Bearing sealing cover

A bearing sealing and sealing cover technology, applied in bearings, bearing assembly, bearing components, etc., can solve the problems of difficult installation and disassembly of sealing covers, poor sealing effect, etc., achieve good sealing performance, improve sealing performance, and facilitate installation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

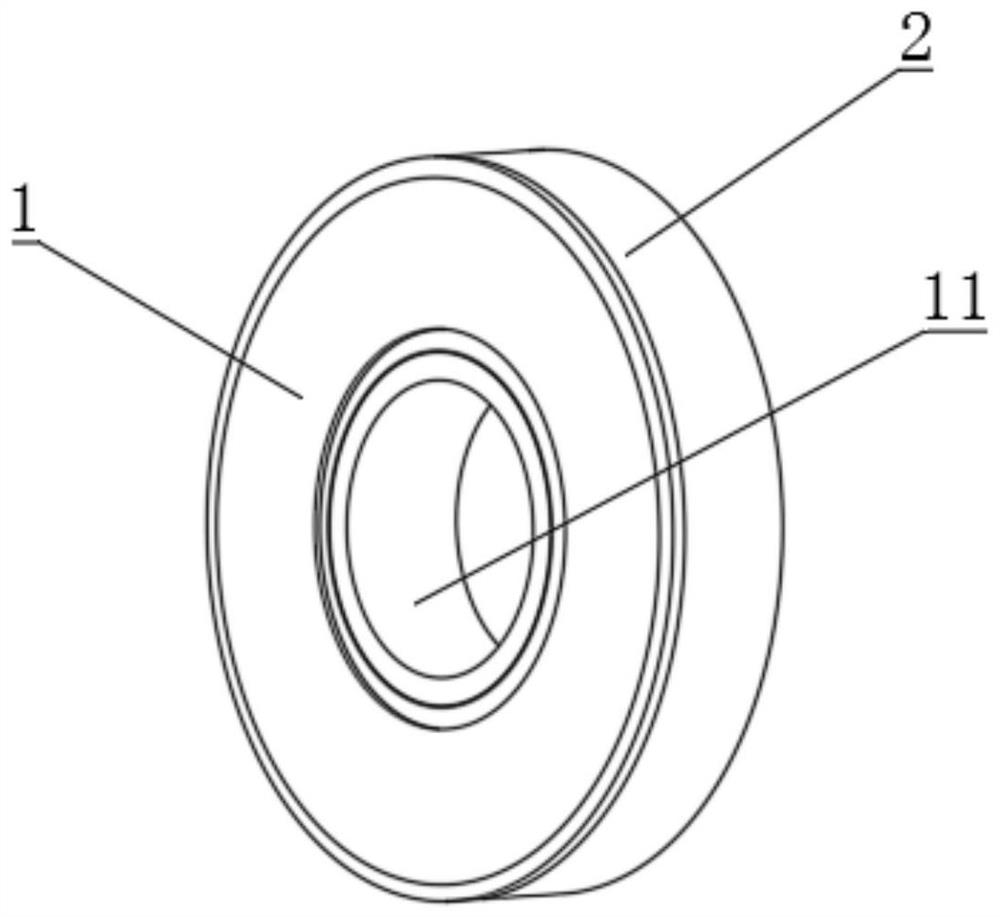

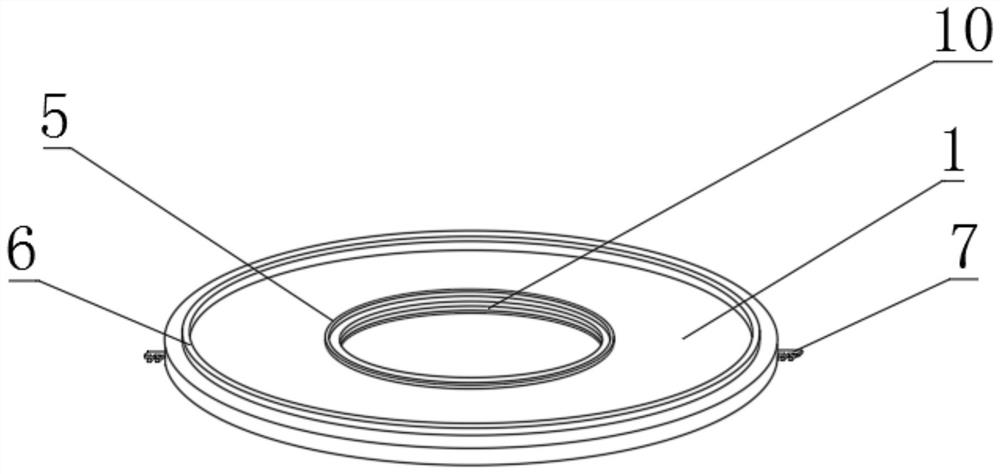

[0019] Such as figure 1 , 2 As shown, a bearing seal cover includes a seal cover main body 1. Fixing claws 7 are arranged on both sides of the seal cover main body 1 to realize the fixation between the seal cover main body 1 and the bearing main body 11. The outer surface of the seal cover main body 1 is provided with There is an outer ring rubber strip 6, an inner ring rubber strip 5 is arranged on the inner side of the outer ring rubber strip 6, a side sealing strip 10 is arranged on the inner outer surface of the sealing cover main body 1, and a bearing main body 11 is arranged on the outer end of the sealing cover main body 1 , The outer side of the bearing main body 11 is provided with a bearing outer ring 2, an inner chute 3 of the bearing outer ring 2, the sealing cover main body 1 can rotate in the chute 3, and the inside of the chute 3 is provided with a limit block 4.

[0020] The rubber strip 6 of the outer ring is fixedly connected with the main body 1 of the seal...

Embodiment 2

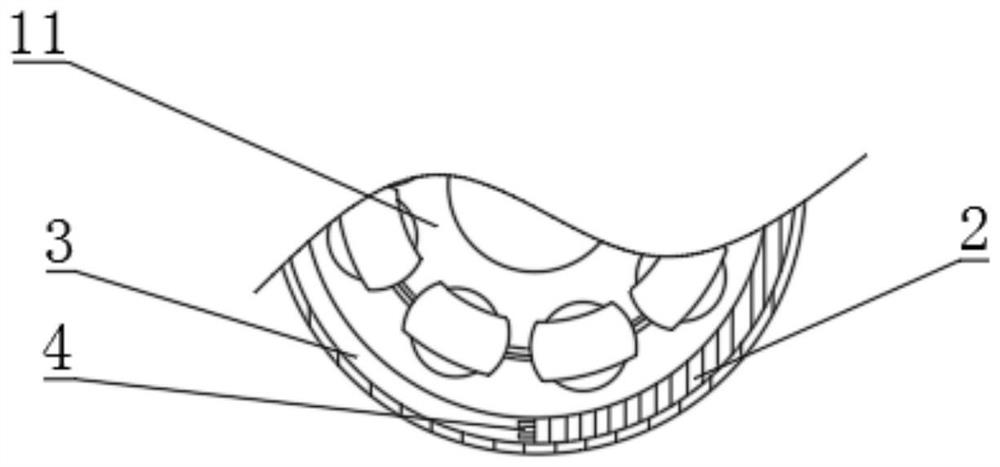

[0024] On the basis of Embodiment 1, such as image 3 , 4 As shown, the chute 3 is embedded inside the outer ring 2 of the bearing. The shape of the chute 3 is semicircular. The number of the limit blocks 4 is several groups. 4 are evenly distributed on both sides of the chute 3, and the two sets of fixed claws 7 are respectively fixed. The material of the limit block 4 is aluminum alloy material, and the number of fixed claws 7 is two groups. The two sides are symmetrically distributed, the fixed claw 7 is fixedly connected with the main body 1 of the sealing cover, the material of the fixed claw 7 is aluminum alloy material, the outer surface of the fixed claw 7 is provided with a first bayonet 8, and the The left side is provided with the second bayonet 9, the first bayonet 8, the second bayonet 9 to realize the fixed effect, the opposite of the second bayonet 9 is provided with the third bayonet 12, the first bayonet 8, the second bayonet The number of the mouth 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com