Intelligent machining production line for movable and fixed plates of elevator

An intelligent processing and production line technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problem of low processing rate of elevator dynamic and static plates, achieve the effects of reducing production costs, improving processing efficiency, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

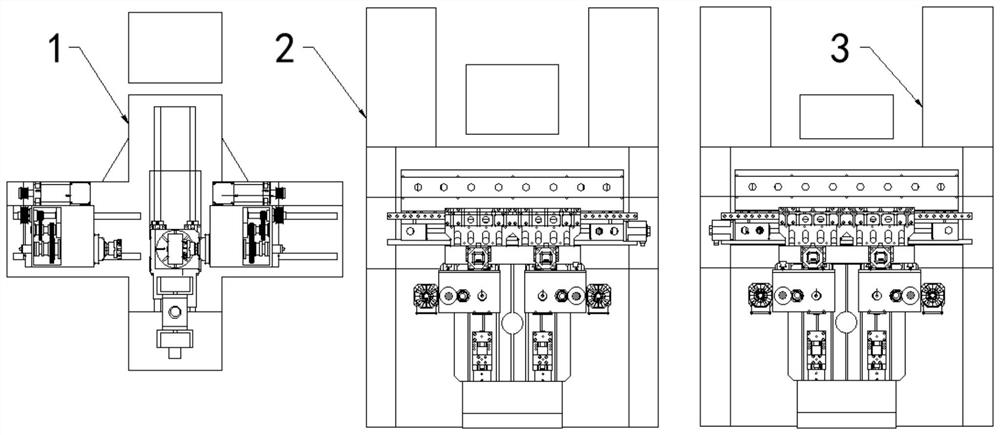

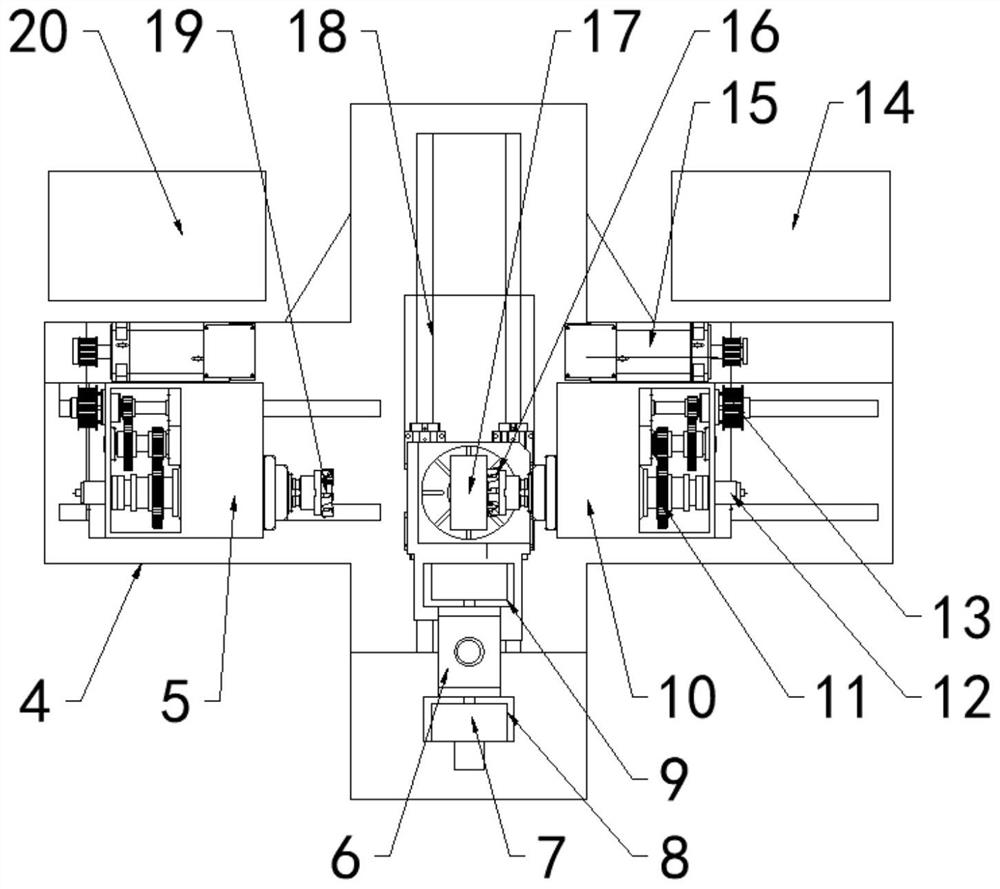

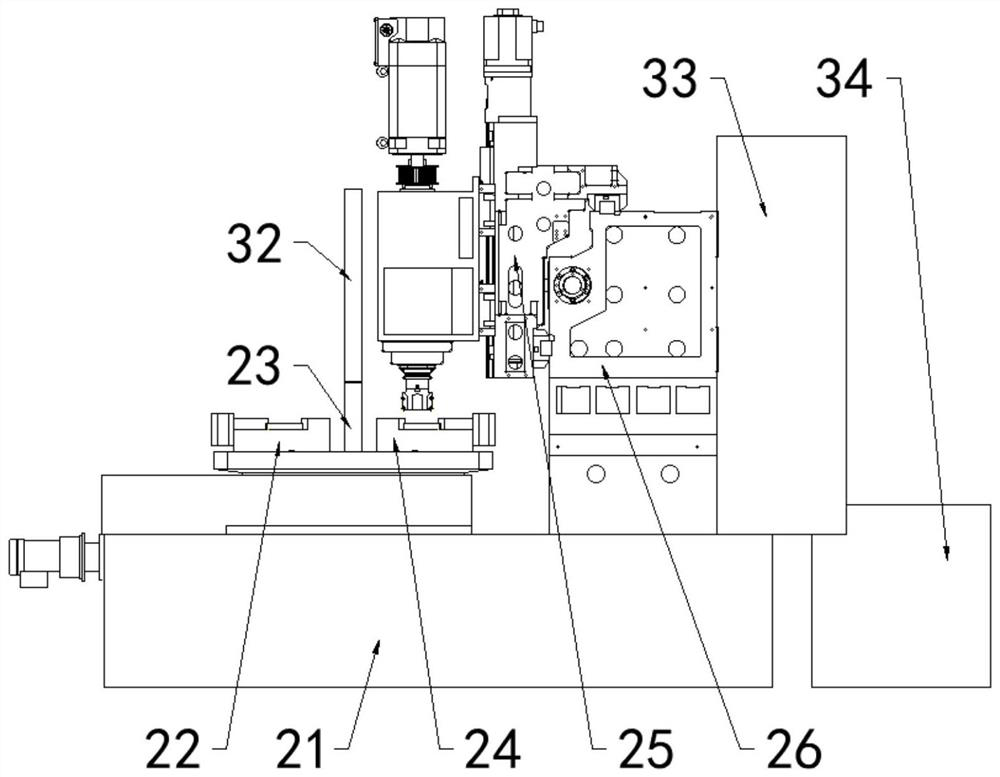

[0024] refer to Figure 1-4 , an elevator dynamic and static plate intelligent processing production line, including a CNC four-sided milling machine 1, a first CNC milling and boring machine 2 and a second CNC milling and boring machine 3, the CNC four-sided milling machine 1 includes a first bed 4, and a second bed is installed on the first bed 4 A main shaft 5 and a second main shaft 10, a main motor 15 for driving the first main shaft 5 and the second main shaft 10 to rotate respectively is installed on the first bed 4, a gear reduction box 11 is installed on the first bed 4, and the gear The reduction box 11 is installed with the corresponding first main shaft 5 or the second main shaft 10 through the synchronous belt transmission mechanism 13, and the first main shaft 5 and the second main shaft 10 are equipped with a tool release mechanism 12, and the first main shaft 5 and the second main shaft 10 are equipped with Disc milling cutters 19 are all installed to mill and ...

Embodiment 2

[0027] refer to Figure 1-4 , an elevator dynamic and static plate intelligent processing production line, including a CNC four-sided milling machine 1, a first CNC milling and boring machine 2 and a second CNC milling and boring machine 3, the CNC four-sided milling machine 1 includes a first bed 4, and a second bed is installed on the first bed 4 A main shaft 5 and a second main shaft 10, a main motor 15 for driving the first main shaft 5 and the second main shaft 10 to rotate respectively is installed on the first bed 4, a gear reduction box 11 is installed on the first bed 4, and the gear The reduction box 11 is installed with the corresponding first main shaft 5 or the second main shaft 10 through the synchronous belt transmission mechanism 13, and the first main shaft 5 and the second main shaft 10 are equipped with a tool release mechanism 12, and the first main shaft 5 and the second main shaft 10 are equipped with Disc milling cutters 19 are all installed to mill and ...

Embodiment 3

[0032] refer to Figure 1-4 , an elevator dynamic and static plate intelligent processing production line, including a CNC four-sided milling machine 1, a first CNC milling and boring machine 2 and a second CNC milling and boring machine 3, the CNC four-sided milling machine 1 includes a first bed 4, and a second bed is installed on the first bed 4 A main shaft 5 and a second main shaft 10, a main motor 15 for driving the first main shaft 5 and the second main shaft 10 to rotate respectively is installed on the first bed 4, a gear reduction box 11 is installed on the first bed 4, and the gear The reduction box 11 is installed with the corresponding first main shaft 5 or the second main shaft 10 through the synchronous belt transmission mechanism 13, and the first main shaft 5 and the second main shaft 10 are equipped with a tool release mechanism 12, and the first main shaft 5 and the second main shaft 10 are equipped with Disc milling cutters 19 are all installed to mill and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com