Three-dimensional modeling method for runner blade of tubular water turbine

A technology of tubular water turbines and runner blades, which is applied in the direction of reaction engines, mechanical equipment, hydroelectric power generation, etc., can solve the problems of not meeting actual requirements, repeating back and forth, prolonging the optimization design cycle, etc., so as to facilitate CNC machining and reduce The effect of seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

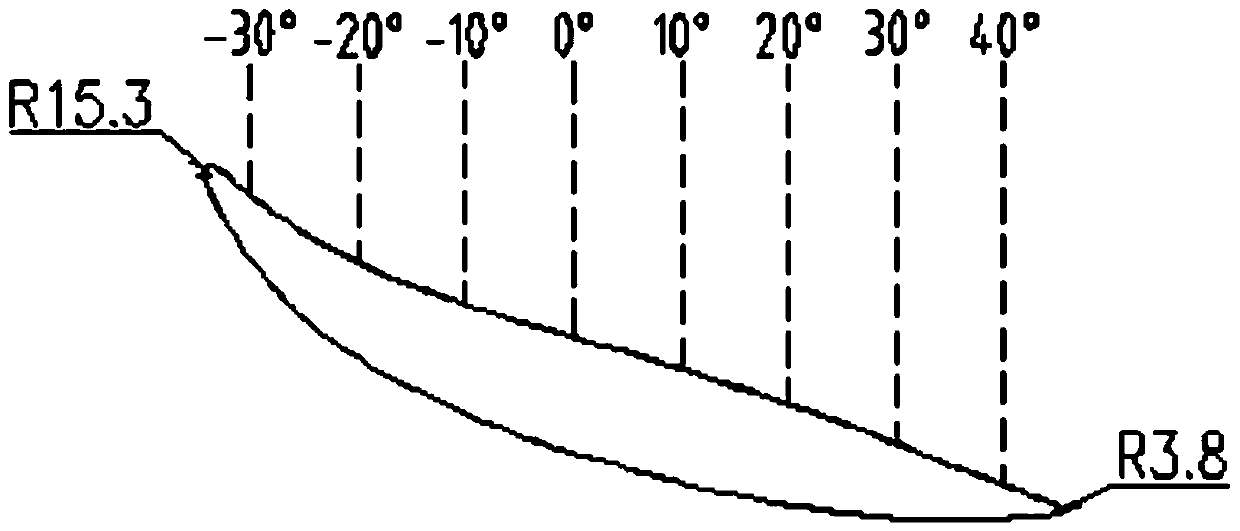

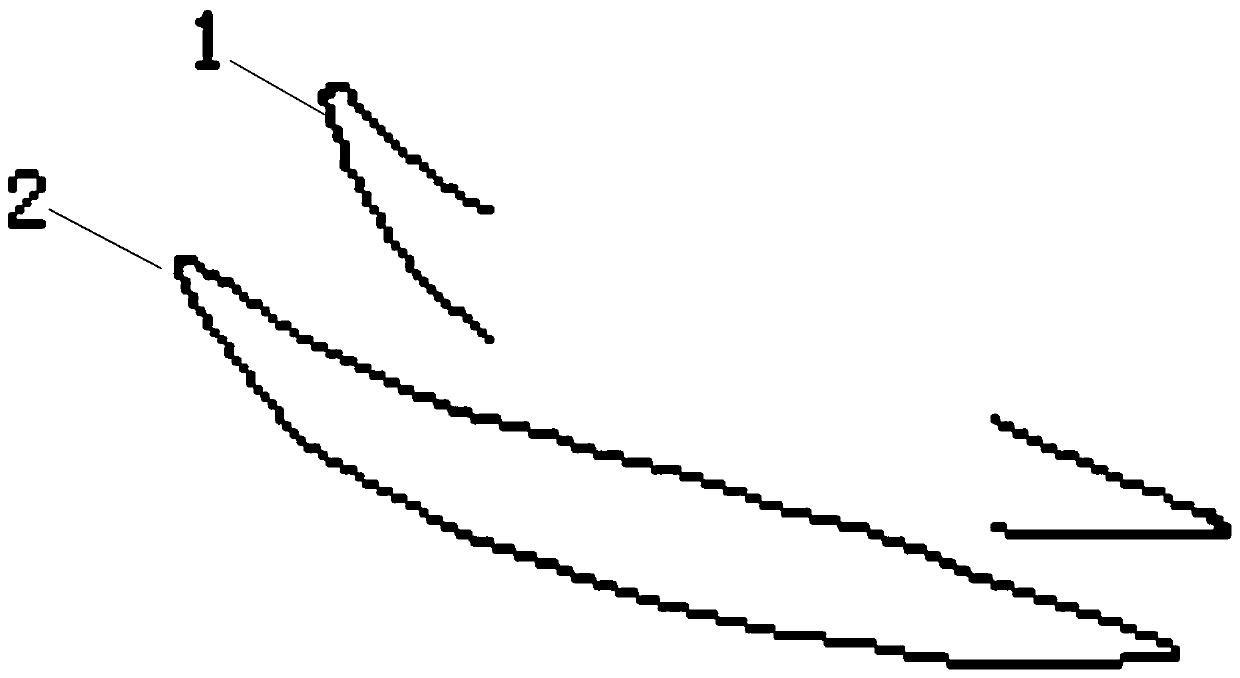

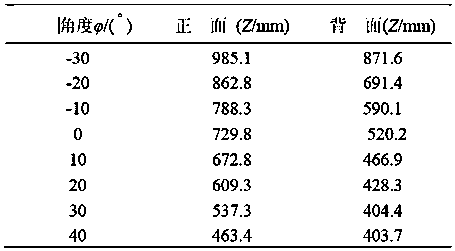

[0021] The present invention is a three-dimensional modeling method for the runner blade of a tubular water turbine, which is characterized in that: the method is carried out in two steps, the first step is to generate the blade profile curve that can be used by the three-dimensional software, and the second step is to use the curve to generate a three-dimensional entity Blades; use 2D AutoCAD software to import the blade shape of the wooden model into Pro / E to generate the blade section curve, and the commands used include from datum, sketch, select sketch plane, sketch from file, and complete; use AutoCAD and Pro / E interface with good performance, does not need to calculate the coordinates of each point, but is suitable for Cartesian coordinate system.

[0022] A method for three-dimensional modeling of runner blades of a tubular water turbine according to the present invention specifically includes the following steps.

[0023] (1) The first step is to generate the blade p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com