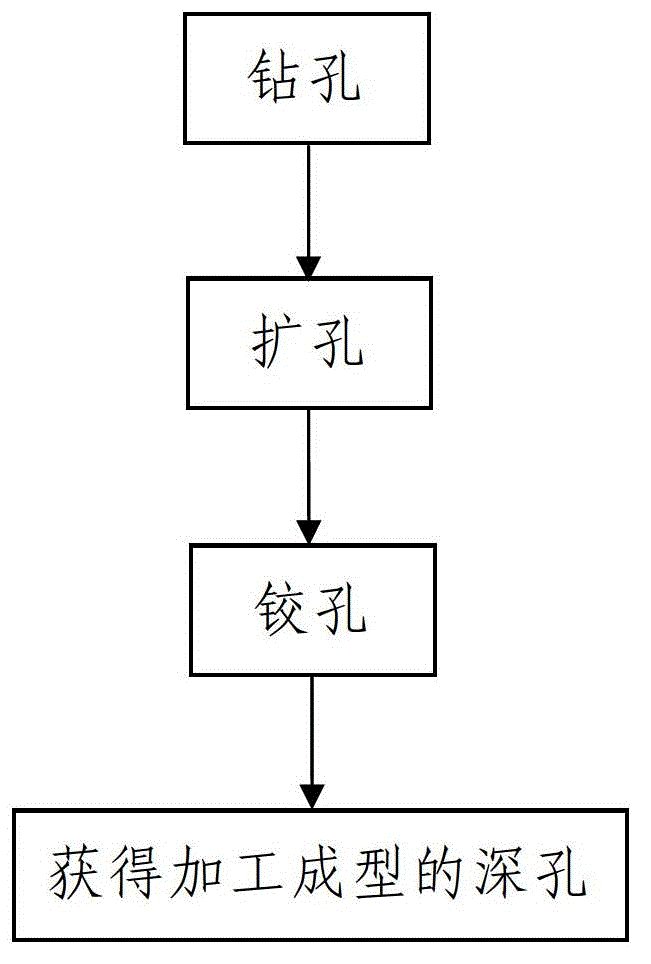

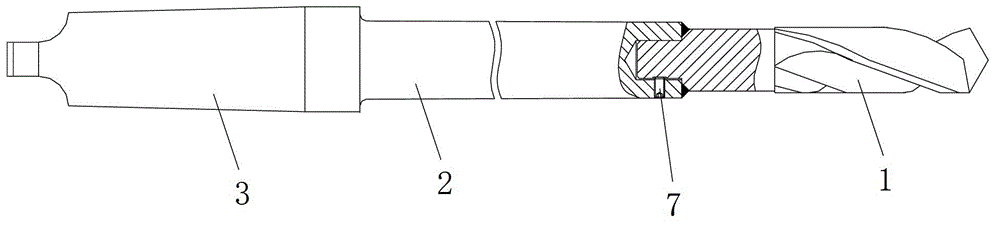

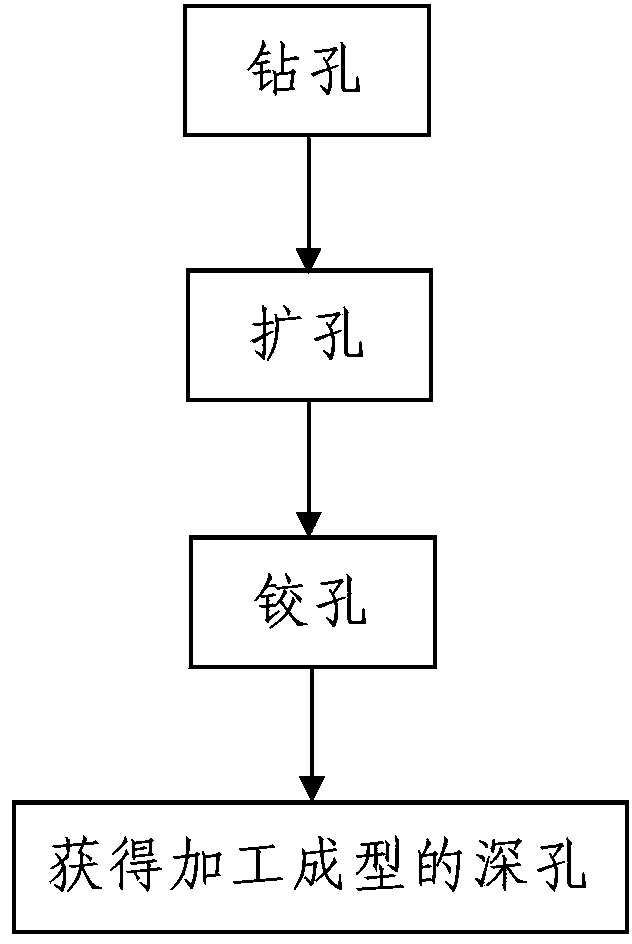

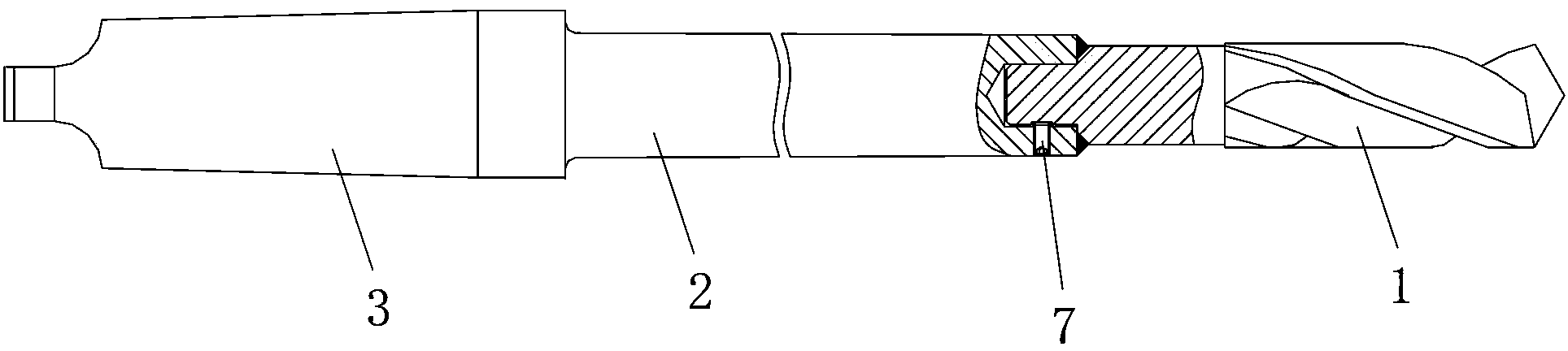

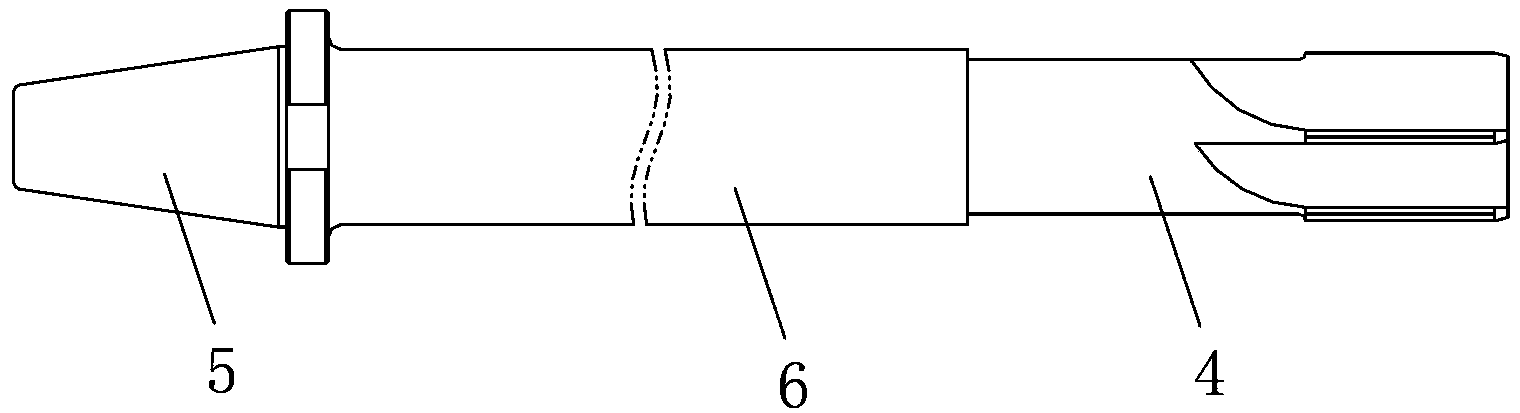

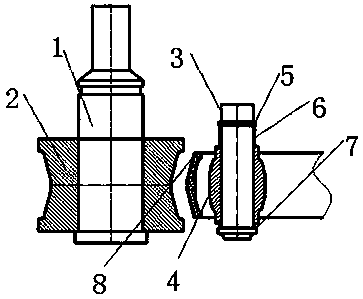

Deep hole machining process

ActiveCN102744561ASimplify processing stepsEasy to operateTransportation and packagingReaming toolsNumerical controlReamer

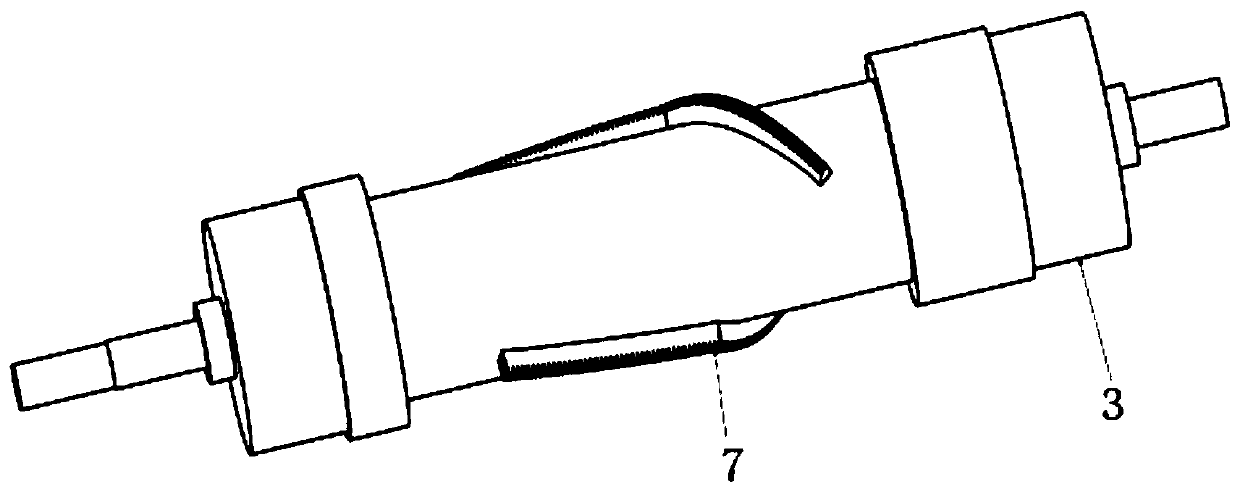

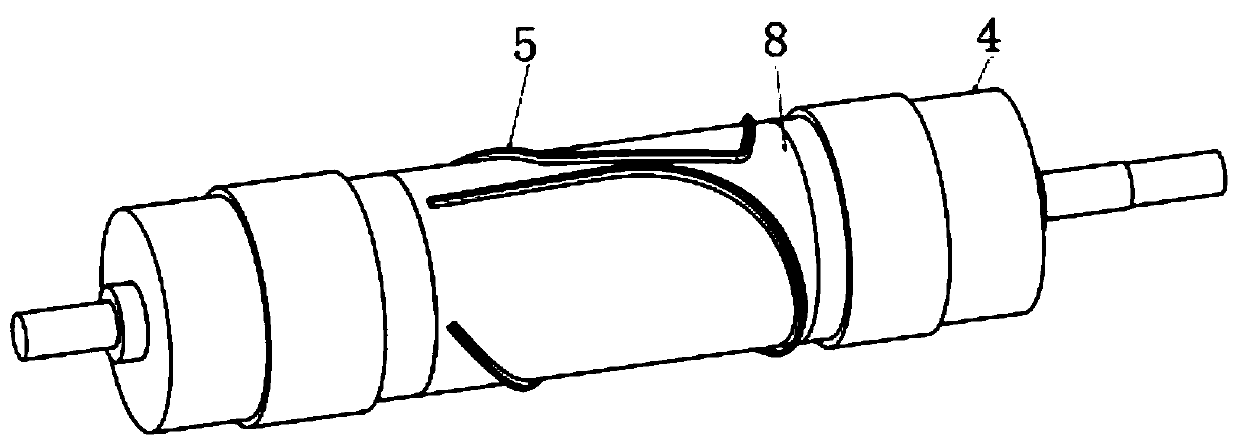

The invention discloses a deep hole machining process. The deep hole machining process includes: step one, drilling: machining deep holes to be machined on a numerical control machine tool by a connecting rod drill; step two, broaching: replacing a cutting drill of the connecting rod drill in the step one with a broach drill, and then machining drilled holes obtained in the step one by the numerical control machine tool; and step three, reaming: machining holes obtained in the step two on the numerical control machine tool by a long-rod reamer. The connecting rod drill comprises the cutting drill, a first handle, and a first connecting rod mounted between the cutting drill and the first handle coaxially. The long-rod reamer comprises a reamer head, a second handle, and a second connecting rod mounted between the reamer head and the second handle coaxially. The deep hole machining process is simple in steps, simple and convenient in actual operation, low in input cost, high in machining quality and quick in machining speed, and the problems that machining is inconvenient, actual operation is not easy to control, machining efficiency is low, machining precision is hard to guarantee and the like in the existing deep hole machining process by drilling prior to boring can be solved effectively.

Owner:XIAN COAL MINING MACHINERY

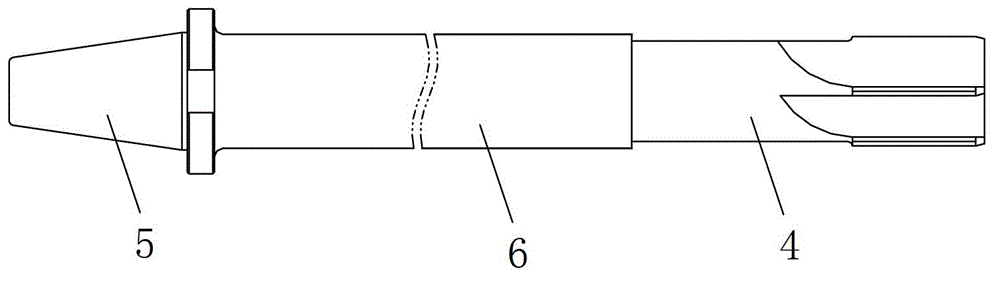

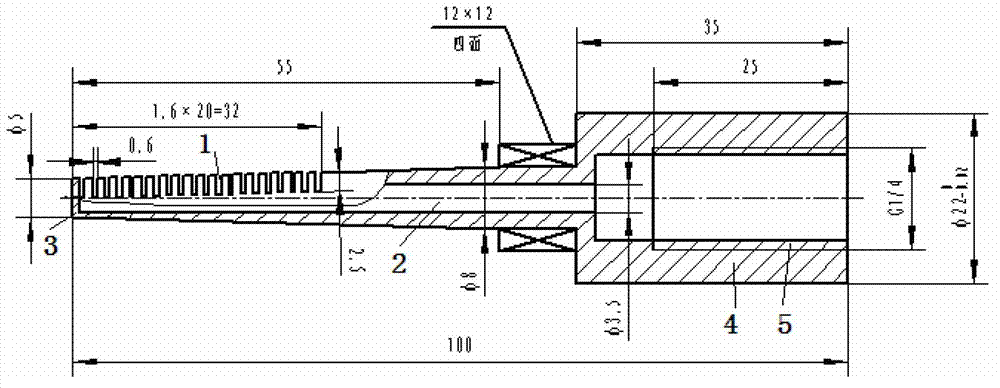

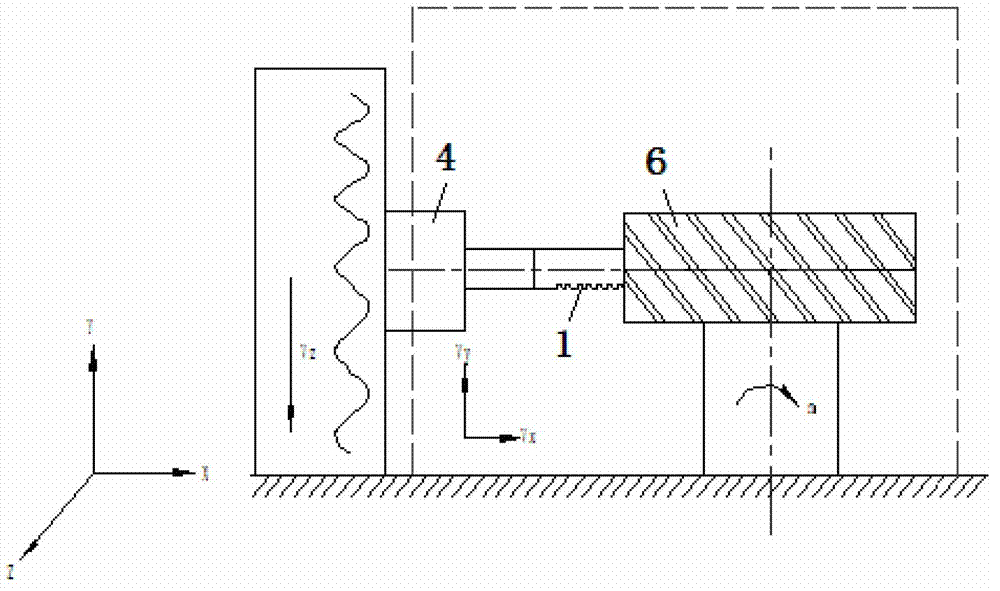

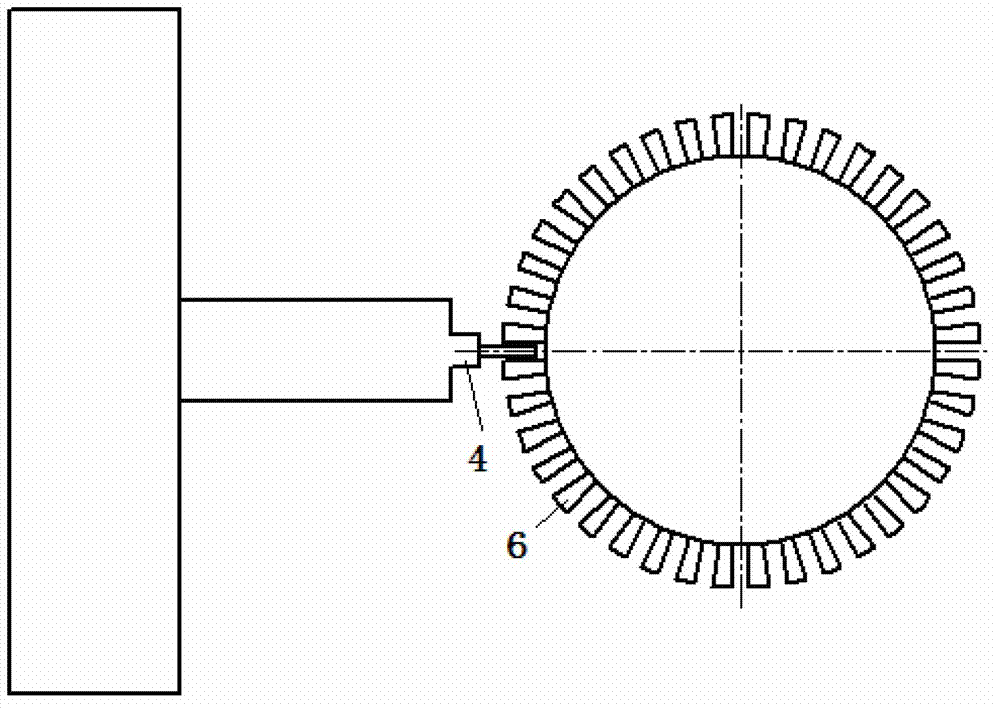

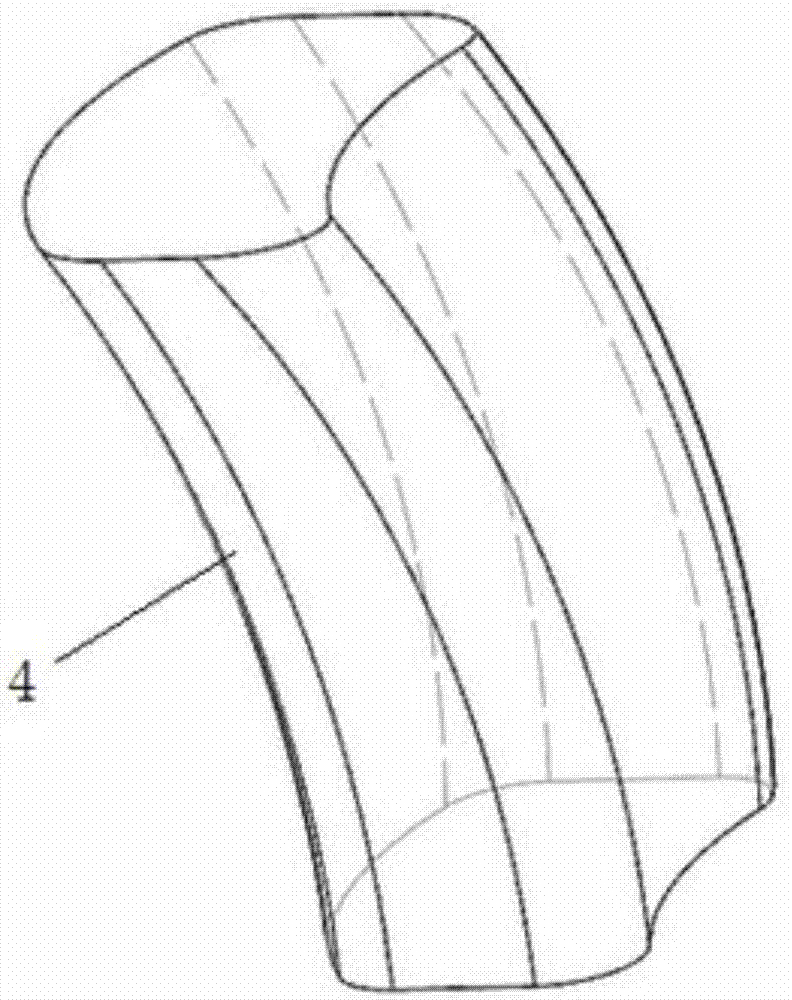

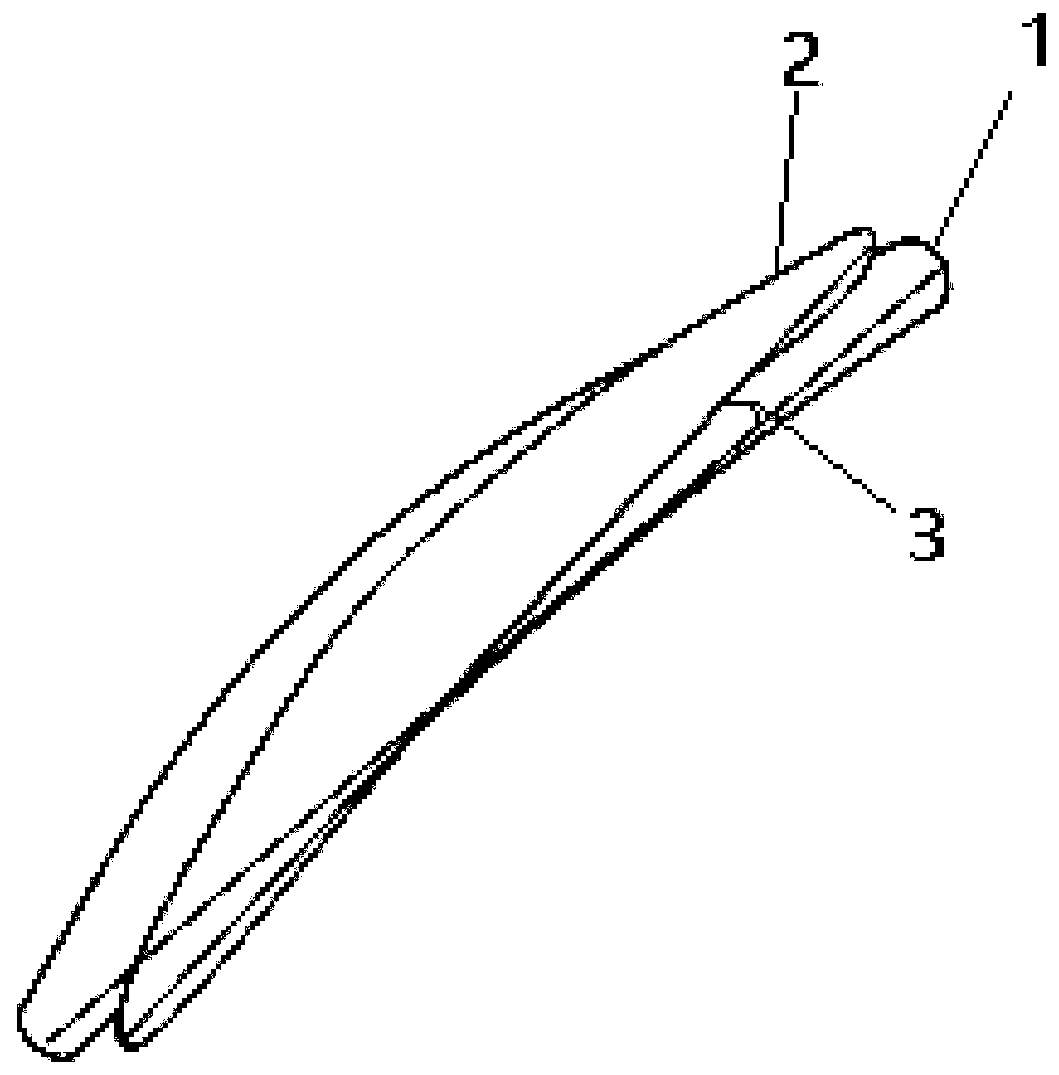

Electrode and machining method for electrolytic grooving of blisks

ActiveCN102873416AHigh precisionUniform balanceMachining electrodesElectrical-based machining electrodesElectrolysisEngineering

An electrode for electrolytic grooving of blisks is integrally of a hollow finger-shaped structure. An electrolyte channel is arranged inside the electrode, narrow grooves (1) with the widths of 0.6mm are circumferentially arranged at intervals of 1mm and are positioned at locations distanced from the upper edge of an outer profile close to a finger end of the electrode by 1 / 3-1 / 2, an electrolyte delivery pipeline (2) is disposed inside the electrode, a plugging structure (3) is arranged at the finger end so that the electrolyte delivery pipeline (2) is of a blind hole structure, and electrolyte only can flow out from the narrow grooves (1). A machining method for electrolytic grooving of the blisks includes that the electrode for electrolytic grooving of the blisks is used as a special tool, and an anode of a workpiece is dissolved in the electrolyte under the action of an electric field, so that the purpose of performing dimension machining for the workpiece is achieved; and the pressure of the electrolyte ranges from 4MPa to 6MPa, and the allowance reserved on a profile of a blisk body is 3.5mm. The electrode and the machining method have the advantages that the allowance reserved during electrolytic machining is uniform, high precision of repetition can be realized easily, a good flow field is obtained during electrolytic machining, and machining efficiency is high.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

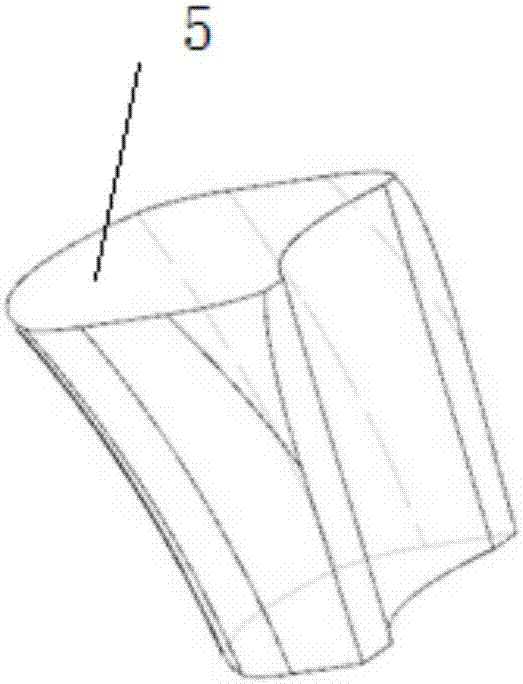

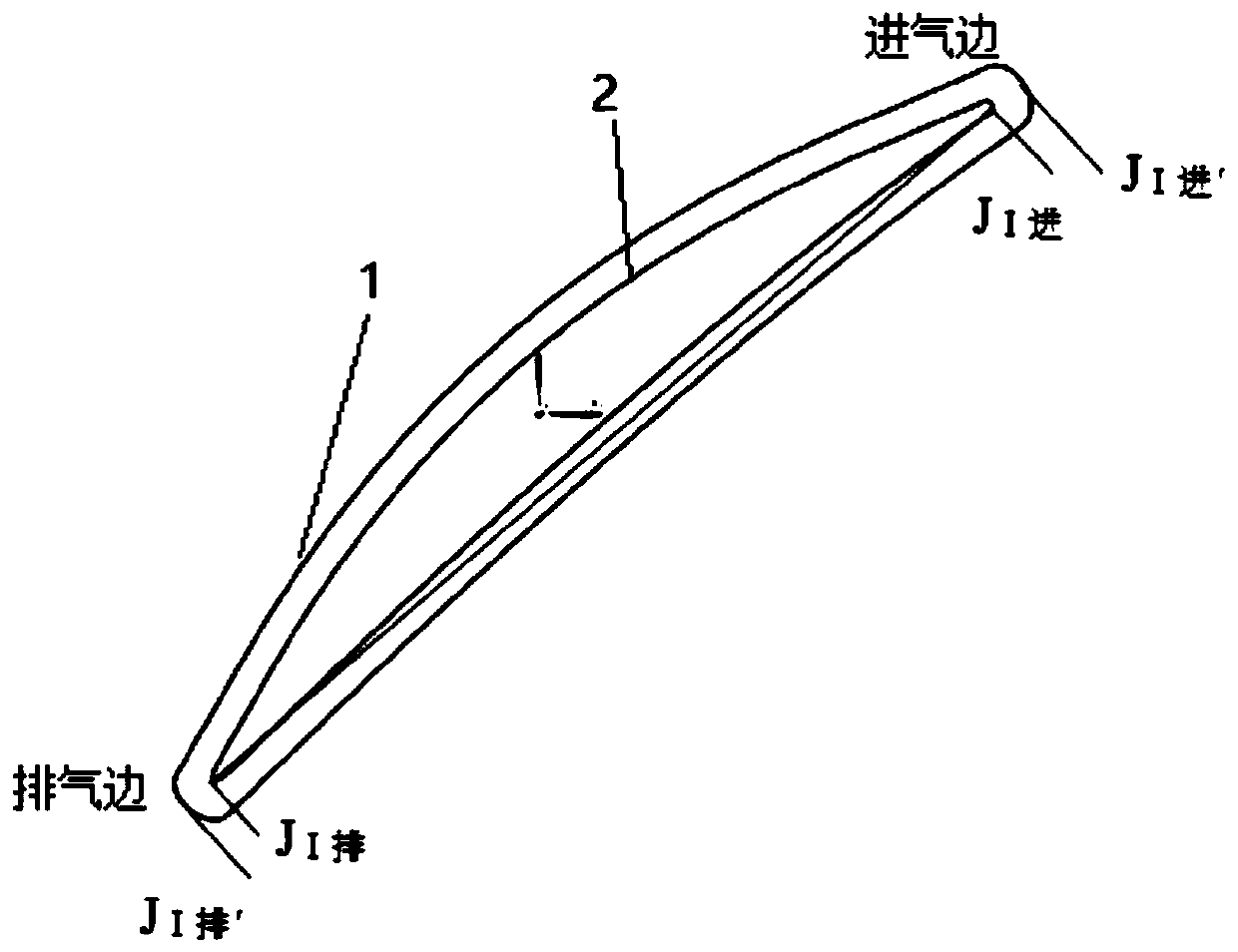

Milling grooving machining method for high-temperature alloy integral blade ring and blade part

The invention belongs to the field of machining, and particularly relates to a milling grooving machining method for a high-temperature alloy integral blade ring and blade part. The method comprises the machining steps of air inlet end pre-drilling, cavity milling of a blade back at the air inlet end, cavity milling of a blade basin at the air inlet end, milling of an air inlet end flow channel and back chipping, exhaust end pre-drilling, cavity milling of a blade basin at the exhaust end, cavity milling of a blade back at the exhaust end, and milling of an exhaust end flow channel and back chipping. The milling grooving machining method for the high-temperature alloy integral blade ring and blade part, the milling modes of driving a fixed shaft through multiple vectors for layering and sectional connecting are adopted, and a common end milling cutter is applied to realize rough grooving machining of uniform allowance.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for milling titanium alloy fan blade profiles

ActiveCN105290475AImprove processing efficiencyImprove machining accuracyMilling equipment detailsMilling cutterFan blade

The invention discloses a method for milling titanium alloy fan blade profiles, which aims to improve precision and milling quality of the titanium alloy fan blade profiles, and comprises steps: 1) parts are clamped by adopting a clamping mode which positions tenon double-degree surfaces and bottom surfaces; and 2) the parts are processed in half precision after being roughly processed, enables the allowances of the parts to be uniform, part blade profiles are finely processed in segments by adopting a ball-end mill after being processed in half precision, are measured on a machine tool on line to guarantee tool setting precision by adopting standard tool setting blocks or digital display setting tools during the process, control closing and tightening force of a processing center hole, and adjust closing and tightening force of machine tool double drivers according to structures and wall thicknesses of blades.

Owner:AECC AVIATION POWER CO LTD

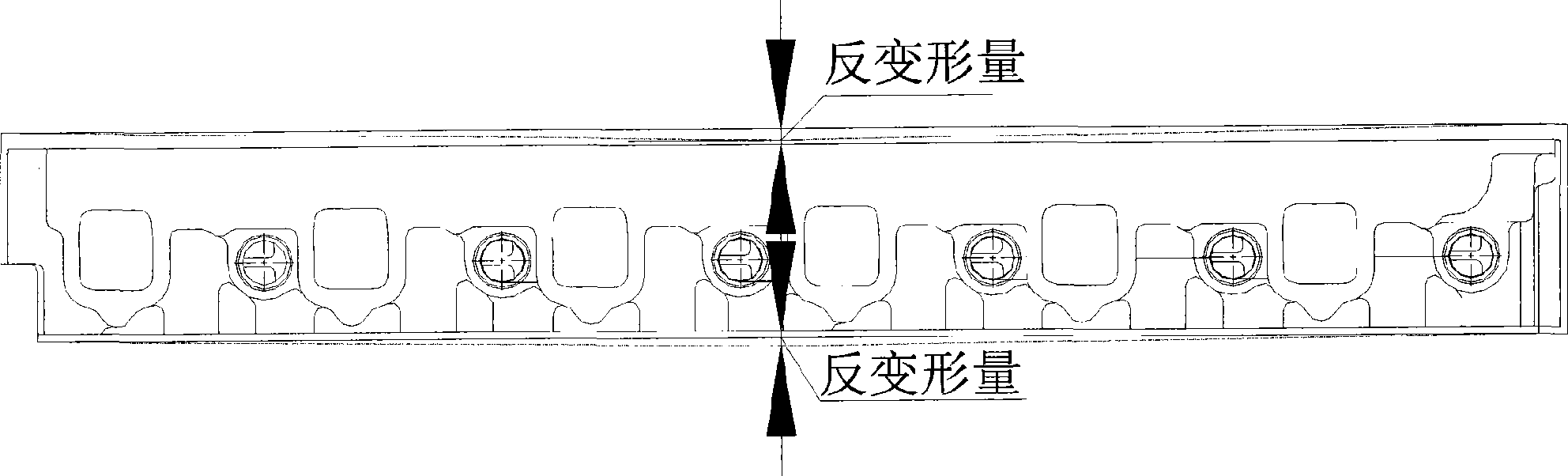

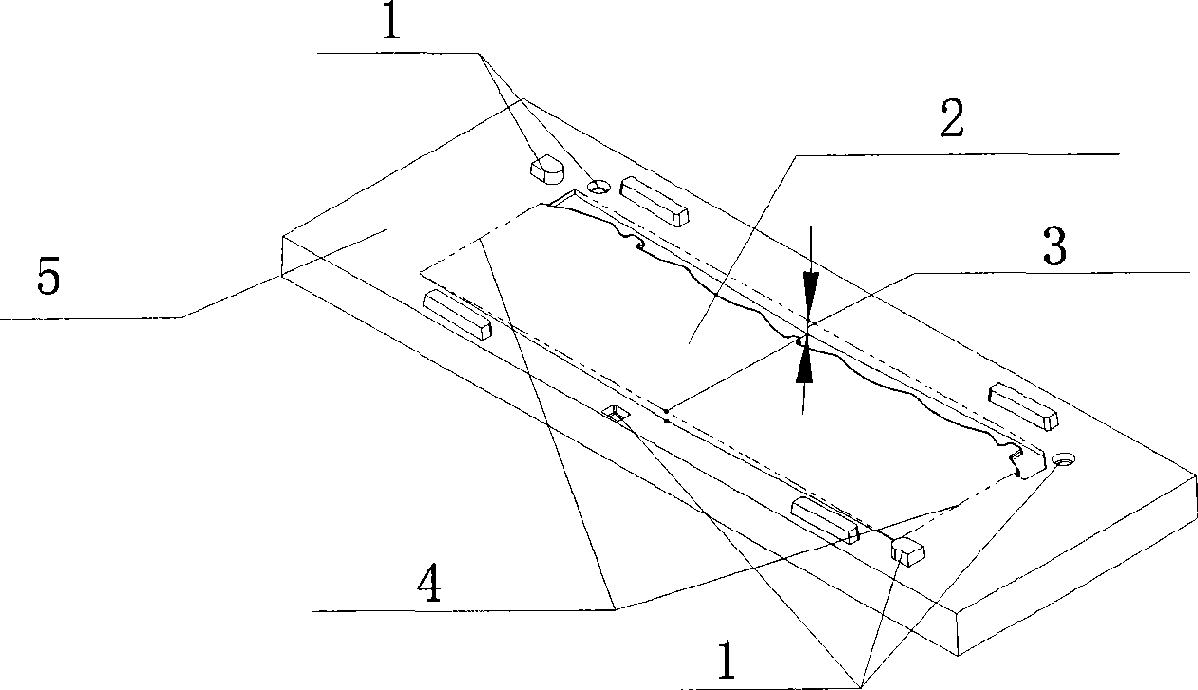

Method for casting cylinder cover of multicylinder one-cover engine

ActiveCN101468383AImprove accuracyUniform machining allowanceFoundry mouldsFoundry coresCylinder headMaterials science

The invention discloses a method for casting a cylinder head of a multi-cylinder single-cover engine, which adopts a reverse deformation amount casting method and comprises the design of shape reverse deformation amount of a casting mould and a mounting structure between sand cores, wherein the reverse deformation amount of the casting mould adopts the design that the part forming the shapes of the bottom and the top of a product is designed into V-shaped, and the initial point of the design of the V-shaped reverse deformation amount takes the central point of longitudinal length of the mould as the highest point, and the design of the V-shaped reverse deformation amount takes a slope surface formed on edges at two initial ends of the longitudinal length of the mould as the lowest final point. The method for casting the cylinder head of the engine adopts a modification method of the reverse deformation amount at the proper position according to the structure of the shape of the cylinder head when designing the mould. The casting process method adopts the structure of reverse deformation shape of the mould to effectively reduce the reverse deformation of a casting, and ensures the accuracy of the shape of the casting, in particular the accuracy of the shape of an air intake and discharge passage at key parts, thereby ensuring the stability of performance parameters of the air passage. The manufacturing cost of the mould and the production cost of the casting do not change.

Owner:GUANGXI YUCHAI MASCH CO LTD

Design optimization method of blisk electrolytic preliminary molding machining path parameters

ActiveCN109693007ASimple designRapid designElectrochemical machining apparatusElectrolysisMolding machine

The invention discloses a design optimization method of blisk electrolytic preliminary molding machining path parameters, and belongs to the technical field of electrolytic machining. When electrolytic preliminary molding machining is provided with a plurality of blisks with characteristic sections, the machining path parameters are optimized through a UG software, the design of the blisk electrolytic preliminary molding machining path parameters can be completed quickly, the obtained path parameters can make an actual section contour curve cover all designed section characteristic curves uniformly and make machining allowance distributed in different positions more uniform, the design problem of the blisk machining path parameters is solved, subsequent machining is convenient, machining efficiency is improved, and the quality of machined products is guaranteed.

Owner:AECC AVIATION POWER CO LTD

Method for assembling and welding curved-surface sector-segment frames

The invention discloses a method for assembling and welding curved-surface sector-segment frames, which relates to a method for welding complex frames. By adopting positioning blocks and special process modules, a plurality of working-equipment matching surfaces and bearing blocks of upstanding-plate welding components are positioned, assembled and fixed respectively. The method has the advantages of raising work speed, saving 17 hours of assembly, reducing work intensity, improving machining quality and reducing rework rate from 40 percent to 5 percent.

Owner:YICHANG JIANGXIA MARINE MACHINERY

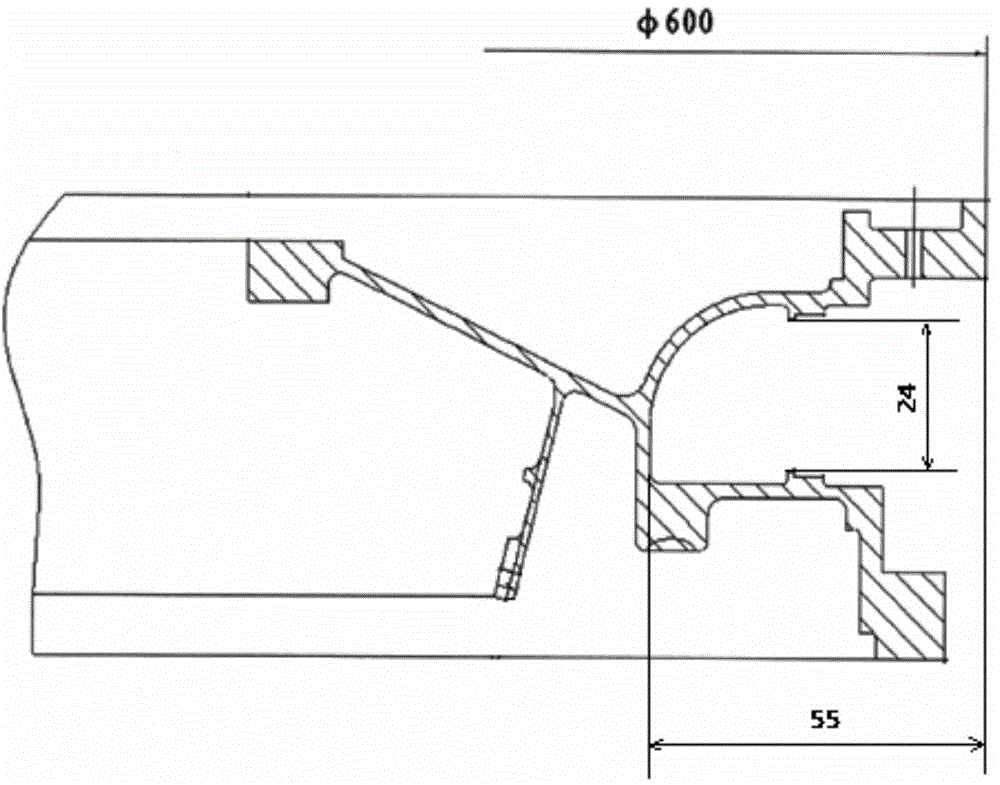

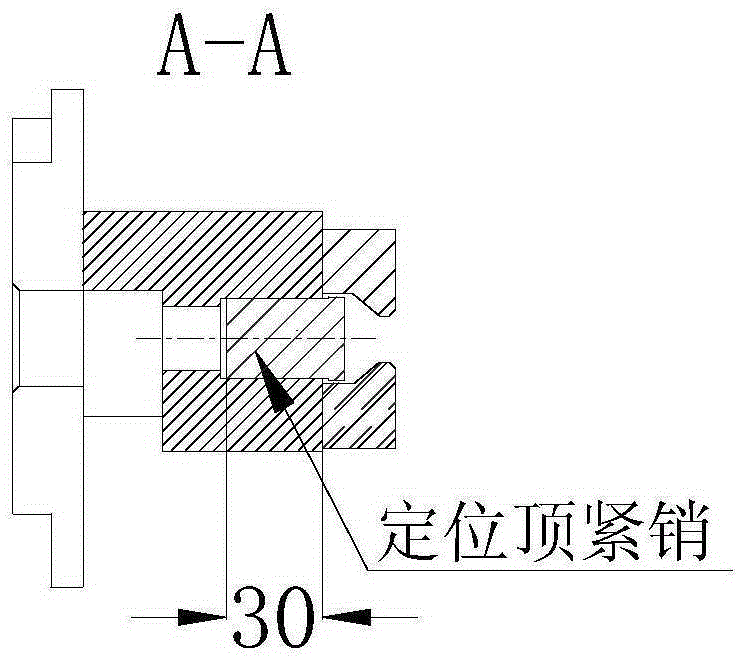

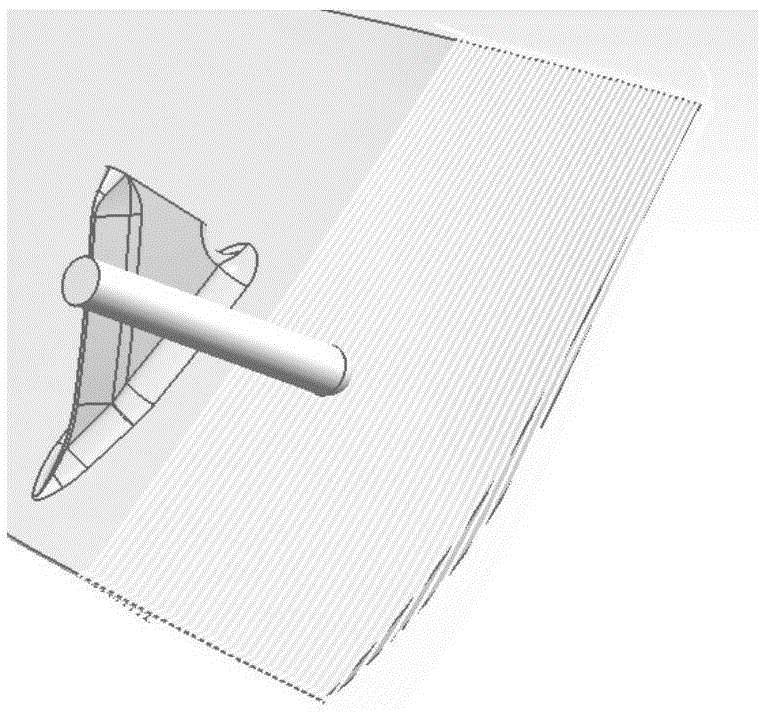

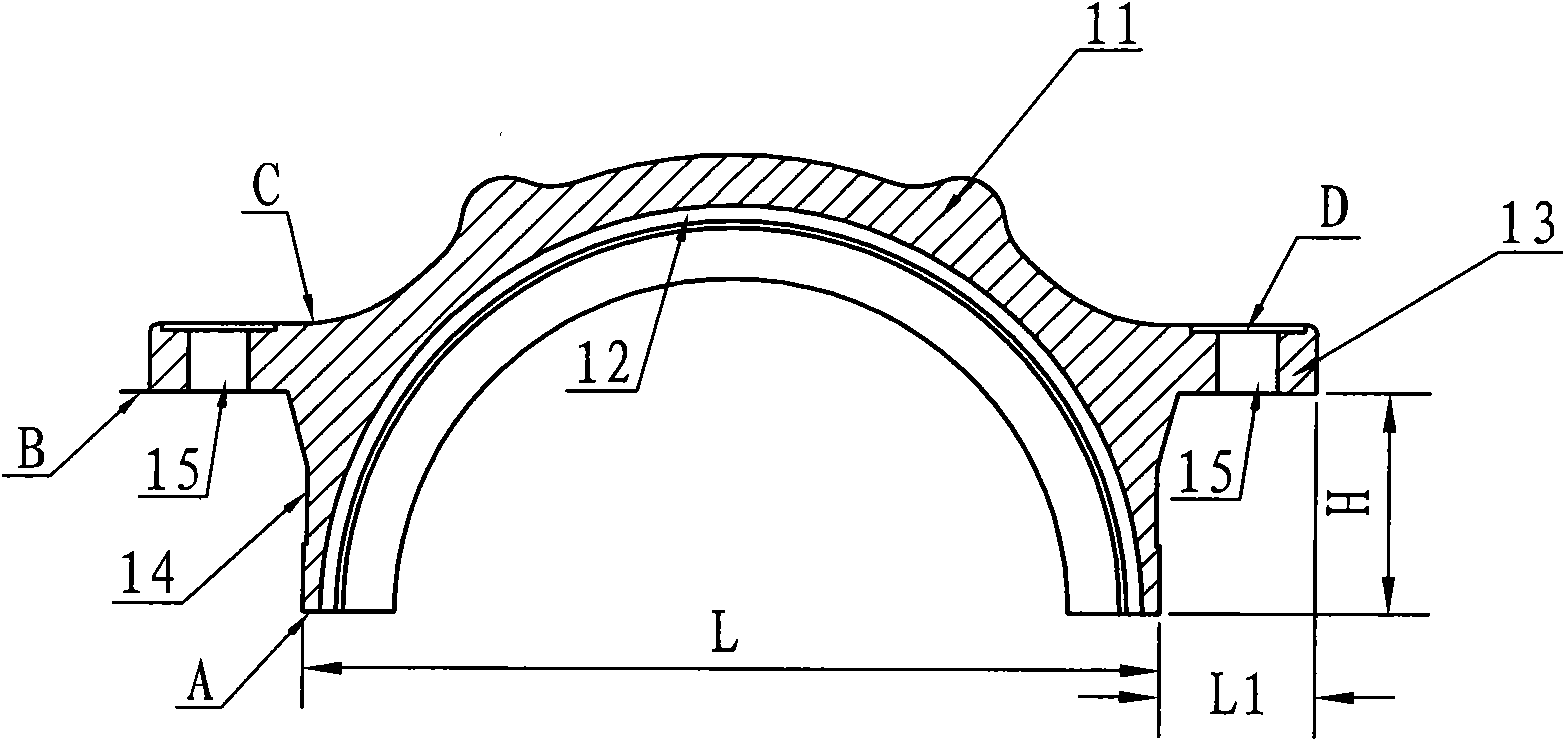

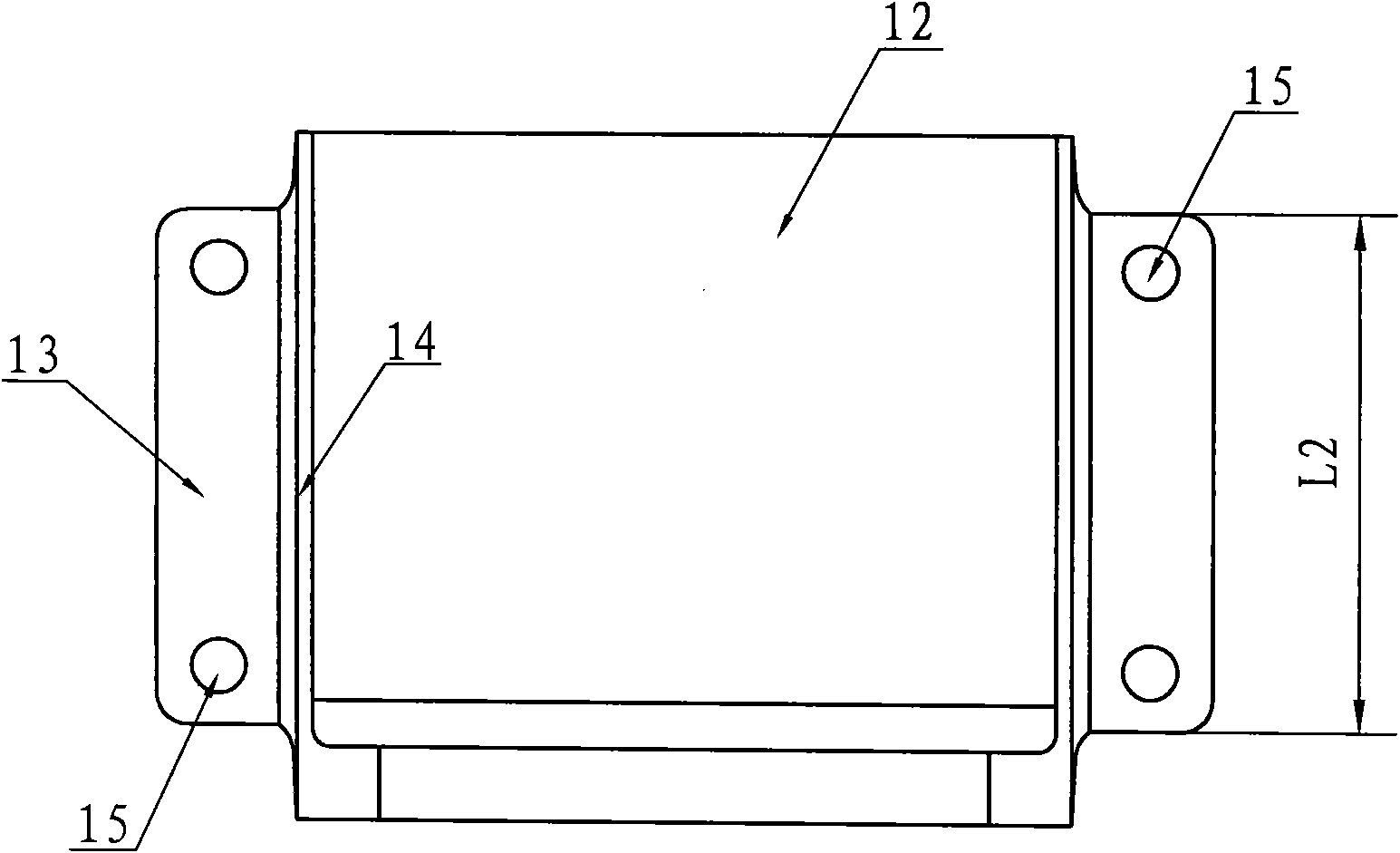

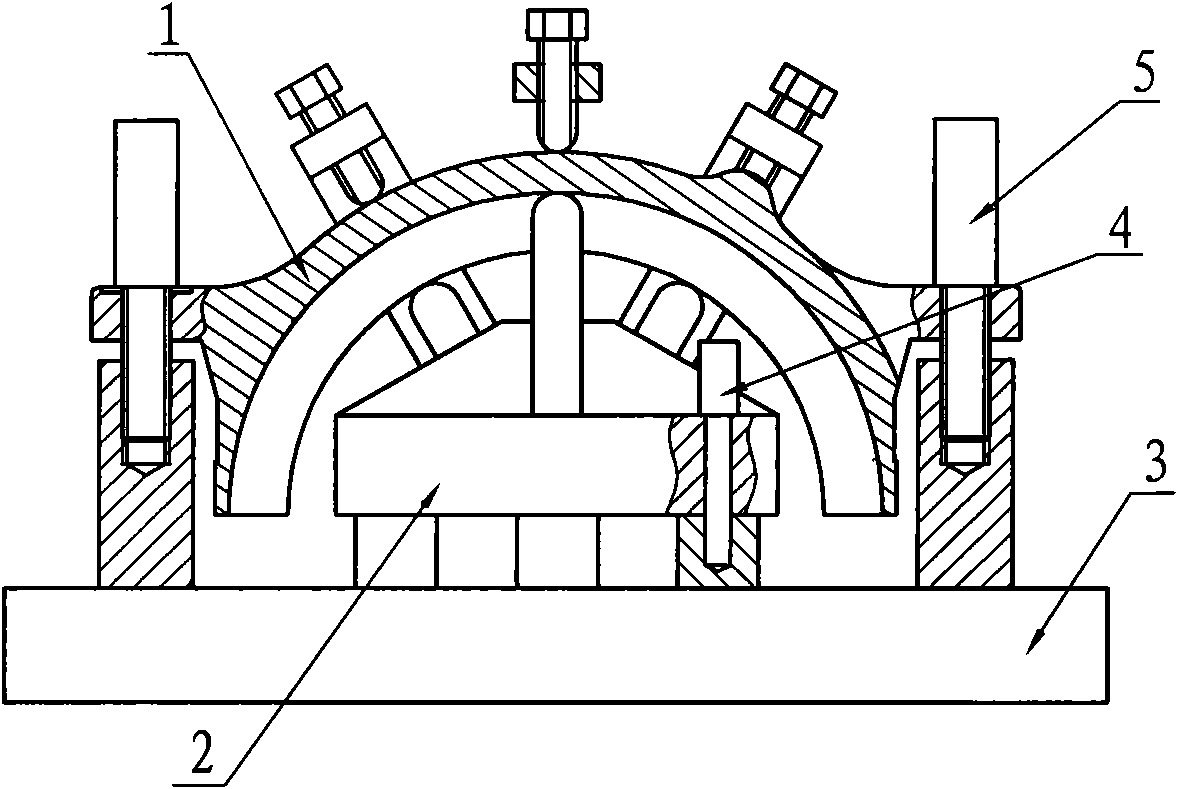

Compound fixture for processing matched seam allowance on upper body of motor car bogie axle box

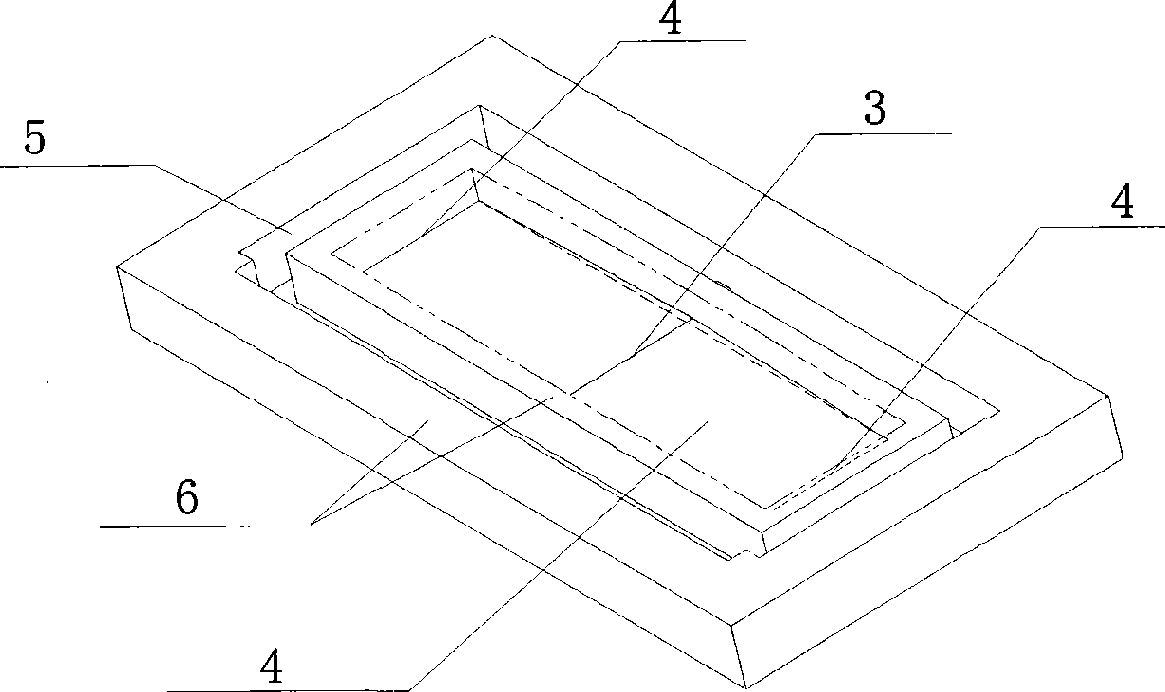

InactiveCN102172841AUniform machining allowanceSmall machining allowancePositioning apparatusMetal-working holdersBogieJoint surface

The invention discloses a compound fixture for processing a matched seam allowance on the upper body of a motor car bogie axle box. A rough machining bearing hole serves as a locating surface; when a workpiece is installed, a movable bottom plate in a movable fixture is placed on an adjusting fixture; the movable fixture and the adjusting fixture are precisely located by two movable bottom plate locating rods; the workpiece is accurately located on the movable fixture by two workpiece locating rods; after the workpiece is located, the workpiece is fixed by a compression screw; then the movable fixture is turned over to be installed on a fixed support; a space is formed between the top surface of the compression screw and a fixed bottom plate; and after the movable fixture is fixed and installed, the matched seam allowance on the workpiece faces upwards. Thus, the workpiece is positioned on a processing center, one-time clamping can be used for milling the matched seam allowance, a lower joint surface and the lower surface of a connected lug and used for profile machining of a connecting hole to ensure that the thickness between the matched seam allowance and two sides of a bearing hole is even, the working procedure quality good rate of the workpiece is 99.8%, and the clamping regulation time is shortened by 105-120 seconds as compared with the prior art.

Owner:CHANGZHOU HUADE MACHINERY

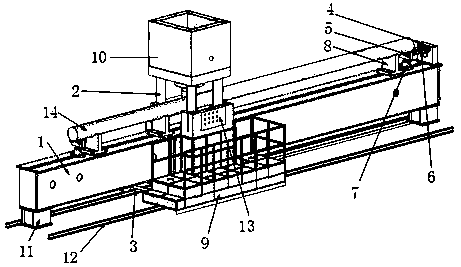

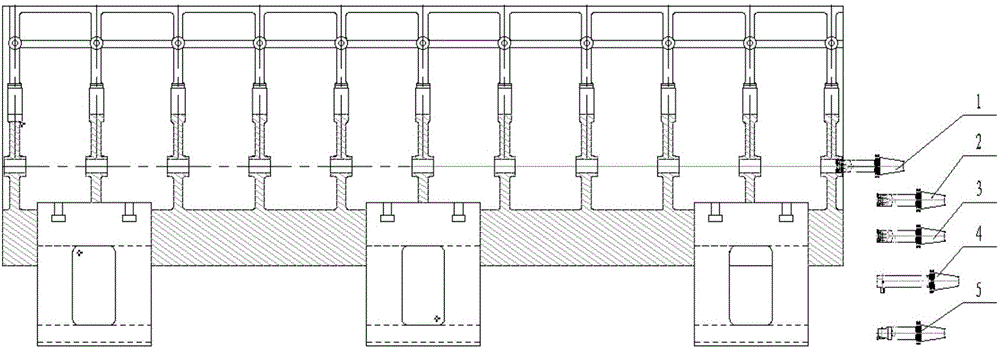

Hydraulic straightening machine with movable type pressure head

The invention provides a hydraulic straightening machine with a movable type pressure head. The hydraulic straightening machine with the movable type pressure head is composed of a lathe bed, a gantrymechanism, a gantry driving base, a rolling adjustment device, a gantry hydraulic driving mechanism, a control panel and a moving walking board. Two ends of the lathe bed are connected with bed legs,the gantry mechanism is of a gantry sealing type structure and spans the lathe bed, the gantry driving base is arranged at the bottom of the gantry mechanism, and four rollers are mounted on the gantry driving base. The rolling adjustment device comprises a rotary driving mechanism, a V-shaped roller bracket, a universal transmission section and a lifting oil cylinder. The gantry hydraulic driving mechanism is composed of a pressure oil pump, a main oil cylinder, an oil tank, an oil circuit integrated block and a hydraulic valve. The moving walking board is arranged on one side of the lathe bed, and the control panel is mounted on the moving walking board. The hydraulic straightening machine with the movable type pressure head can be widely applied to steel-making plants and large-scale steel markets and used for straightening thin and long shaft type part workblanks or straightening circular steel materials or steel pipes, so that the allowance for machining of straightened workpieces is uniform, the allowance for machining is reduced, and the hydraulic straightening machine with the movable type pressure head has the advantages of reasonable design, convenient use and high-efficiency straightening.

Owner:SHANDONG HUAYU UNIV OF TECH

Design optimization method for blisk electrolytic preforming machining track parameters

InactiveCN110385489AImprove efficiencyReduce manufacturing costElectrochemical machining apparatusAviationElectrolysis

The invention is suitable for the technical field of electrolytic machining, and provides a design optimization method for blisk electrolytic preforming machining track parameters. A blade back and ablade basin of every two adjacent blades are subjected to electrolytic machining through a machining tool, then one machining head simultaneously has a blade basin profile surface and a blade back profile surface, the relative positions of the blade basin profile surface and the blade back profile surface are determined and are invariable, and it can be guaranteed that the relative positions of the electrolytic machining forming surfaces of the blade basins and the blade backs of the blades are stable and invariable only enabling the machining tool to run to the set position; and meanwhile, the machining track parameters are optimized, and design of the blisk electrolytic preforming machining track parameters is quickly completed. Therefore, the blisk machining and manufacture cost is low,the efficiency and the precision are high, the machining optimization method is simple, and the machining requirements of aero-engines in the military and civil fields are met.

Owner:HEFEI UNIV

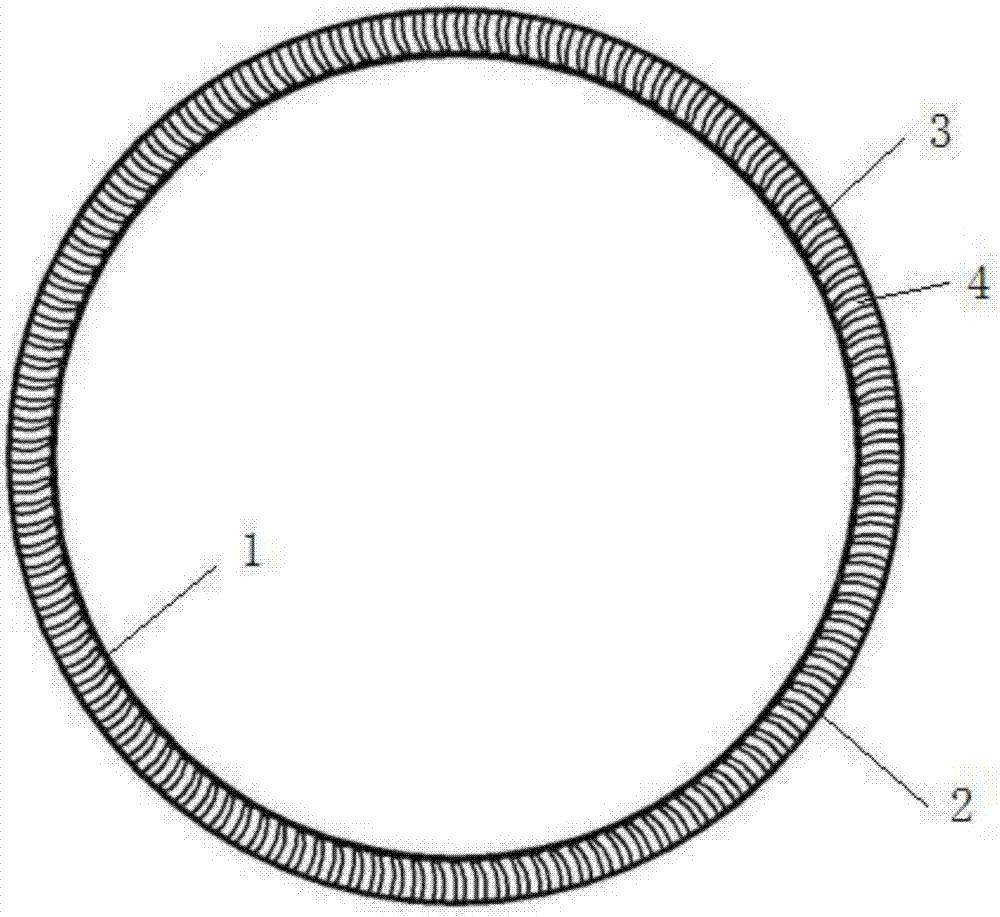

Technological method for reducing deformation of sectioning thin-walled cylinder type workpieces

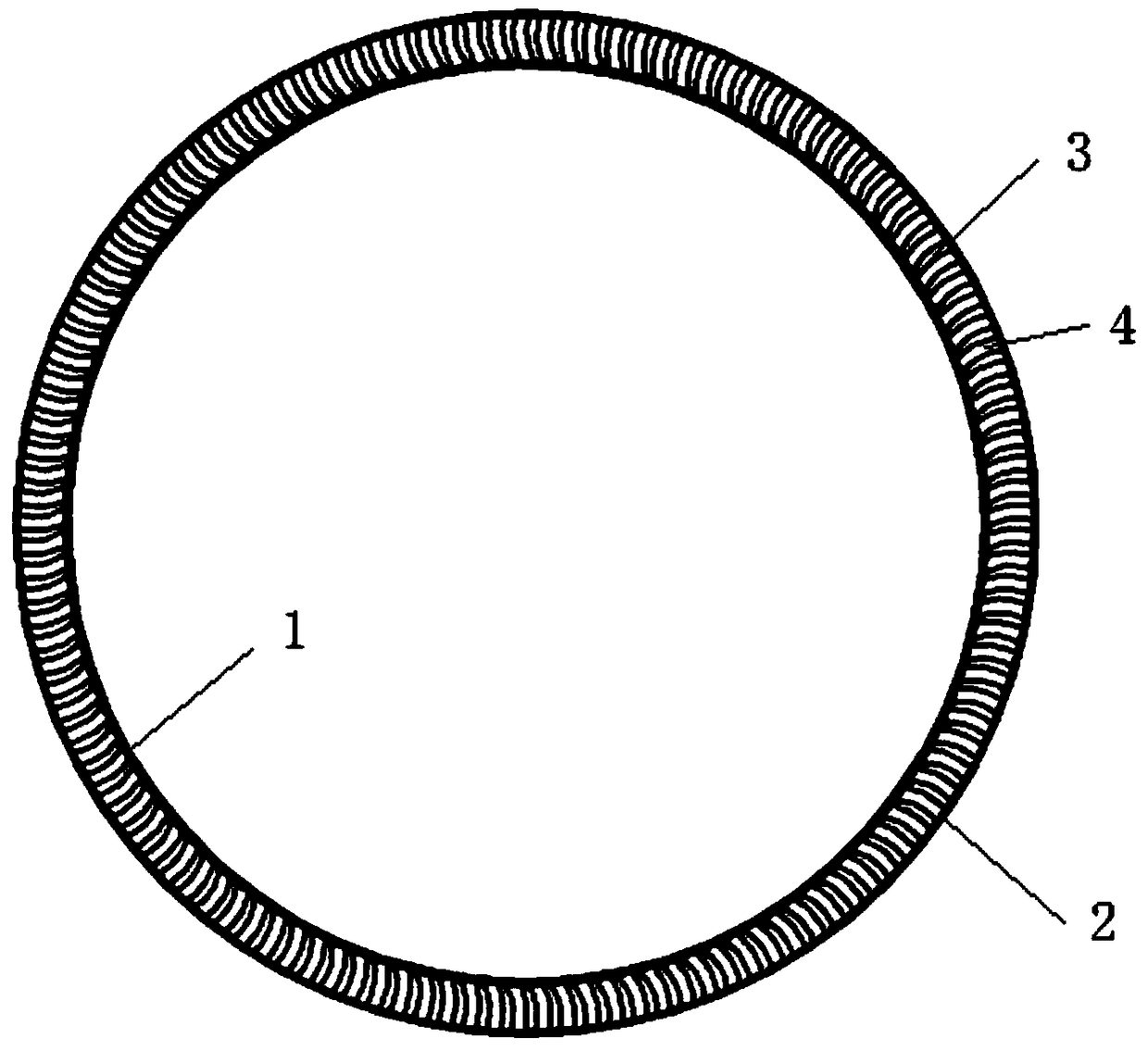

The invention relates to a technological method for reducing deformation of sectioning thin-walled cylinder type workpieces. According to structural characteristics of the sectioning thin-walled cylinder type workpieces, by means of the combination of various methods of beforehand sizing, sizing and time keeping, auxiliary supporting, rough and fine machining, aging treatment and the like, the cylinder type workpieces are better in cylindricity after being sized, the requirement for working allowance is met after sizing, meanwhile, machining allowance is uniform, machining stress is uniform, and deformation is uniform; the thin-walled cylinder type workpieces are placed under application of a special sizing tool for a period of time before being roughly machined, welding deformation of the thin-walled cylinder type workpieces is better eliminated; the thin-walled cylinder type workpieces are placed again under application of the special sizing tool for a period of time before being finely machined, workpiece deformation caused after stress release in aging treatment is further reduced; meanwhile, the sizing tool is used as a machining auxiliary supporting tool, the workpiece strength is increased, and machining deformation is reduced.

Owner:HARBIN ELECTRIC MASCH CO LTD

Machining technology for cylinder head valve seat ring and valve guide pipe hole

InactiveCN107378381AGuaranteed cleanlinessReduce generationMachines/enginesLift valveCylinder headCooling effect

The invention proposes a process for processing a cylinder head valve seat ring and a valve guide hole, comprising the following steps: (1) preparation of raw materials; (2) initial molding; (3) finishing; (4) inspection. The production process proposed by the present invention is reasonable, ensures the processing accuracy of the product, and effectively improves the production efficiency. At the same time, the process flow is optimized, and the production efficiency is improved through the CBN cutter. The single-edged reamer is used to overcome the machining allowance The machining error caused by offset, and the use of internal coolant flow improves the cooling effect and facilitates chip removal to ensure the cleanliness of the air passage. The positioning method makes the machining allowance uniform and reduces the generation of unqualified products. Reduced production costs.

Owner:上柴动力海安有限公司

Piston ring manufacturing process beneficial to chromium plating quality

The invention discloses a piston ring manufacturing process beneficial to chromium plating quality. The piston ring manufacturing process comprises the steps of clamping, inner and outer circle profiling, inlaying groove shaping, chamfering of an external angle, chromium plating, outer circle shaping grinding and honing; the inlaying groove shaping step adopts turning treatment; the turning treatment comprises two processes of rough turning and finish turning; the finish turning process comprises two process steps of half finish turning and finish turning. The process route is high in processing efficiency, uniform in thickness of a chromium coating, high in turning precision and long in service life of the cutting tool.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

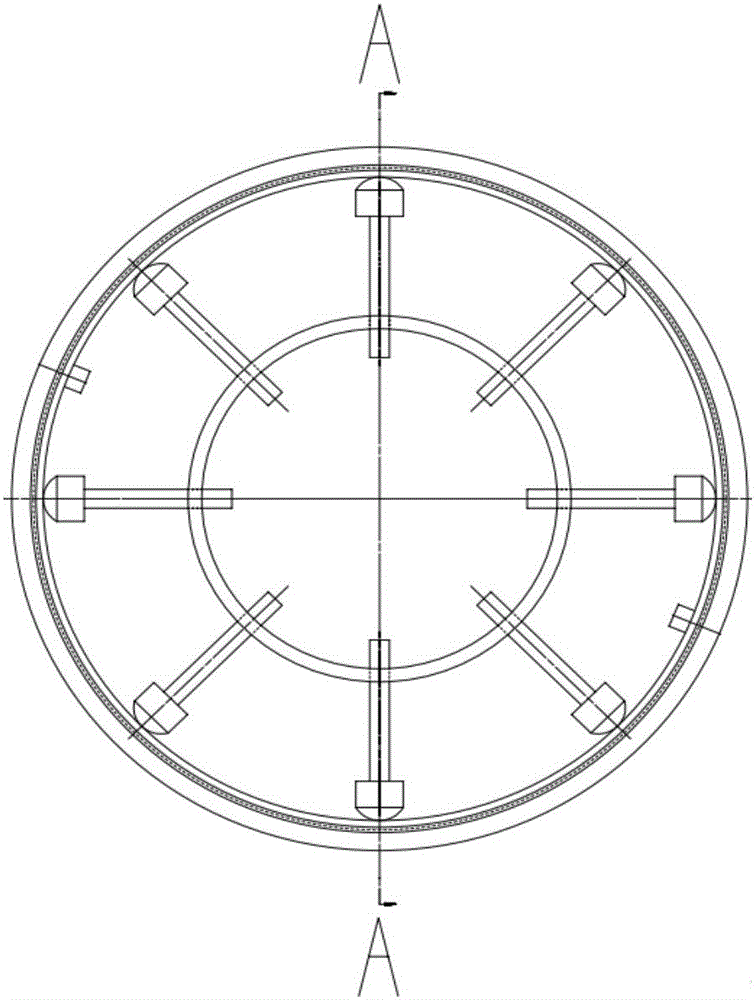

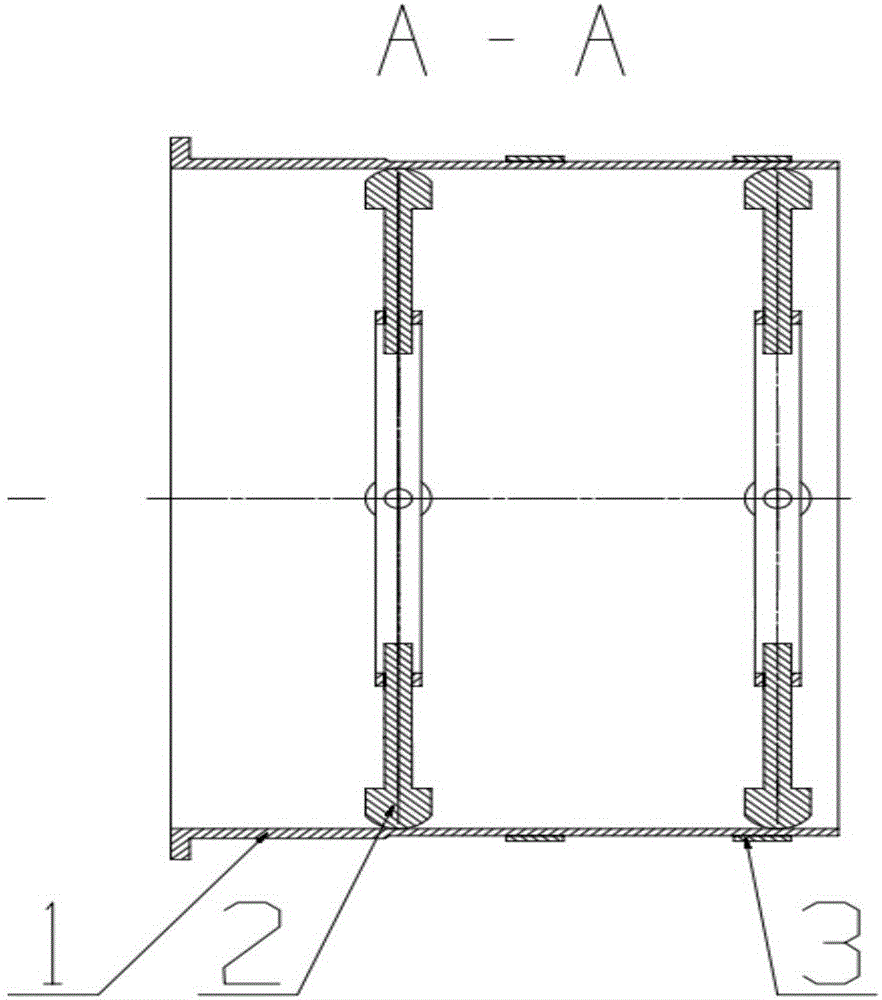

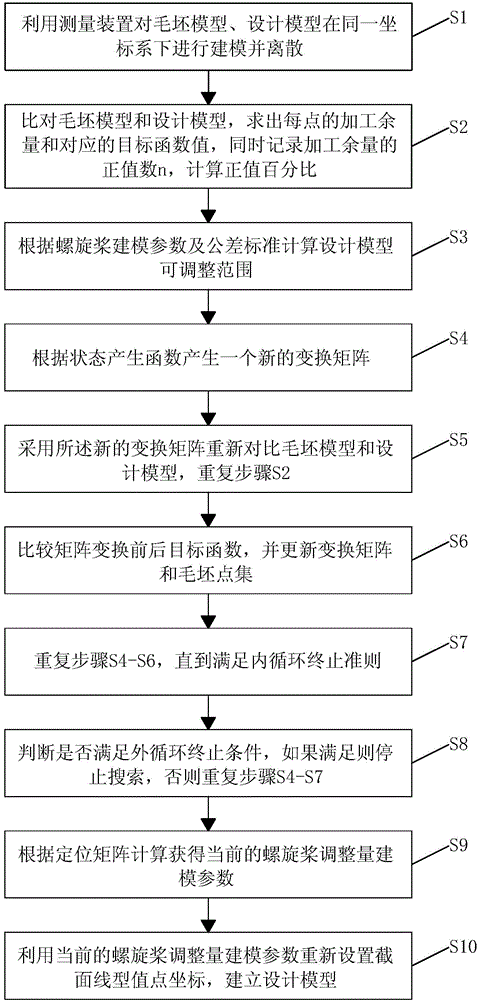

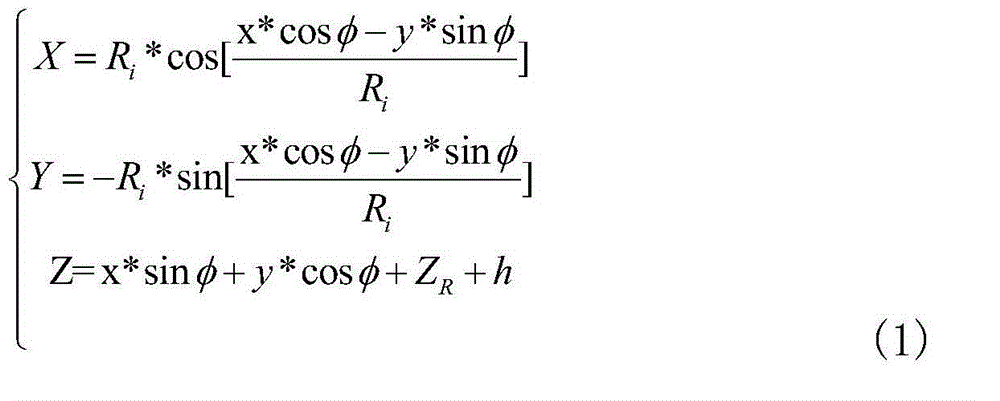

Method for adjusting nonuniform machining allowance of propeller

ActiveCN104699904AUniform machining allowanceQuick matchSpecial data processing applicationsPropellerEngineering

The invention discloses a method for adjusting a nonuniform machining allowance of a propeller. The method overcomes the defect that the nonuniform machining allowance of the propeller needs to be manually adjusted, the pose of a design model is automatically adjusted according to a technological tolerance and the current machining allowance distribution situation, quick matching between a propeller blank model and the design model is achieved on the premise that the tolerance standard is met, the situation that the machining allowance of a blank is uniform is guaranteed, and machining quality of blades is improved.

Owner:HUST WUXI RES INST +1

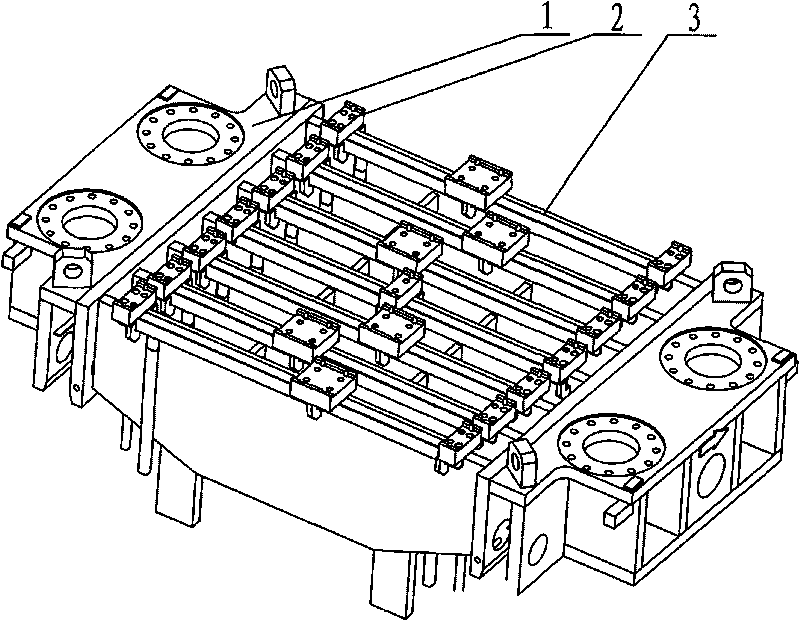

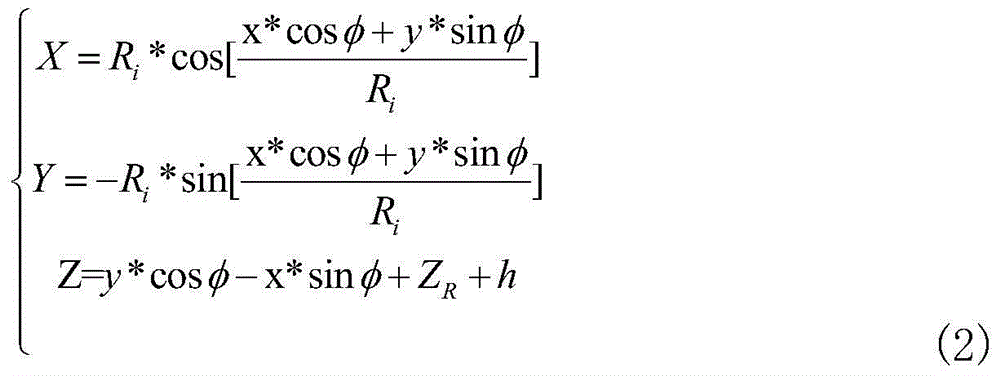

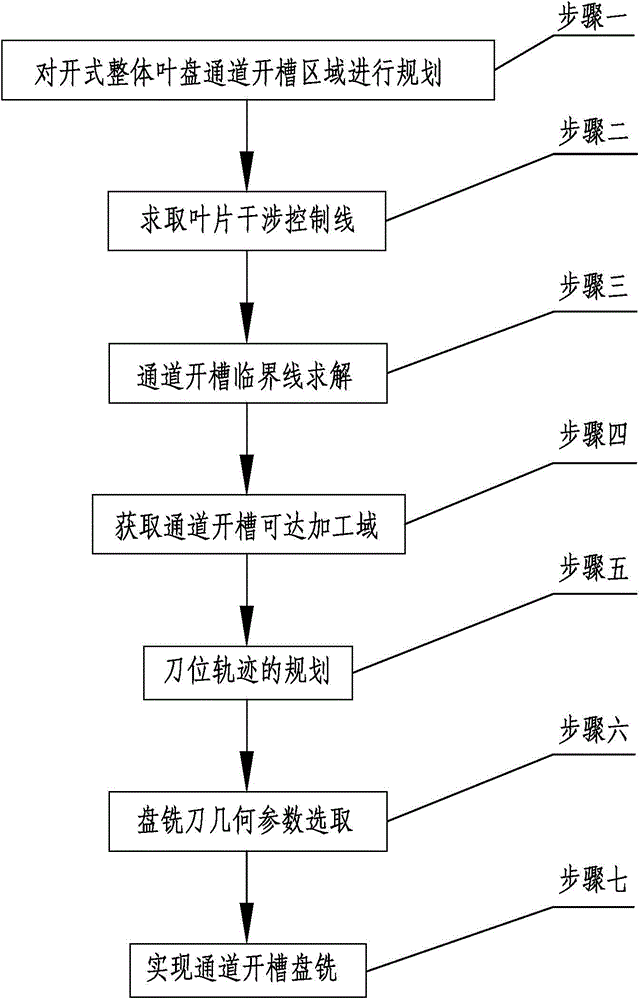

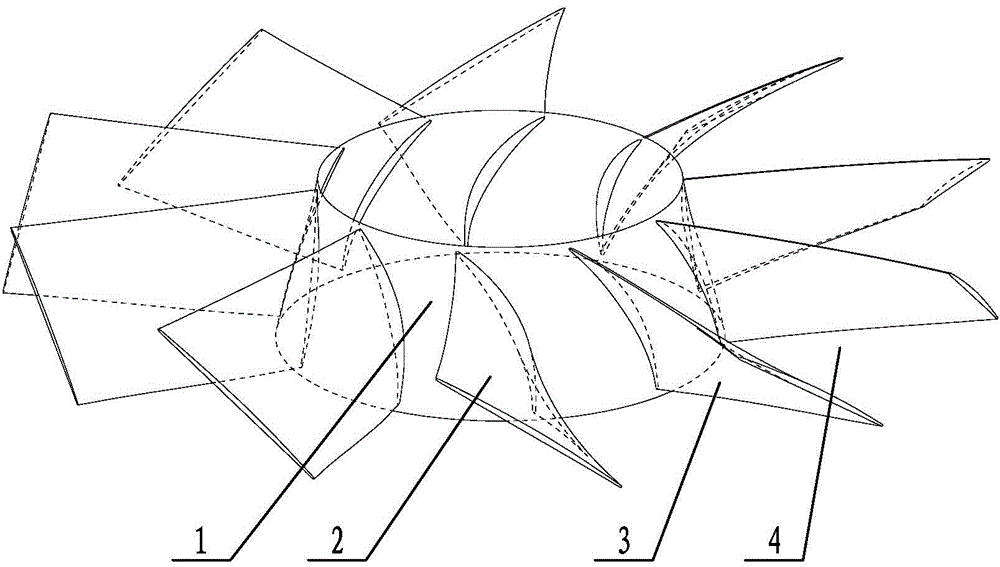

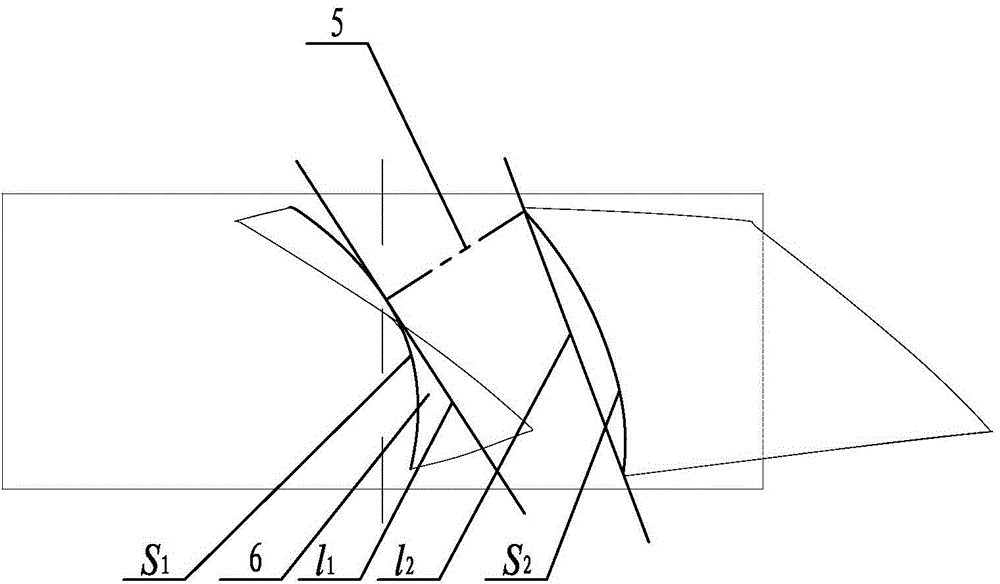

A method for milling and slotting an open blisk

InactiveCN103586518BSimplify channel spaceDoes not affect the processingMilling equipment detailsFree formMaterial removal

The invention discloses a method for disc-milling grooving processing on an open-type blisk. The method solves the problem that the existing open-type blisk channel rough grooving process has a large material removal amount and low processing efficiency, and produces interference between a cutter and a free-form surface blade because of narrow and deep grooving channels so that the cutter is worn easily. The method comprises the following steps of planning an open-type blisk channel grooving area, calculating a blade interference control line, calculating a channel grooving critical line, acquiring a channel grooving reachable processing area, planning a cutter position track, selecting disc-milling cutter geometrical parameters, and carrying out channel grooving disc-milling. The method is suitable for open-type blisk grooving disc-milling.

Owner:HARBIN UNIV OF SCI & TECH

Reduction gearbox machining process

The invention relates to the technical field of reduction gearboxes, and discloses a reduction gearbox machining process which comprises the machining of the main surface of a reduction gearbox, the plane machining of a box body, the machining of a main shaft hole and the machining of a hole system. According to the reduction gearbox machining process, a tool is simple in structure, a machine tool is convenient to adjust, a plurality of tool rests can be used on a gantry side machine tool, a plurality of surfaces can be machined at the same time in one-time workpiece installation, therefore, the position precision of the surfaces is economically guaranteed, the production rate of box plane milling is higher than that of planing, milling is often adopted in batch production. When the batch is large, a plurality of planes are commonly machined on a multi-shaft planer type milling machine by using a plurality of milling cutters at the same time, so that the position precision between the planes is ensured, and the productivity is also improved.

Owner:无锡市聚英机械制造有限公司

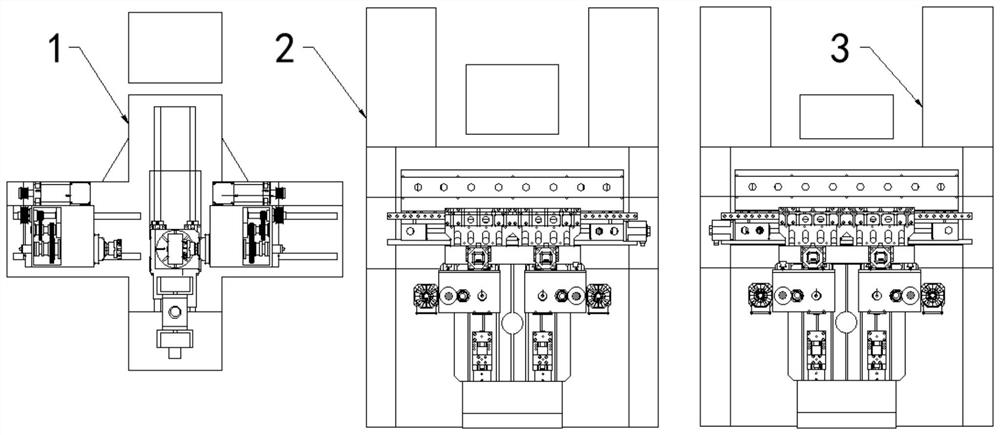

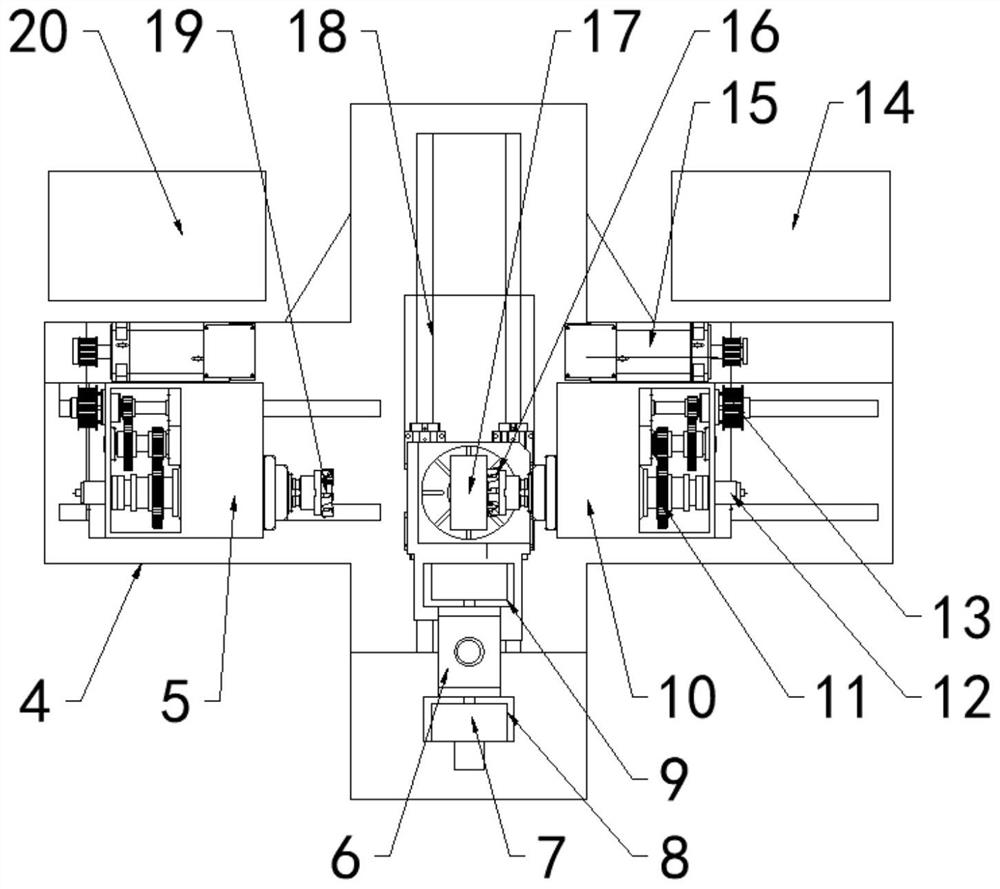

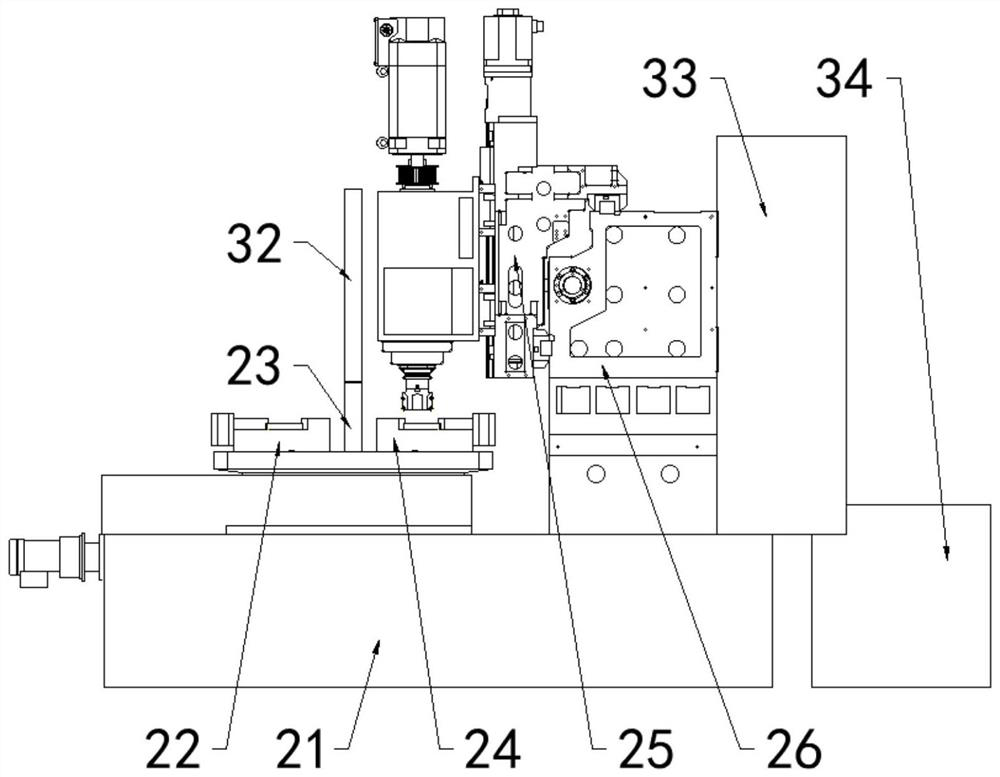

Intelligent machining production line for movable and fixed plates of elevator

PendingCN112872830AReduce the number of clampingImprove processing efficiencyAutomatic control devicesFeeding apparatusNumerical controlProduction line

The invention discloses an intelligent machining production line for movable and fixed plates of an elevator. The intelligent machining production line comprises a numerical control four-side milling machine, a first numerical control milling and boring machine and a second numerical control milling and boring machine. The numerical control four-side milling machine comprises a first machine body, and a first main shaft and a second main shaft are installed on the first machine body. A main motor used for driving the first main shaft and the second main shaft to rotate is installed on the first machine body. The numerical control four-side milling machine is used for milling and grinding the periphery of a workpiece or chamfering the periphery of the workpiece, the workpiece is manually placed into the first numerical control milling and boring machine to mill and grind the upper end face and the lower end face of the workpiece, and the workpiece is manually transferred into the second numerical control milling and boring machine to excavate coil grooves in the workpiece. The production line is composed of three pieces of equipment, and a hydraulic clamp and an exchange workbench are adopted, so that the workpiece clamping frequency, the equipment number and operators are greatly reduced. The production line only needs to be operated by three persons, the production efficiency is greatly improved, the production cost is reduced, and the workpiece machining efficiency is improved.

Owner:南京速锋数控技术有限公司

Deep hole machining process

ActiveCN102744561BSimplify processing stepsEasy to operateTransportation and packagingReaming toolsNumerical controlEngineering

The invention discloses a deep hole machining process. The deep hole machining process includes: step one, drilling: machining deep holes to be machined on a numerical control machine tool by a connecting rod drill; step two, broaching: replacing a cutting drill of the connecting rod drill in the step one with a broach drill, and then machining drilled holes obtained in the step one by the numerical control machine tool; and step three, reaming: machining holes obtained in the step two on the numerical control machine tool by a long-rod reamer. The connecting rod drill comprises the cutting drill, a first handle, and a first connecting rod mounted between the cutting drill and the first handle coaxially. The long-rod reamer comprises a reamer head, a second handle, and a second connecting rod mounted between the reamer head and the second handle coaxially. The deep hole machining process is simple in steps, simple and convenient in actual operation, low in input cost, high in machining quality and quick in machining speed, and the problems that machining is inconvenient, actual operation is not easy to control, machining efficiency is low, machining precision is hard to guarantee and the like in the existing deep hole machining process by drilling prior to boring can be solved effectively.

Owner:XIAN COAL MINING MACHINERY

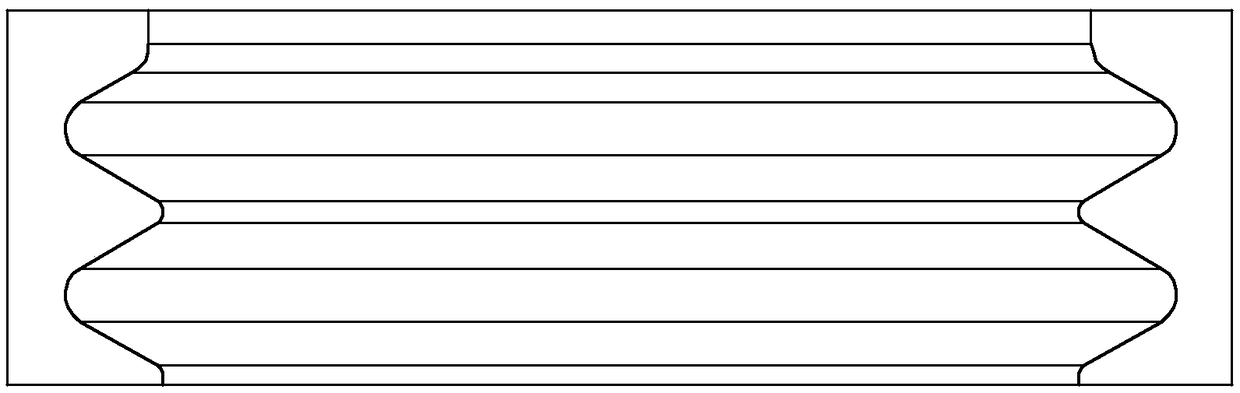

Equal-diameter dust cover mould machining method

The invention provides an equal-diameter dust cover mould machining method. In the method, ball-end cutters are adopted for plunge milling of the corrugated surfaces of an upper mould and a lower mould. According to the equal-diameter dust cover mould machining method, primary machining is performed on an upper mould plate and a lower mould plate through 3d modeling, the uniformity of the machining allowance of each corrugation on the corrugated surfaces of the upper mould and the lower mould is guranateed, subsequent finish machining is facilitated, and the machining quality is improved; milling of an upper mould and a lower mould is performed through 3d modeling protection reference lines, a machine tool does not need to slow down or stop in the finish machining process, in the finish machining process, it is only needed to gather the first ball-end cutter and the second ball-end cutter, cutter connecting marks can be easily reduced, the sanding difficulty can be lowered, and the working efficiency can be improved.

Owner:安徽宁国中鼎模具制造有限公司

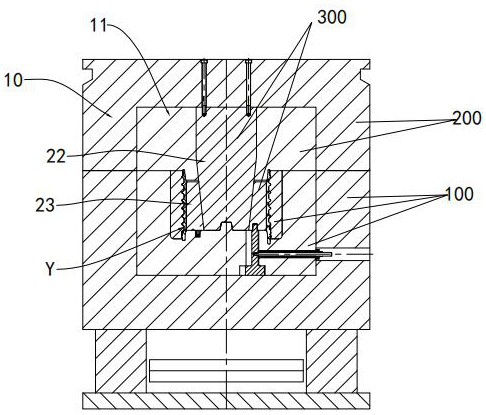

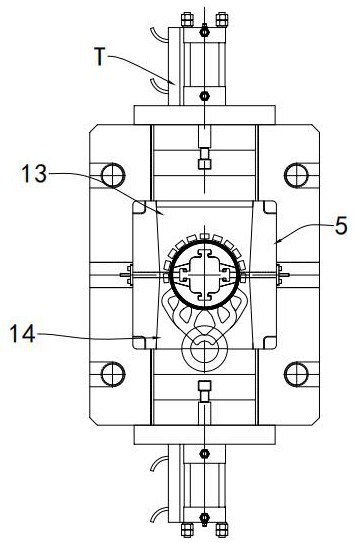

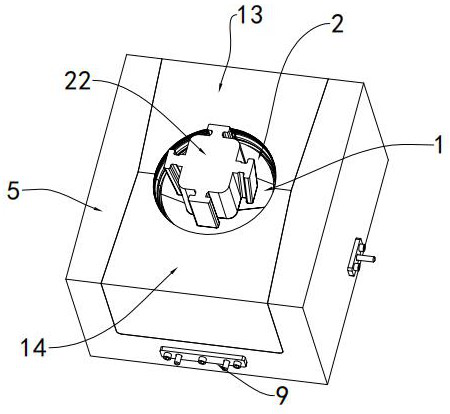

Die casting mold and method of use for aluminum die casting with center hole

The invention discloses a die-casting mold of an aluminum die-casting with a center hole and a use method thereof, comprising a movable mold assembly, a fixed mold assembly and an inner core assembly; The inner slider assembly around the parts, the inner slider assembly includes at least two groups of first inner slider and second inner slider that are laterally fitted and can move radially; the inner wall of the first inner slider and the inner drawer The included angle α between the axes of the parts, the included angle β between the inner wall of the second inner slider and the axis of the inner drawer, the included angle α is greater than the included angle β; the first inner slider and the second inner slider The side walls are matched by a radial slope structure, and the radial slope structure can make the first inner slider move inward relative to the second inner slider; in the second state, the inner drawer is drawn away from the center cavity of the inner slider assembly, The first inner slider and the second inner slider contract inwardly so that the outer walls of each inner slider are away from the inner hole of the aluminum die casting.

Owner:IKD CO LTD

Method for machining roller by adopting nine-axis machine tool and roller produced by using method

ActiveCN111390505AHigh precisionGuaranteed machining accuracyDomestic articlesMilling equipment detailsMilling cutterCnc grinding

The invention relates to a method for machining a roller by adopting a nine-axis machine tool and the roller produced by using the method. The method comprises the following steps that S1, a round baris taken and is machined into a stepped shaft by using a lathe, and grinding is carried out on the maximum-diameter part of the stepped shaft by using a numerical control grinding machine; S2, a milling cutter in the nine-axis machine tool is used for dynamically roughing the stepped shaft to machine protruding structures, and secondary dynamic roughing is conducted on the stepped shaft to guarantee that the machining allowances reserved for finish machining of the protruding structures are uniform and consistent; S3, inner and outer side positions, shapes and inclination angles of the protruding structures on the stepped shaft are corrected by using spherical milling cutters with gradually reduced diameters in sequence so that the protruding structures can be machined and formed at a time; and S4, after machining of the protruding structures is completed, a turning tool is used for back chipping of filleted corners, milled through the spherical milling cutters, of the stepped shaft.According to the method for machining the roller by adopting the nine-axis machine tool and the roller produced by using the method, through cooperation of multi-axis linkage, dynamic roughing and themulti-diameter spherical milling cutters of the nine-axis machine tool, one-time part clamping type one-time forming for machining of the roller is achieved, the precision is improved, and the production cycle is shortened.

Owner:安徽天航机电有限公司

A milling and slotting processing method for high-temperature alloy integral leaf ring blade parts

The invention belongs to the field of machining, and particularly relates to a milling grooving machining method for a high-temperature alloy integral blade ring and blade part. The method comprises the machining steps of air inlet end pre-drilling, cavity milling of a blade back at the air inlet end, cavity milling of a blade basin at the air inlet end, milling of an air inlet end flow channel and back chipping, exhaust end pre-drilling, cavity milling of a blade basin at the exhaust end, cavity milling of a blade back at the exhaust end, and milling of an exhaust end flow channel and back chipping. The milling grooving machining method for the high-temperature alloy integral blade ring and blade part, the milling modes of driving a fixed shaft through multiple vectors for layering and sectional connecting are adopted, and a common end milling cutter is applied to realize rough grooving machining of uniform allowance.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A processing method for controlling processing deformation of titanium-aluminum alloy thin-wall casing

The invention relates to a processing method for controlling processing deformation of a titanium-aluminum alloy thin-wall case. The technical scheme of the processing method is as follows: the processing method comprises the steps as follows: a primary rough turning process, a primary heat treatment process, a secondary rough turning process, a secondary heat treatment process, a fine turning process, a third heat treatment process and a finish turning process. According to the processing method for controlling the processing deformation of the titanium-aluminum alloy thin-wall case, reasonable processing parameters are set, and an appropriate cutter is used, so that the processing deformation of the titanium-aluminum alloy thin-wall case is controlled, and the processing requirement is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

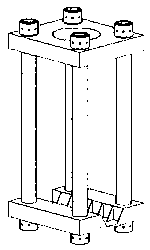

Special grinding machine for ground finish of crystal silicon square billet

InactiveCN101612716BWide range of processingAdaptableEdge grinding machinesPlane surface grinding machinesEngineeringManipulator

The invention relates to a special grinding machine for the ground finish of a crystal silicon square billet, comprising a base on which a guide rail and a worktable are arranged, a first lateral grinding power head, a second lateral grinding power head, a first chamfering mechanism, a second chamfering mechanism, a carrying mechanical hand and an overturning platform. The invention has the advantages that multiple times of clamping are dispensed with, the production efficiency and the machining accuracy are high, and the defective rate is low.

Owner:ZHEJIANG UNIV OF TECH

Method for processing rolls with nine-axis machine tool and rolls produced by the method

ActiveCN111390505BIncrease frictionHigh precisionDomestic articlesMilling equipment detailsConvex structureMilling cutter

The present invention relates to a method for processing rollers using a nine-axis machine tool and the rollers produced by the method, comprising the following steps: the first step: take a round bar, process it into a stepped shaft through a lathe, and measure the maximum diameter of the stepped shaft through a CNC grinder The second step: use the milling cutter in the nine-axis machine tool to perform dynamic roughing on the stepped shaft to process the raised structure, and perform a second dynamic roughing on the stepped shaft to ensure that it remains for the finishing of the raised structure The machining allowance is uniform; the third step: use the spherical milling cutter with gradually decreasing diameter to correct the inner and outer positions, shapes and inclination angles of the raised structure on the stepped shaft so that the raised structure can be processed at one time; the fourth step: the convex After the machining of the lifting structure is completed, use the turning tool to clean the fillet of the stepped shaft milled by the ball milling cutter. The invention utilizes the multi-axis linkage of the nine-axis machine tool, dynamic roughing and the cooperation of multi-diameter spherical milling cutters to process the rollers to realize one-time clamping and one-time molding of parts, improve precision and reduce production cycle.

Owner:安徽天航机电有限公司

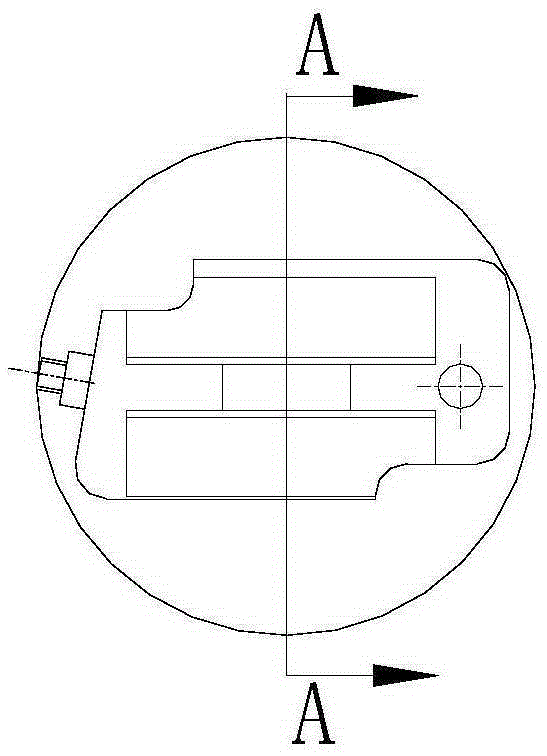

Near net forming method of extra-large bearing iron retainer

InactiveCN110625056AAct as a constraintGuaranteed geometric toleranceForging/hammering/pressing machinesEngine componentsRoll formingMachining

The invention discloses a near net forming method of an extra-large bearing iron retainer. The method comprises the following steps that S1, a ring piece is pre-ground into a rectangular ring piece, acore roller forming die penetrates through an inner hole of the ring piece, and positioning is completed; S2, the core roll forming die drives the ring piece to gradually attached to a main roller forming die, and a ring grinding rolling system is established; S3, the ring piece enters a cavity of the main roller forming die, the upper end face and the lower end face of the ring piece are restrained through blocking edges on the two sides, and the core roller forming die extrudes the ring piece to be gradually attached to the main roller forming die; and S4, under the extrusion action of themain roller forming die and the core roller forming die, the wall thickness of the ring pieces is gradually reduced, the inner diameter and the outer diameter of the ring piece are gradually increased, and finally the ring piece is ground and formed. According to the method, by adopting the idea of near net forming, the shape contour of a retainer forged piece is designed to be approximate to thecontour of a finished product, the overall machining allowance of the product is uniform, material saving is maximized, meanwhile, the subsequent machining amount is reduced due to the reduction of the allowance, and the machining cost is reduced.

Owner:江苏翔能科技发展有限公司

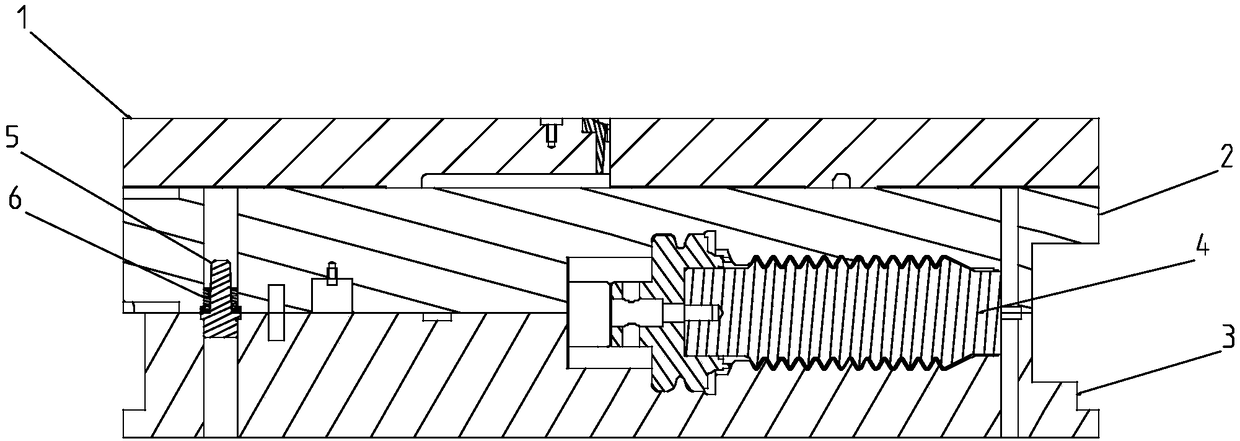

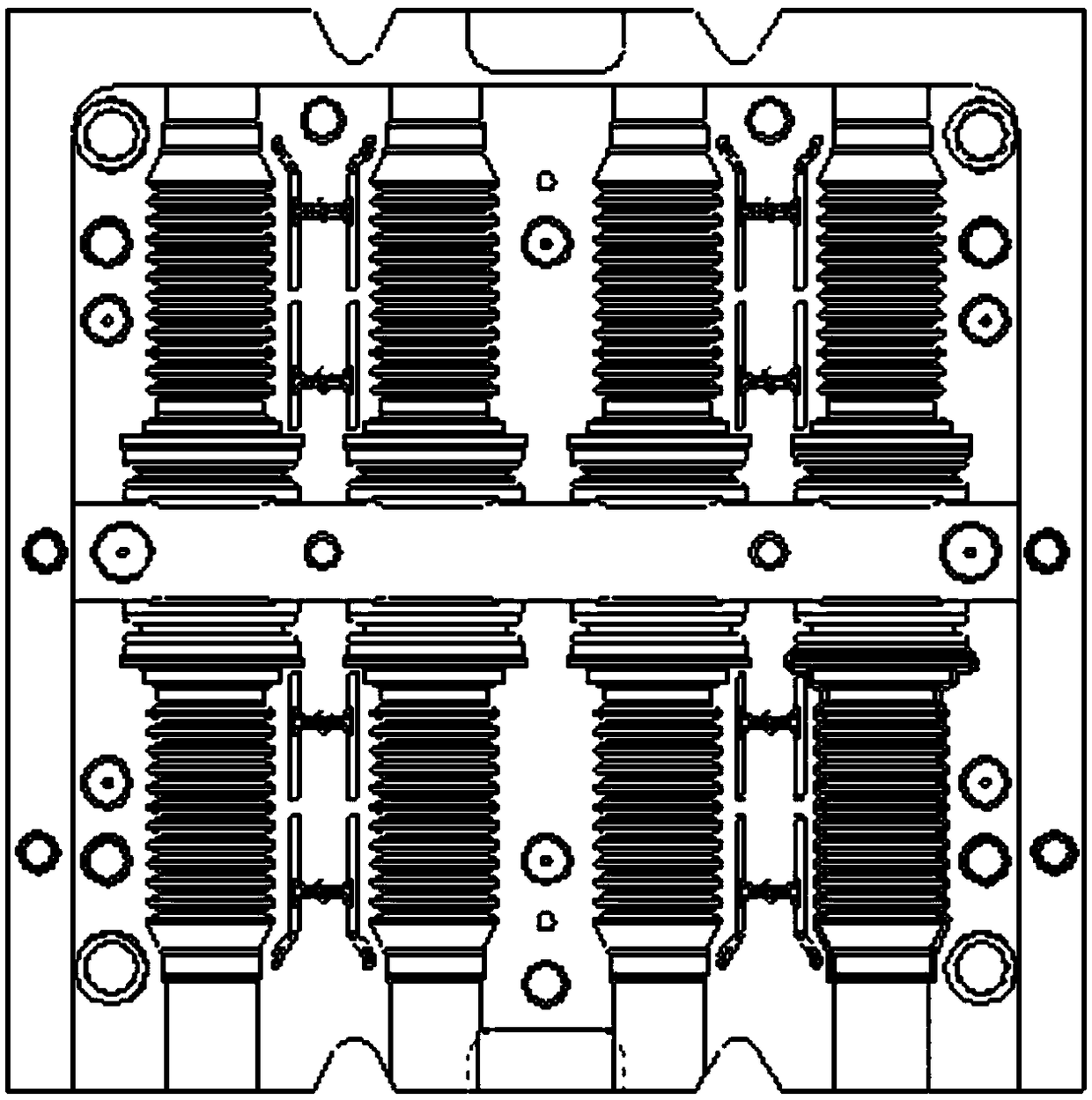

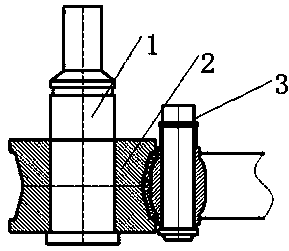

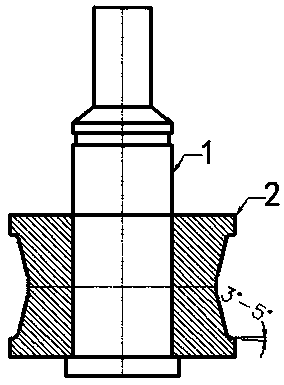

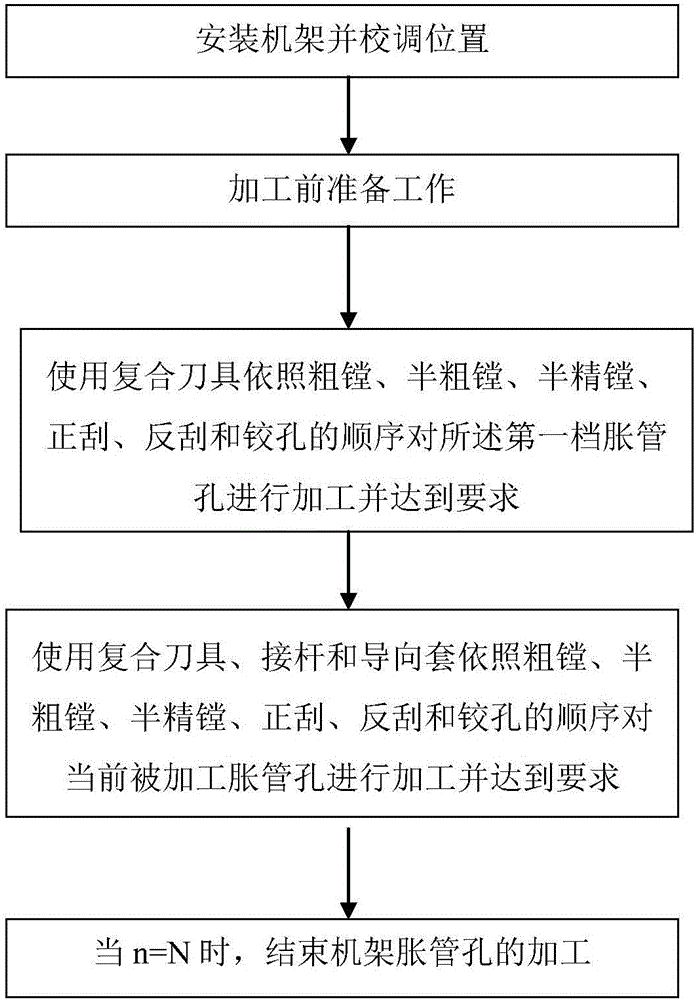

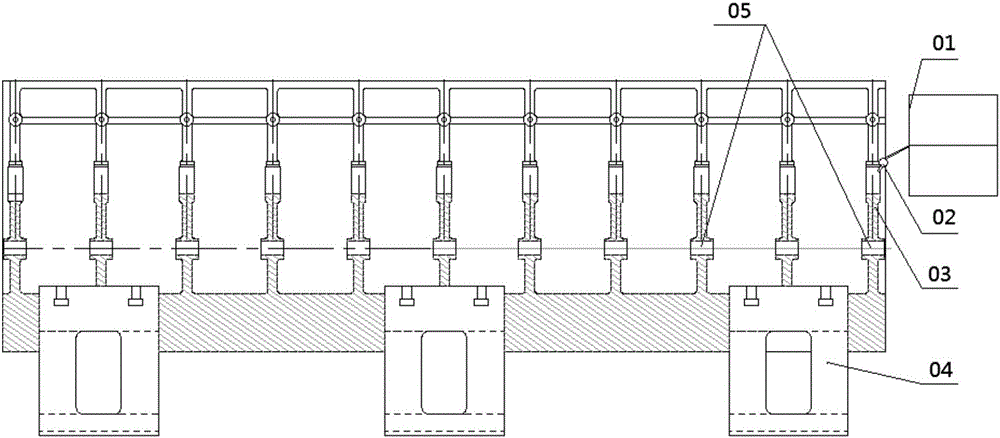

Machining method for tube expansion hole of diesel engine rack

ActiveCN106695257AReduce the number of installationsReduce positioning errorsBoring/drilling machinesEngineeringDiesel engine

The invention relates to a machining method for a tube expansion hole of a diesel engine rack, wherein the rack comprises N coaxial tube expansion holes. The machining method is characterized in that through adopting a compound tool formed by combining at least two hole machining tools and being in combination with the supporting effect of a guide sleeve mounted in machined tube expansion holes on a tool bar, the machining of the tube expansion holes in different working procedures can be completed at the same working station; the machining method comprises the following specific steps: 1) mounting the rack and correcting the position; 2) preparing before machine; 3) using the compound tool to machine first tube expansion holes according to the sequence of rough boring, semi-rough boring, semi-fine boring, forward scraping, reversed scraping and reaming to meet the requirements; 4) using the compound tool, an extension rod and the guide sleeve to machine tube expansion holes to be machined one by one according to the sequence of rough boring, semi-rough boring, semi-fine boring, forward scraping, reversed scraping and reaming to meet the requirements till the machining of all tube expansion holes of the rack is completed. The machining method for the tube expansion hole of the diesel engine rack improves the machining efficiency, enhances the rigidity of the tool system, ensures the machining accuracy, and is suitable for machining of high precision deep holes like the tube expansion holes of the diesel engine rack.

Owner:HUDONG HEAVY MACHINERY

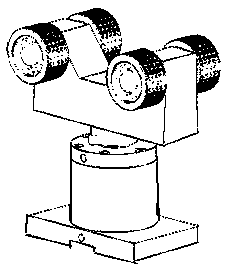

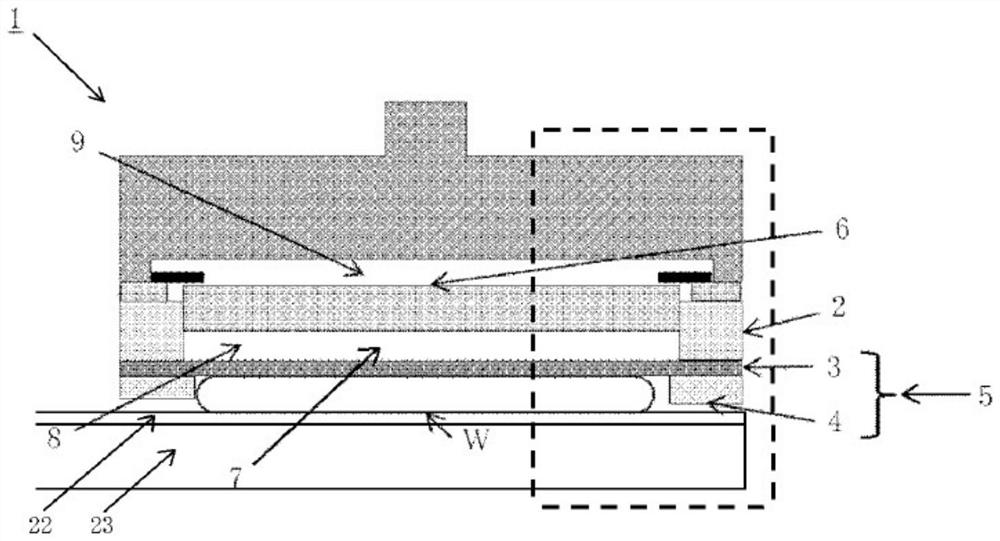

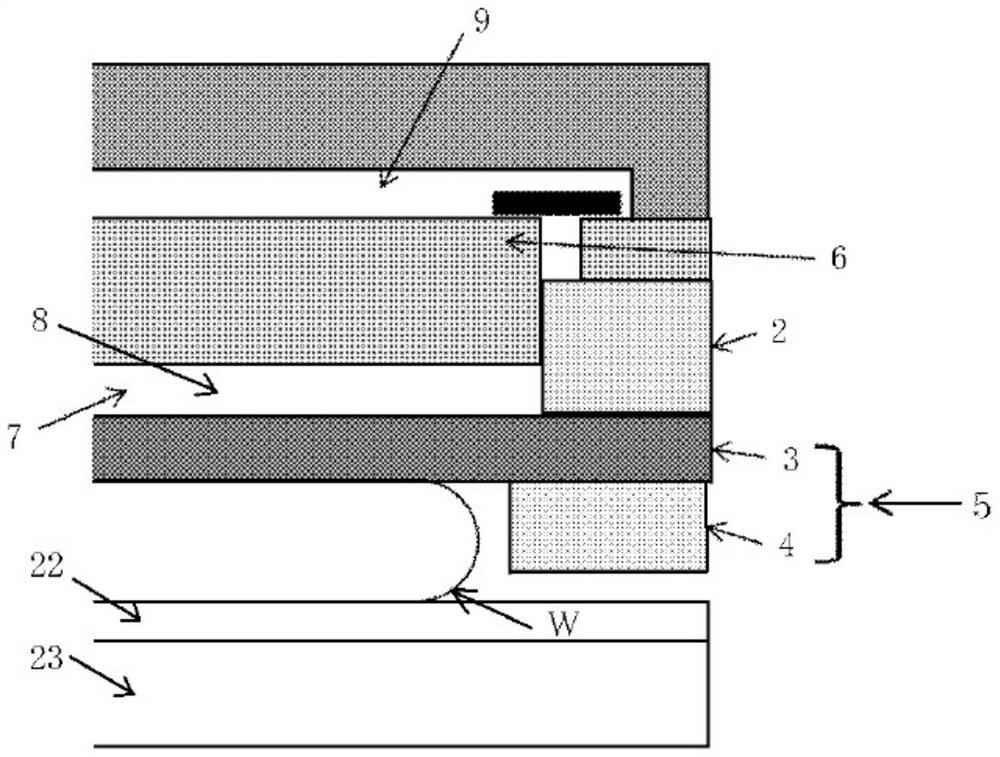

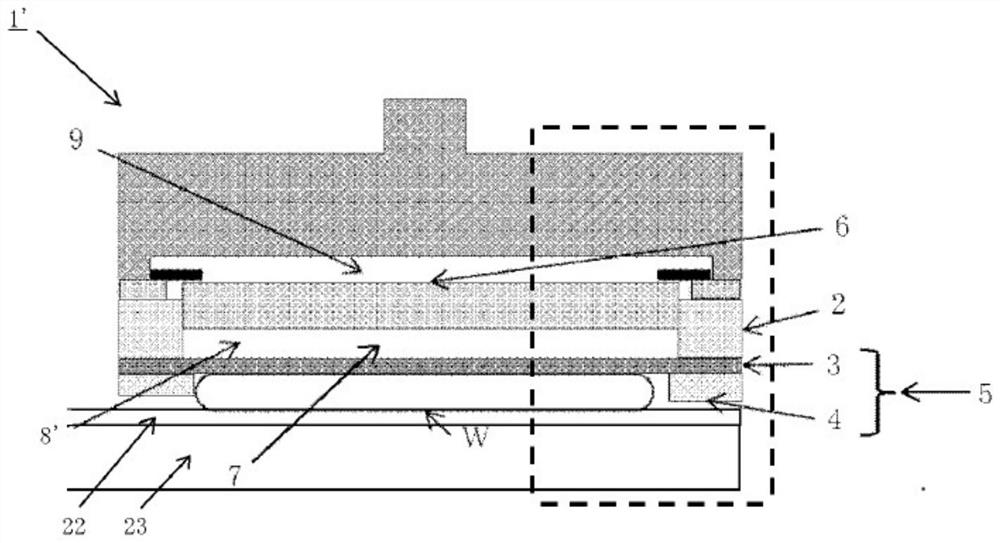

Polishing head and wafer polishing method

PendingCN111971146AUniform machining allowanceReduce local deformationSemiconductor/solid-state device manufacturingWork carriersWaferViscosity

The polishing head comprises at least: an annular ceramic ring; a template which is adhered to the ceramic ring and in which a backing pad and a guide ring are integrated; and a backplate which is joined to the ceramic ring, and which forms a space together with the backing pad and the ceramic ring. The polishing head retains the back surface of a wafer on a bottom surface part of the backing pad,and polishes the top surface of the wafer by slidingly contacting the top surface to a polishing cloth that is adhered to a surface plate. The polishing head is characterized in that a non-compressive fluid is sealed in the space, and the viscosity of the non-compressive fluid is 10 to 1200 mPa.s. Due to the configuration, a polishing head and a polishing method are provided with which deformation of the backing pad occurring in a slight gap that is formed between the template and the wafer can be reduced, and the uniformity of polishing at the outermost peripheral section of the wafer can beimproved.

Owner:SHIN-ETSU HANDOTAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com