Vacuum heat collecting tube

A technology of vacuum heat collecting tubes and vacuum layers, which is applied in solar heat collectors, solar heat collectors using working fluids, heating devices, etc., can solve problems such as increasing the number of joints, increasing the difficulty of operation, and increasing the difficulty of maintaining vacuum. Achieve the effects of reducing costs, improving absorption efficiency, and reducing manufacturing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

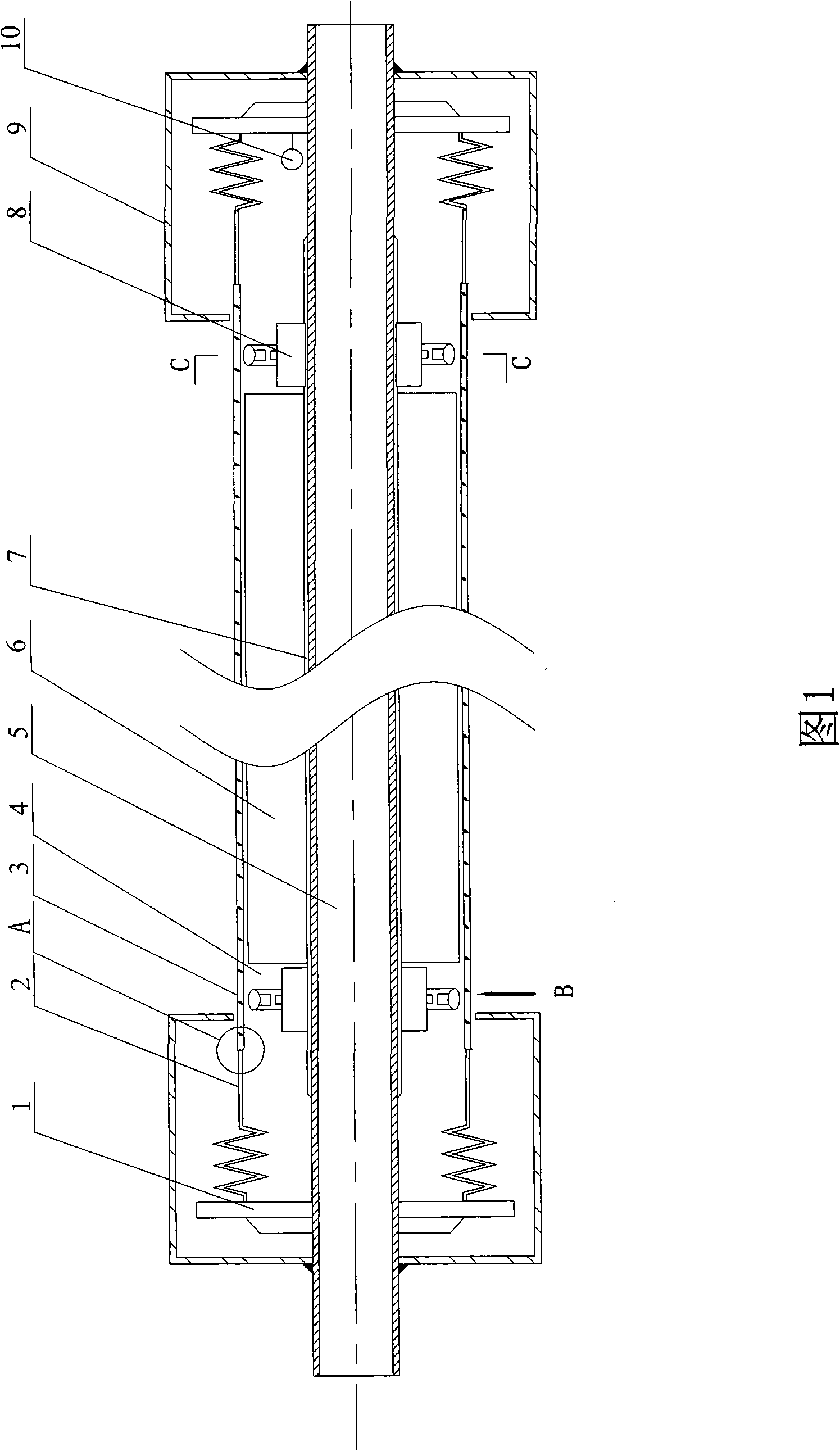

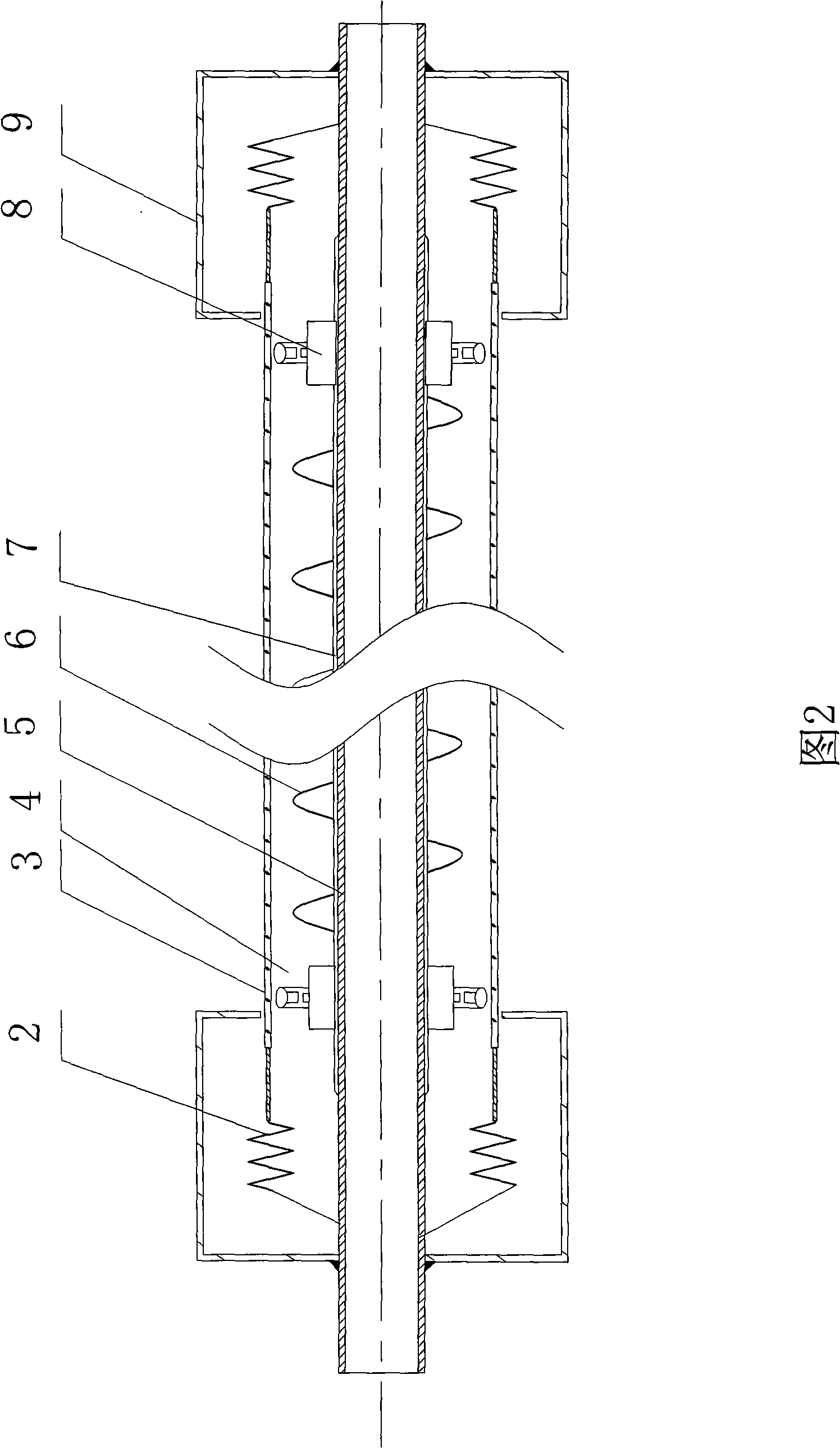

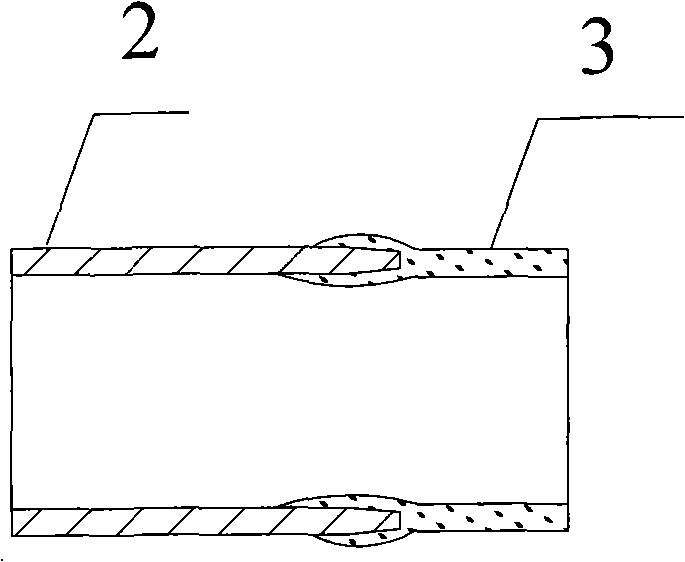

[0018] The vacuum heat collecting tube shown in Figure 1 includes a metal tube 5 covered with a solar absorbing coating 7 on the surface, a glass tube 3 is arranged outside the metal tube 5, and a vacuum layer 4 is formed between the glass tube 3 and the metal tube 5 The getter 10 can be placed in the vacuum layer 4 between the glass tube 3 and the metal tube 5 to maintain the vacuum degree. The two ends of the glass tube 3 are provided with bellows 2, and of course only one end thereof A corrugated tube 2 is provided, one end of the corrugated tube 2 is directly sealed with the glass tube 3, the other end of the corrugated tube 2 is connected with the metal tube 5, the corrugated tube 2 and the metal tube 5 and the corrugated tube 2 and the The interface of the glass tube 3 is respectively equipped with a protective cover 9 to better protect the connection seam. The bellows 2 adopts a linear expansion coefficient of 3×10 -6 m / m·℃ to 5×10 -6 m / m·℃ material, so because the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com