Polyurethane anechoic tile product and preparation method thereof

A technology of polyurethane and anechoic tiles, which is applied in the application fields of new underwater sound-absorbing materials, acoustic stealth materials and products, and can solve problems such as increasing the area of a single tile, many tile-to-tile joints, and manufacturing process bottlenecks. Achieve the effect of reducing the probability of stress cracking, reducing the number of joints, and reducing the probability of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

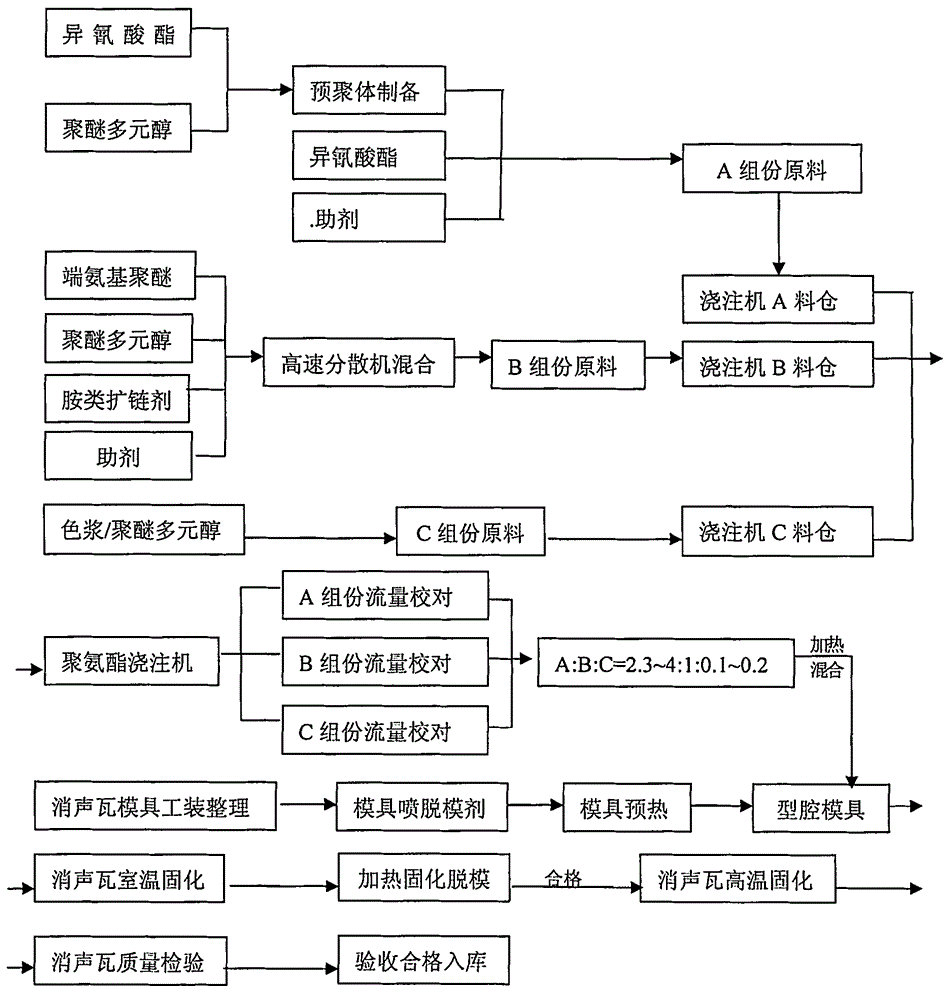

Method used

Image

Examples

Embodiment 1

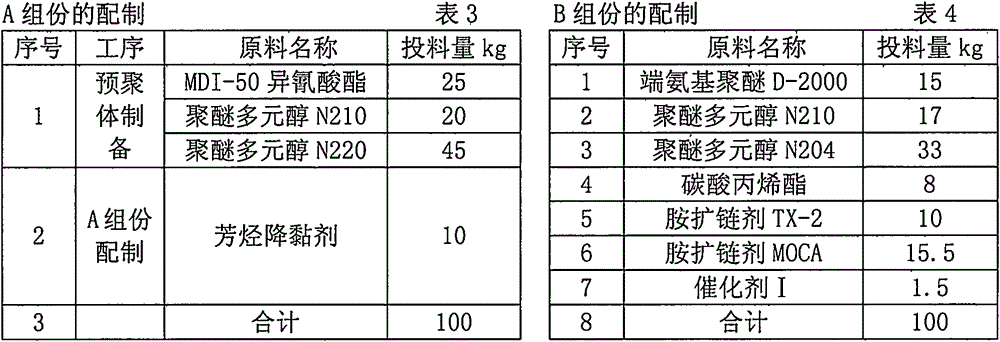

[0028] Preparation of polyurethane casting raw materials:

[0029]

[0030] Preparation of component C: mix one part of polyurethane color paste with two parts of polyether glycol to prepare 5.5%

[0031] Preparation of pouring raw materials: put the raw material MDI isocyanate in Table 3 into a 500-liter polymerization reactor after weighing according to the feeding amount, and adopt the polyol polyether metering and dropping pre-polymerization process; The time is 1.5~2.0hr, the holding temperature is controlled at 75~80°C, and the holding time is 2.0hr, and the prepolymer with isocyanate content of 7.65% and viscosity ≤3500cps can be prepared; add additives and disperse in a high-speed disperser to make component A , and set aside after filtering. Put the amino-terminated polyether, polyol polyether, polyaminoamine chain extender, catalyst, etc. in Table 4 into a 400-liter batching tank according to the amount of feed, and under high-speed dispersion conditions, the mix...

Embodiment 2

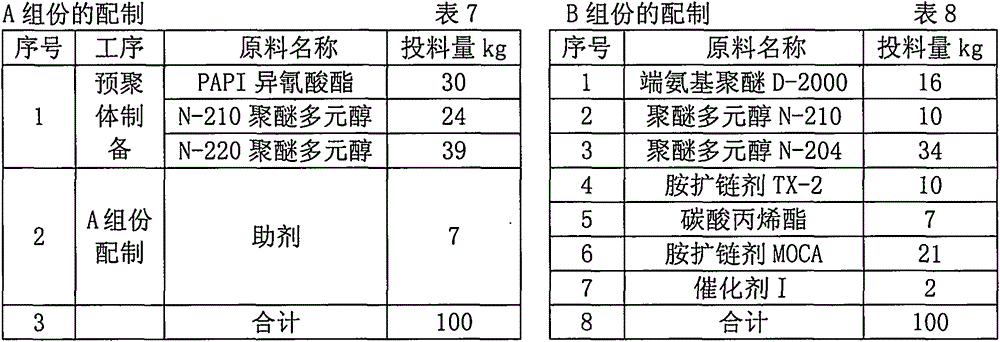

[0042] Preparation of polyurethane casting raw materials:

[0043]

[0044] Preparation of component C: mix one part of polyurethane color paste with two parts of polyether glycol to prepare 5.5%

[0045] The entire implementation process of embodiment 2 is the same as that of embodiment 1, and will not be described again; only the material formula is somewhat different, and the material performance test data is also somewhat different, which will be listed later.

[0046] The present invention adopts the above-mentioned preparation method, and the material mechanical properties and sound-absorbing properties of polyurethane sound-absorbing tiles can be reflected as follows:

[0047] project Tensile Strength Elongation hardness low temperature brittleness Performance ≥22MPa ≥220% 64 Shao D No cracking at -30℃

[0048] sound frequency 1-4KHz 5-12KHz 13-24KHz Polyurethane sound-absorbing tile Pressure 0-2MPa 70 87 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com