Novel door window system

A new type of technology for doors and windows, applied in windows/doors, building components, buildings, etc., can solve the problems of equipment investment, large floor area, long production cycle, complicated process, etc., and achieve quality improvement, time saving, and corner strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

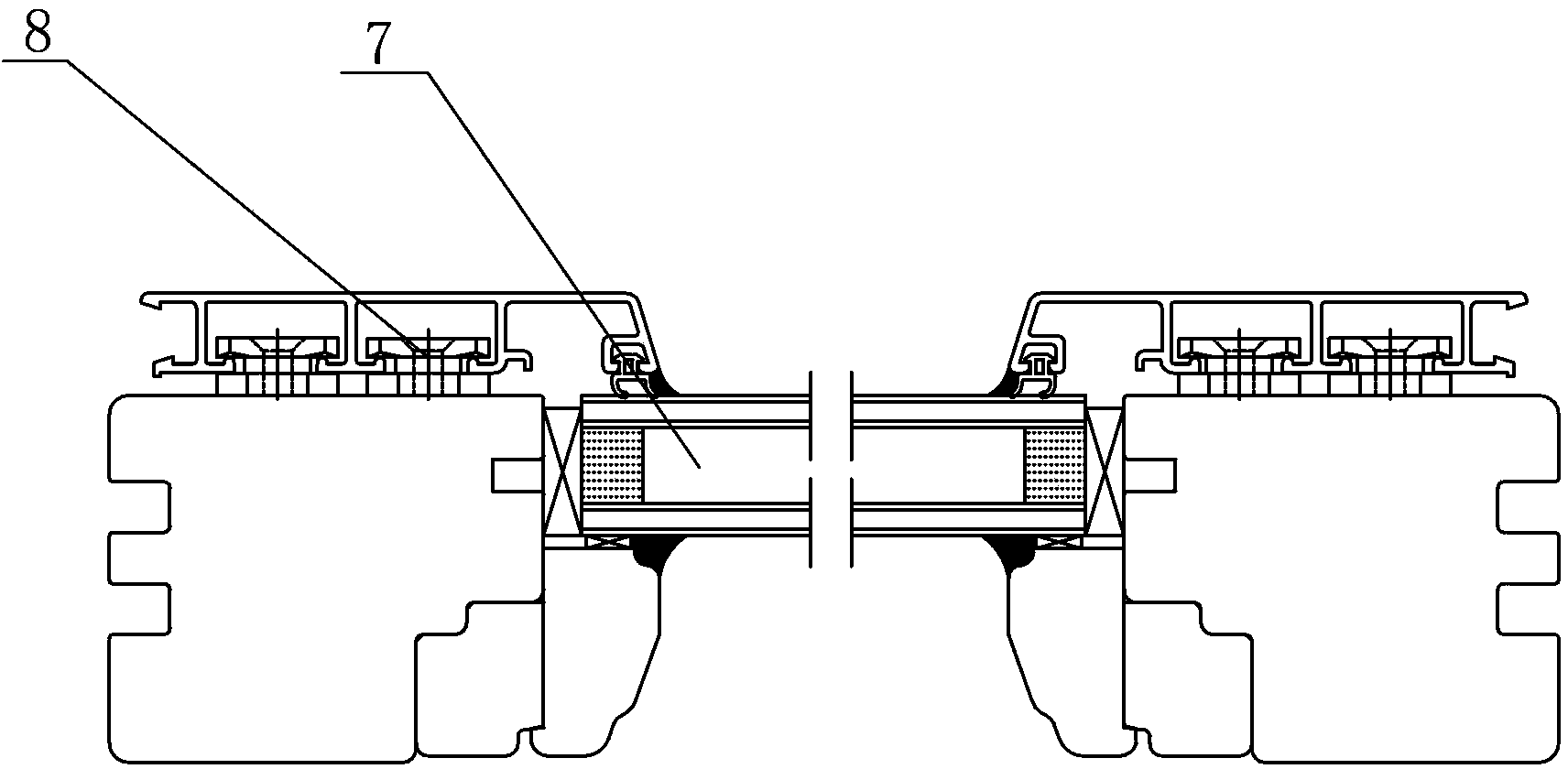

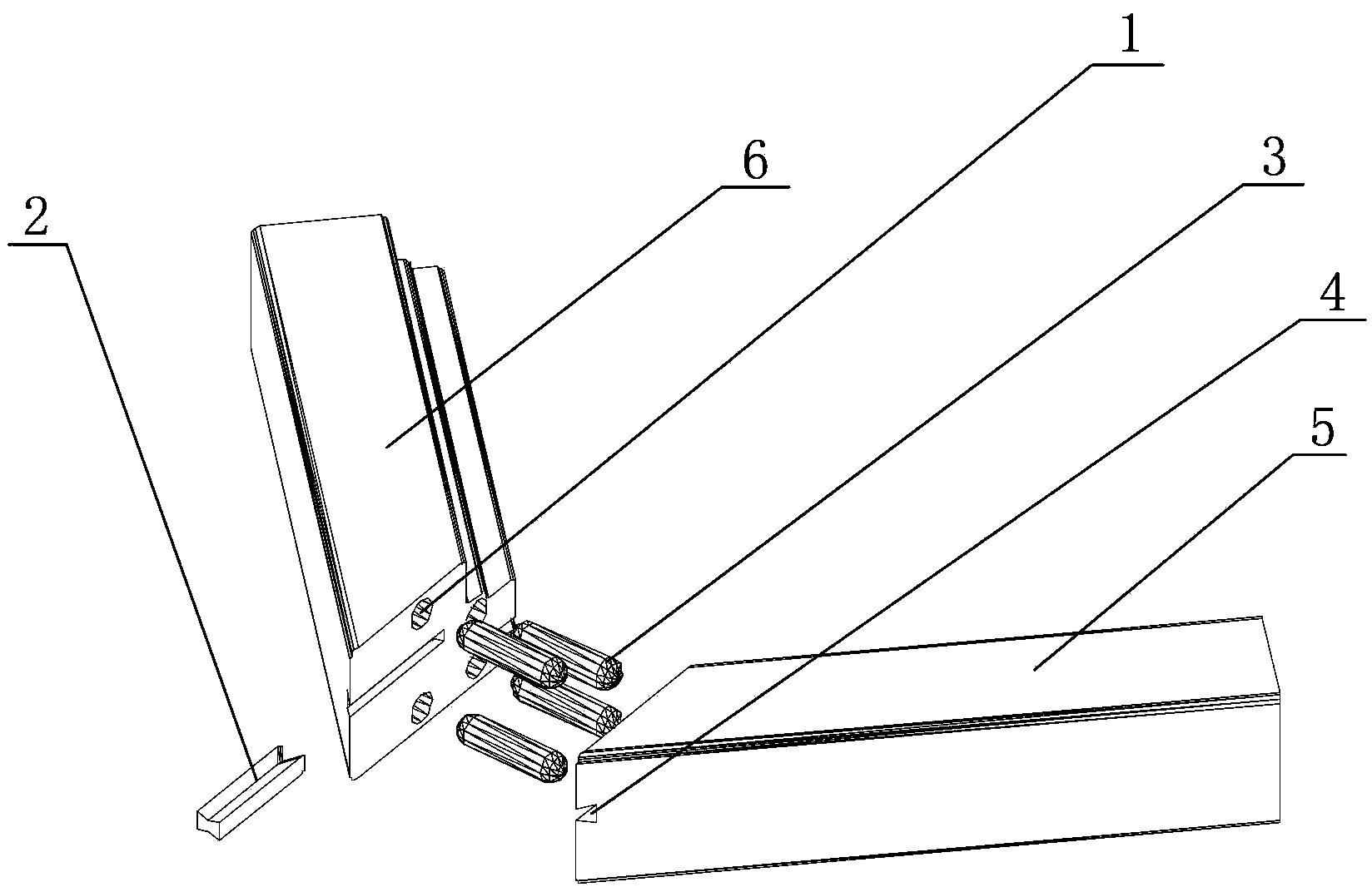

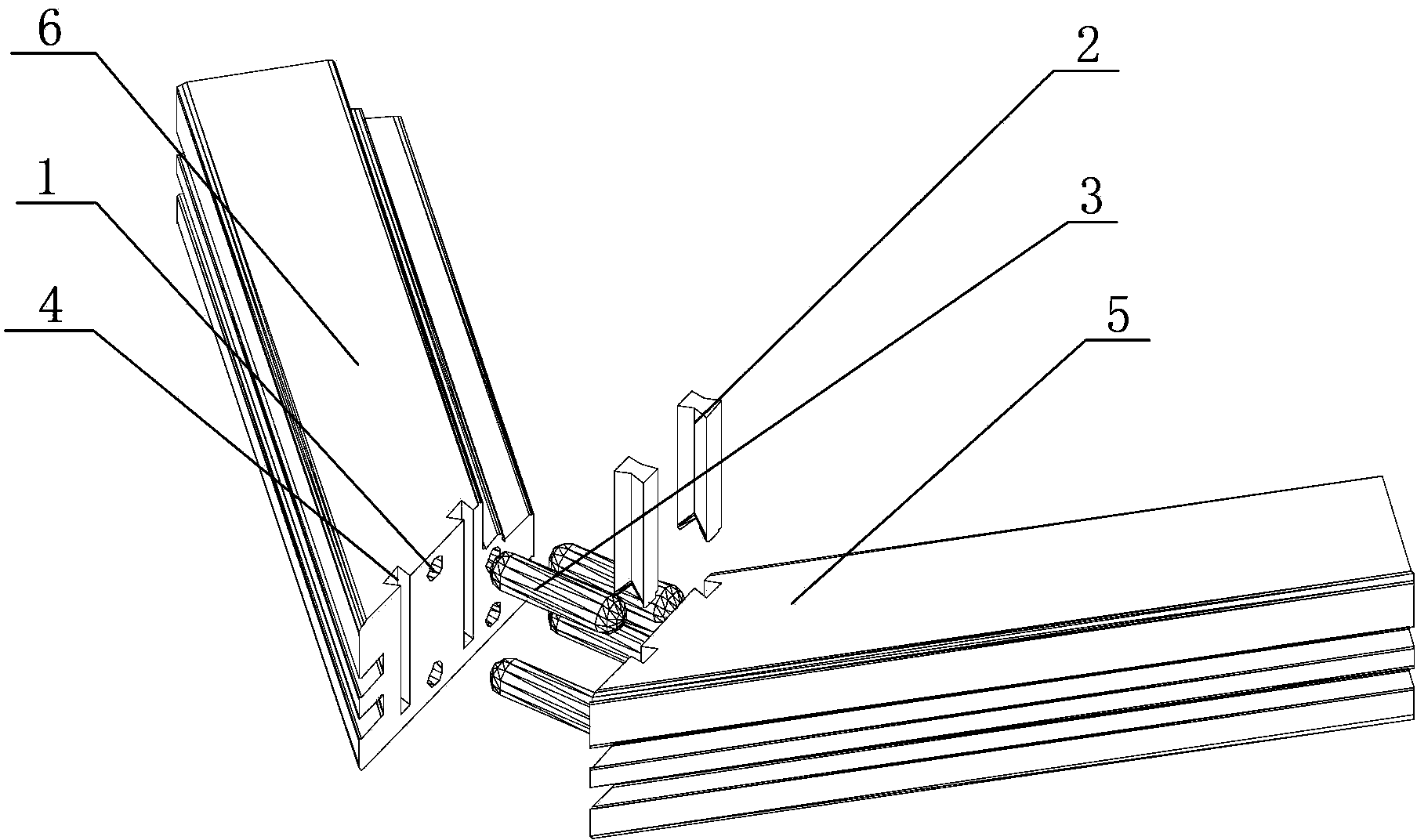

[0019] Such as figure 1 , figure 2 , image 3 A new type of door and window system shown includes frame profiles, fan profiles, crimping lines and insulating glass 7, the fan profiles include aluminum profiles and wood profiles, the aluminum profiles are fixed on the outdoor side of the wood profiles through connectors 8, and the wood profiles The group corner structure includes the first frame 5, the second frame 6, the round tenon rod 3 and the dovetail tenon 2. First, both ends of the first frame 5 and the second frame 6 to be framed are cut at 45°, Four holes 1 and a half-groove 4 of a dovetail hole are processed in the vertical direction of the section; the round tenon rod 3 can be made of hardwood or other materials such as plastic, which requires high strength; the dovetail 2 adopts The special inverted tooth structure, that is, the cross section of the dovetail tenon is a trapezoid with two upper bases connected together. If required, different colors and sizes are...

Embodiment 2

[0025] Such as figure 1 , figure 2 , image 3 A new type of door and window system shown includes frame profiles, fan profiles, crimping lines and insulating glass 7, the fan profiles include aluminum profiles and wood profiles, the aluminum profiles are fixed on the outdoor side of the wood profiles through connectors 8, and the wood profiles The group corner structure includes the first frame 5, the second frame 6, the round tenon rod 3 and the dovetail tenon 2. First, both ends of the first frame 5 and the second frame 6 to be framed are cut at 45°, Process four holes 1 and half grooves 4 of two dovetail holes in the vertical direction of the cross section; the round tenon rod 3 can be made of hardwood or other materials such as plastic, and requires high strength; the dovetail 2 A special inverted tooth structure is adopted, that is, the cross-section of the dovetail is a trapezoid with two upper bases connected together. If required, different colors and sizes are ava...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com