Patents

Literature

72results about How to "Reduce seams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reducing seam artifacts when applying a texture to a three-dimensional (3D) model

ActiveUS20090219281A1Minimize artifactReduce artifacts3D-image renderingComputational scienceDual graph

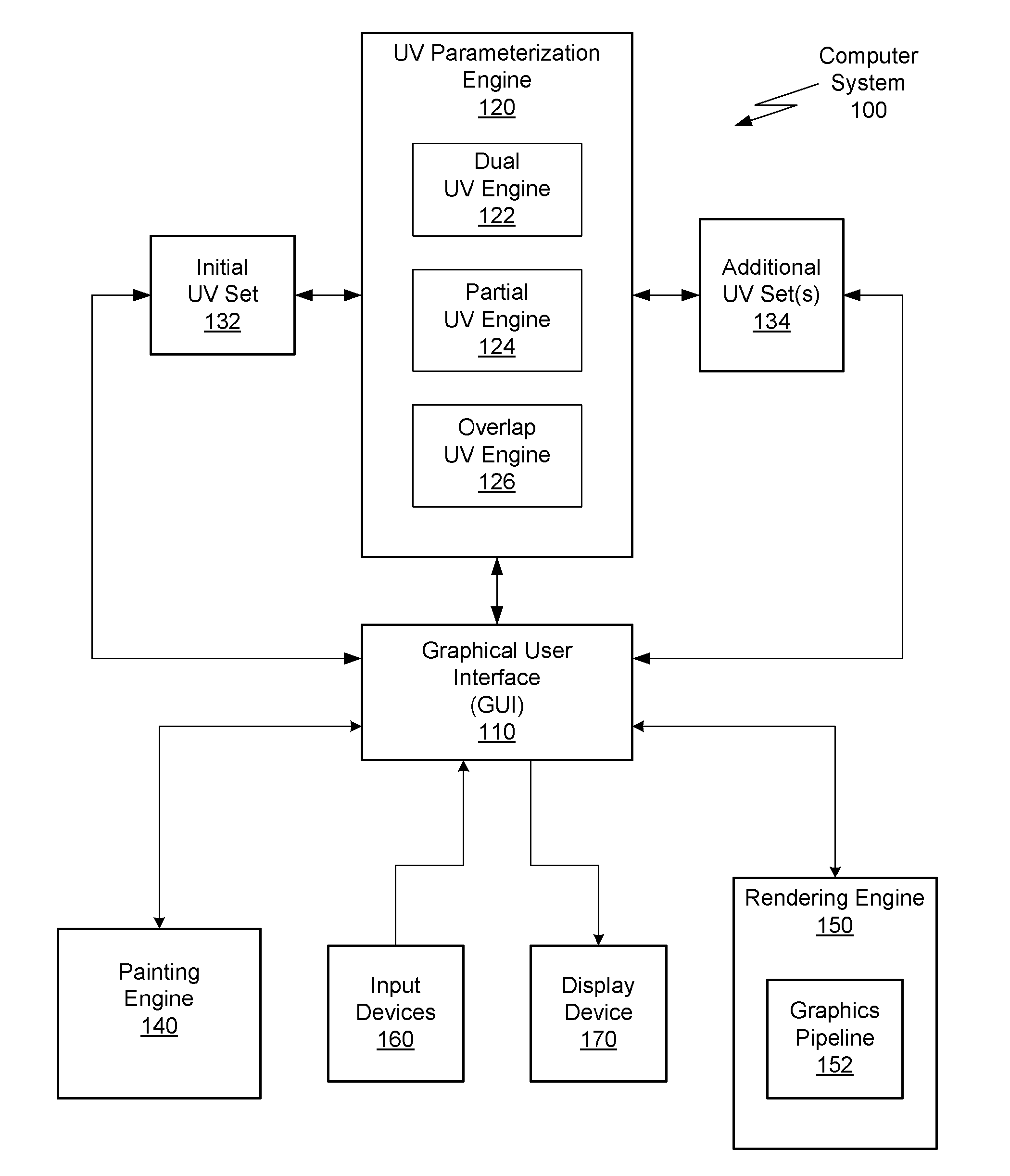

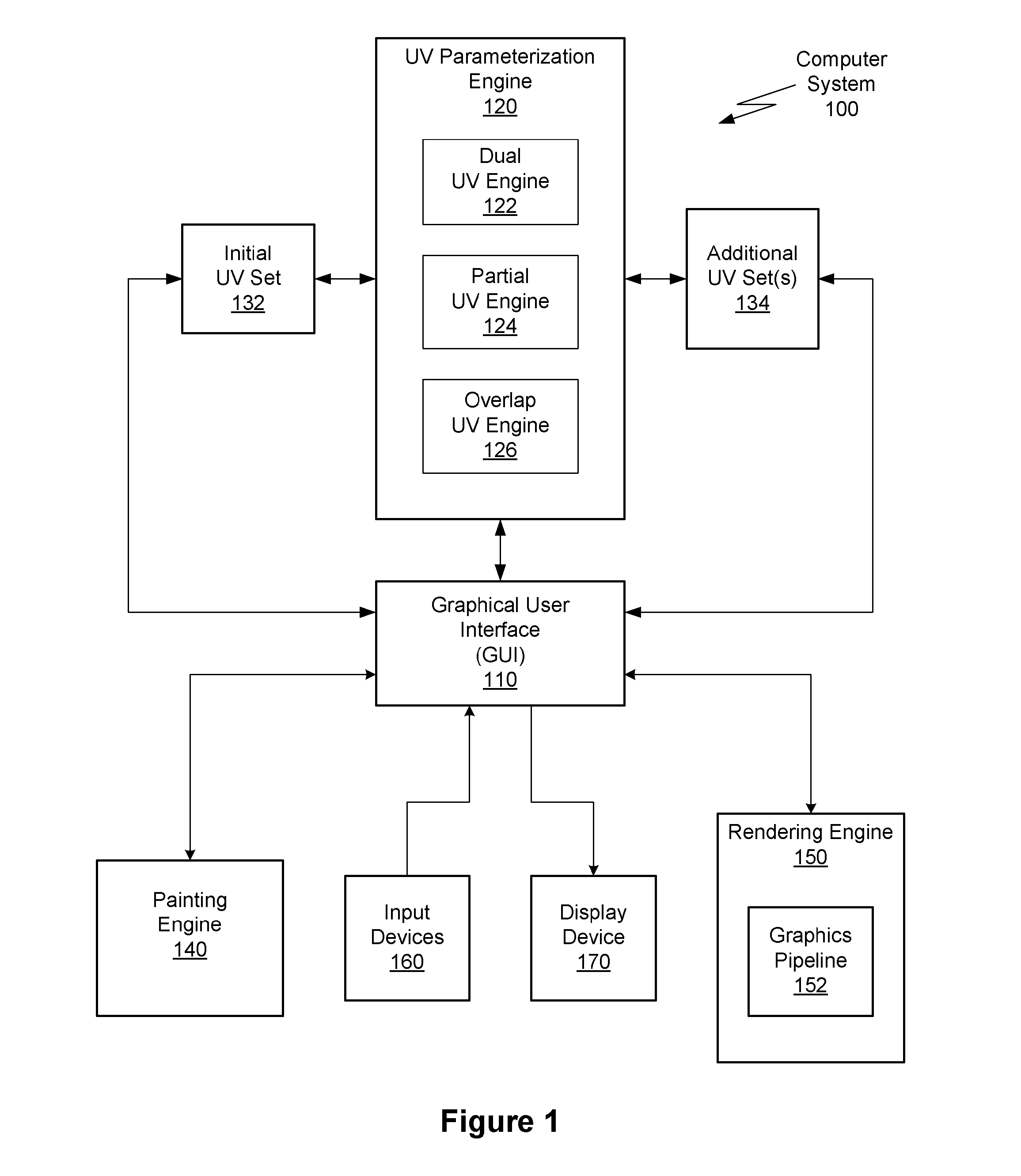

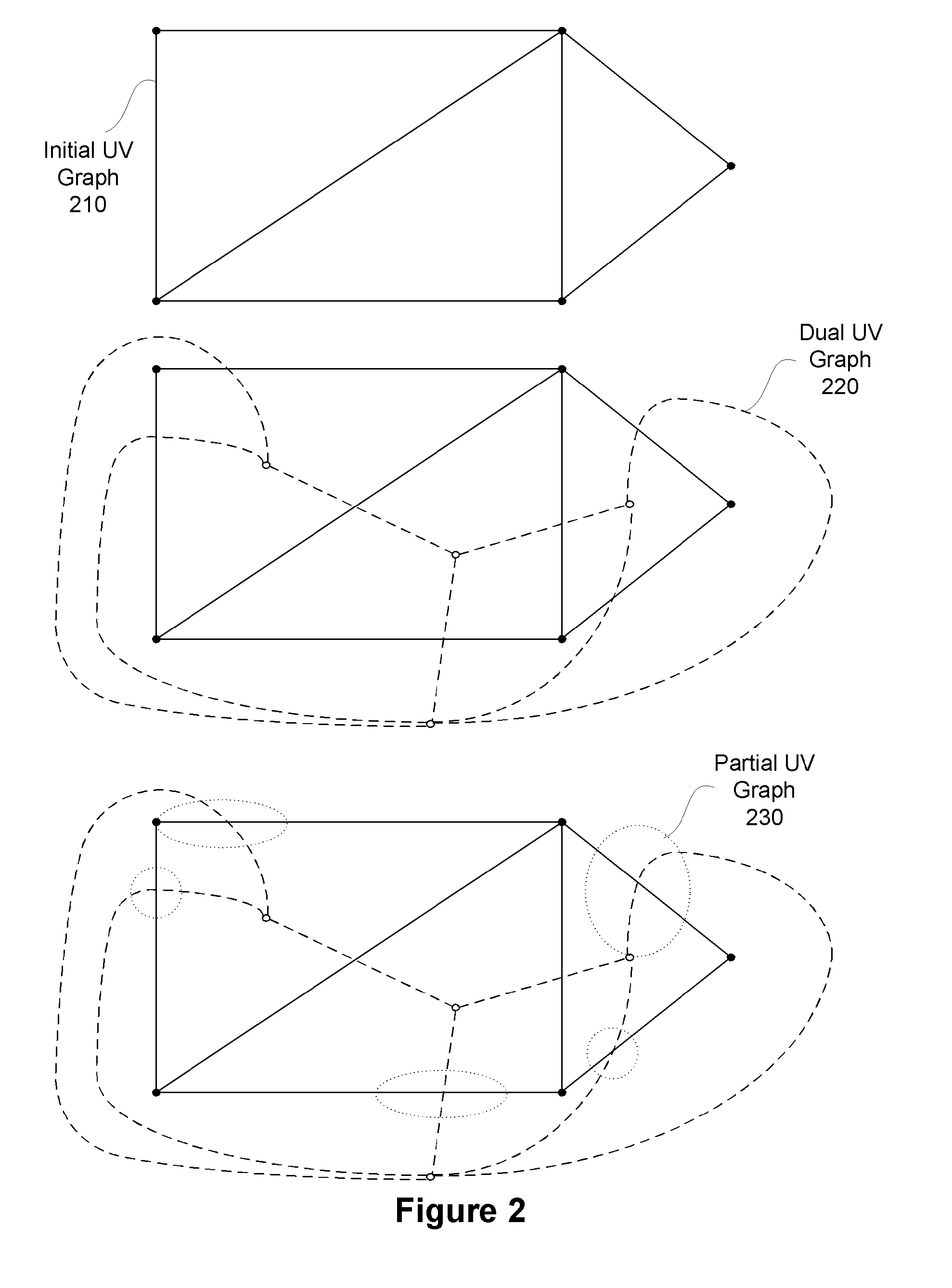

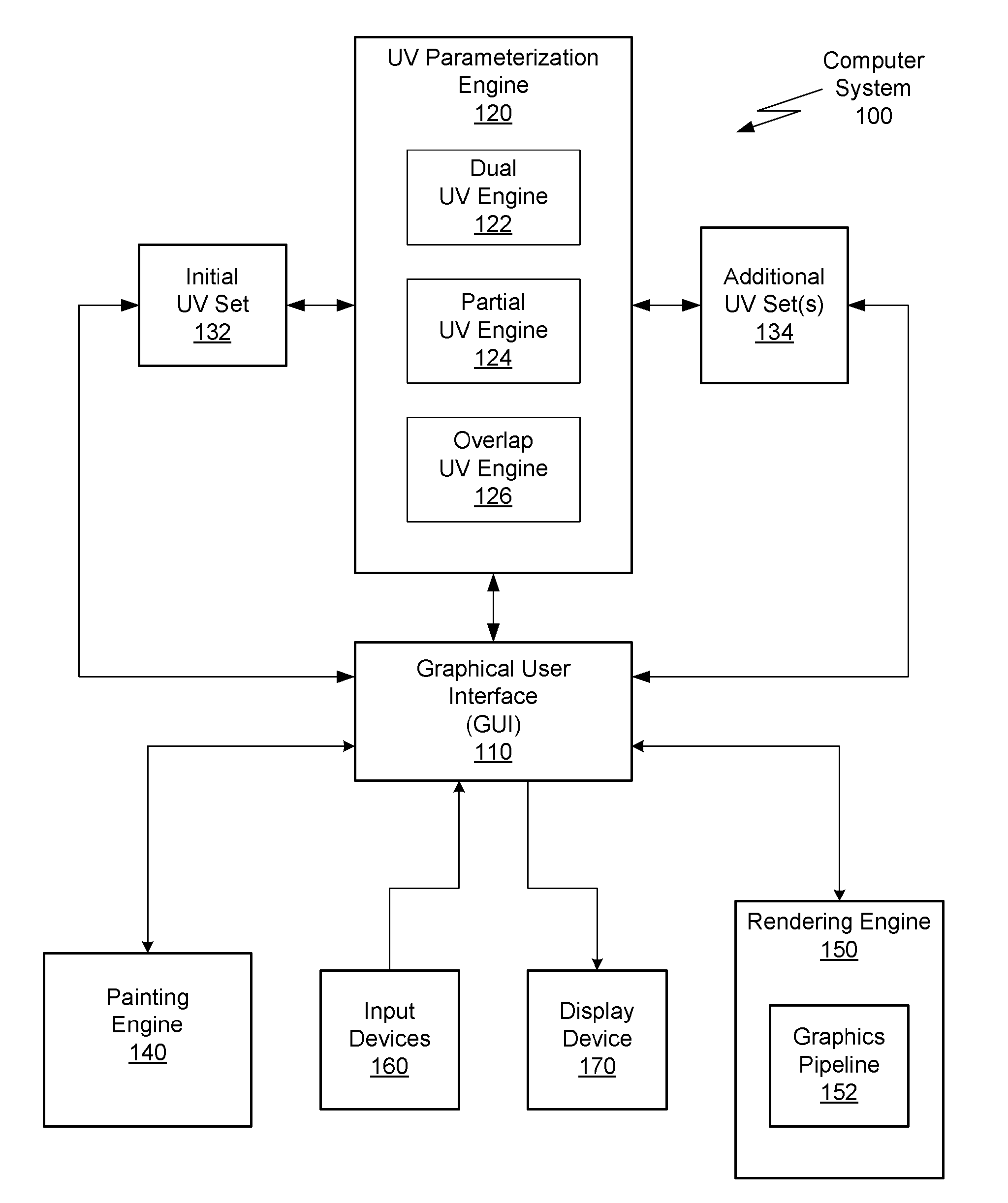

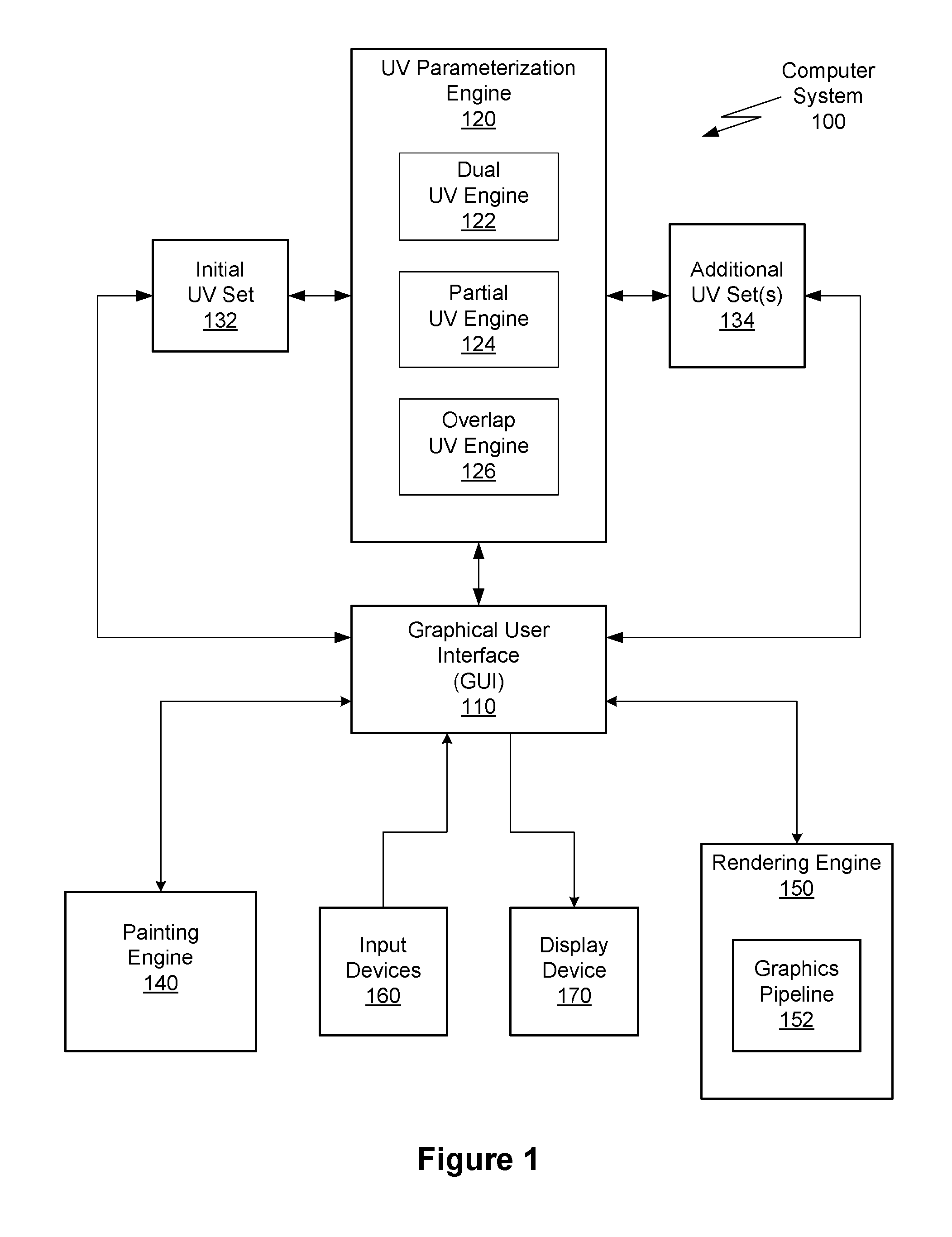

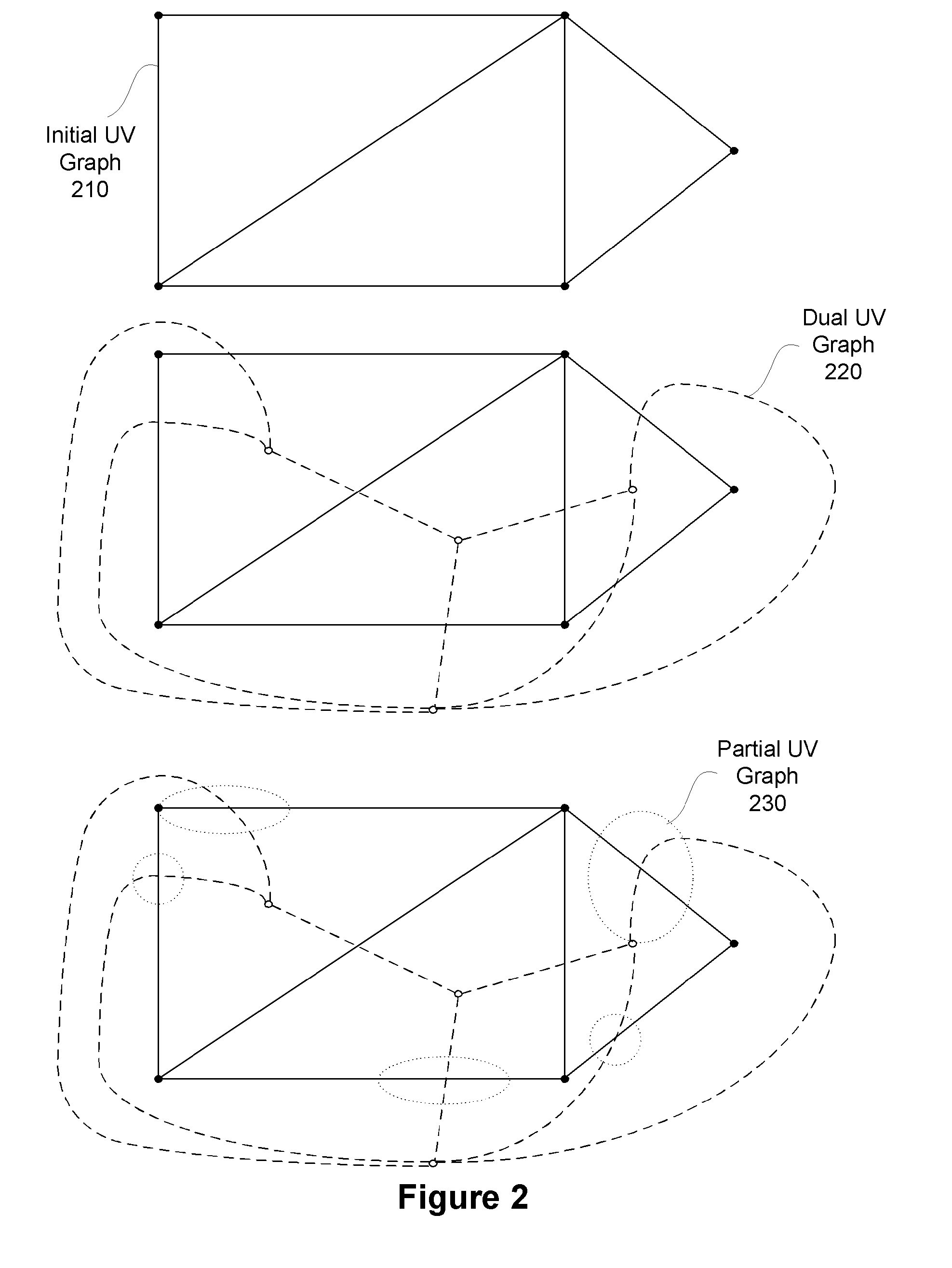

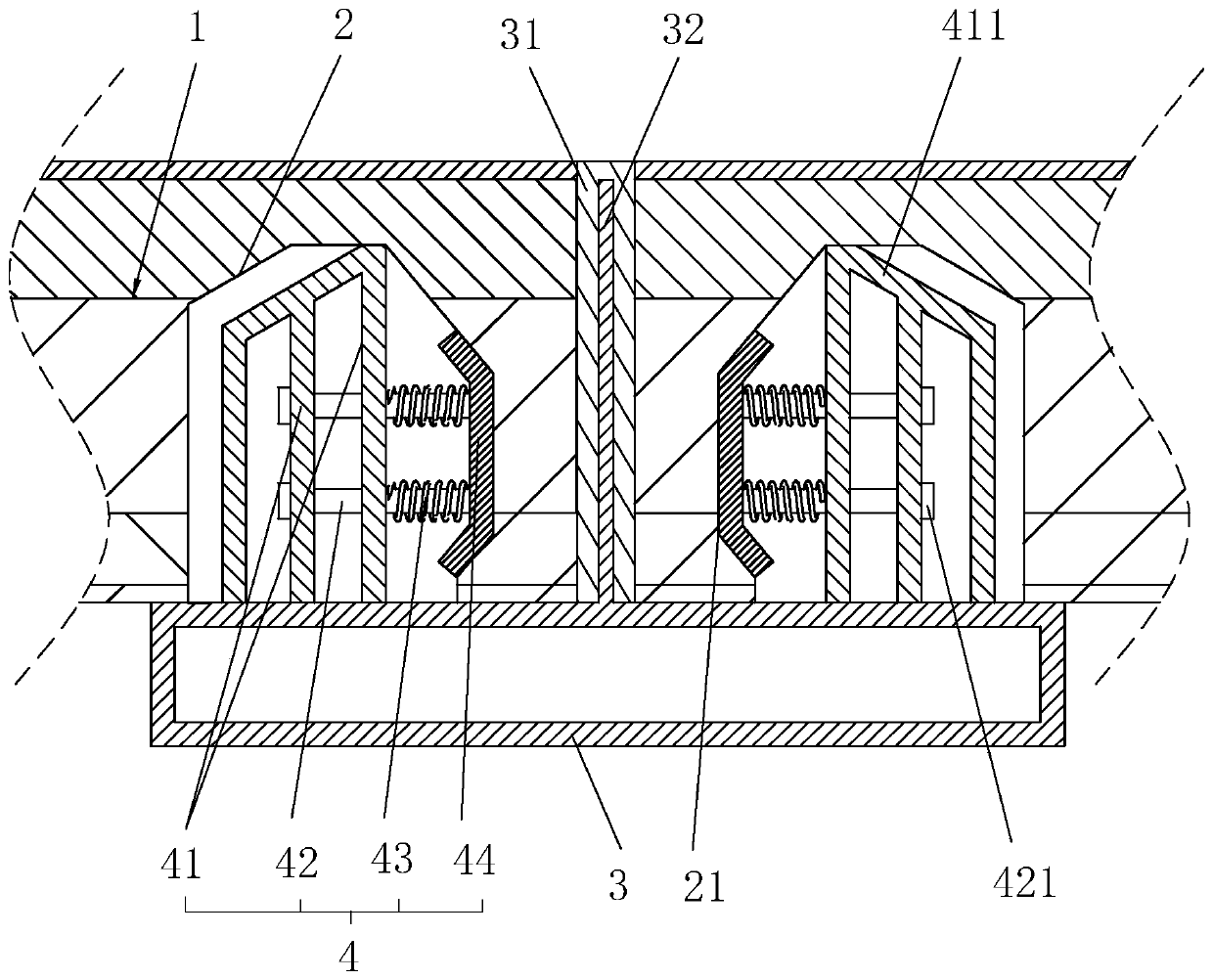

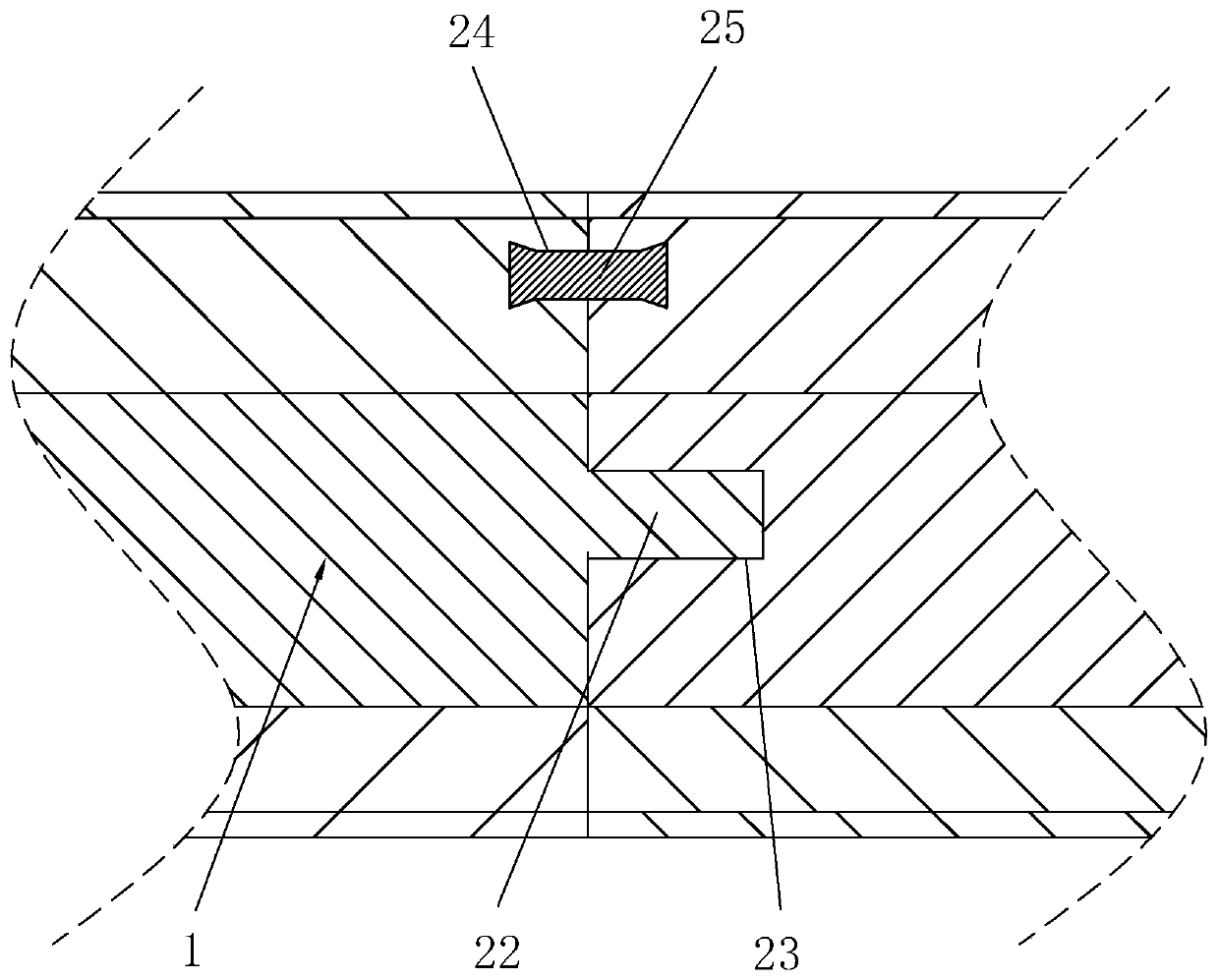

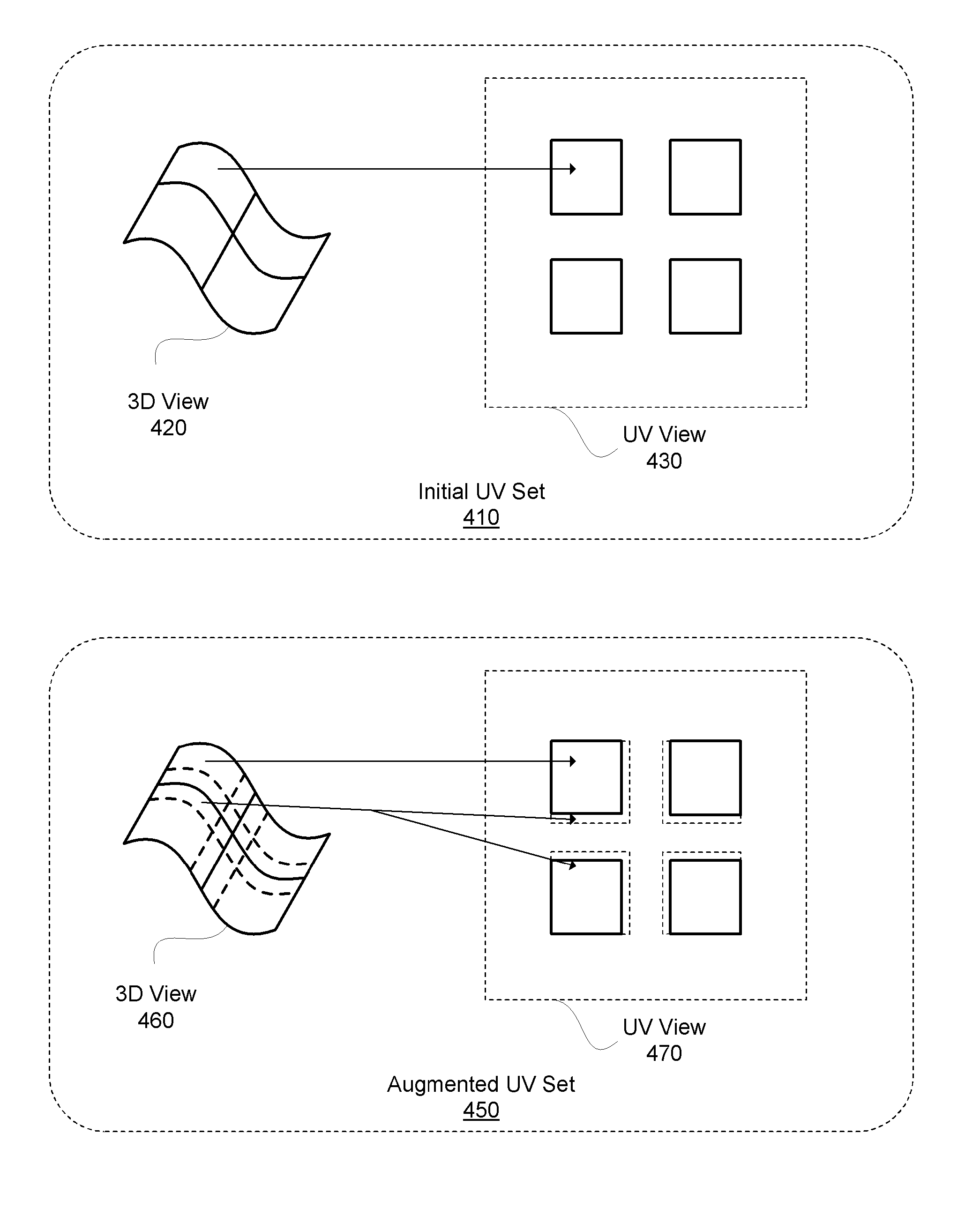

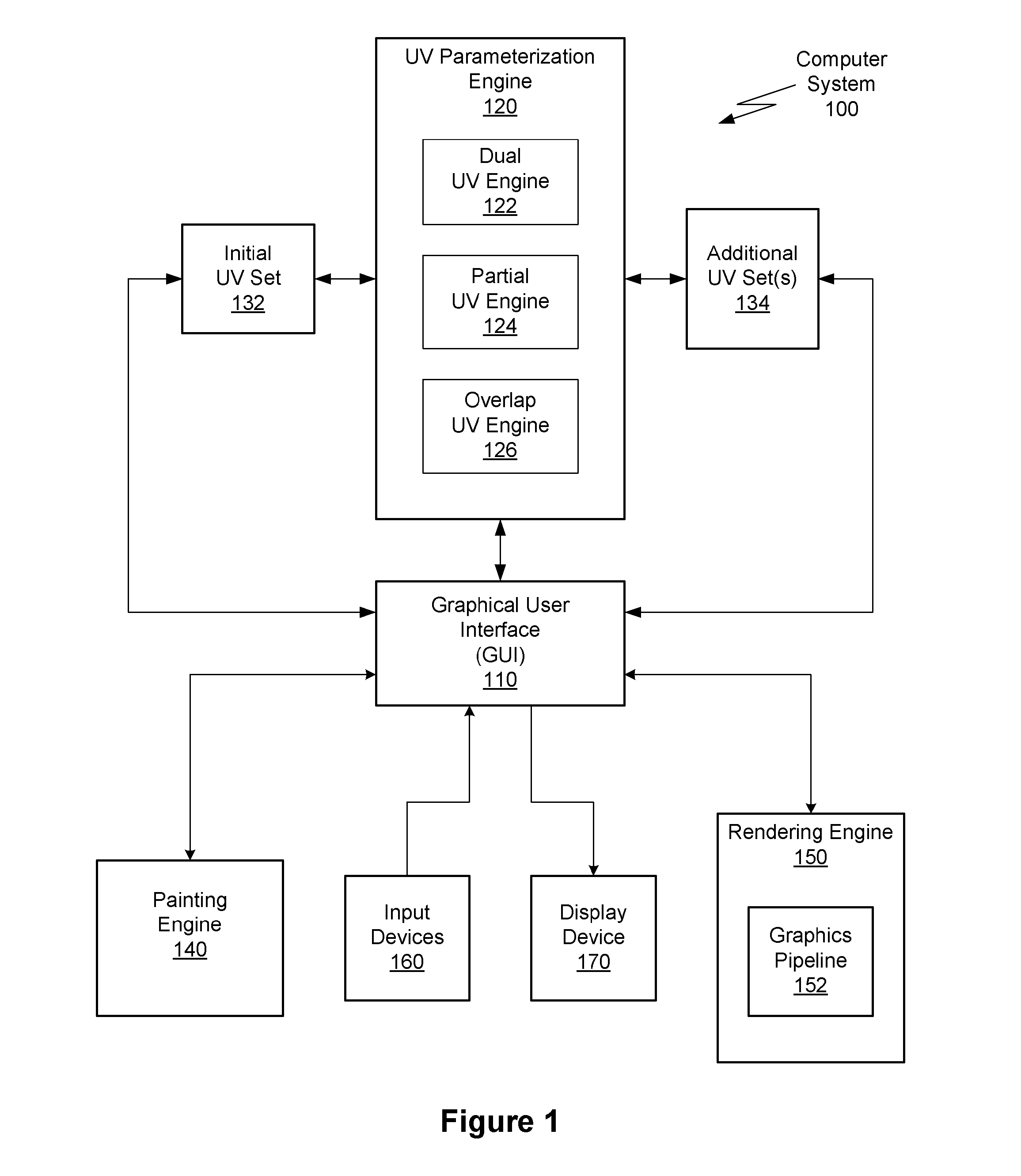

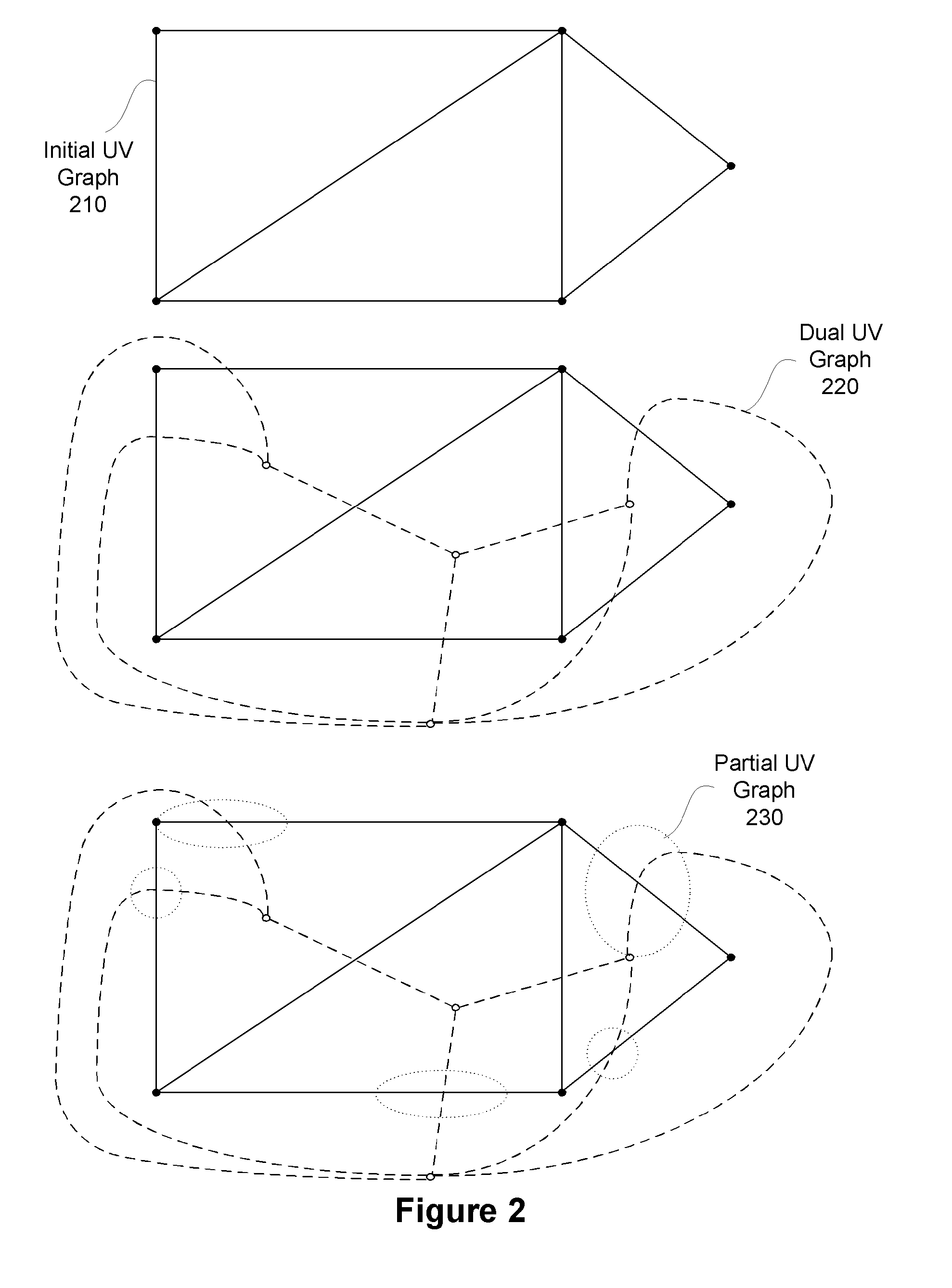

Embodiments of the present invention include techniques for reducing artifacts in rendered images. In one embodiment, a dual UV engine generates a dual of the graph defined by an initial UV set associated with a 3D model. The dual UV engine then uses existing flattening and layout engines to generate a dual UV set from this dual graph. Using the dual graph to define the dual UV set ensures that the seams corresponding to the initial UV set and the dual UV set minimally intersect.

Owner:AUTODESK INC

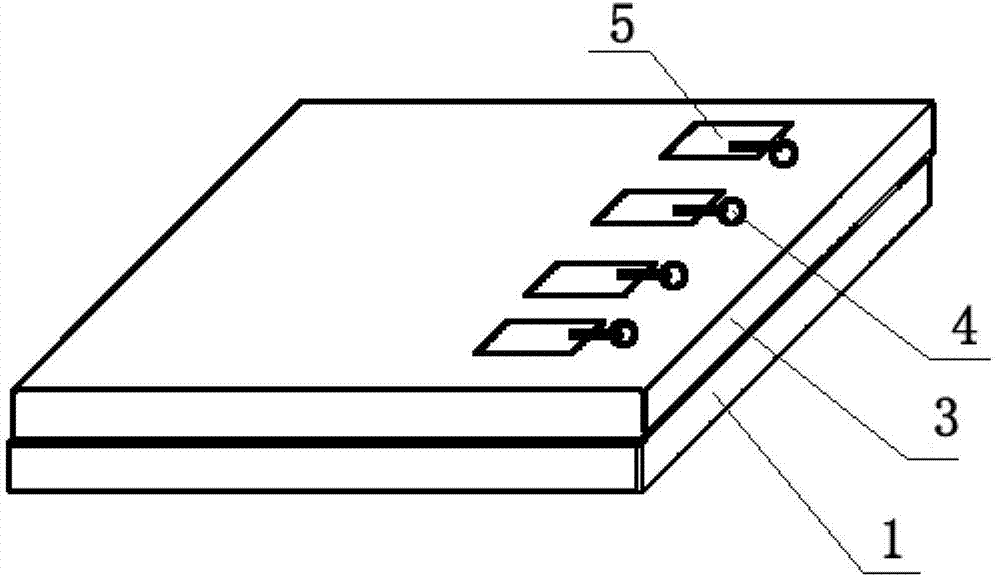

A single crystal short rod splicing method using diamond wire cutting

InactiveCN102294757AIncrease profitThere will be no pull-out phenomenonFine working devicesWire cuttingEngineering

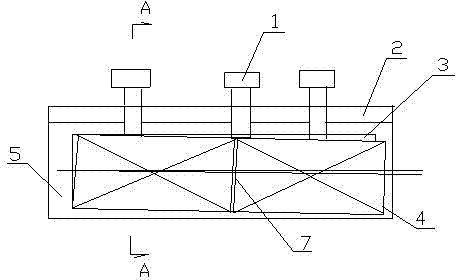

The invention discloses a single crystal short rod splicing method using diamond wire cutting. First, the end face of the single crystal silicon short rod is detected, and the flatness of the end face is required to be less than 0.3mm, and then the short rod is bonded by coating the end face with glue. After bonding, it is pressurized and solidified, and then the splicing rods are squared, end-face ground, and rolled. After passing the inspection, the splicing rods are cut into single-crystal silicon wafers in the slicing cabin. Make full use of all short monocrystalline silicon rods, greatly improve the utilization rate of short monocrystalline silicon rods, and reduce production costs. Since the splicing rods are not perpendicular to the diamond wire, the diamond wire does not need Adjusting the position of the wire cutting device can make the diamond wire never appear empty when cutting the splicing rod. The splicing rod method of the present invention can make full use of the single crystal silicon short rod to be processed into silicon wafers, which improves the round silicon The utilization rate of rods reduces the processing cost.

Owner:江西金葵能源科技有限公司

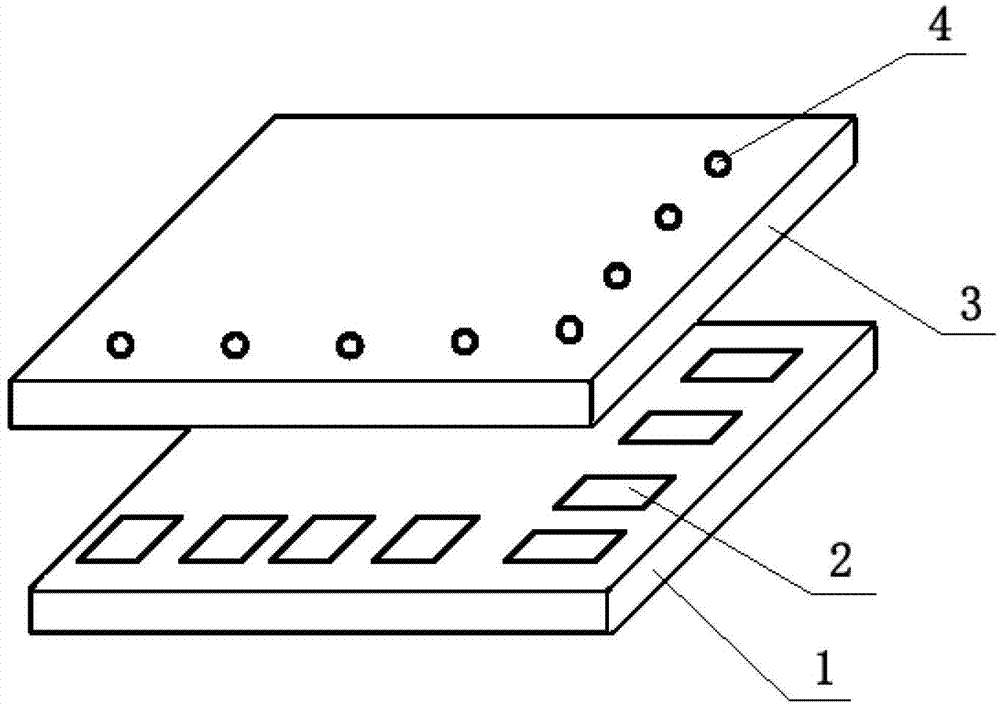

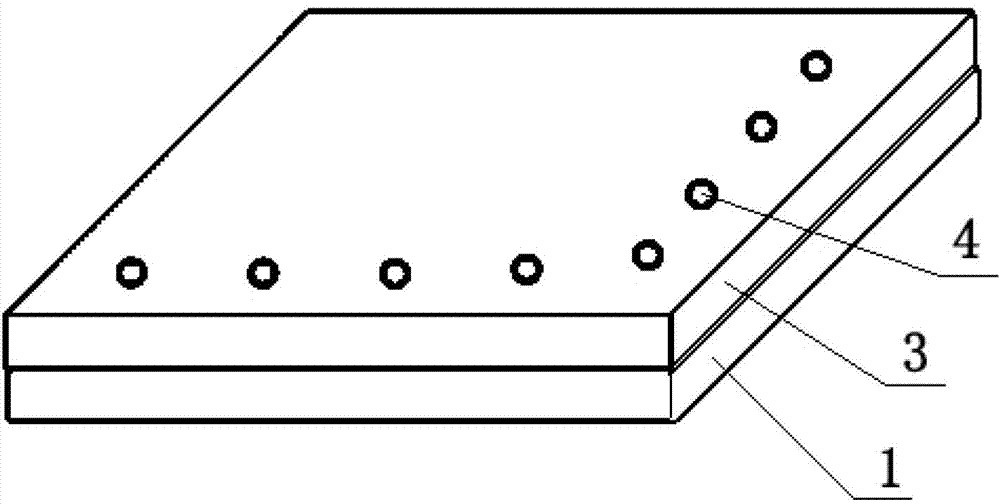

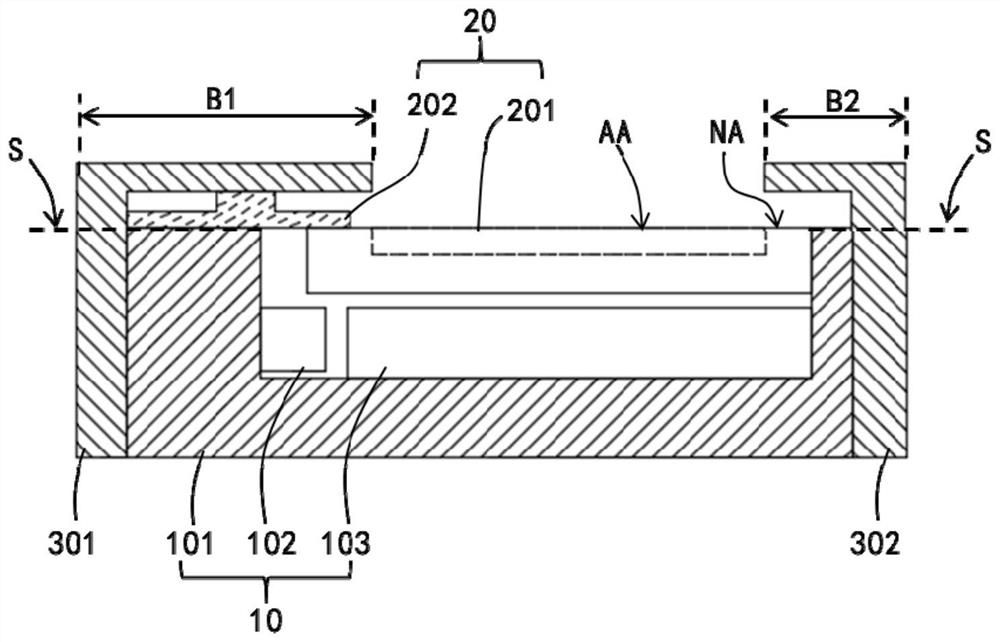

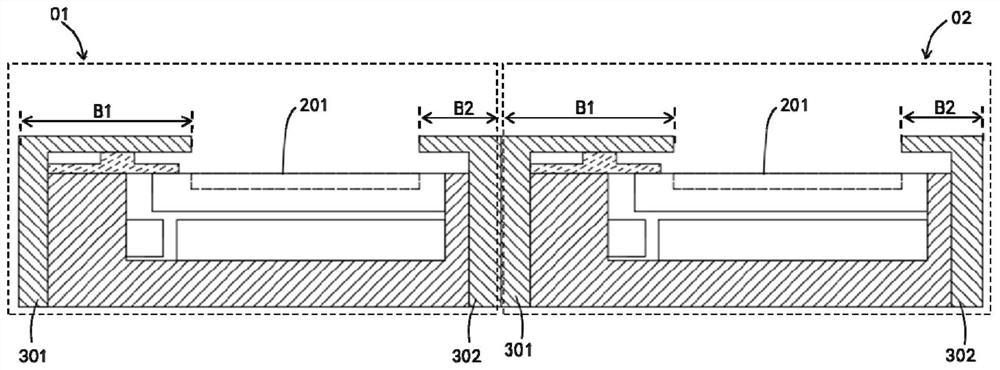

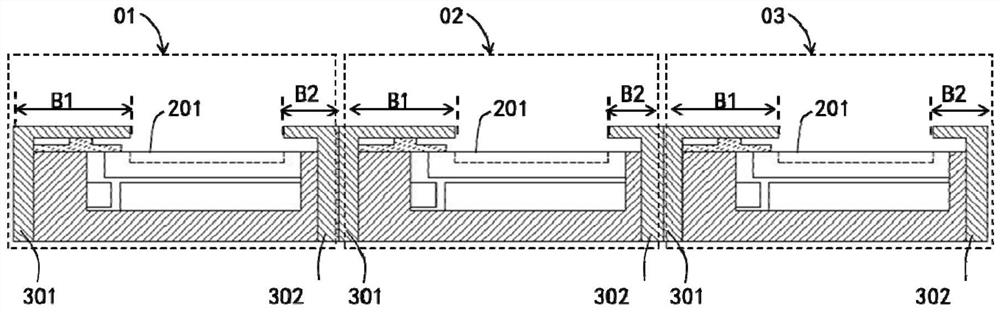

Organic light emitting diode (OLED) display unit and OLED display device adopting display unit

InactiveCN102931214AReduce seamsImprove finenessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceDevice Panel

The invention relates to an organic light emitting diode (OLED) display unit and an OLED display device adopting the OLED display unit. The OLED display unit comprises a luminous device panel and an packaging substrate and is characterized in that electrode terminals are arranged on the luminous device panel; penetration holes which are in one-to-one correspondence to the electrode terminals are formed in the packaging substrate; one face of the packaging substrate is attached to the face (provided with the electrode terminals) of the luminous device panel; the packaging substrate is adhered to and packaged with the periphery of the luminous device panel; conductive substances are filled into the penetration holes in the packaging substrate and are leaded to the other face of the packaging substrate to form display unit electrodes; the display unit electrodes are connected and conducted with electrode terminals on a display substrate in a one-to-one correspondence manner; and the display unit electrodes are connected with a driving control unit. Display devices with various sizes can be assembled; spliced joints between standard display modules in the display device are greatly reduced; the precision of the display device is improved; and a good vision effect is achieved.

Owner:李崇

System and method for removing seam artifacts

ActiveUS20090219280A1Minimize artifactReduce artifactsDrawing from basic elementsCharacter and pattern recognitionAlgorithmDual graph

Embodiments of the present invention include techniques for reducing artifacts in rendered images. In one embodiment, a dual UV engine generates a dual of the graph defined by an initial UV set associated with a 3D model. The dual UV engine then uses existing flattening and layout engines to generate a dual UV set from this dual graph. Using the dual graph to define the dual UV set ensures that the seams corresponding to the initial UV set and the dual UV set minimally intersect.

Owner:AUTODESK INC

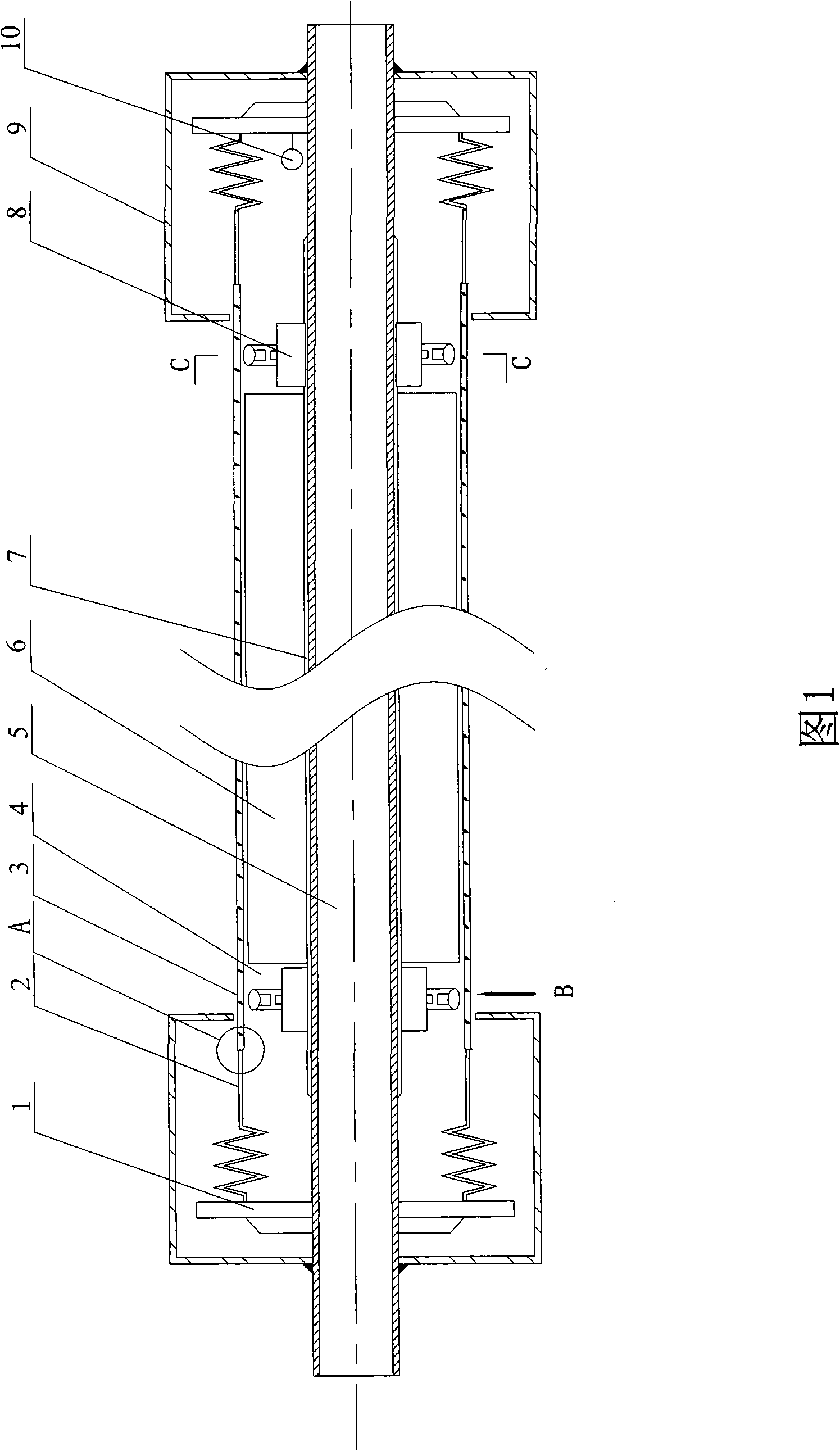

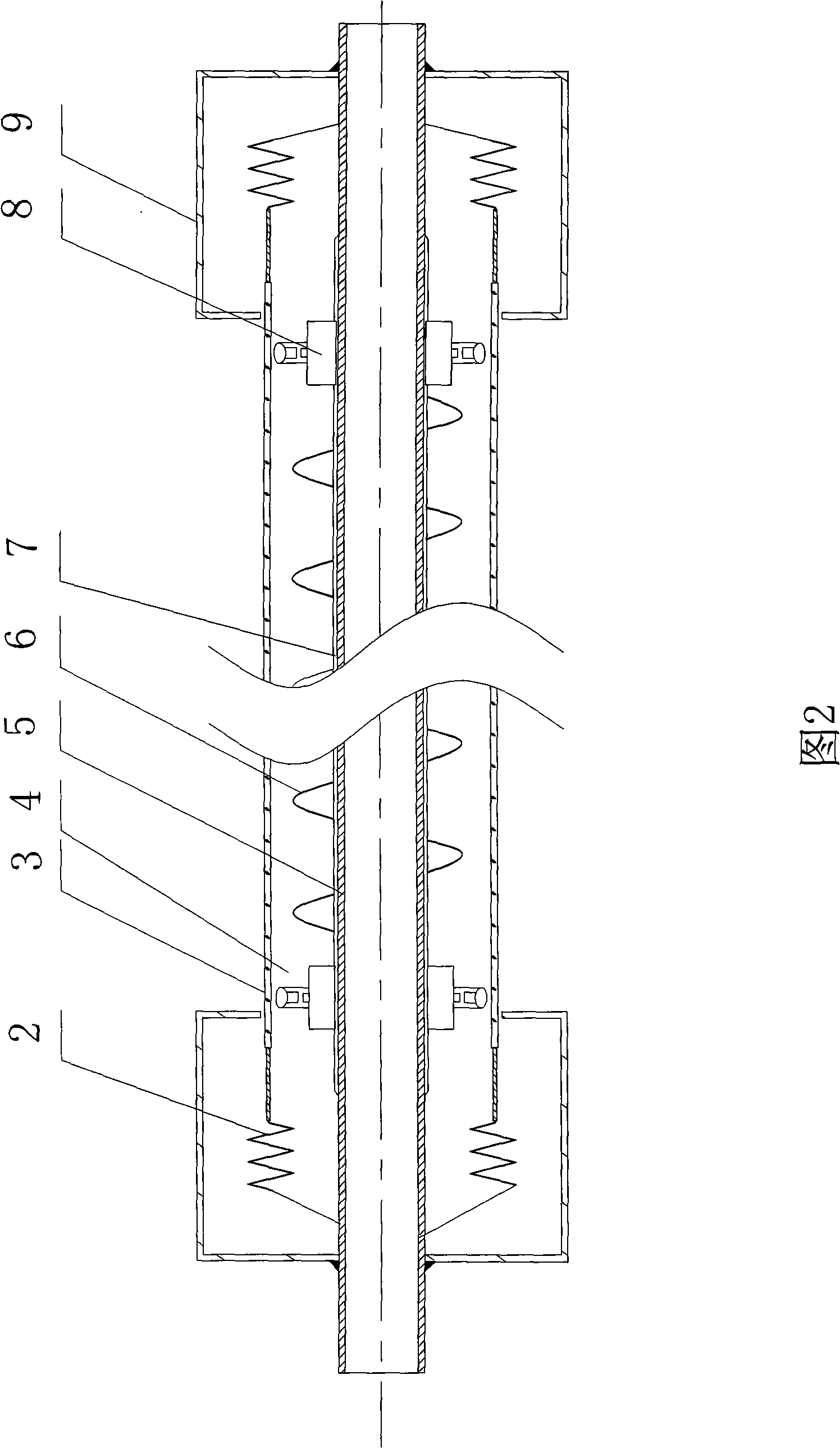

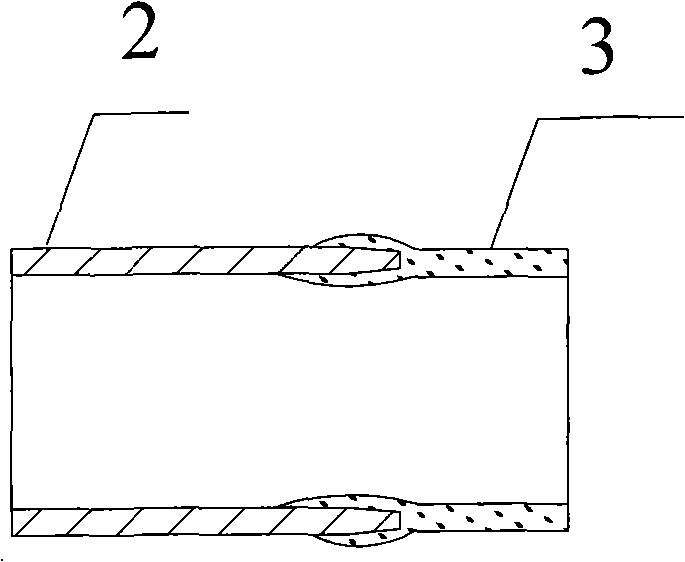

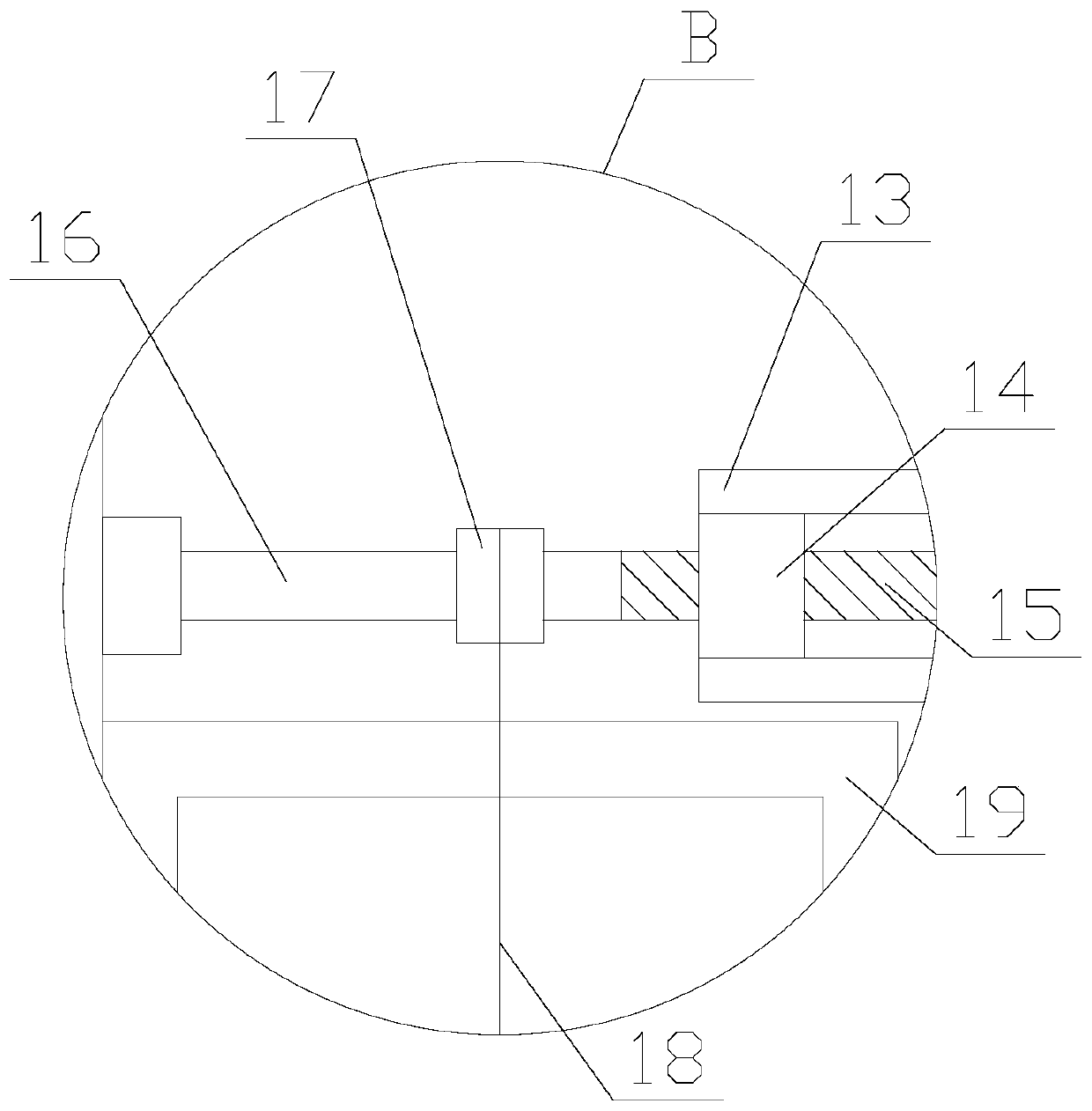

Vacuum heat collecting tube

InactiveCN101270923AImprove reliabilityReduce seamsSolar heating energySolar heat devicesGetterLinear expansion coefficient

The invention relates to the solar energy technical field, mainly related to a vacuum tube collector, comprising a metal pipe with the surface coated with a solar energy absorption coating layer, wherein a glass pipe is arranged outside the metal pipe; a vacuum layer is arranged between the glass pipe and the metal pipe, and getter can be put in the vacuum layer between the glass pipe and the metal pipe to maintain the vacuum degree; at least one end of the glass pipe is provided with a corrugated metal pipe, one end of the corrugated metal pipe is directly connected and sealed with the glass pipe, and the other end of the corrugated metal pipe is connected with the metal pipe; the joint between the corrugated metal pipe and the metal pipe and the corrugated metal pipe with the glass pipe are both provided with a shield to better protect the connecting joints. The corrugated pipe is made of material with the linear expansion coefficient between the 3 multiplied by 10<-6> / degrees to 5 multiplied by 10<-6> / degrees. The expansion coefficient is close to that of glass, thereby the corrugated pipe can be directly connected and sealed with the glass pipe arranged outside rather than connected through Kovar, thus reducing the number of the joints, improving the reliability of the pipes and better ensuring the vacuum degree.

Owner:SOUTHEAST UNIV

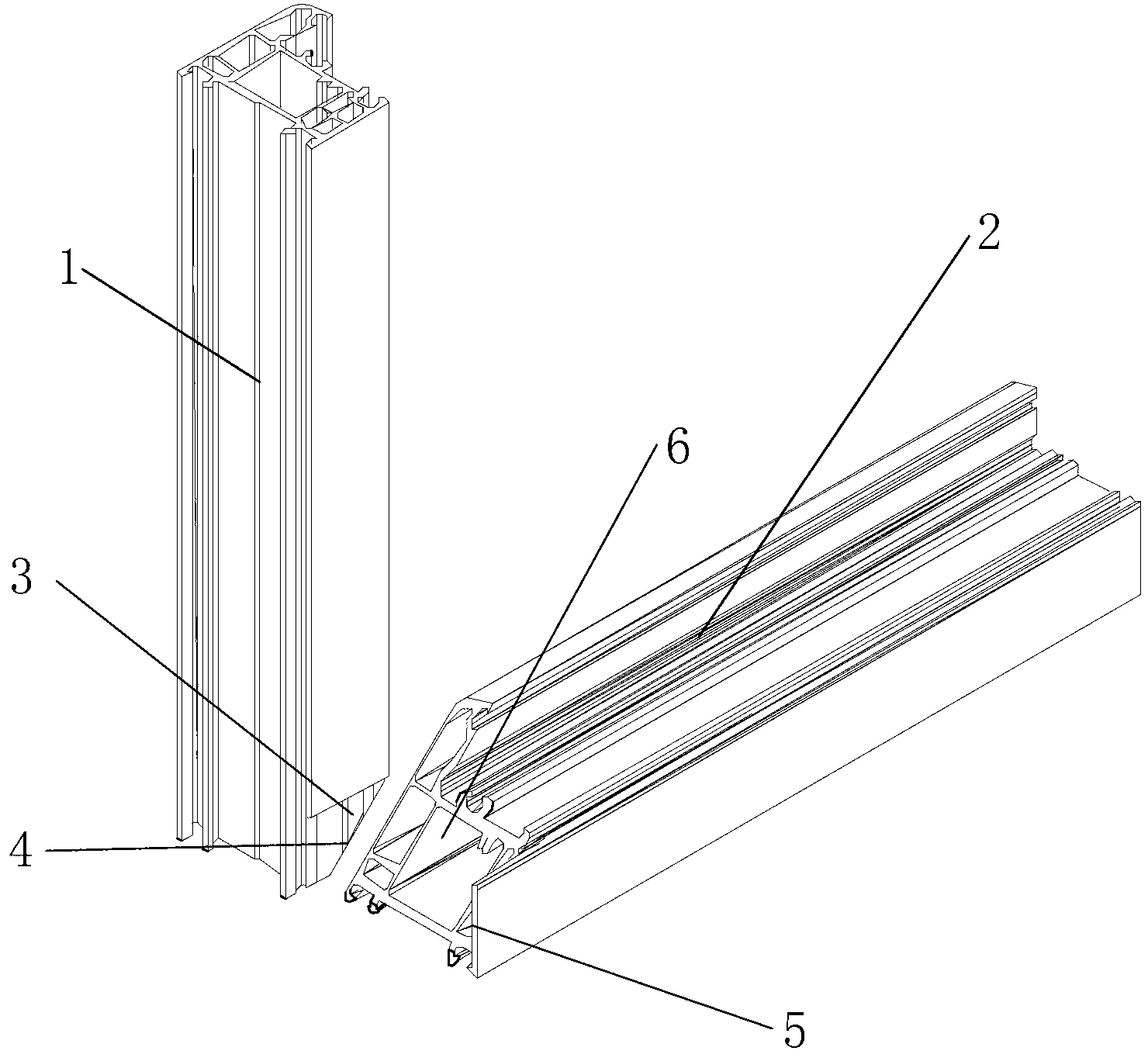

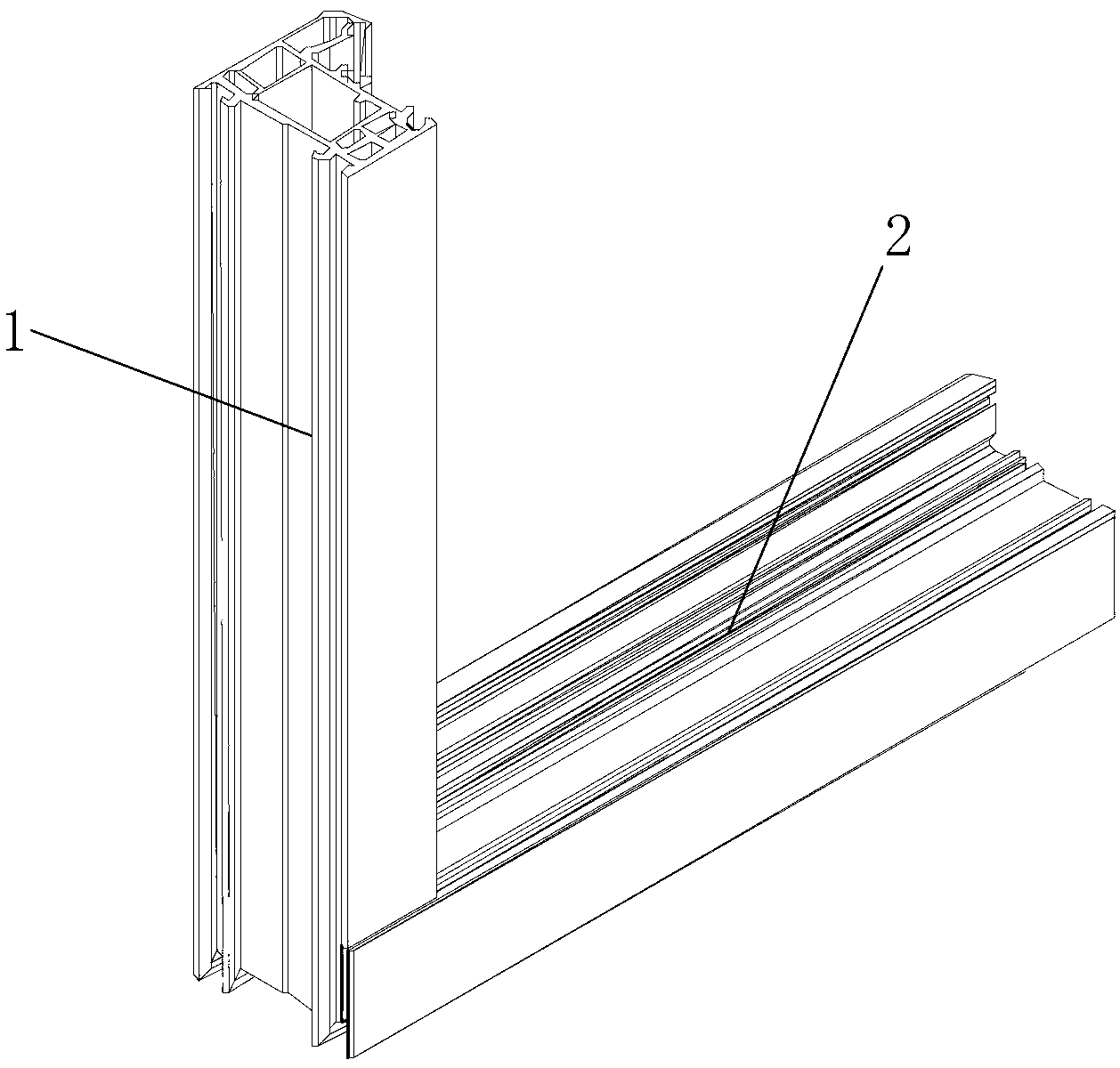

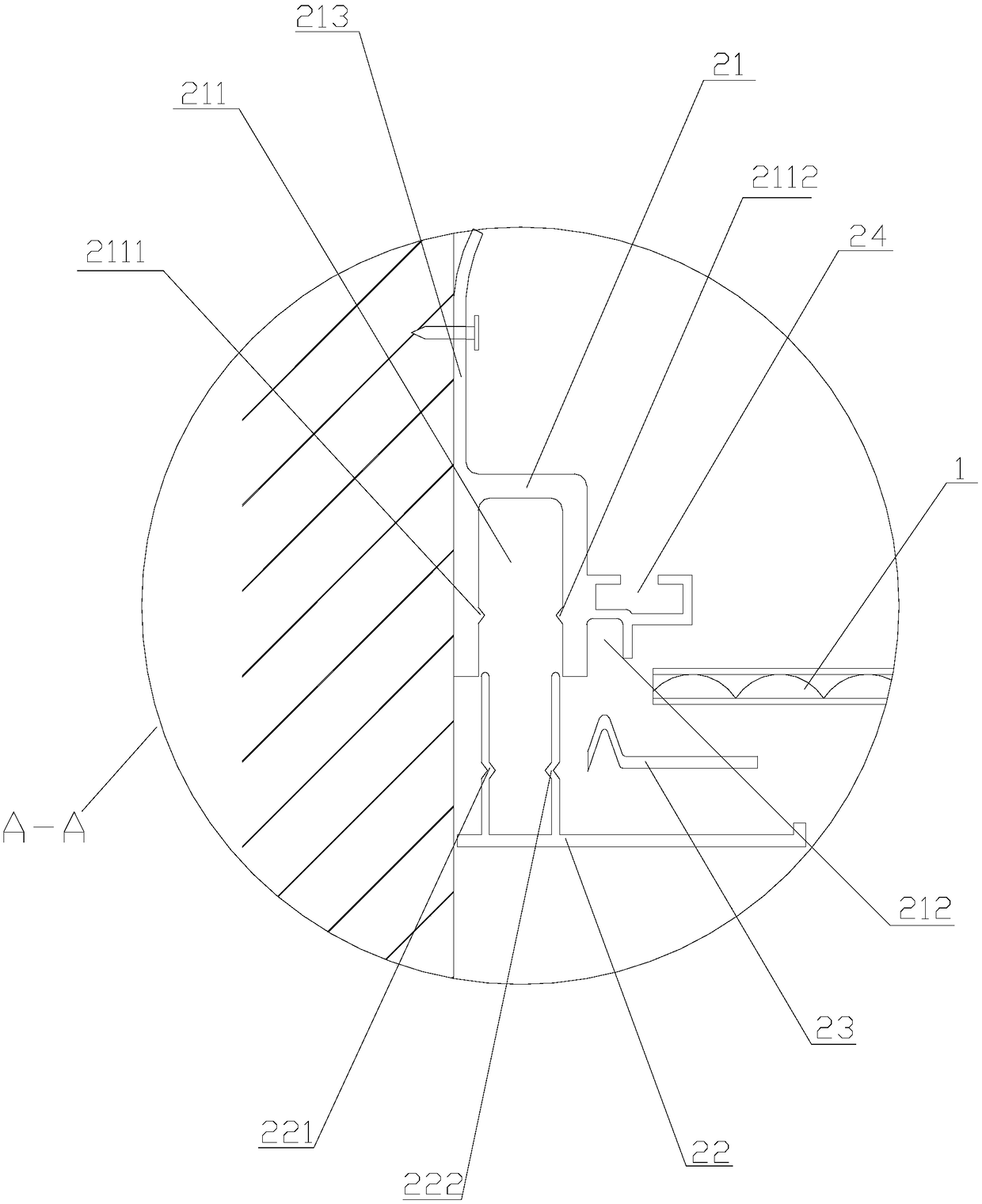

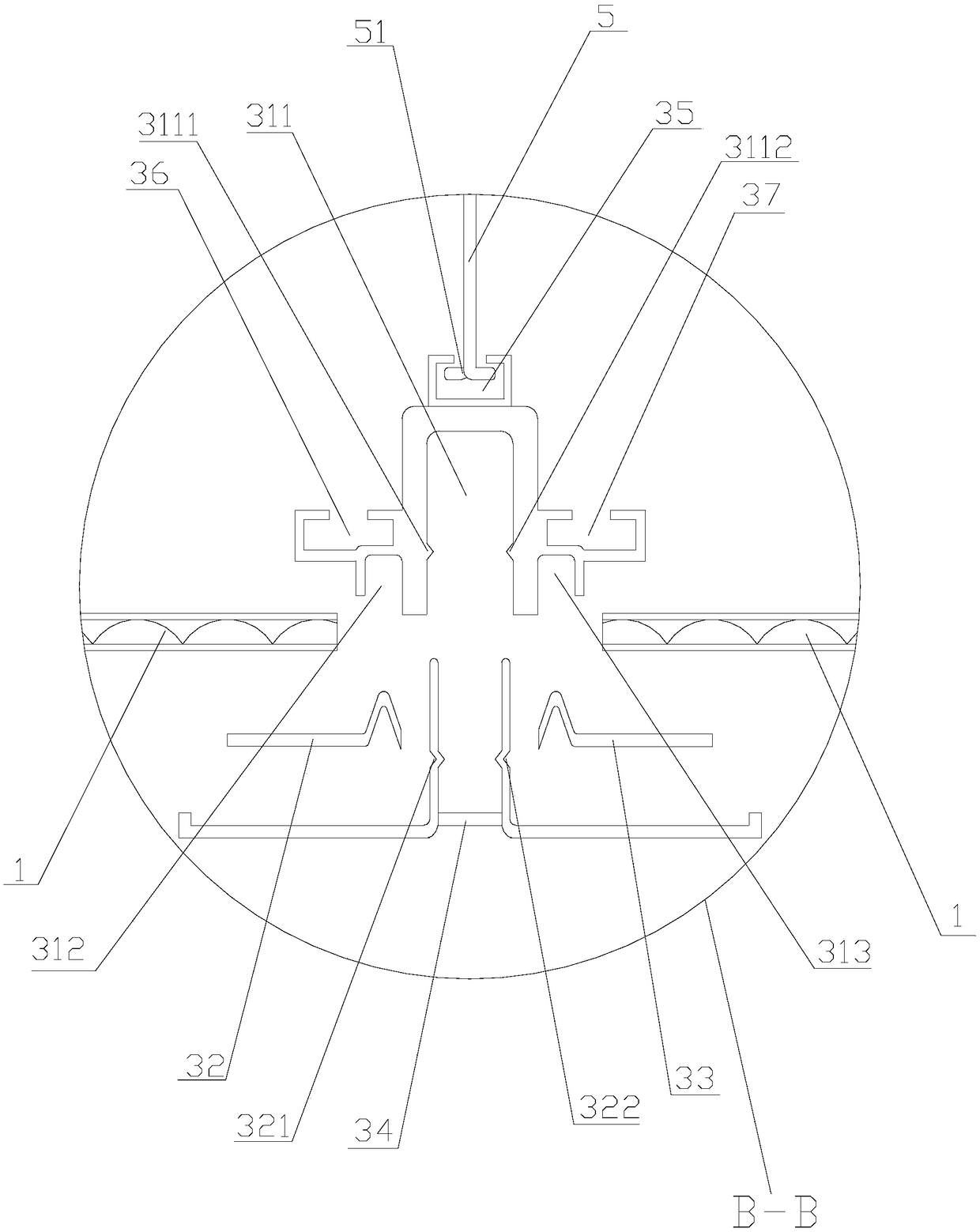

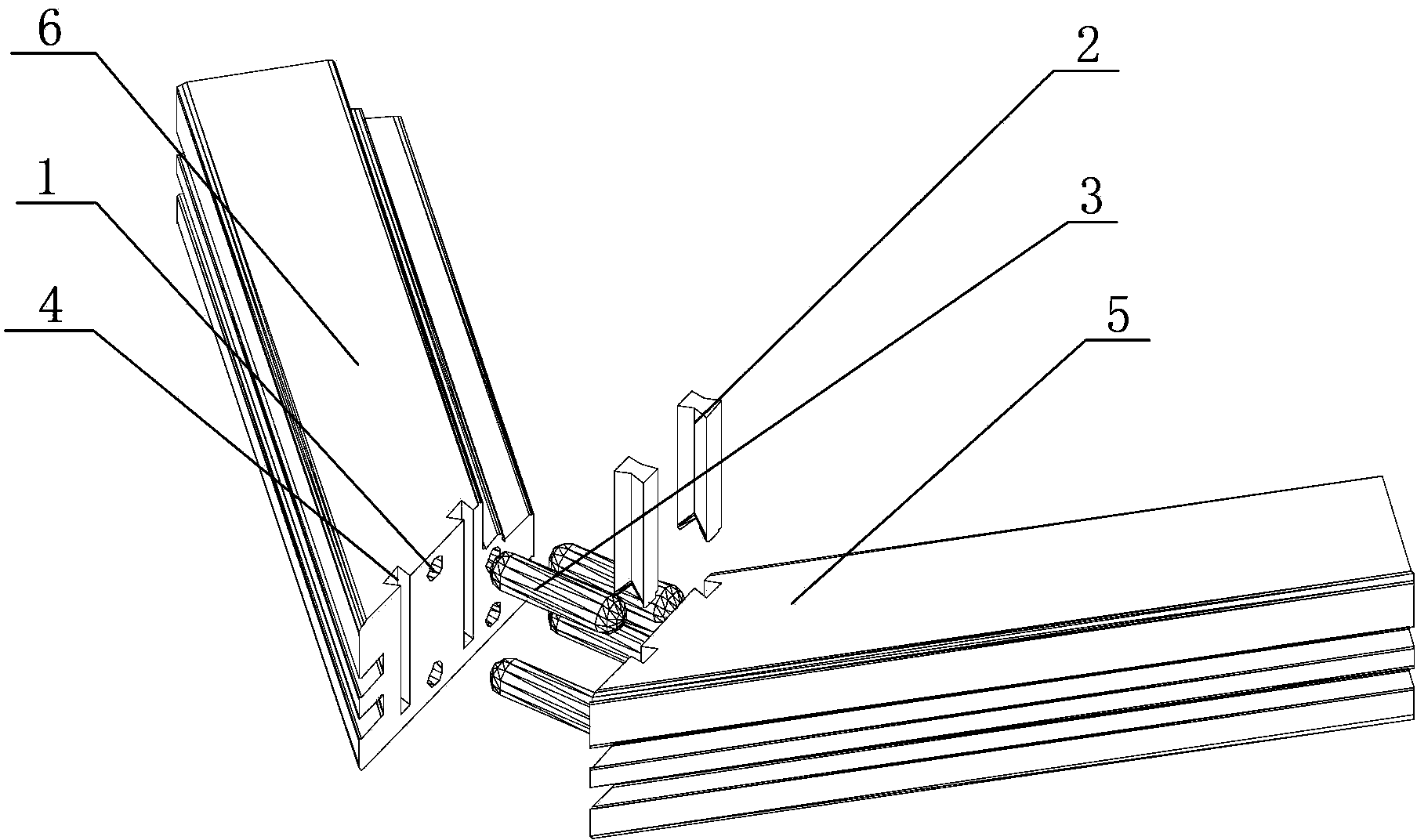

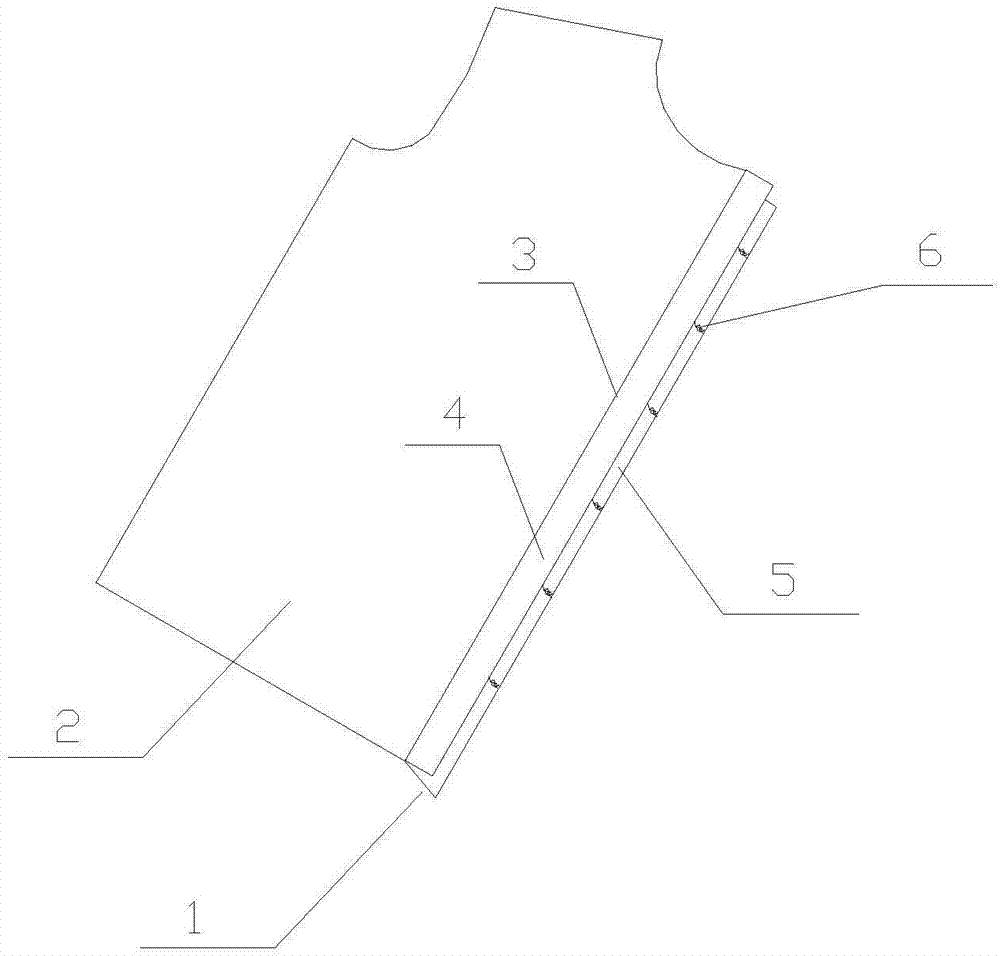

Novel corner connection structure for door and window profiles

The invention relates to a novel corner connection structure for door and window profiles. The connection structure comprises a vertical profile and a transverse profile, wherein a connection end of the vertical profile is provided with a first inclined face, an included angle a is formed by the first inclined face and a horizontal plane, a connection end of the transverse profile is provided with a second inclined face, an included angle b is formed by the second inclined face and the horizontal plane, a + b = 90 degrees, a>=30 degrees, b>=30 degrees, the first inclined face is matched with the second inclined face, and the first inclined face and the second inclined face are jointed and welded; and a connection groove or connection grooves is / are formed in one or two side faces of the connection end of the vertical profile respectively, an included angle c is formed by the upper side face of the connection groove or the upper side faces of the connection grooves and a vertical plane, 90 degrees >= c >= 75 degrees, a connecting piece or connecting pieces is / are arranged on one or two side faces of the connection end of the transverse profile, and the connecting piece or the connecting pieces is / are matched with the connection groove or the connection grooves and arranged inside the connection groove or the connection grooves in an attached mode through adhesives. After the connection structure is used for corner combining, a corner is flat, joints are small, interior side surfaces are attractive in appearance, and the quality of polyvinyl chloride (PVC) plastic corner combining is improved.

Owner:浙江瑞明节能门窗技术有限公司

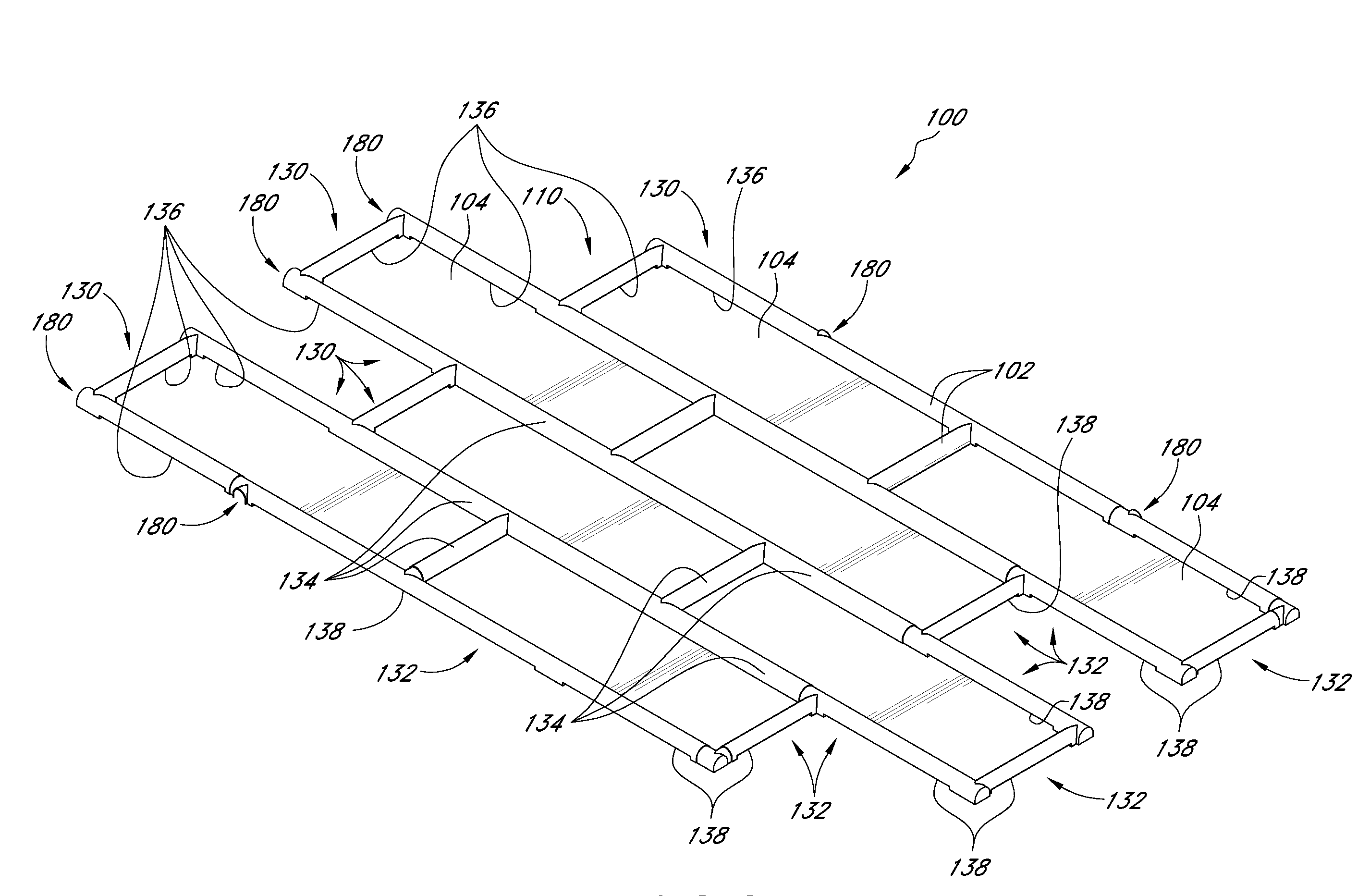

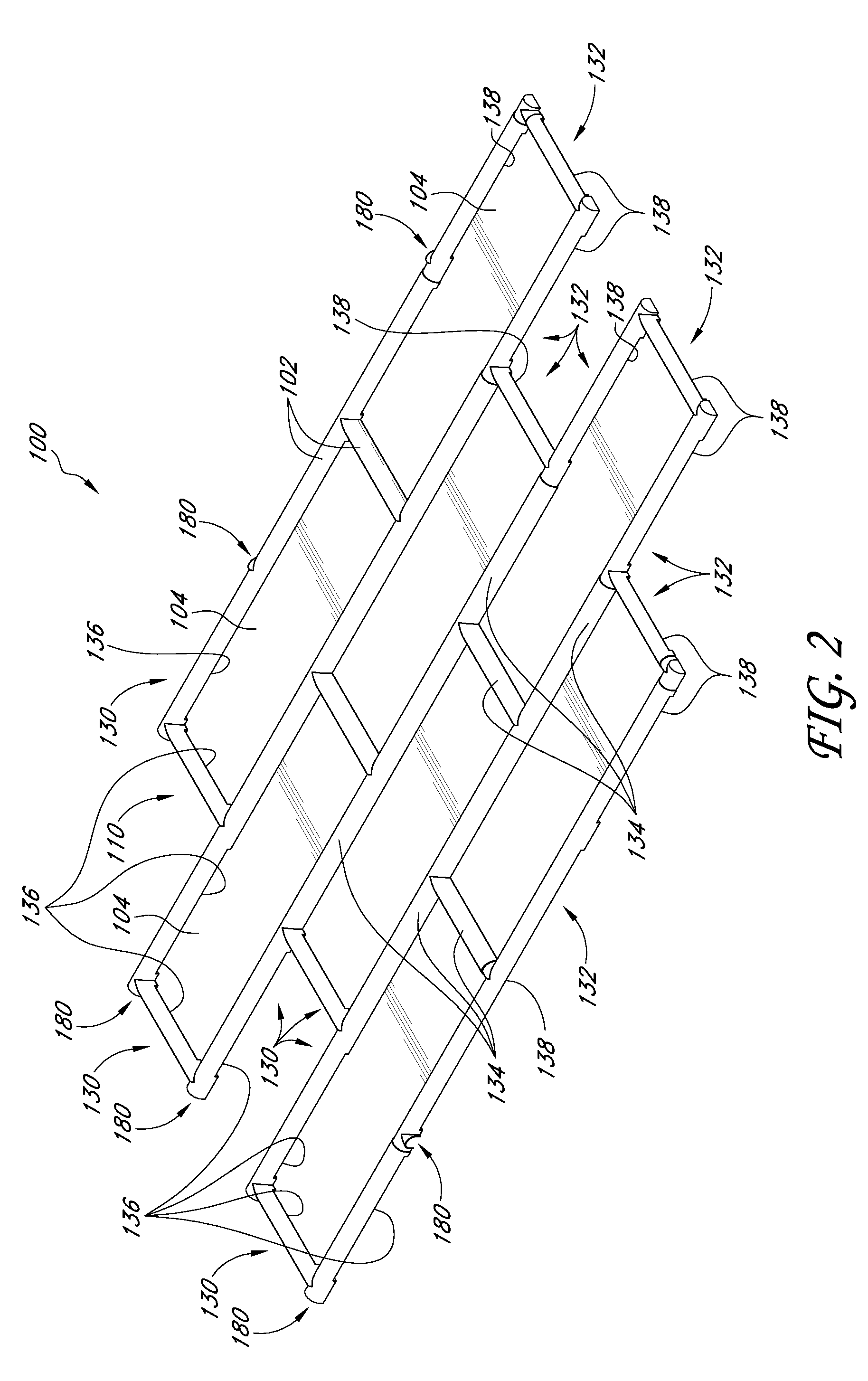

Formliner and method of use

ActiveUS20100072346A1Without costMinimizing and eliminating seamLiquid surface applicatorsCovering/liningsAdhesiveEngineering

Owner:PRIME FORMING & CONSTR SUPPLIES INC DBA FITZGERALD FORMLINERS

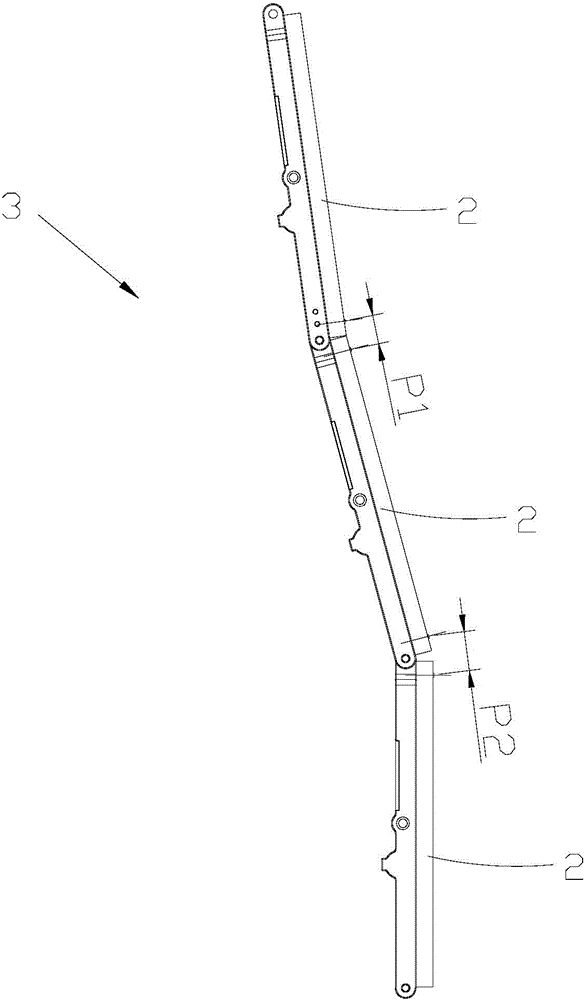

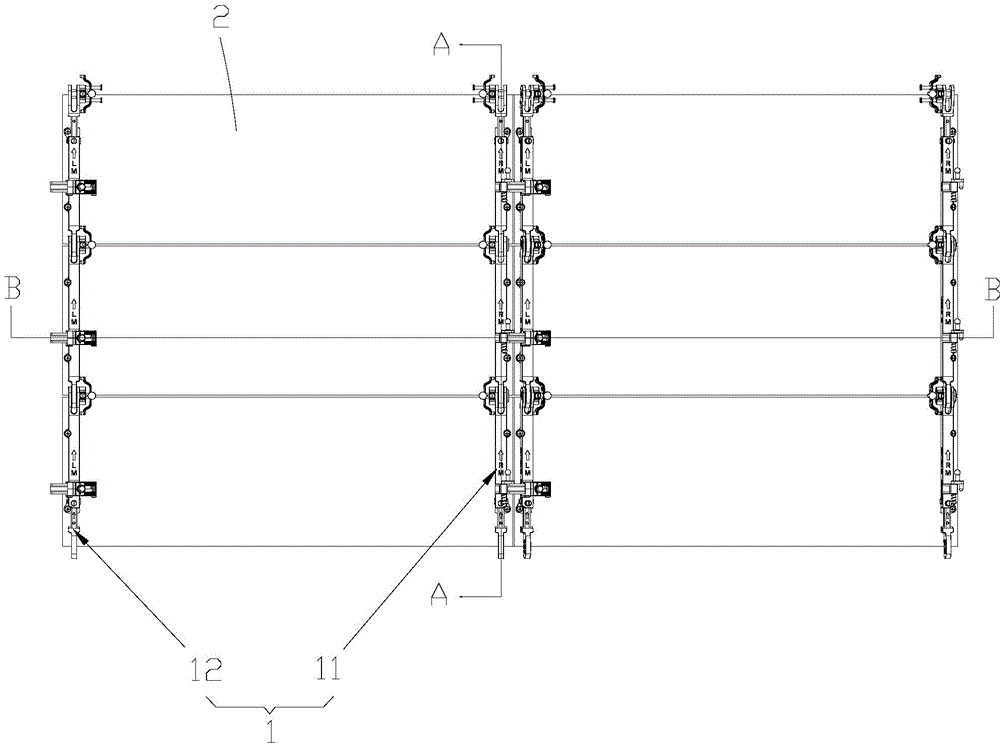

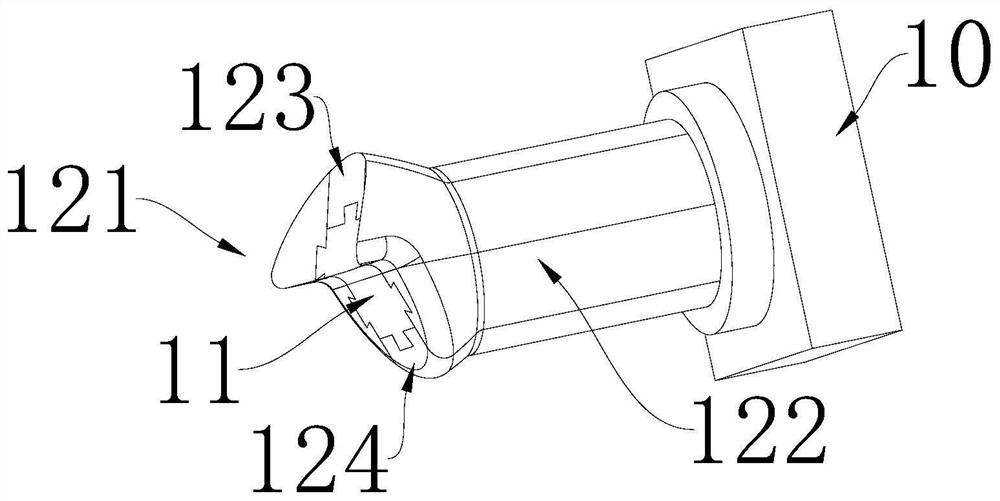

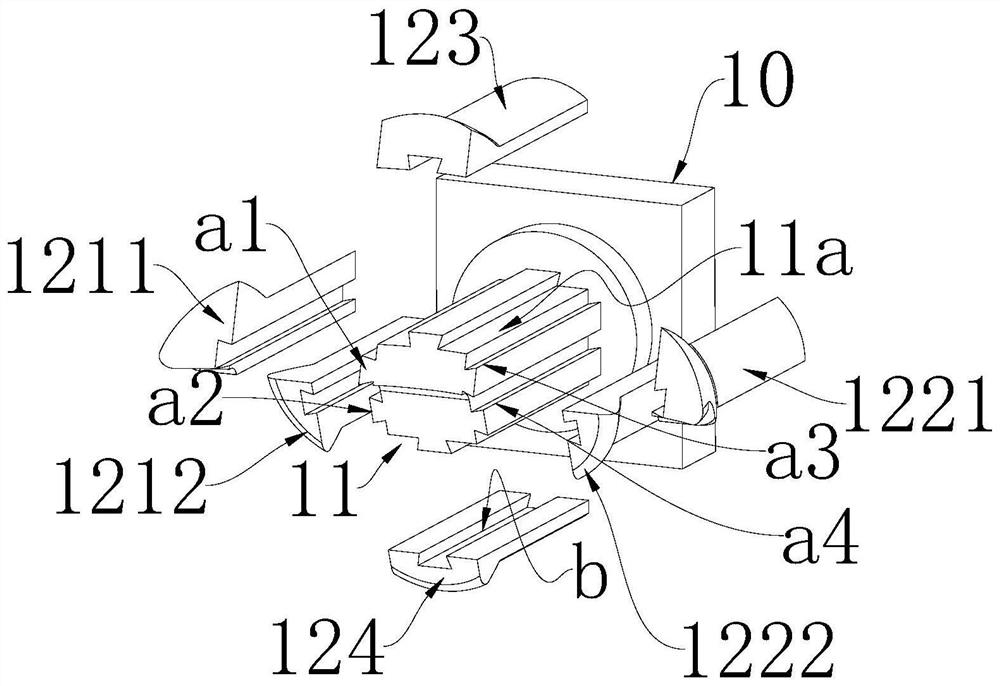

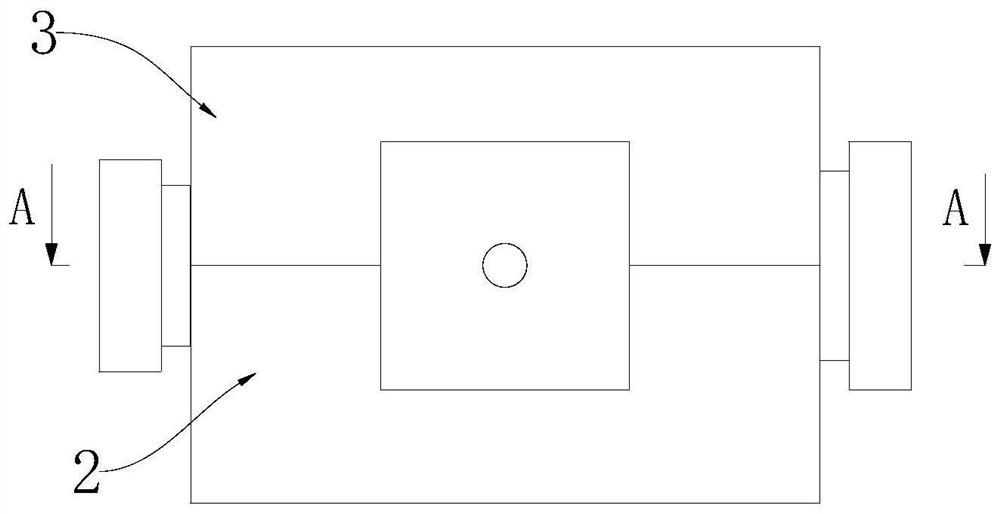

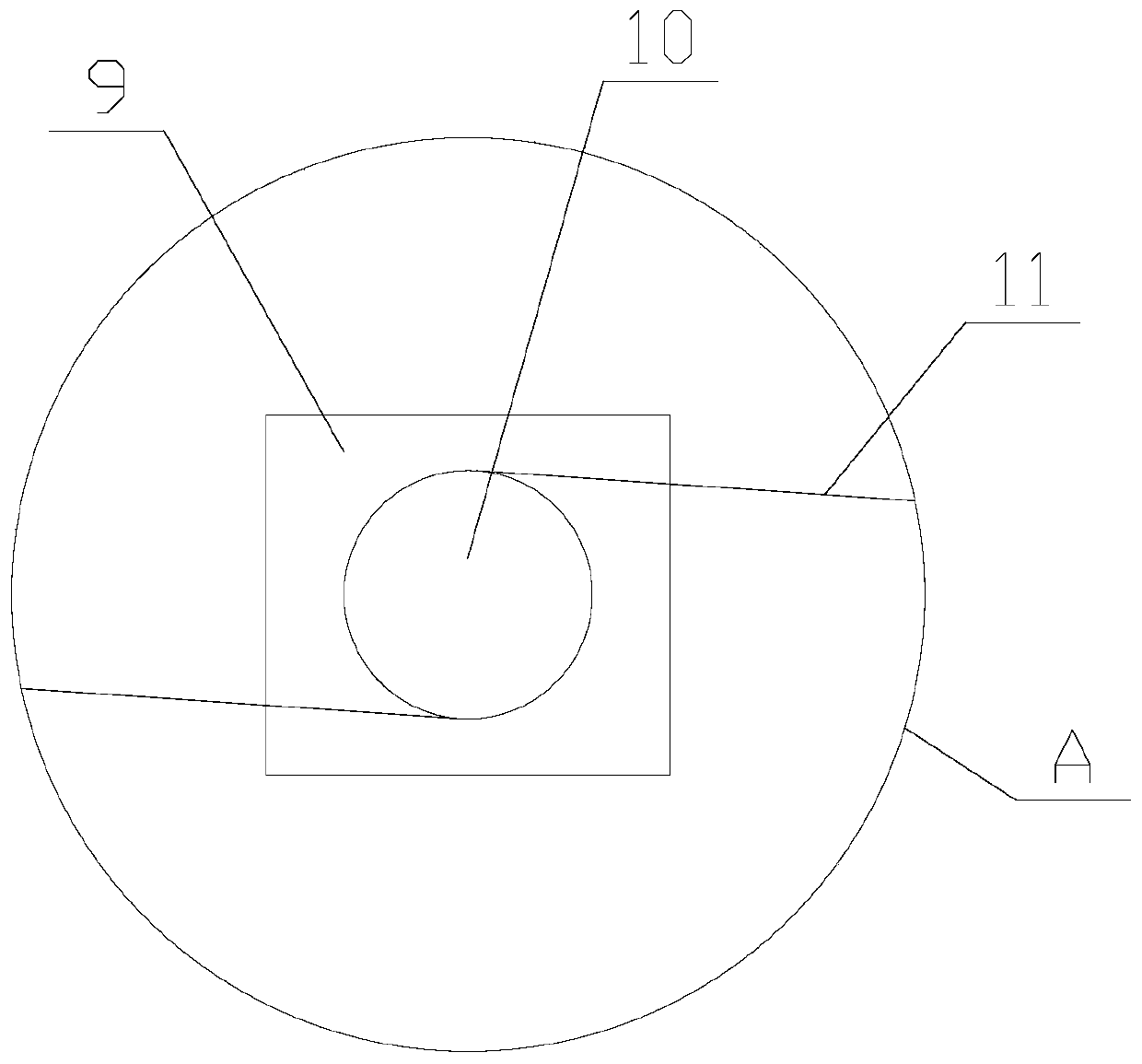

Seamless connecting structure and bending type splicing screen

The invention relates to the technical field of display equipment and discloses a seamless connecting structure and a bending type splicing screen. The seamless connecting structure comprises a first chain component and a second chain component, wherein the first chain component comprises a plurality of first connecting rods, each first connecting rod is bended to form a circular arc, the first connecting rods are hinged to one another through second hinge holes of the circular arcs, the second chain component comprises a plurality of second connecting rods, and the hinge mode among the second connecting rods is the same as the connecting mode of first connecting rods; arc-shaped lock bodies are arranged on the second connecting rods, arc-shaped lock tongues capable of rotating in an arc-shaped mode are arranged inside the arc-shaped lock bodies, and one end of each arc-shaped lock tongue is hinged to the corresponding first connecting rod. By the adoption of the seamless connecting structure, the special arc-shaped connecting mode is adopted in the insides of the first chain component and the second chain component and between the first chain component and the second chain component, the actual rotation axes of LED lamp plates are changed, splicing seams are not prone to occuring after the adjacent LED lamp plates rotating, and the excellent display effect is achieved.

Owner:SHENZHEN AOTO ELECTRONICS

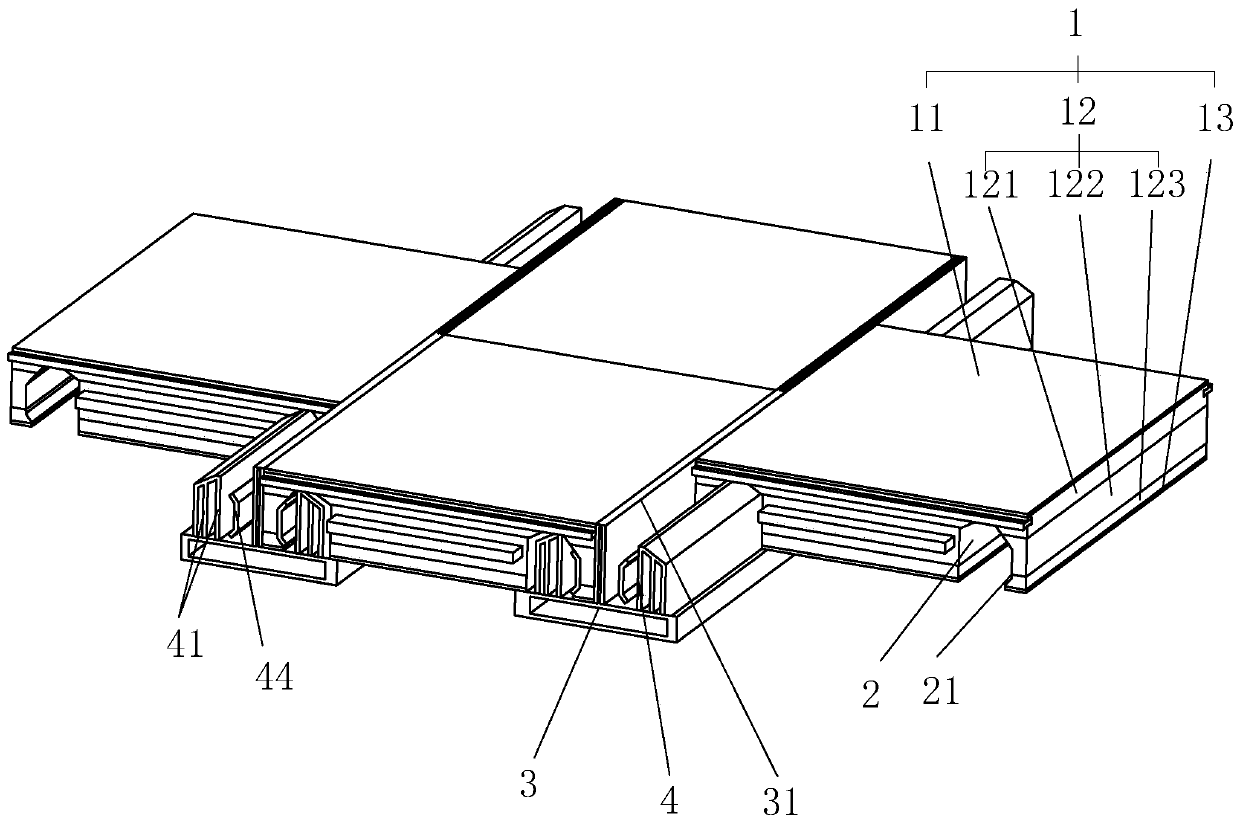

Spliced display screen

ActiveCN111768716AReduce seamsReduce the space occupied by insufficient bendingIdentification meansPhysicsThin membrane

The invention provides a spliced display screen. The spliced display screen comprises a plurality of panels and a plurality of chip-on-films. Each panel comprises a display surface and a back surfacewhich are oppositely arranged, and the direction from the display surface to the back surface is a first direction. Each chip-on-film comprises a first surface and a second surface which are oppositely arranged, and the direction from the first surface to the second surface is a second direction. One chip-on-film is clamped between every two adjacent panels. The first direction is perpendicular tothe second direction. One chip-on-film is clamped between every two adjacent panels, so that the space occupied by insufficient bending of the chip-on-films is reduced, the width of the bonding areais reduced, and the splicing seam between every two adjacent panels is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

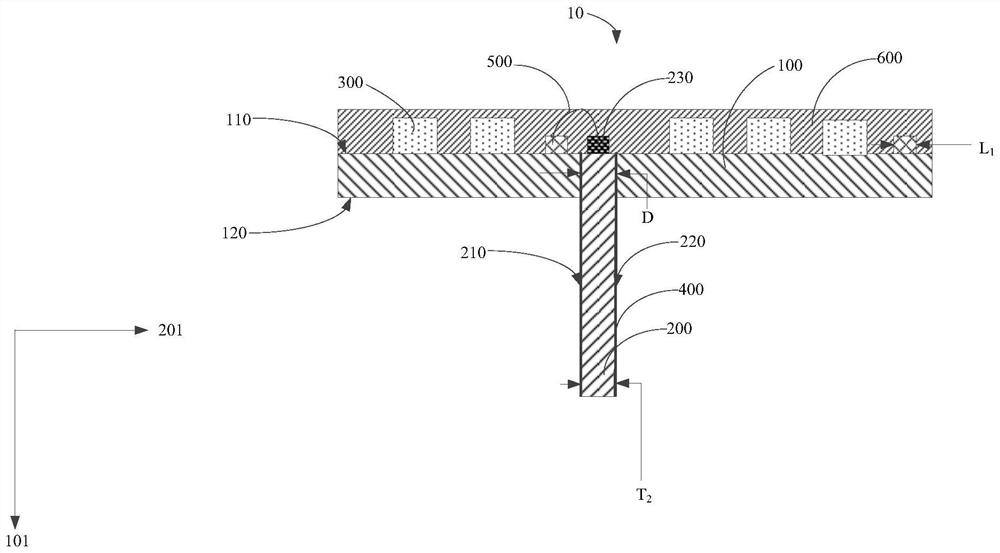

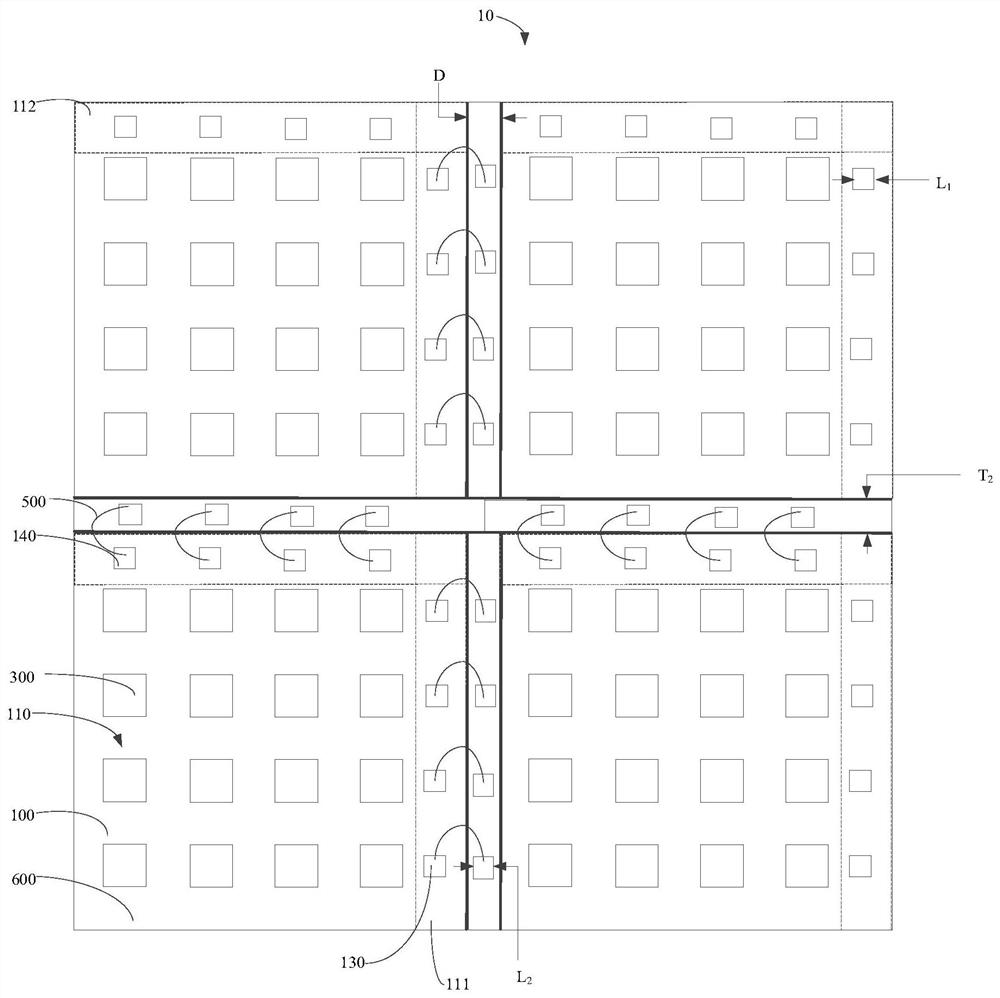

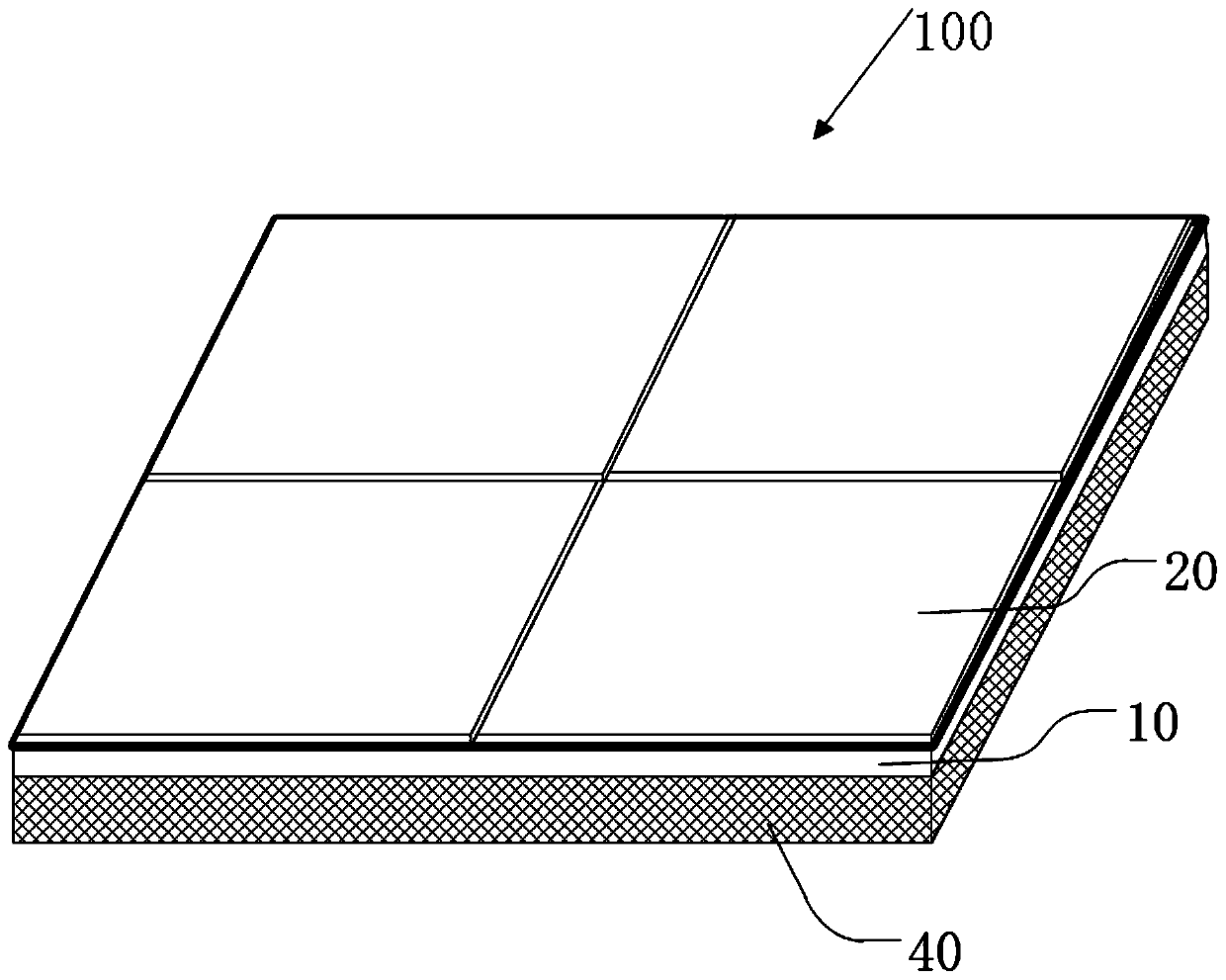

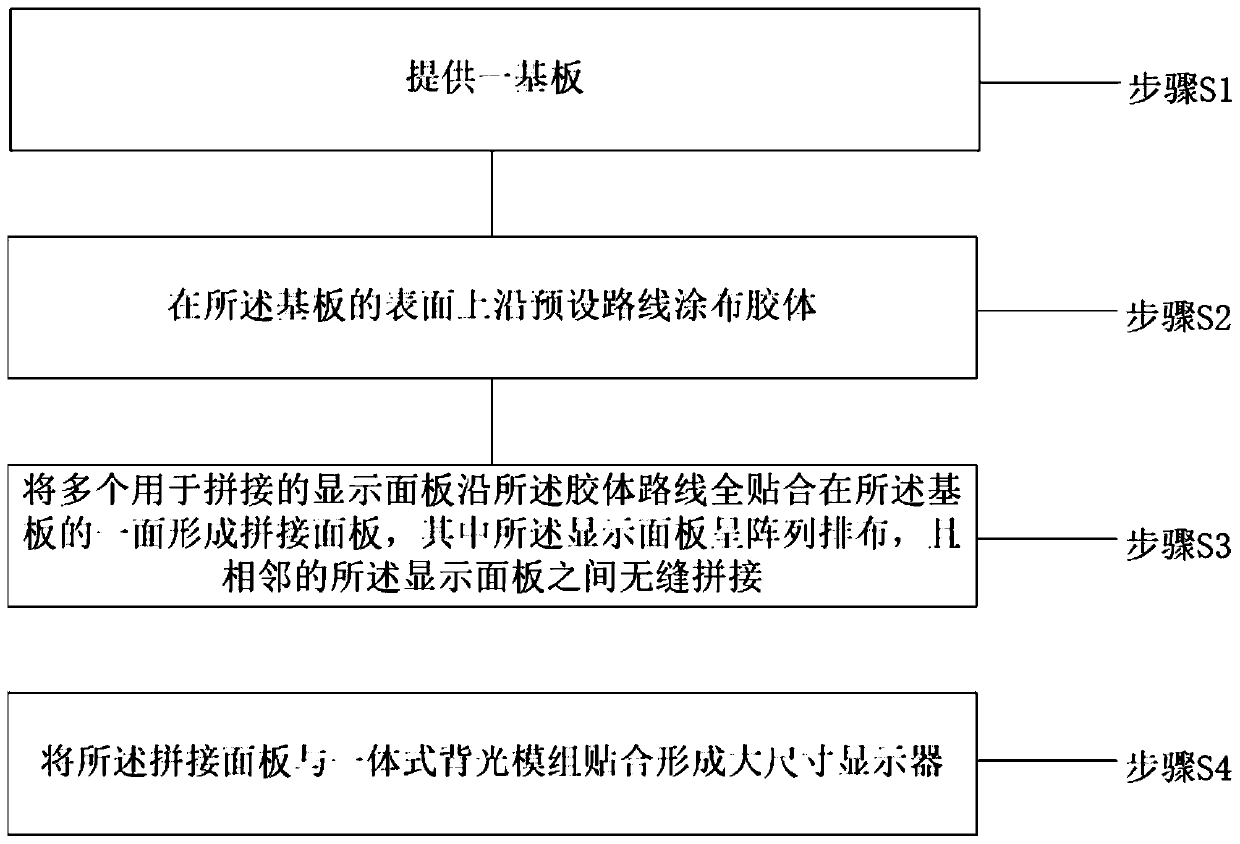

Large-size display and splicing method thereof

InactiveCN111128051AAvoid Assembly GapsReduce seamsNon-linear opticsIdentification meansDisplay deviceEngineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

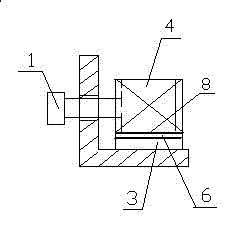

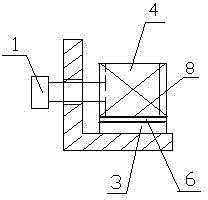

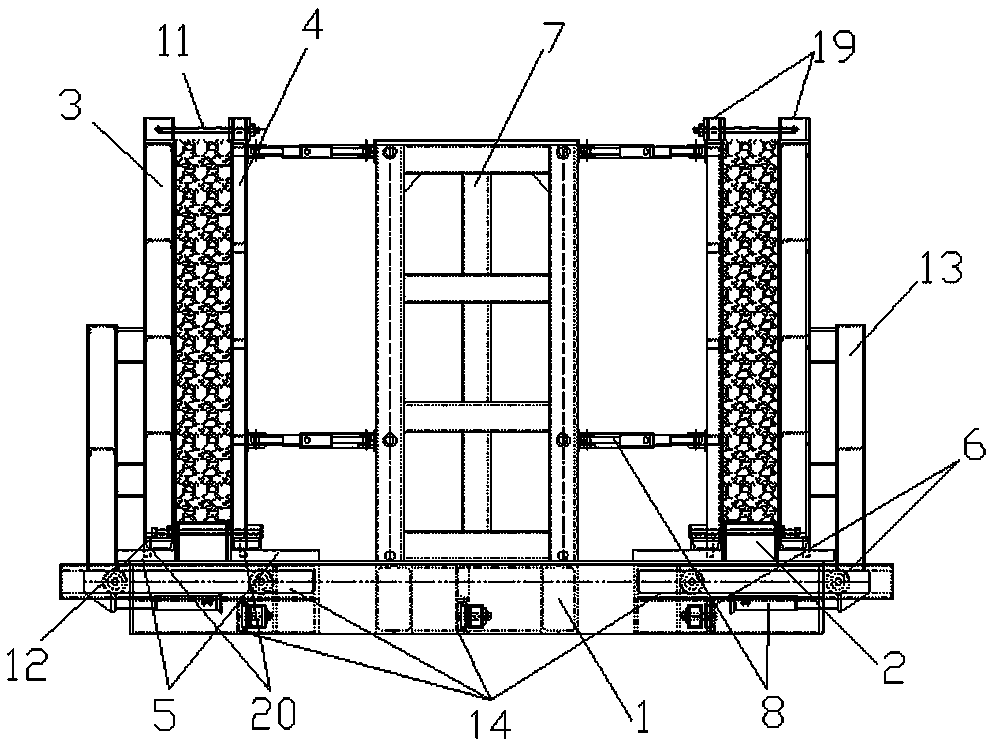

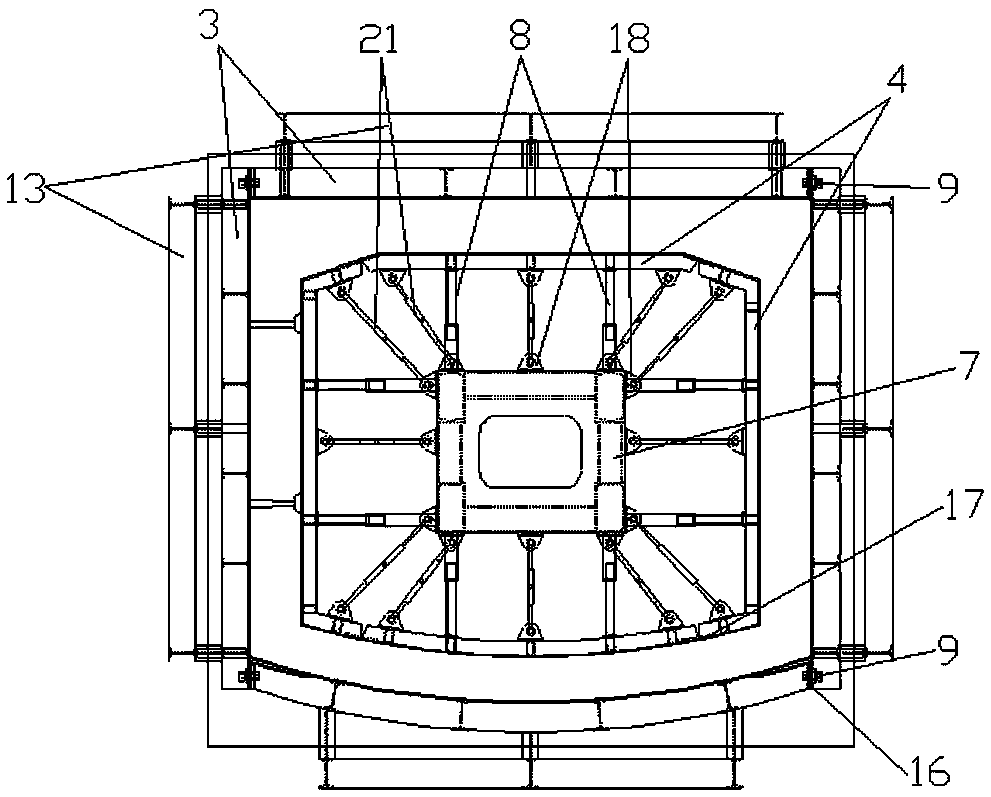

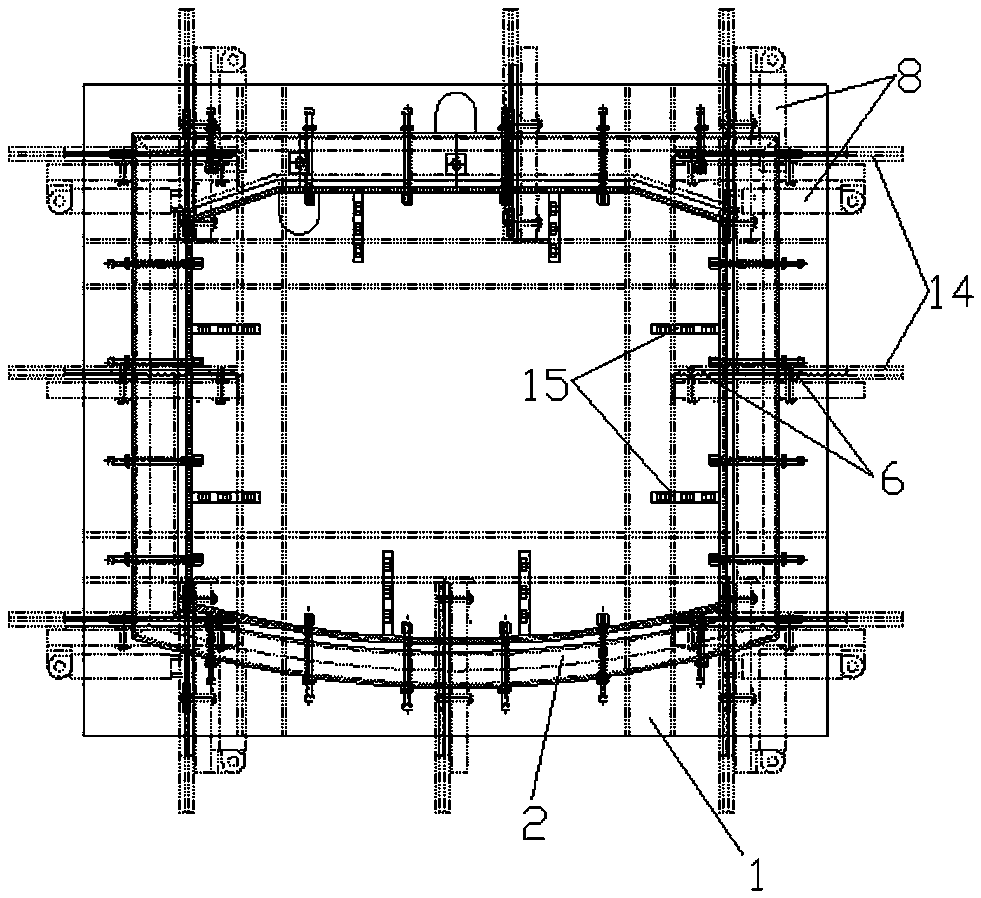

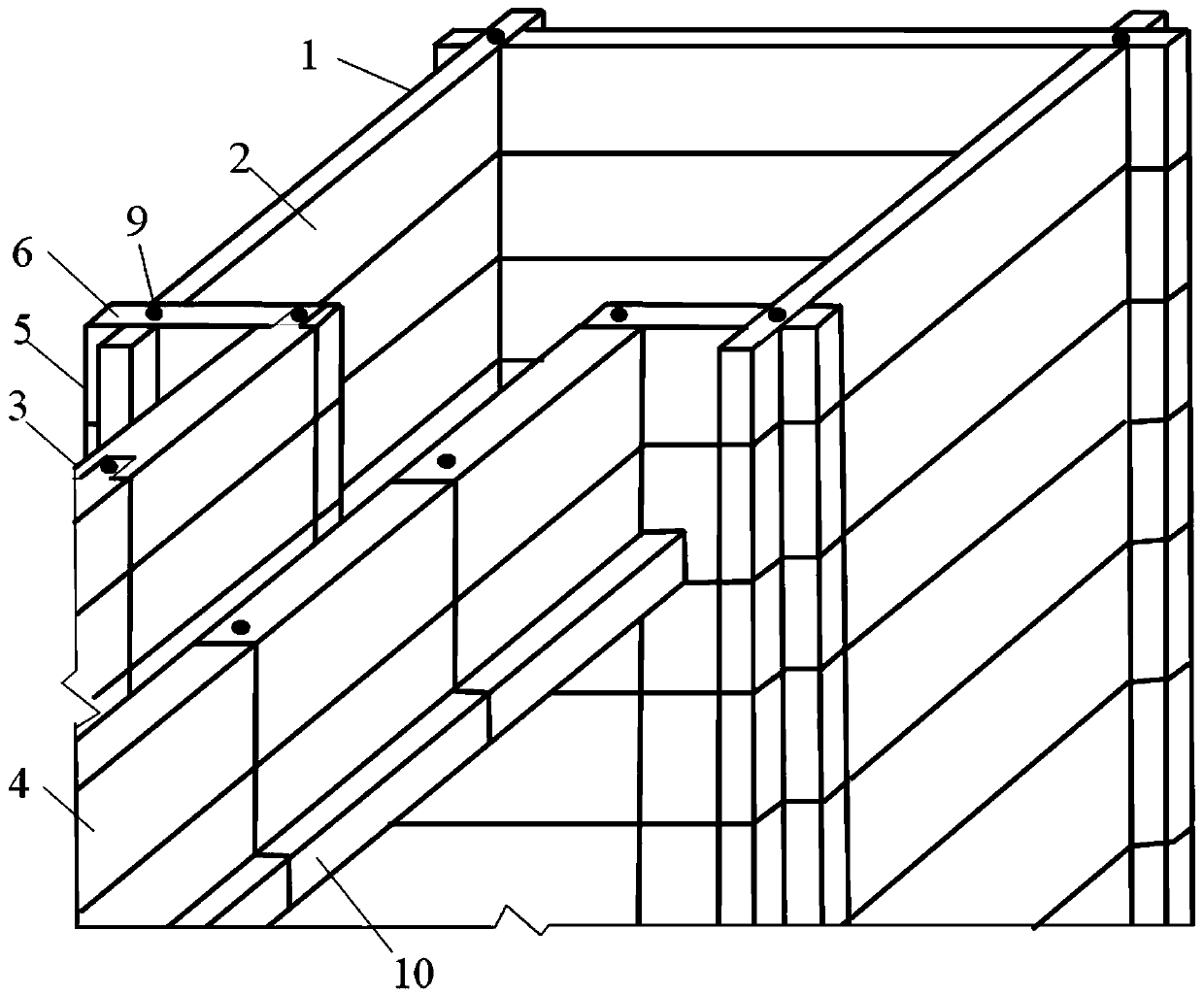

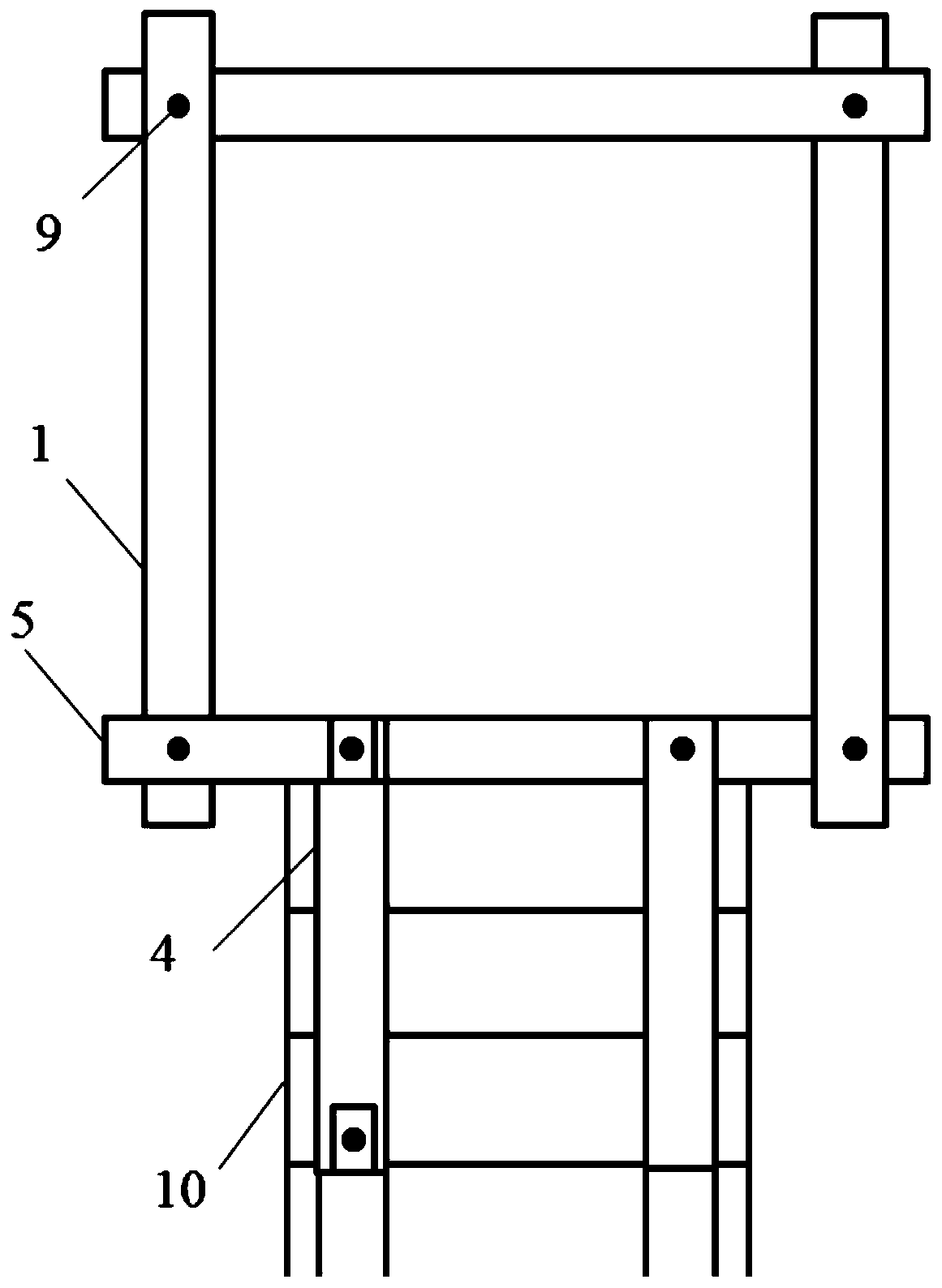

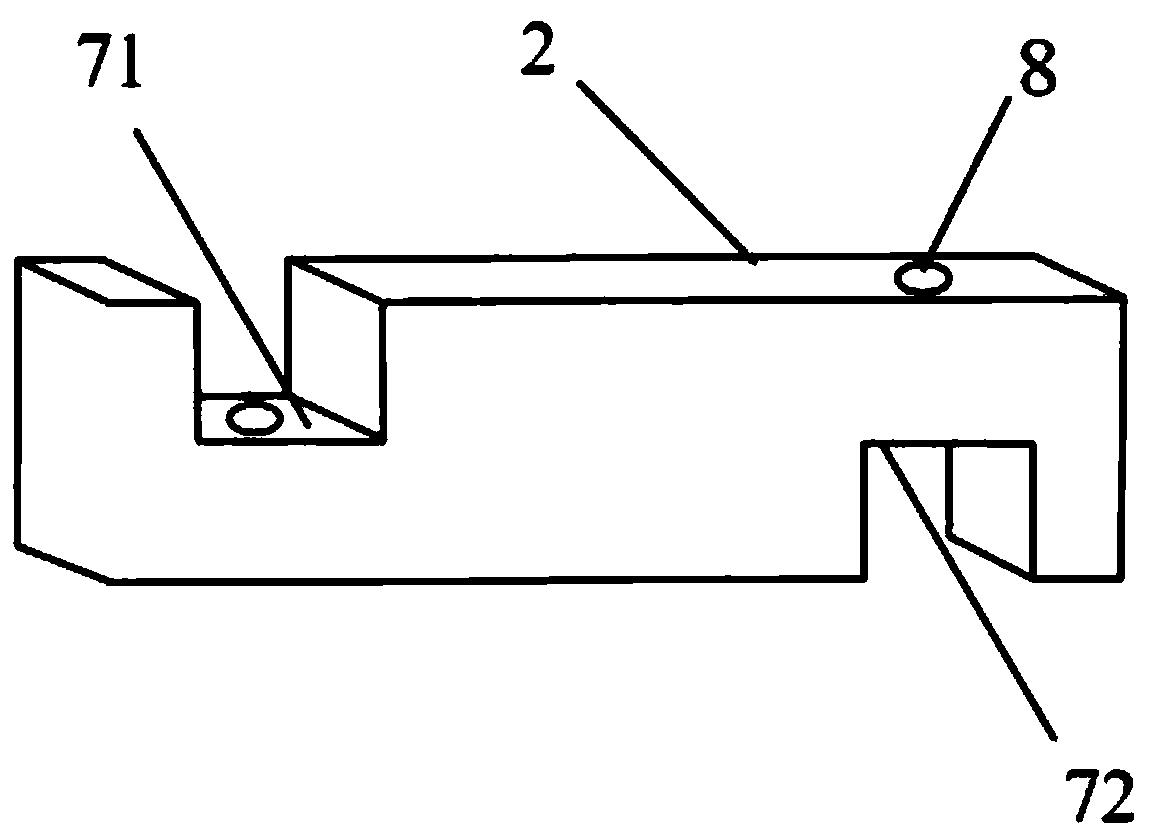

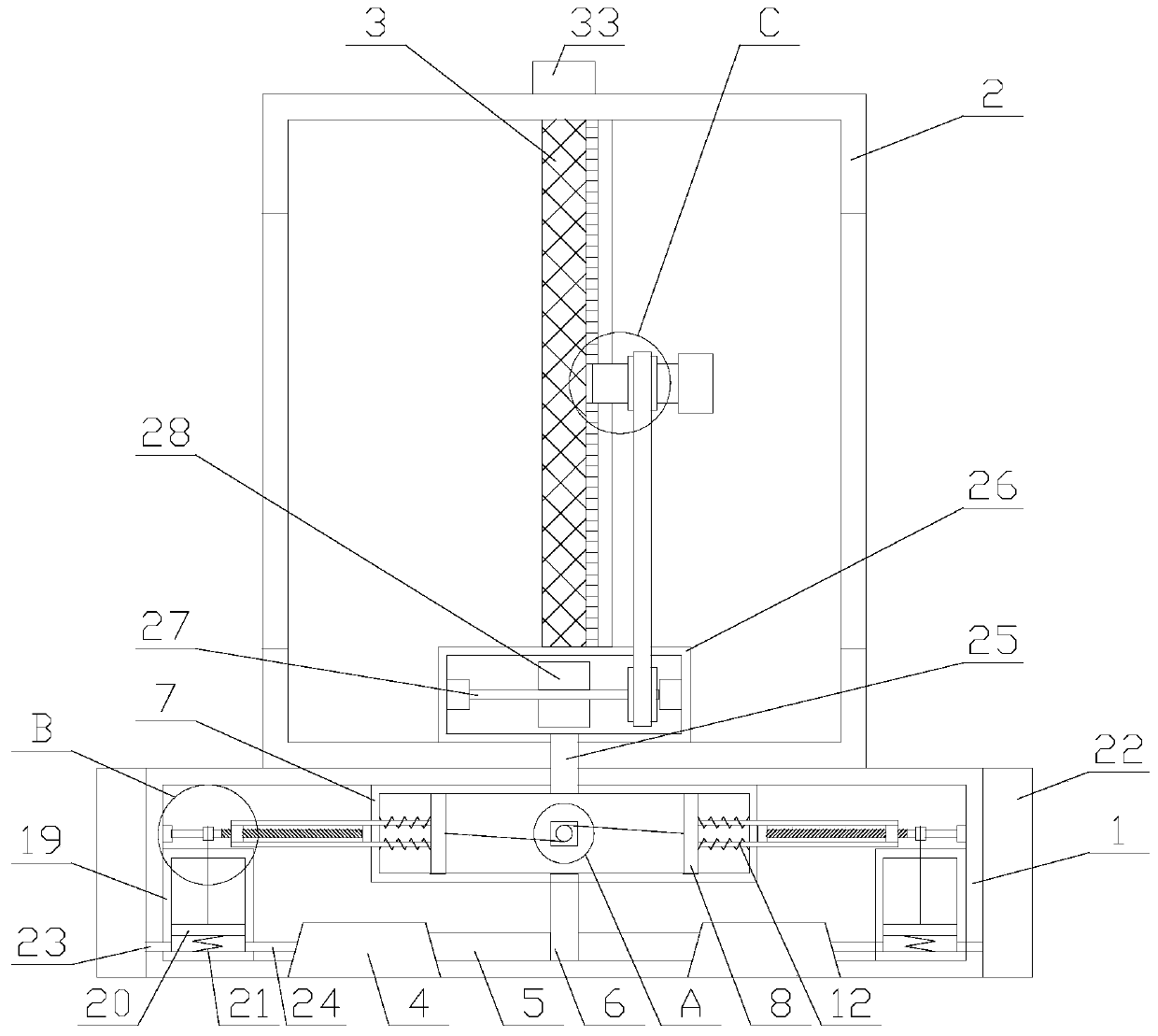

Hydraulic die plate system of precast box culvert and use method thereof

PendingCN108189203AReduce seamsImprove appearance qualityDischarging arrangementMould separation apparatusHydraulic cylinderEngineering

The invention discloses a hydraulic die plate system of a precast box culvert. The hydraulic die plate system comprises a base, a bottom die, an outer die, an inner die, a sliding rail system, a hydraulic system and a locating system, wherein the bottom die is enclosed by the inner die and the outer die, forming a box culvert die plate of a box type structure, and die disassembly and die assemblyare realized by driving the inner die and the outer die through the hydraulic system; the base is fixed to a ground embedded component through welding, and the bottom die is mounted above the base through welding; a central bracket is arranged in the center of the base, and hydraulic cylinder lug plates used for mounting a hydraulic cylinder are welded both below the base and on the central bracket; and the periphery of the bottom die is provided with grooves used for arranging rubber strips. The invention further discloses a use method of the hydraulic die plate system of the precast box culvert. As the box culvert die plate of the box type structure is formed by enclosing the bottom die by the inner die and the outer die, the splicing seams of the die plate are greatly reduced, and the appearance quality of the precast box culvert can be greatly improved; and die disassembly and die assembly are realized by driving the inner die and the outer die through the hydraulic system, so thatthe production efficiency can be greatly increased.

Owner:中铁十四局集团房桥有限公司

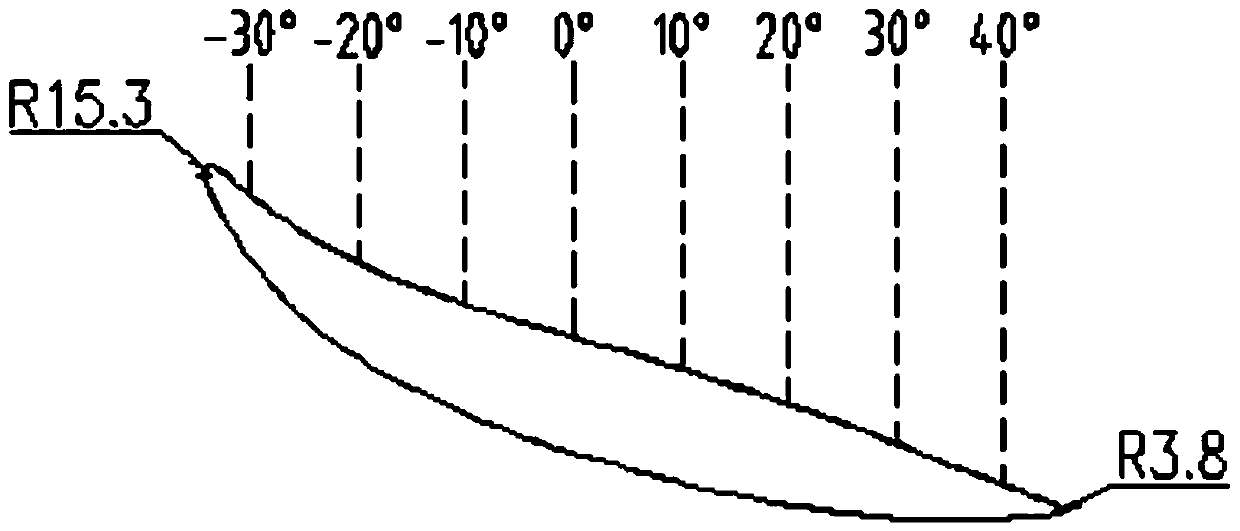

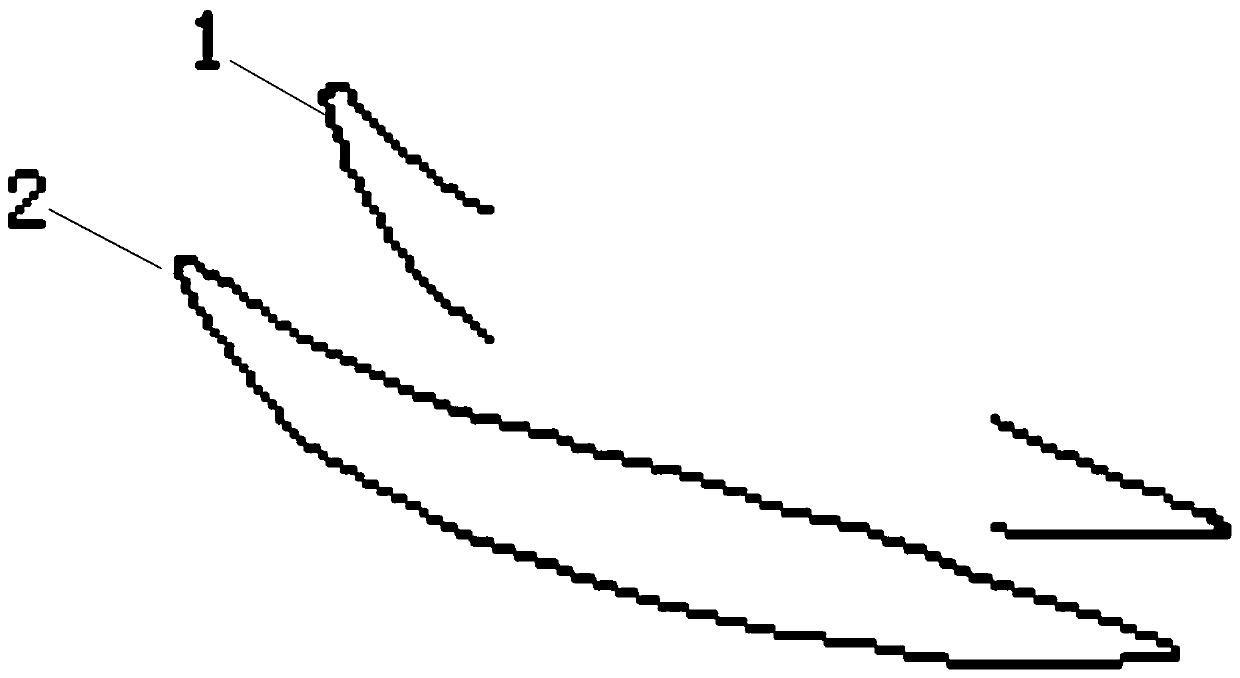

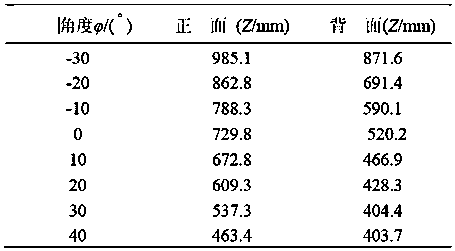

Three-dimensional modeling method for runner blade of tubular water turbine

InactiveCN108121837AReduce seamsReduce workloadHydro energy generationDesign optimisation/simulationNumerical controlWater turbine

The invention discloses a three-dimensional modeling method for a runner blade of a tubular water turbine. The method is implemented by the two steps of 1, generating a blade profile curve usable forthree-dimensional software; and 2, generating a three-dimensional entity blade by utilizing the curve. Two-dimensional AutoCAD software is adopted for importing a blade profile of a wooden pattern toPro / E to generate a blade section curve; used commands include a from-reference command, a sketching command, a sketch plane selection command, a sketch-from-file command and a completion command; AutoCAD and Pro / E interfaces with good performance are adopted; and coordinates of points do not need to be calculated but are suitable for a Cartesian coordinate system. A blade body is generated by adopting point, line, surface and body methods, then the blade body is subjected to shape modification, and finally a three-dimensional model of the blade is realized; and the runner blade of the tubularwater turbine is subjected to accurate three-dimensional modeling, thereby facilitating numerical control machining, hydromechanics calculation analysis and performance prediction.

Owner:SHENYANG GETAI HYDROPOWER EQUIP

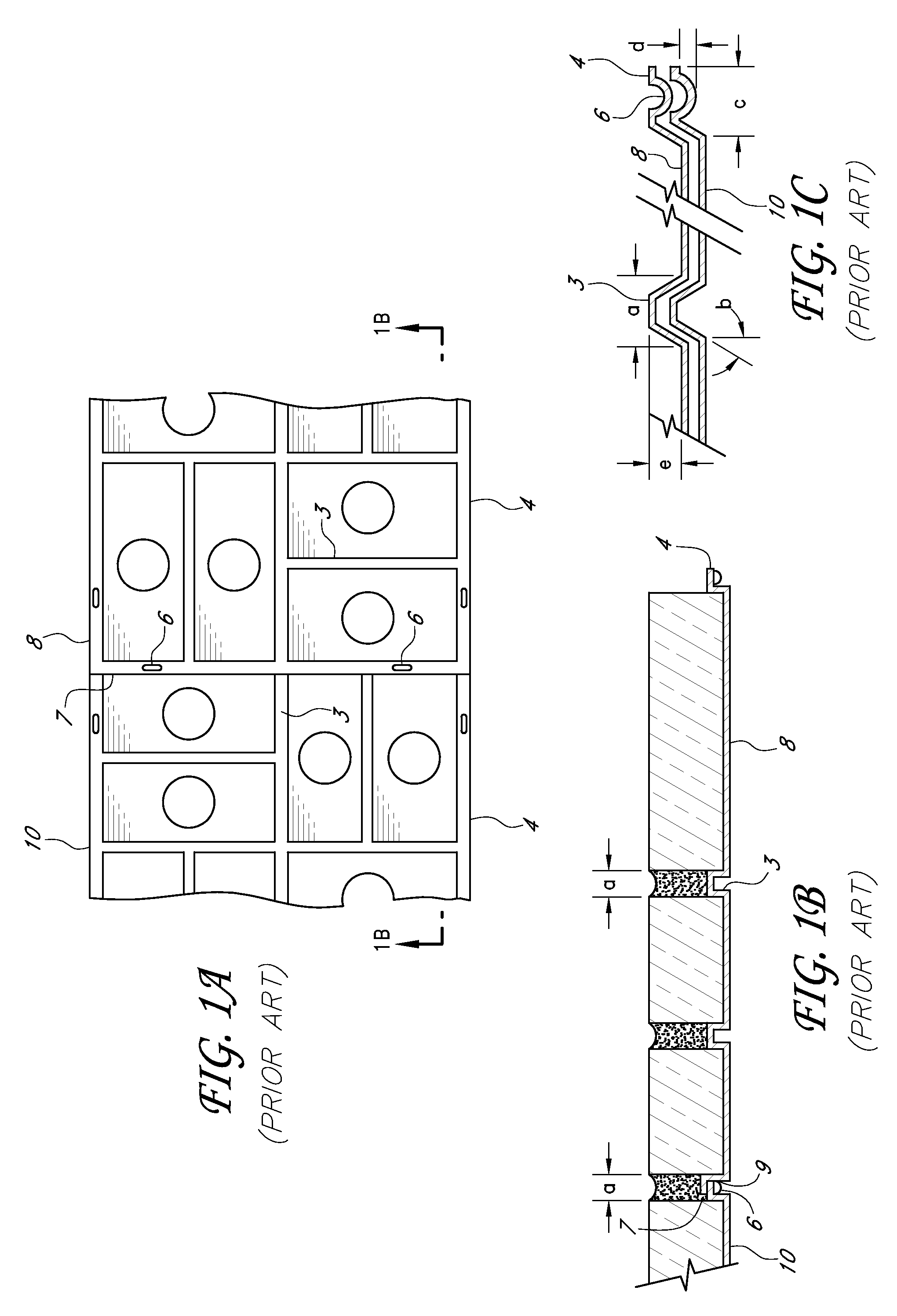

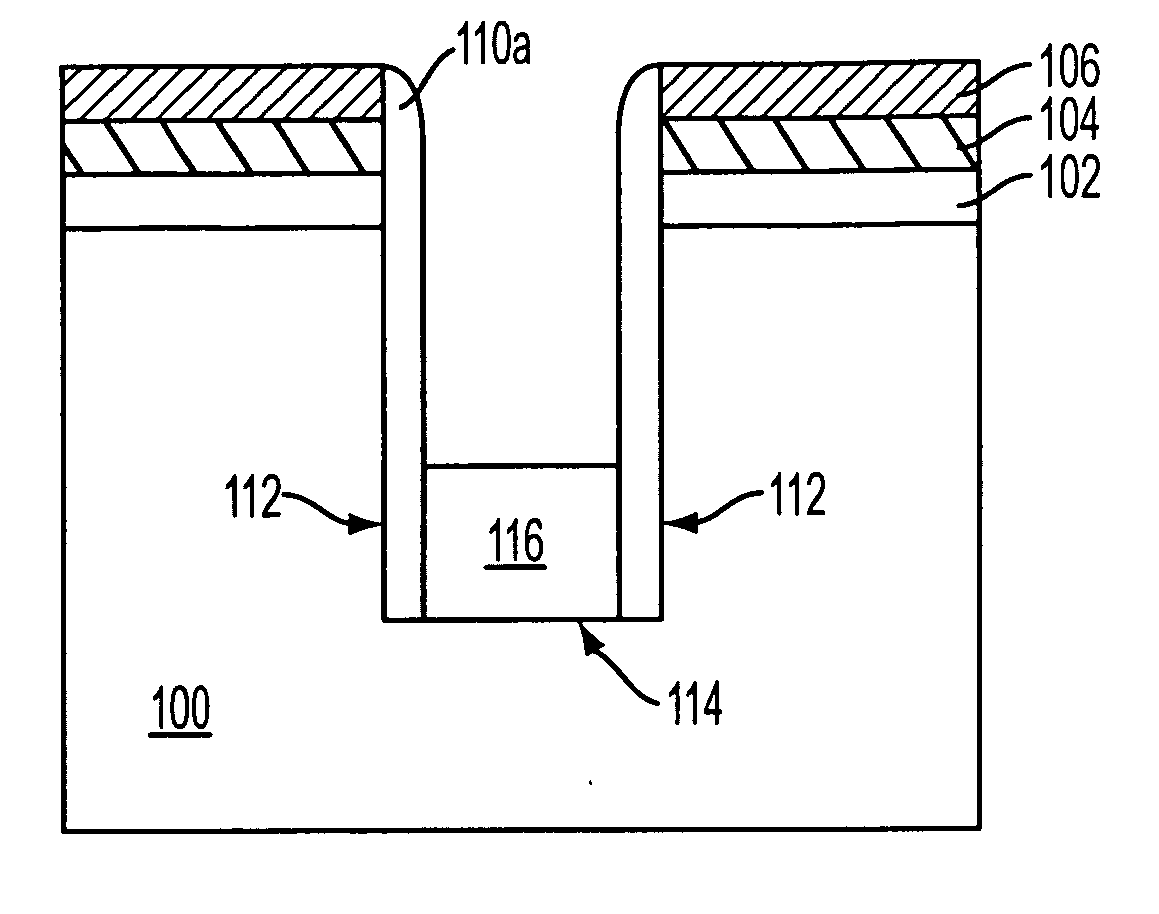

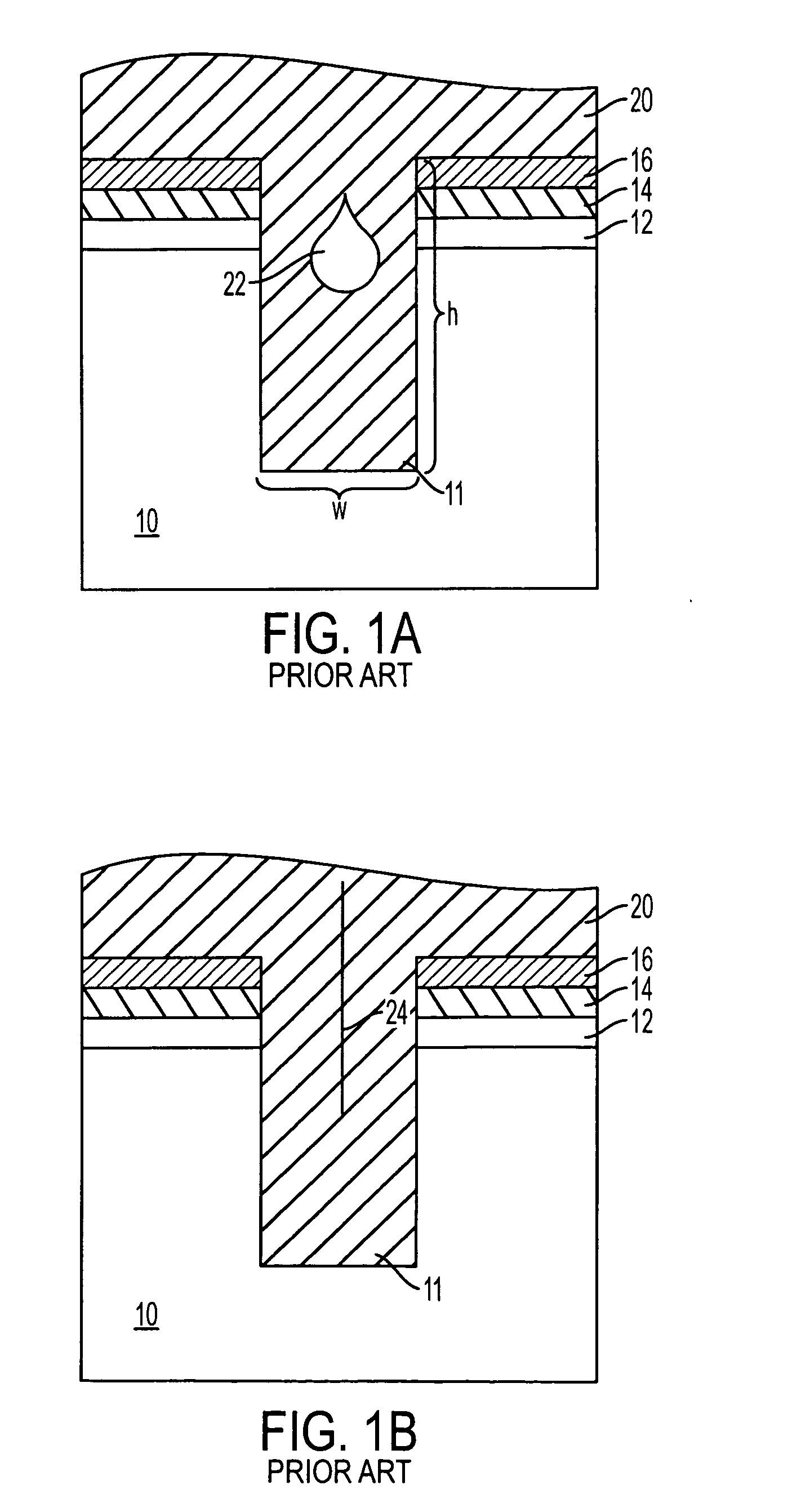

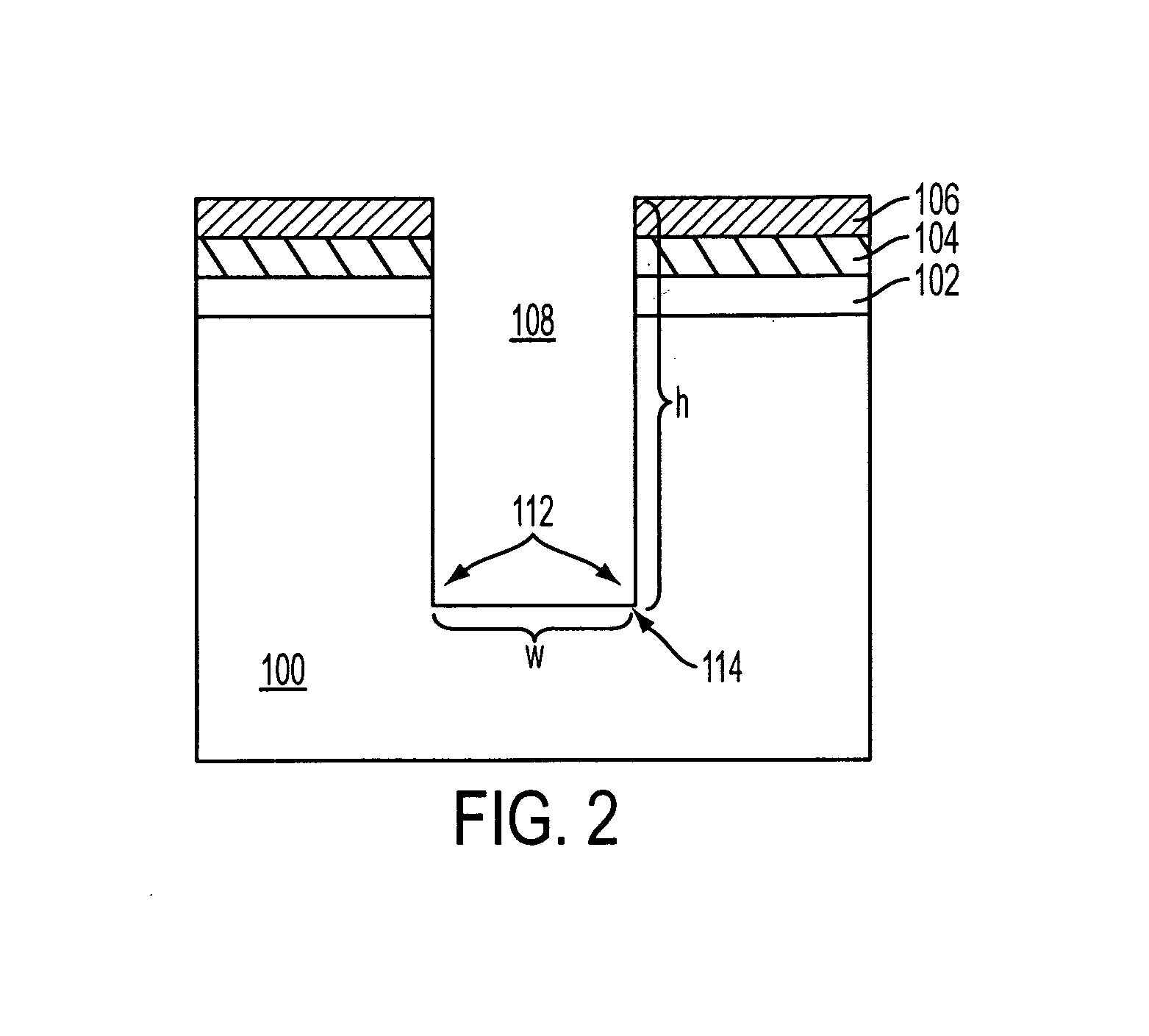

Method of filling a high aspect ratio trench isolation region and resulting structure

InactiveUS20070170542A1CharacteristicReduce voidsSolid-state devicesSemiconductor/solid-state device manufacturingGas phaseChemical vapor deposition

A method of filling a high aspect ratio trench isolation region, which allows for better gap-fill characteristics and avoids voids and seams in the isolation region. The method includes the steps of forming a trench, forming an oxide layer on the bottom and sidewalls of the trench, etching the oxide layer to expose the bottom of the trench, providing an epitaxial silicon layer on the bottom of the trench, and providing a high quality oxide chemical vapor deposition layer over the epitaxial silicon layer.

Owner:MICRON TECH INC

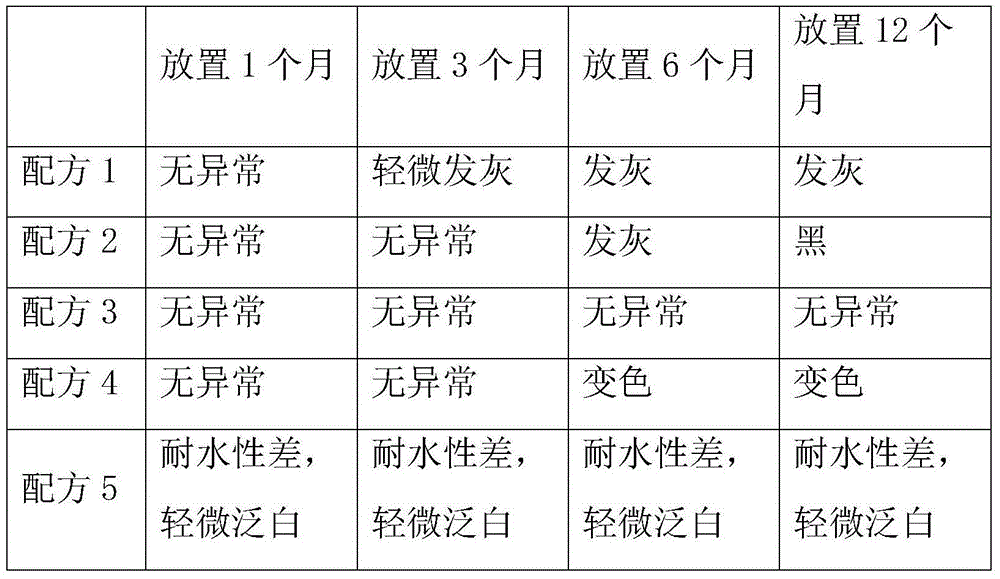

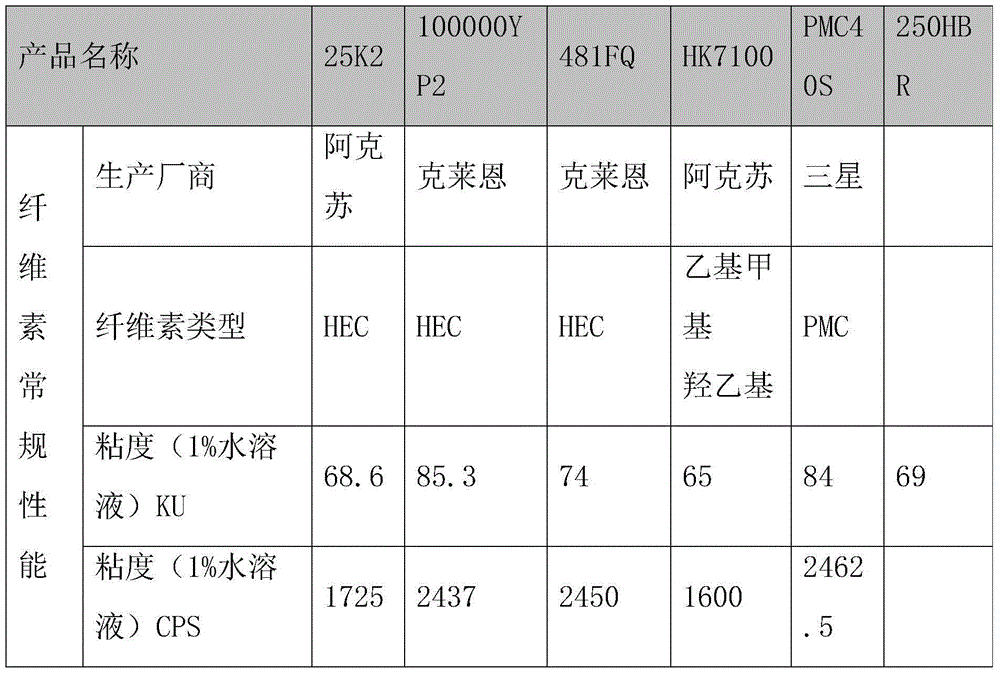

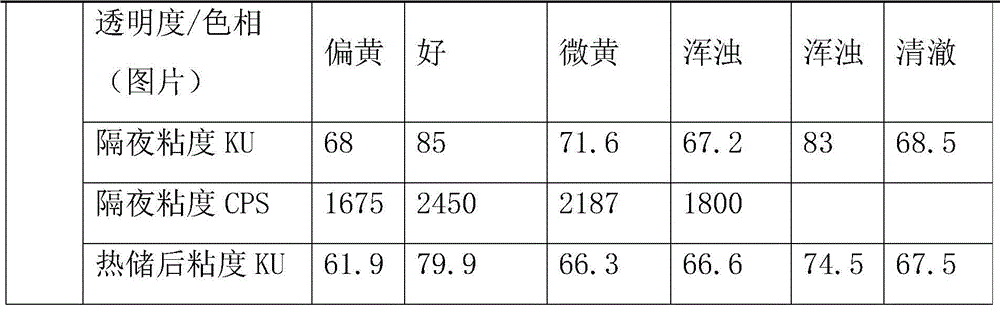

Painted ceramic stone and production technology thereof

The invention provides a building decoration coating painted ceramic stone and a production technology thereof. The coating painted ceramic stone adopts 40-80 mesh ceramic sands, the thickness of the coating layer of the above product is 2mm, and the disadvantages of single color, easy efflorescence, insufficient thickness and no crack resistance function of traditional emulsion paints are overcome; the color of the ceramic sands can be sintered arbitrarily, and is stable, so the painted ceramic stone has the advantages of grittiness of texture coatings, no need of any color paste, no color fading risk, uniform particle size, and great reduction of the lapping defect generation; and silica sol is introduced in the formula of the painted ceramic stone, a film composite base material is arrayed in a spherical or subglobular manner, and the surface is flat and compact and has few apertures, so fine dust particles cannot intrude the apertures, and cannot adhere, thereby the coating layer has good contamination resistance.

Owner:上海贝塔建筑科技有限公司

Mold core for valve body casting and valve body wax pattern forming die

PendingCN111842796ALarge space obstruction effectIncrease in sizeFoundry mouldsFoundry coresEngineeringStructural engineering

The invention relates to a mold core for valve body casting and a valve body wax pattern forming die. The valve body wax pattern forming die comprises an upper die body, a lower die body and the moldcore. The upper die body is buckled to the lower die body, a cavity is formed in the joint surface of the upper die body and the lower die body and communicates with the outside through a wax ejectionport in the side wall, and the cavity communicates with the outside through a first mounting hole, a second mounting hole and a third mounting hole. The first mounting hole internally cooperates witha first mold core for forming an upper flow channel of a shut-off valve, the second mounting hole internally cooperates with a second mold core for forming a valve rod hole of the shut-off valve, andthe third mounting hole internally cooperates with a third mold core for forming a lower flow channel for the shut-off valve. The end, close to the second mold core, of the first mold core is provided with a lateral forming concave surface matched with a lateral protrusion on the second mold core, the second mold core is internally provided with a locking rod extending in the axial direction of the second mold core, the inner extending end of the locking rod penetrates through a column used for forming a valve flap hole and is fixedly connected with a corresponding connecting hole in the third mold core, and the two end surfaces of the column abut against the second mold core and the third mold core respectively.

Owner:四川省简阳川田机械阀业有限公司

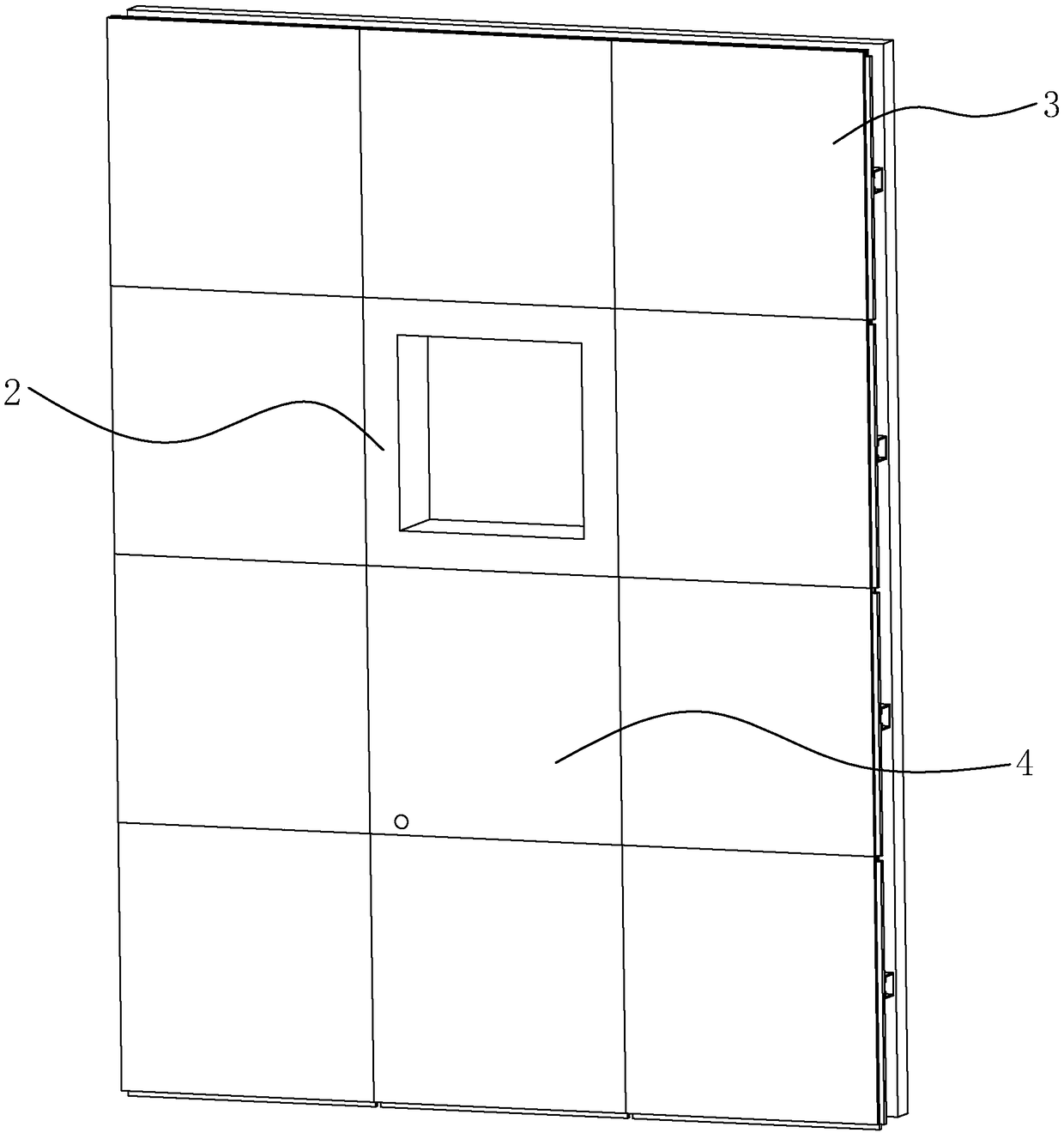

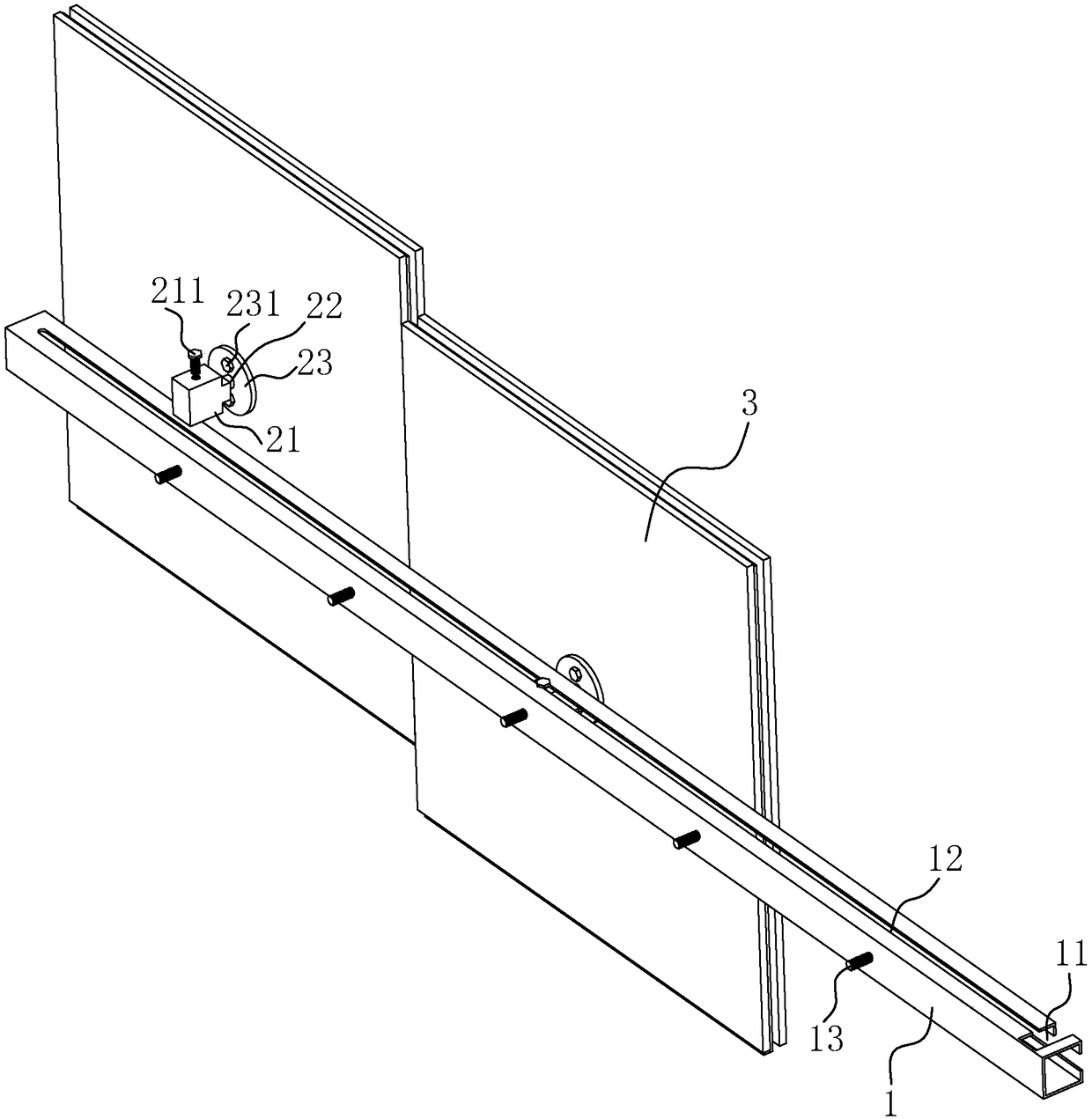

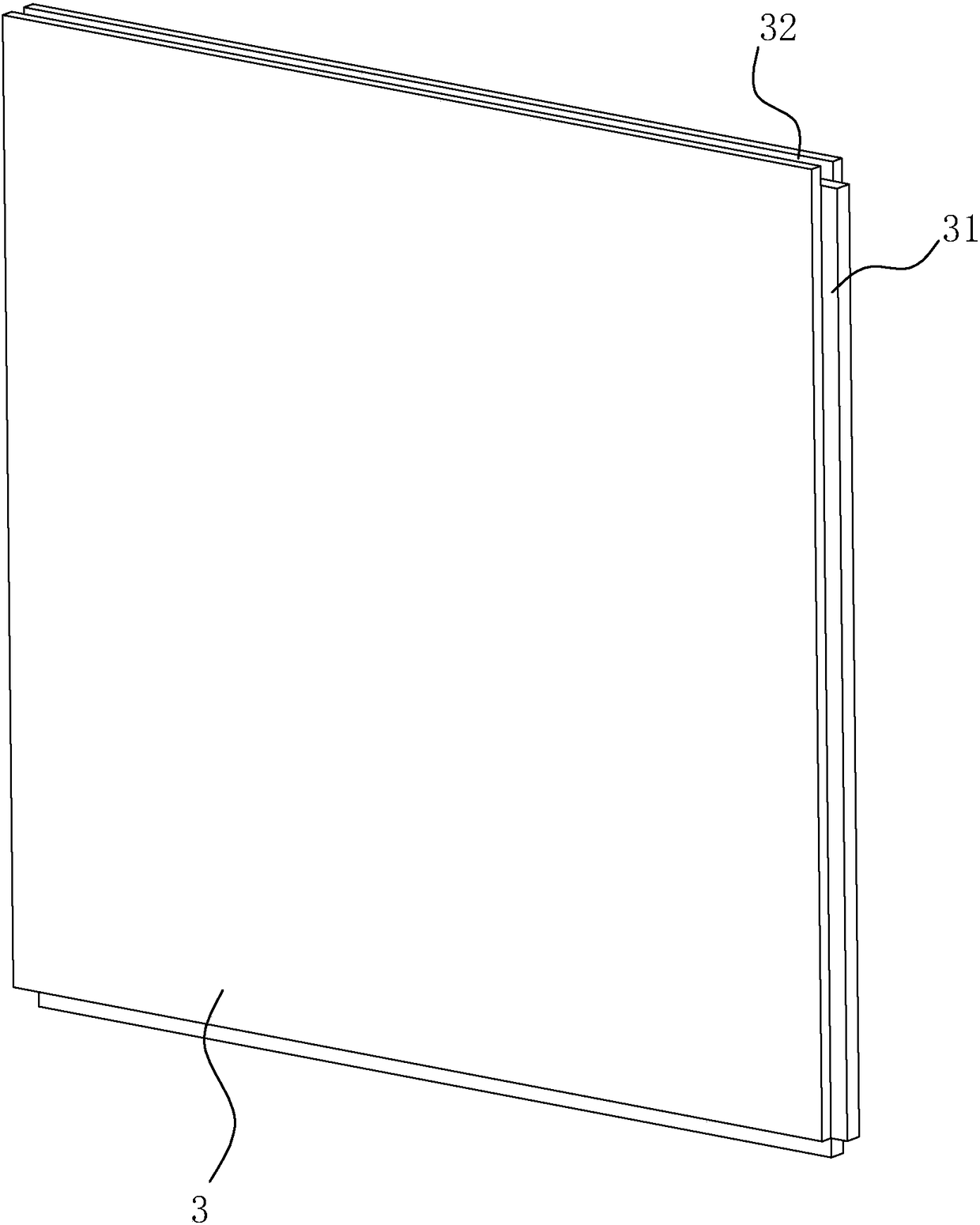

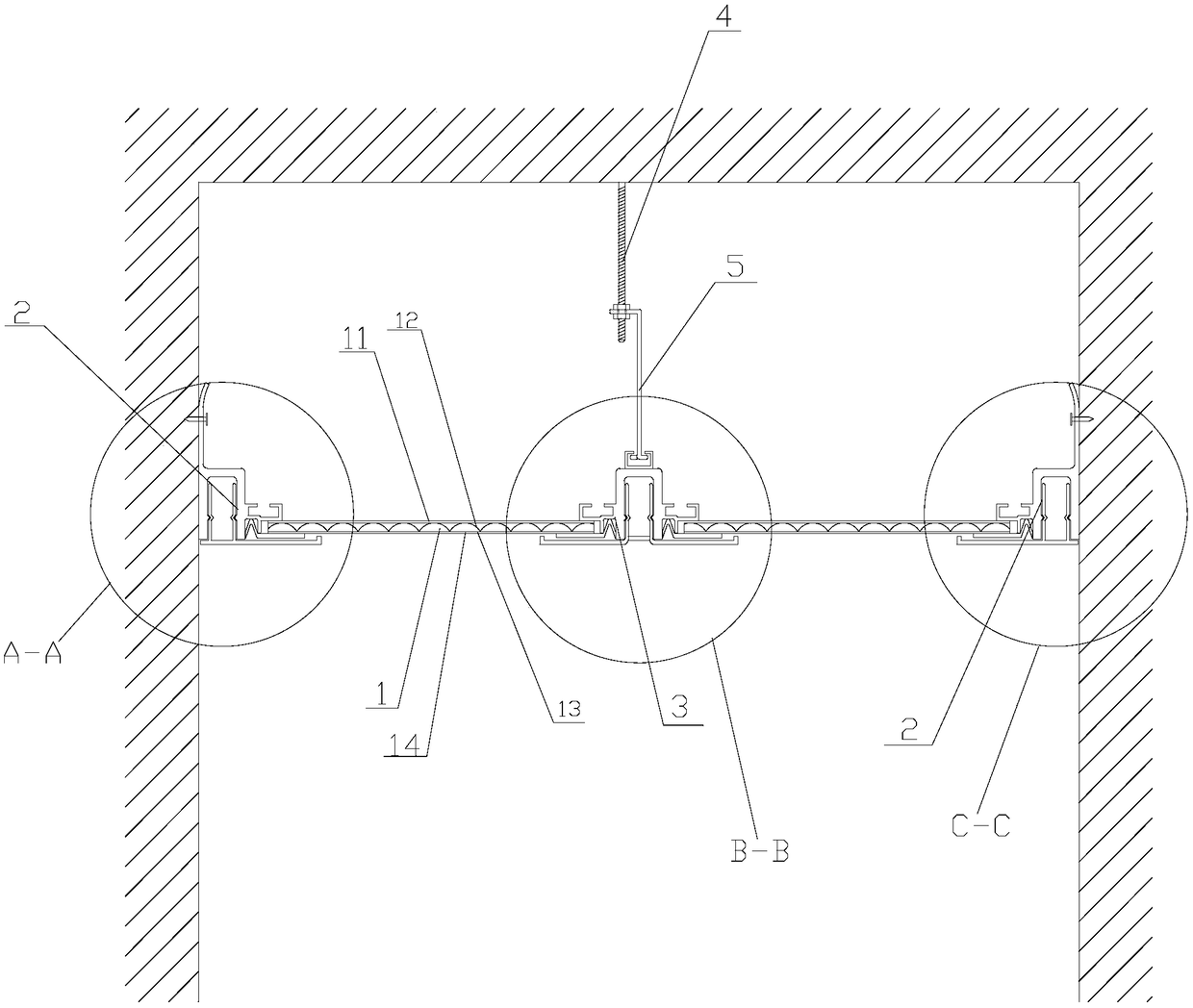

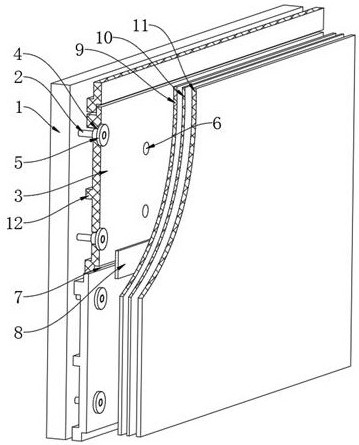

Integrated fabricated heat preservation external wall

ActiveCN108252427AReduce exchangeImprove insulation effectHeat proofingBuilding insulationsWindow openingEnergy conservation

The invention relates to the field of external heat preservation of building external walls, aims to solve the problems that heat preservation external walls of structures such as windows and balconies need multi-block splicing resulting in multiple splicing seams and poor heat preservation performance, and particularly relates to an integrated fabricated heat preservation external wall. The integrated fabricated heat preservation external wall comprises a plurality of horizontally-arranged groove steel, the groove steel is connected with first wall plates corresponding to the window opening position and second wall plates corresponding to the wall surface position, the first wall plates are formed integrally, and the second wall plates are spliced mutually. The first wall plates and the second wall plates are sealed through sealing glue. Protruding edges are arranged on one set of adjacent side edges of the second wall plates in the length direction correspondingly in an extending mode. Grooves matched with the protruding edges are formed in the other set of adjacent side edges of the second wall plates. The protruding edges and the grooves are located in the middles of the side edges of the second wall plates. The first wall plates are manufacture and formed integrally according to a concrete window or balcony structure, the number of the splicing seams is decreased effectively, and heat preservation performance of the heat preservation external wall is improved, so that indoor and outdoor heat exchanging is reduced, and the effect of energy saving is achieved.

Owner:江苏南通三建建筑装饰集团有限公司

Suspended ceiling convenient to assemble and disassemble

PendingCN109252610ANot easy to damageReduce the number of single piecesCeilingsEngineeringThreaded rod

The invention discloses a suspended ceiling convenient to assemble and disassemble. The suspended ceiling convenient to assemble and disassemble comprises a plurality of aluminum plates, a plurality of edge closing lines, a mounting beam, a suspended ceiling threaded rod and a hanging piece, wherein the upper end of the suspended ceiling threaded rod is fixedly connected with the top surface of awall; the hanging piece is arranged at the lower end of the suspended ceiling threaded rod; the hanging piece is detachably connected with the suspended ceiling threaded rod; the mounting beam is arranged at the lower end of the hanging piece; the aluminum plates are symmetrically arranged on the two sides of the mounting beam separately; each edge closing line is arranged at the other end of eachaluminum plate; and the upper ends of the side closing lines are fixedly connected with the side walls of the wall. By cooperation of the side closing lines and clamping pieces, the aluminum plates of the suspended ceiling are fixed, the suspended ceiling is simple to mount, is attractive and firm, is convenient to repair and disassemble, and cannot be damaged easily when disassembled, the size of a suspended ceiling can be randomly cut according to sizes, attractiveness and design requirements of different suspended ceilings, the number of single pieces of the suspended ceiling plates is greatly reduced, the circumstance that the number of single pieces of embedded suspended ceiling buckle plates in conventional fixed sizes is over large is changed, and too much splicing seams of the suspended ceiling are reduced.

Owner:HAIYAN MDHO ELECTRICAL APPLIANCE TECH

Oxidation-resistant graphite electrode surface coating and preparation process thereof

InactiveCN109678516ASolve the contradiction of thermal expansion coefficient mismatchPrevent oxidationScanning electron microscopeOxidation resistant

The invention discloses an oxidation-resistant graphite electrode surface coating and a preparation process thereof. The oxidation-resistant coating comprises the following raw materials in parts by mass: 45 to 55 parts of SiC, 32 to 38 parts of AL2O3, 25 to 36 parts of ZrO2, 25 to 30 parts of solvent methanol, 30 to 35 parts of solvent ethanol, 2 to 5 parts of dispersant stearic acid and 12 to 18parts of a binding agent acrylic acid resin. The oxidation-resistant coating is prepared by the following steps: pulverizing the raw materials, sieving, preparing transition layer coating, preparingsealing layer coating, performing graphite electrode surface pretreatment, performing graphite electrode surface coating, performing vacuum sintering and performing scanning electron microscope representation. The oxidation-resistant coating of silicon carbide-aluminum oxide-zirconium oxide (SiC-AL2O3-ZrO2) is a composite coating, wherein the SiC belongs to a transition layer and is used for solving the conflict that the thermal expansion coefficient between a graphite composite material and the coating is not matched; and the AL2O3 and the ZrO2 serve as a barrier layer to provide a barrier for diffusion of oxygen, so that oxidation of the graphite electrode is avoided.

Owner:HEFEI CARBON CO LTD

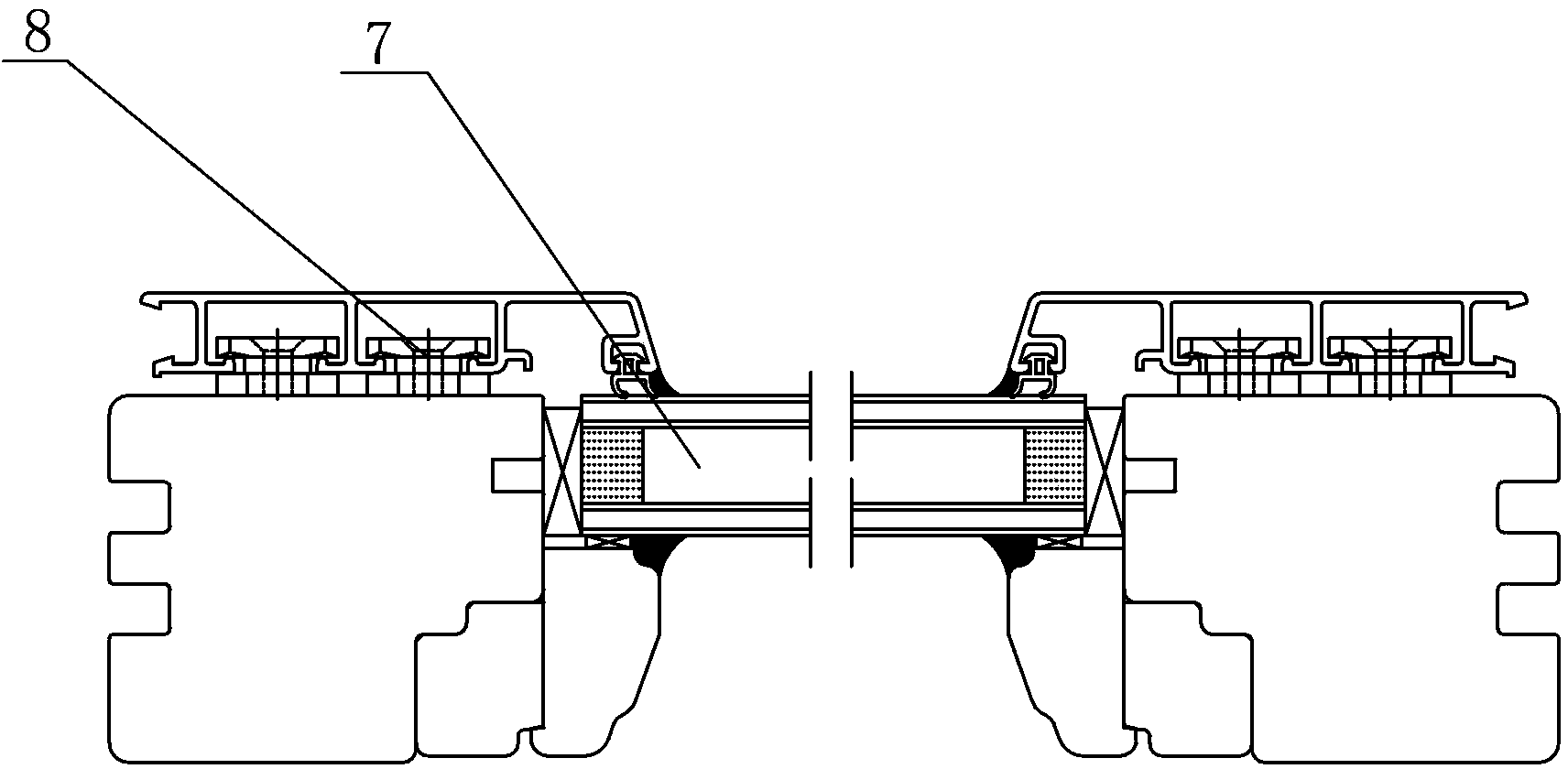

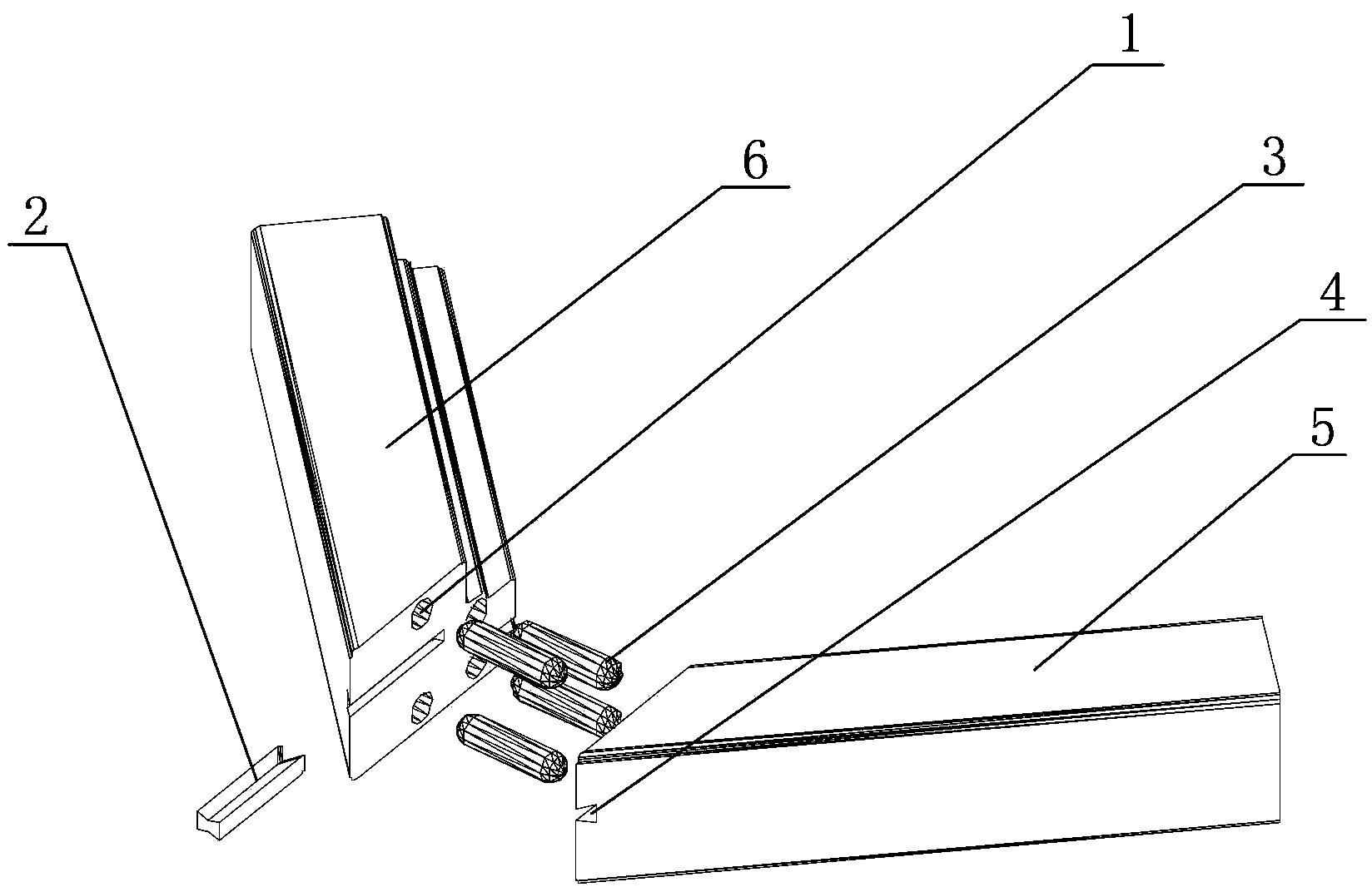

Novel door window system

InactiveCN103382802AQuality improvementFlat surfaceDoors/windowsStructural engineeringUltimate tensile strength

The invention relates to a novel door window system which comprises a frame profile, a fan profile, a pressing line and a piece of hollow glass, wherein the hollow glass is clamped in the middle between the pressing line and the fan profile; the frame profile, as well as the fan profile, comprises a first frame, a second frame, round tenon rods and dovetail tenons; the end surfaces of the first frame and the second frame are inclined at 45 degrees; one or more than one hole and a plurality of dovetail hole semi-slots are formed in the direction perpendicular to the 45-degree inclined surfaces; glue is coated on the holes, the dovetail hole semi-slots and the inclined surfaces; the round tenon rods are inserted into the corresponding holes in the two frames so as to be connected with the two frames in combination with the glue; the dovetail tenons are inserted into the corresponding dovetail hole semi-slots in the two frames, so as to fix the two frames in combination with the glue. Due to the adoption of the structure, the plane of the assembled frame is even, the diagonal error is small, the butted seam is small, the formed angle is high in strength, and accordingly, the assembled frame quality is improved; meanwhile, with the dovetail tenon outline and an inverted tooth-type structure thereof, enough connecting pulling force can be provided when the frame is used; solidification of the glue is not required, so that the time is saved.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

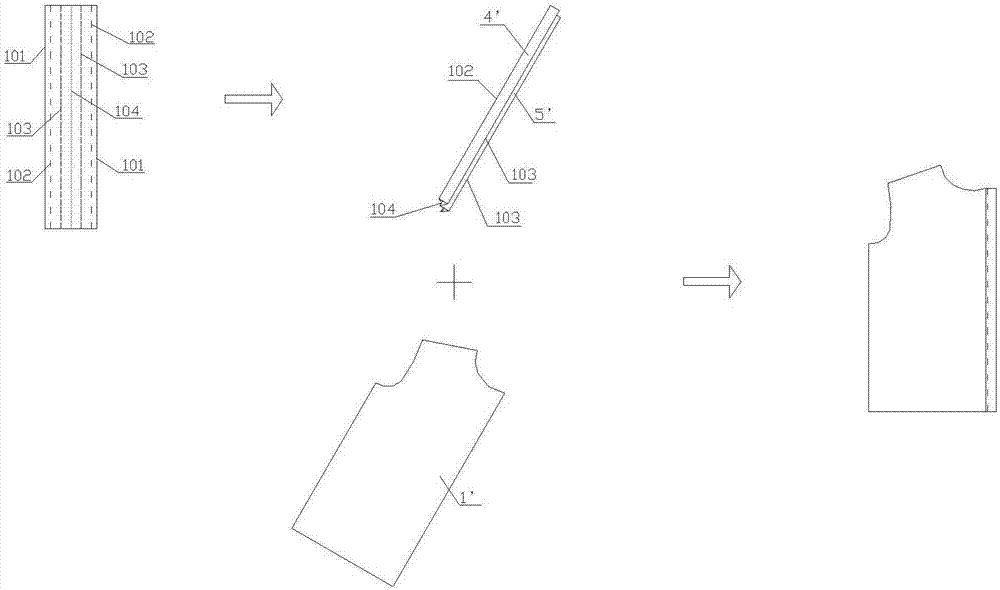

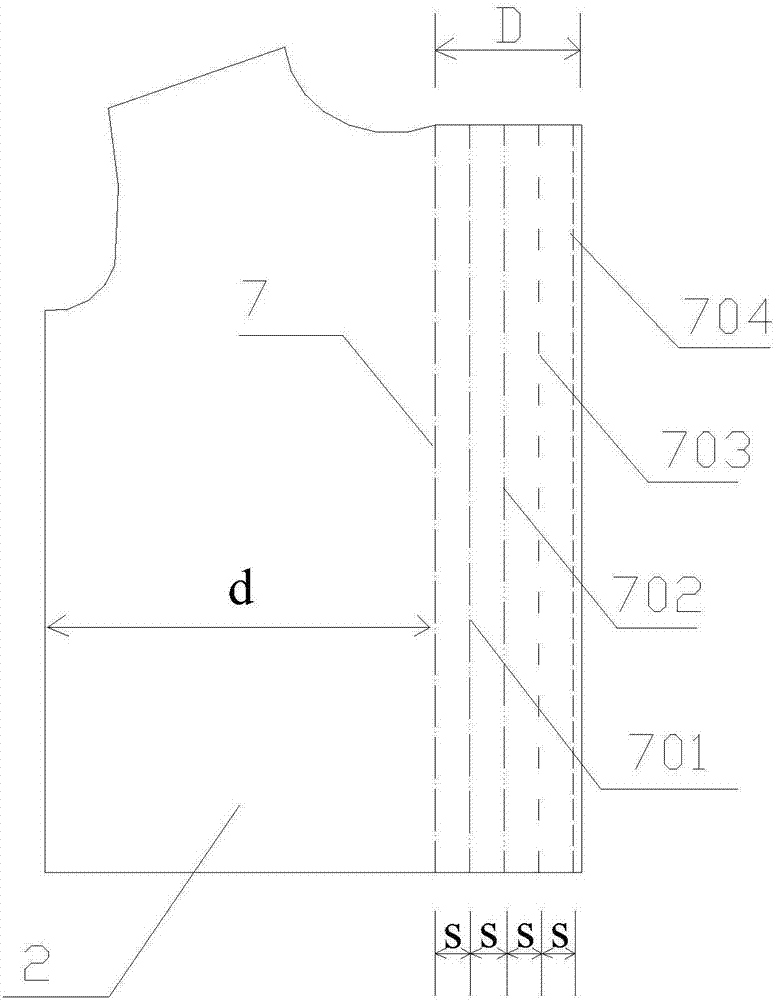

Shirt with hidden placket and manufacturing method for same

The invention provides a shirt with a hidden placket. The shirt comprises a hidden placket and a shirt front part. The hidden placket and the shirt front part are made of the whole piece of cloth. The invention further provides a manufacturing method for the shirt with the hidden placket. The method comprises steps of determining a width (s) of the hidden placket, improving a piece of cloth, arranging the width of the shirt front part as d and the cloth width as D, and forming a d+4s=<D=<d +5s, arranging a public side of the hidden placket and the shirt front part as a benchmark line, arranging a first trace line, a second trace line, a third trace line and a fourth trace line parallel to the benchmark line in distance of s, 2s, 3s and 4s, inwardly folding the cloth along the third trace line, then secondary folding the cloth along the second trace line, fixedly sewing the three-layered cloth via threads along the second trace line, and outwardly folding the internal layer placket along the second trace line to enable the internal layer placket to be overlapped with the external layer placket, and ironing the internal and external plackets. The shirt hidden placket can be simply manufactured; and threads are exposed to one surface of the shirt.

Owner:宁波太平鸟潮服饰营销有限公司

Spliced screen and display device

InactiveCN112817174AReduce seamsImprove display qualityNon-linear opticsInput/output processes for data processingComputer hardwareChip on film

The invention provides a spliced screen and a display device. The spliced screen comprises at least two display screens which are spliced with each other, wherein each display screen comprises an outer frame, a backlight module and a display panel, each outer frame comprises a first frame and a second frame opposite to the first frame, each backlight module comprises a light-emitting element close to the corresponding first frame, the display module comprises a chip on film arranged close to the first frame, and at least one of the two adjacent display screens is spliced along the second frame. By optimizing the positions of the chip on film and the light-emitting element in the display screen, the width of the first frame is greater than that of the second frame, the second frame serves as the splicing edge, the spliced screen has a small splicing seam, and the display quality and attractiveness of the spliced screen are improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

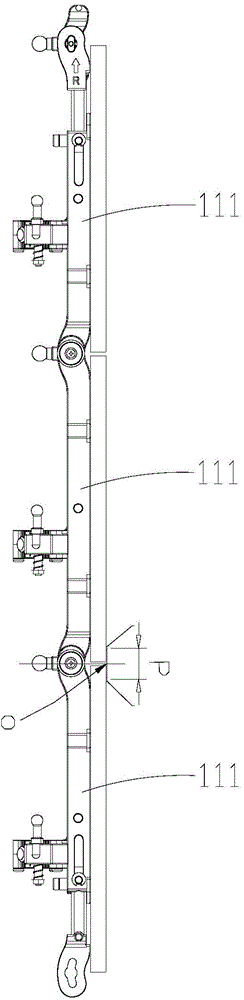

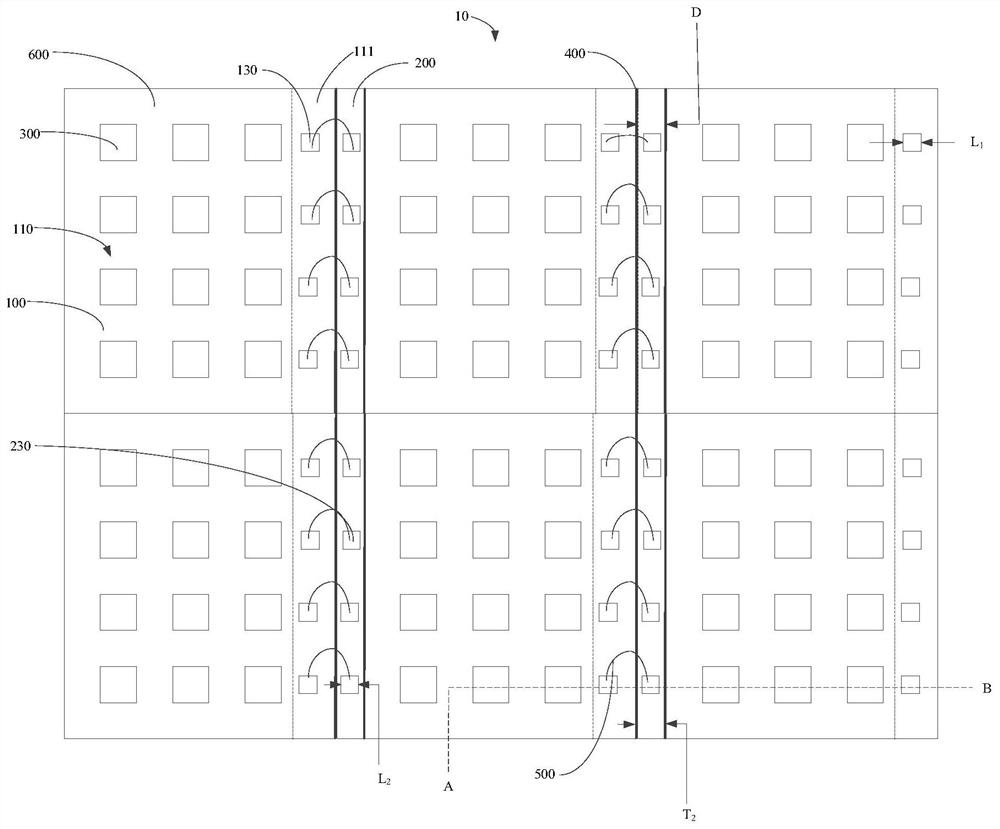

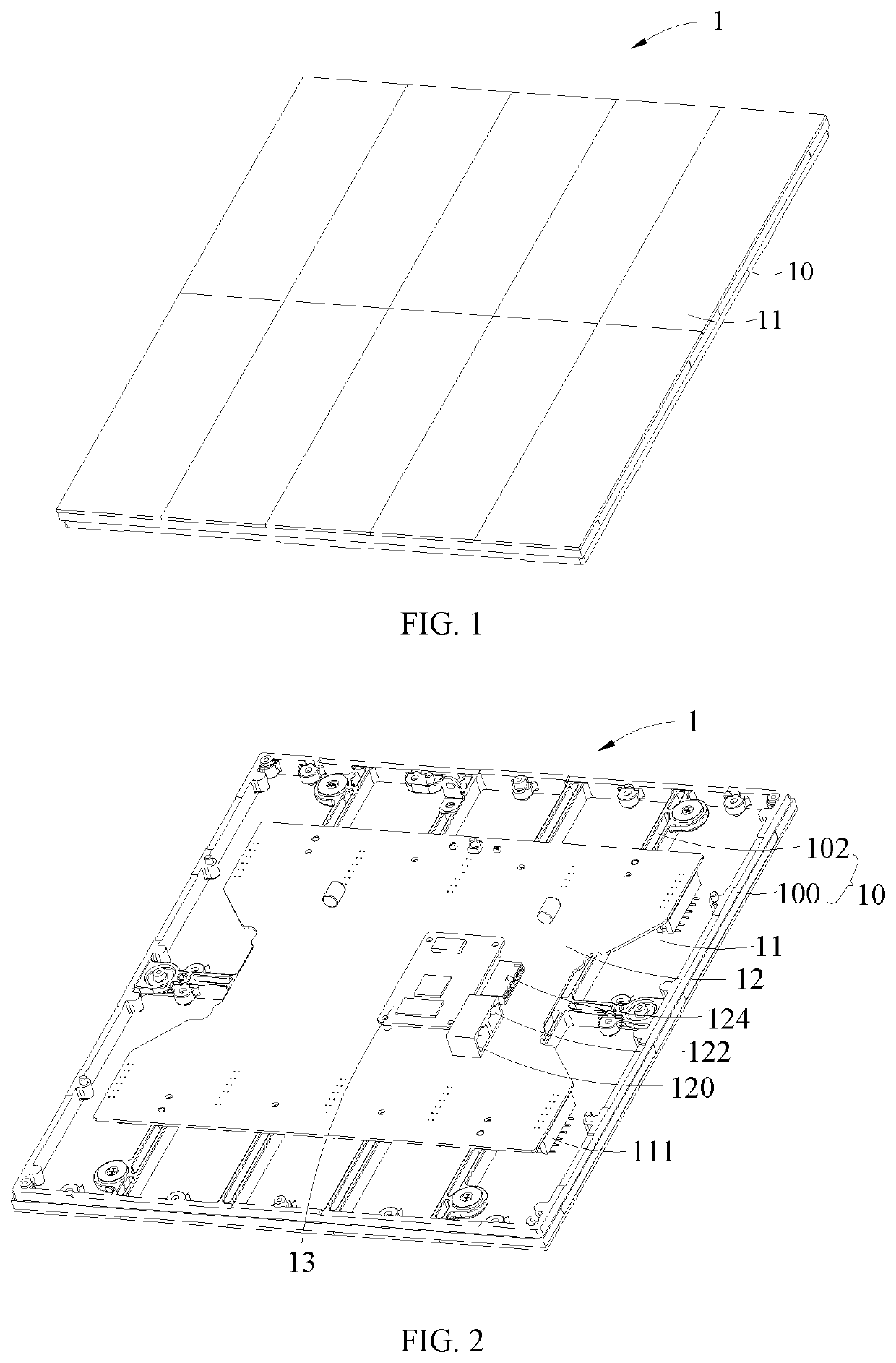

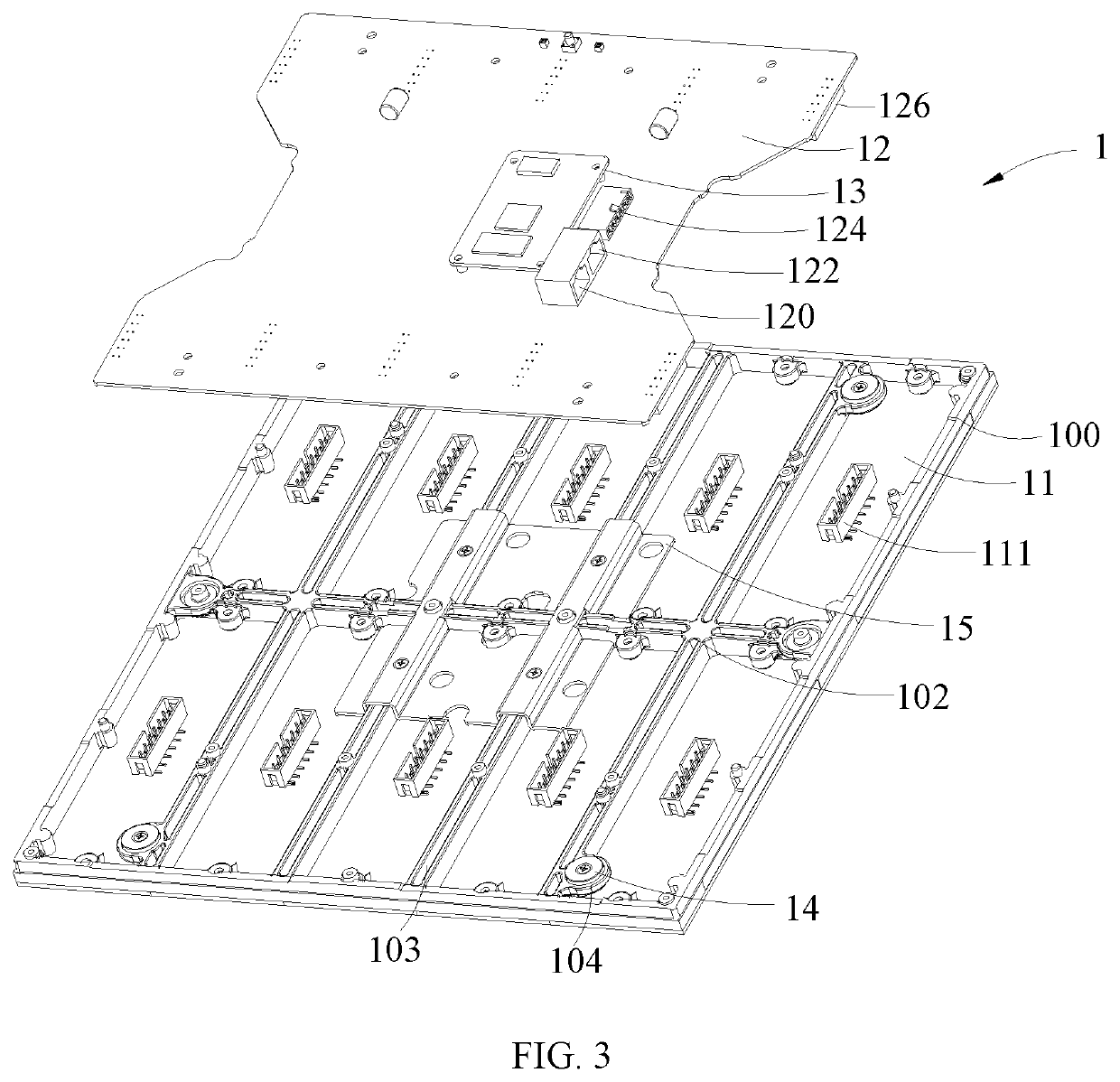

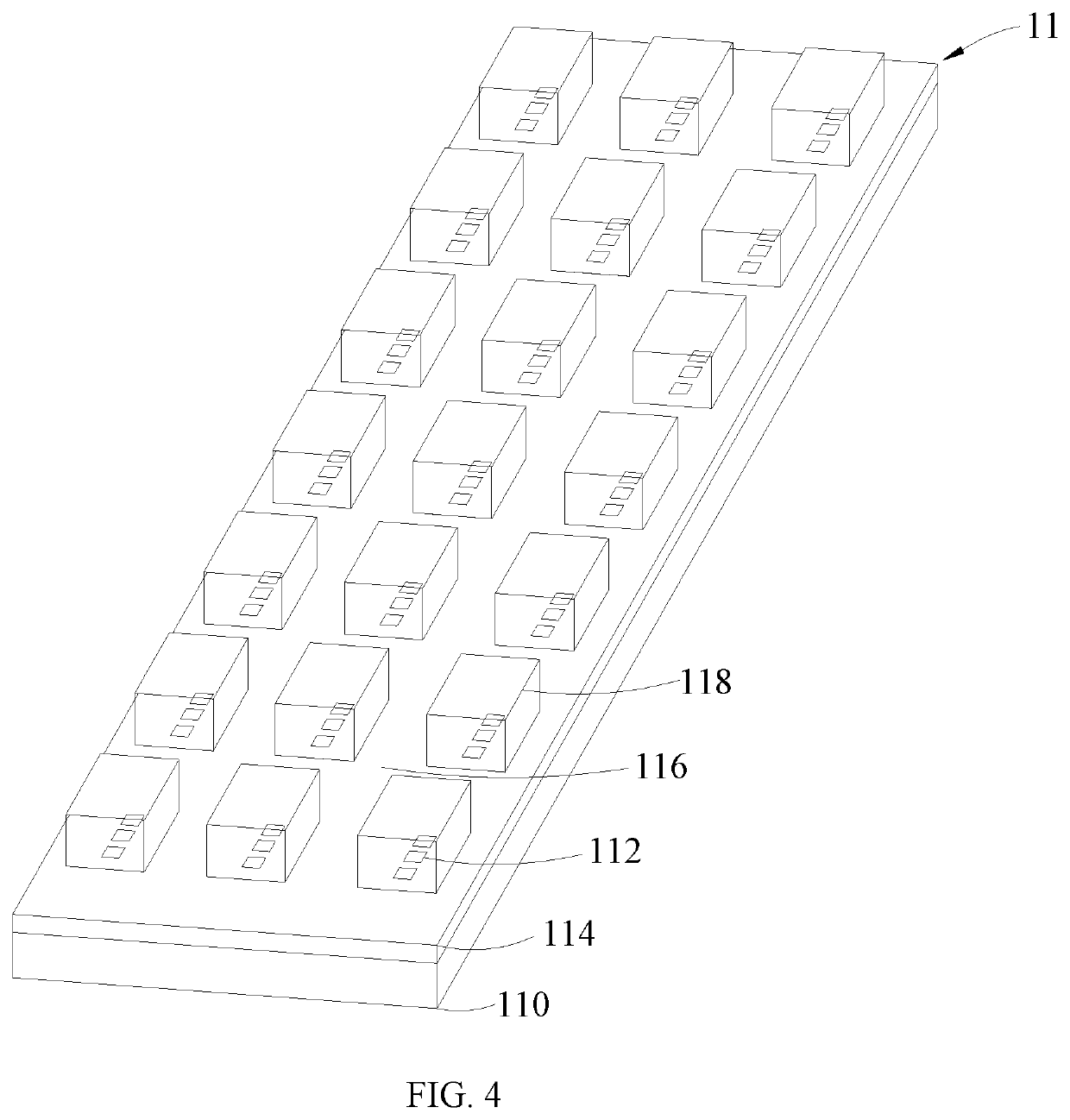

Display module, display screen and display system

ActiveUS20210050486A1Simple and reliable processAssembly uniformityDigital data processing detailsSolid-state devicesComputer hardwareEngineering

A display module, a display screen and a display system are disclosed. The display module comprises a frame and multiple display unit boards assembled and installed on the frame to form a display surface. The frame comprises a border and a support frame installed in the border. Each display unit board comprises a circuit board and multiple pixel points installed on a front side of the circuit board, wherein a back side of the circuit board is installed on the border and the support frame, and each pixel point includes at least one LED chip. According to the display module of the invention, multiple display unit boards are assembled on the frame to form a display surface.

Owner:LEDMAN OPTOELECTRONICS

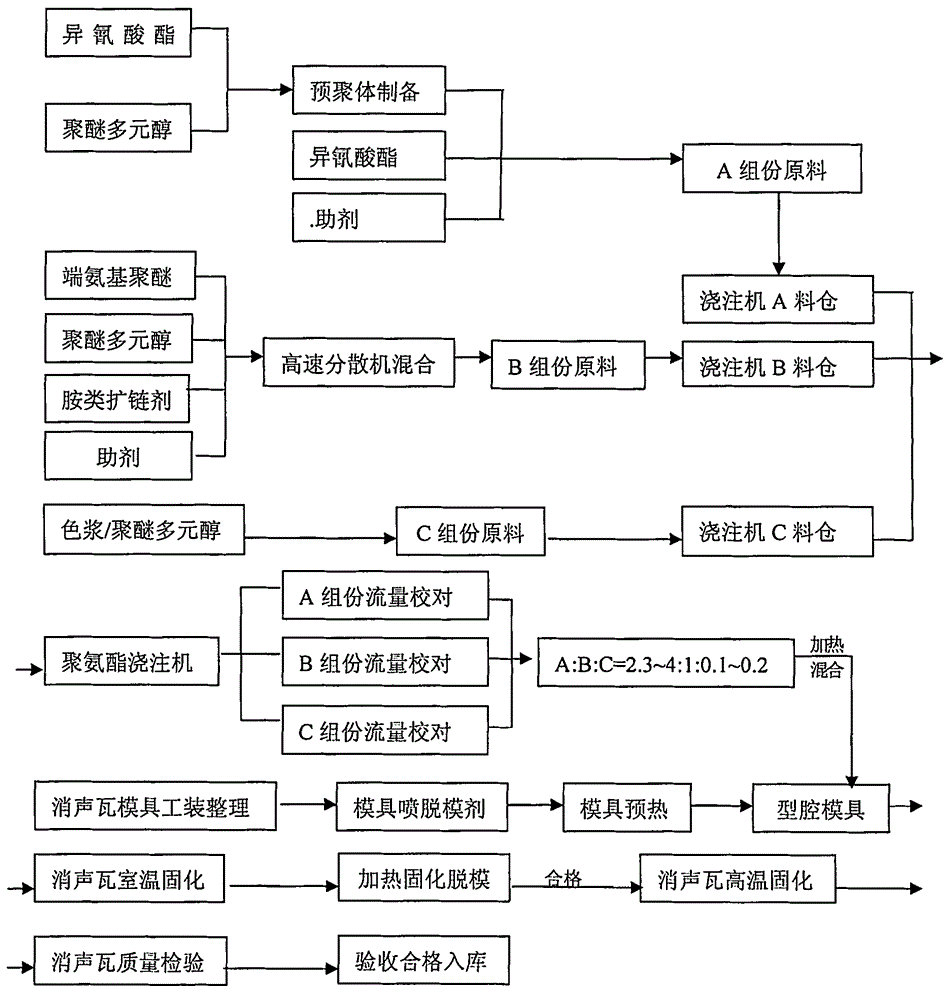

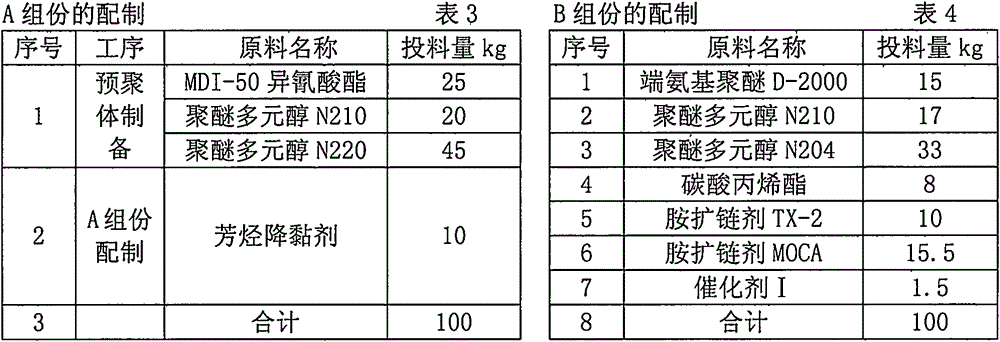

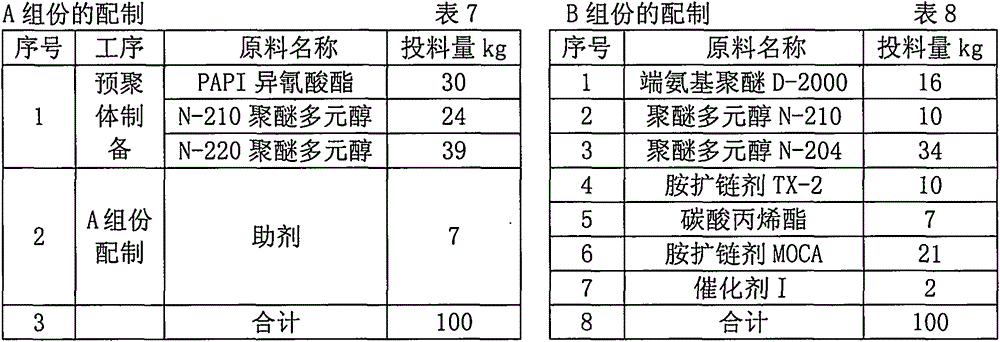

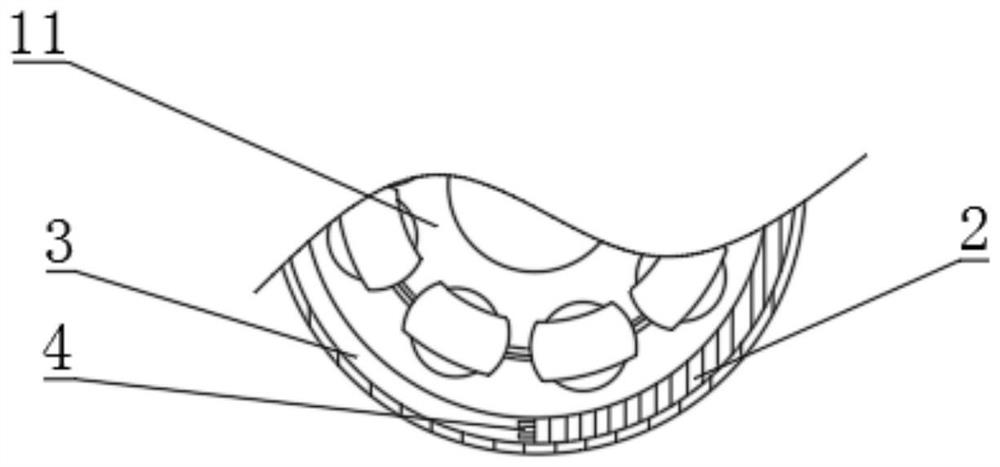

Polyurethane anechoic tile product and preparation method thereof

The invention introduces a polyurethane anechoic tile product and a preparation method thereof. A thick plate of a polyurethane anechoic tile is prepared into a slabbed construction which is 40-60mm thick with a vocal tract hole structure and the size can be determined according to the size of a die. The tile can be prepared by simulating 10 times of the area of the existing acoustic tile, so that the single tile area of the anechoic tile is effectively improved, the joint of the anechoic tile is effectively reduced and the damage probability of the anechoic tile is effectively reduced. The polyurethane anechoic tile prepared by the preparation method realizes the material performance and the water acoustic absorption performance of the existing rubber anechoic tile and is technically probable of replacing original rubber anechoic tile. The tile is the invention which is suitable for the technical field of coating anechoic tiles outside ships and has an actual application value.

Owner:上海瑞义聚氨酯科技有限公司

Beam-column concrete pouring dense-type combined formwork in building construction

ActiveCN110067383AImprove connection strengthReduce usageForms/shuttering/falseworksUltimate tensile strengthBeam column

The invention provides a beam-column concrete pouring dense-type combined formwork in building construction. The beam-column concrete pouring dense-type combined formwork comprises a column formwork,wherein the column formwork is a rectangular frame formed by buckling a plurality of column modules, an opening is formed in one side of the upper end of the column formwork, a beam formwork is arranged at the position of the opening, the cross section of the beam formwork is of a U-shaped structure, an opening of the beam formwork is upward, and the end of the beam formwork is connected with theopening of the column formwork through a connecting plate. According to the beam-column concrete pouring dense-type combined formwork in building construction, the connection strength between the column formwork and another column formwork is improved through the mutual fastening among the column modules, connection blocks and beam modules, the use of a screw connection mode is reduced, the disassembly and assembly are convenient, and the labor intensity is reduced; positioning ribs penetrate through through holes vertically or horizontally to fasten the adjacent column modules and beam modules, splicing seams are reduced, the connection strength between the beam formwork and the column formwork is further enhanced, the assembly is simple and easy, and the engineering practicability is high.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

Construction method of high-strength short fiber composite building outer wall heat preservation layer

The invention discloses a construction method of a high-strength short fiber composite building outer wall heat preservation layer. The construction method comprises the following specific steps that S1, the surface of an outer wall body is pretreated, specifically, floating sand and bulges on the surface of the outer wall body are cleaned, a vertical datum line is hung, and cement mortar is smeared on the sunken part of the wall surface for leveling; S2, threaded expansion bolts are mounted, specifically, mounting holes are drilled in the surface of the outer wall body through a handheld drill, the threaded expansion bolts are inserted into the mounting holes, and the threaded ends of the threaded expansion bolts are exposed out of the outer wall body; and S3, heat preservation plates are mounted, specifically, the heat preservation plates are hung on the threaded expansion bolts. According to the construction method, the heat preservation plates are hung on the surface of the outer wall body in advance, then the flatness of the heat preservation plates is adjusted, then adhesive cement is injected into gaps between the heat preservation plates and the outer wall body for bonding and fixing, the heat preservation plates do not need to be smeared with adhesives one by one, the plate width of the heat preservation plates can be properly increased, the coverage area of each mounted heat preservation plate is large, and the construction speed is greatly increased.

Owner:精易建工集团有限公司

Environment-friendly composite tundish dry liner

ActiveCN100398495CImprove the ability to resist slag penetration and erosionImproves the ability of penetration and erosionMelt-holding vesselsCalciteMagnesite

The invention relates to black inside linings for metallurgical continuous casting tundish, wherein the constituents of the lining material comprise (by weight percent) magnesite 30-70 parts, calcite or lime stone 5-50 parts, spinelle 2-15 parts, bauxite 2-15 parts, conjugation agent 1-15 parts, agglutinant 0.2-5 parts. The conjugation agent is selected from inorganic salts or frosted sugar, refined white sugar and crystallized sugar, the agglutination strengthening agent is selected from boracic acid, borax, table salt, silicate, iron oxide red and microcosmic salts.

Owner:海城利尔麦格西塔材料有限公司 +1

High-stability air purification equipment with cleaning function

InactiveCN111420479APrevent dumpingReduce the chance of damageDispersed particle filtrationTransportation and packagingPistonStructural engineering

The invention relates to high-stability air purification equipment with a cleaning function. The air purification equipment comprises a main body, a base, a filter screen, an air inlet and an air outlet. The air purification equipment further comprises a fixing mechanism and a cleaning mechanism. The fixing mechanism comprises an air cylinder, a driving assembly, an air inlet pipe, an air outlet pipe, a fixing box, a power assembly, two connecting pipes, two pistons, two sucking discs and two water adding assemblies. The cleaning mechanism comprises a first bearing, a rotating shaft, a transmission assembly and a plurality of cleaning rods. According to the high-stability air purification equipment with the cleaning function, the fixing mechanism is arranged, and the sucking discs are adsorbed on the ground, so a fixing function is realized, the equipment is prevented from being accidentally touched and toppled over, the damage probability of the equipment is reduced, and the safety ofthe equipment is improved; and in virtue of the cleaning mechanism, the function of cleaning the filter screen is realized, and dust is prevented from blocking the filter screen and influencing the circulation of the filter screen.

Owner:南京昕知环保科技有限公司

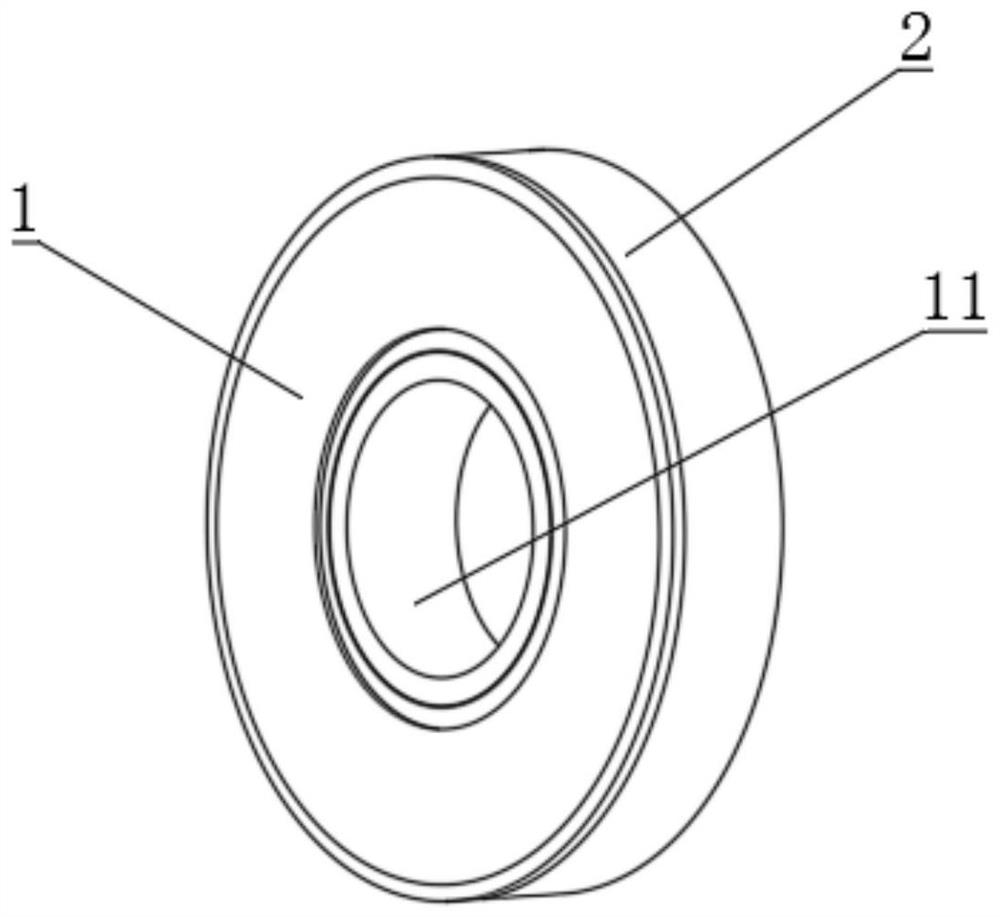

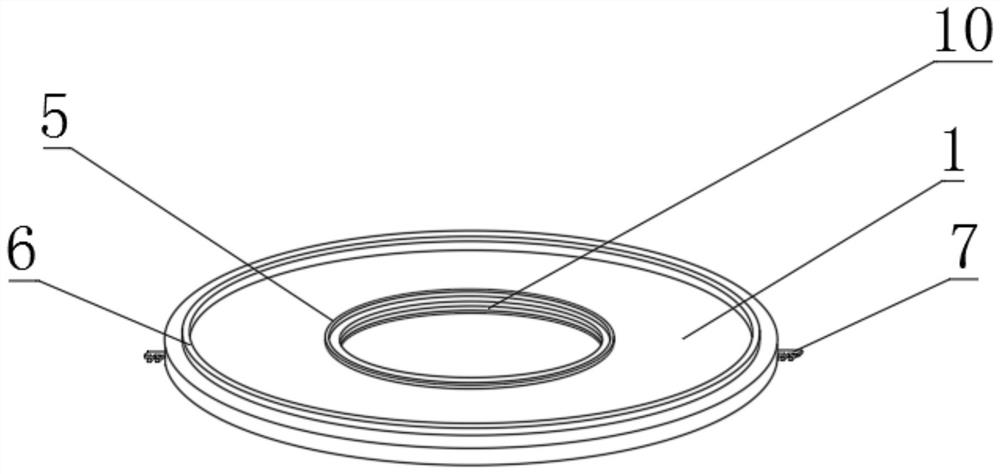

Bearing sealing cover

InactiveCN112032203AEasy to installEasy maintenanceBearing assemblyShaft assemblyStructural engineeringMechanical engineering

The invention discloses a bearing sealing cover. The bearing sealing cover comprises a sealing cover body. Fixing claws are arranged on the two sides of the sealing cover body, an outer ring rubber strip is arranged on the outer surface of the sealing cover body, an inner ring rubber strip is arranged on the inner side of the outer ring rubber strip, and a side edge sealing strip is arranged on the outer surface of the inner side of the sealing cover body. A bearing body is arranged at the outer end of the sealing cover, a bearing outer ring is arranged on the outer side of the bearing body, asliding groove is formed in the bearing outer ring, and a limiting block is arranged in the sliding groove. The bearing sealing cover has a good sealing effect, and is relatively easy and convenientto mount and dismount.

Owner:HUNAN MEIBEIDA TECH CO LTD

Decoration sound-insulation floor installation structure and construction method

ActiveCN110748115ANot easy to penetrateReduce seamsCovering/liningsFlooring insulationsClassical mechanicsEngineering

The invention relates to a decoration sound-insulation floor installation structure and a construction method, and belongs to the technical field of interior decoration. The decoration sound-insulation floor installation structure comprises a floor body, wherein a connecting strip is arranged under the floor body; a length direction of the connecting strip is parallel to a length direction of thefloor body; and two extrusion assemblies are arranged on two sides of the upper surface of the connecting strip. The decoration sound-insulation floor installation structure provided by the inventionachieves an effect that a seam line between floor bodies is not easy to infiltrate with water.

Owner:深圳市桦林达装饰设计工程有限公司

Reducing seam artifacts when applying a texture to a three-dimensional (3D) model

Embodiments of the present invention include techniques for reducing artifacts in rendered images. In one embodiment, a dual UV engine generates a dual of the graph defined by an initial UV set associated with a 3D model. The dual UV engine then uses existing flattening and layout engines to generate a dual UV set from this dual graph. Using the dual graph to define the dual UV set ensures that the seams corresponding to the initial UV set and the dual UV set minimally intersect.

Owner:AUTODESK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com