A single crystal short rod splicing method using diamond wire cutting

A diamond wire and single crystal technology, which is applied in the field of single crystal short rod splicing using diamond wire cutting, can solve the problems of affecting the processing progress, consuming energy, and increasing the cost of working hours, so as to reduce processing costs, reduce process losses, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is a detailed description of the process of splicing single silicon crystal short rods into spliced rods cut by diamond wire:

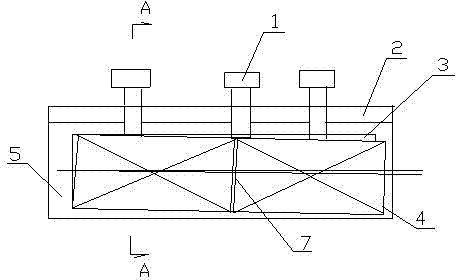

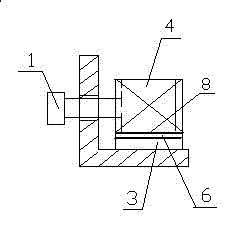

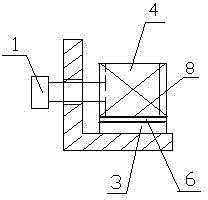

[0021] For the end face detection of short single silicon crystal rods, the flatness of the end face is required to be less than 0.3mm to ensure that the kerf is small; after passing the test, directly use AB glue to evenly spread on the end face, and bond the short rods to the round rods with a fixed length; for splicing rods Carry out square cutting, end face grinding, barrel grinding, and dimensional inspection. Design an L-shaped clamp with adjustment threads (such as figure 1 with figure 2 shown), the fixture is L-shaped, and it is composed of two rectangular plates at 90°, one rectangular plate is the bottom plate 5 and is set horizontally, and the other rectangular plate is the backing plate 2 and is vertically set, and the backing plate is set at intervals There is an adjusting screw 1, the axis of the adjusting screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com