Patents

Literature

57results about How to "Reduce the number of forging fires" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

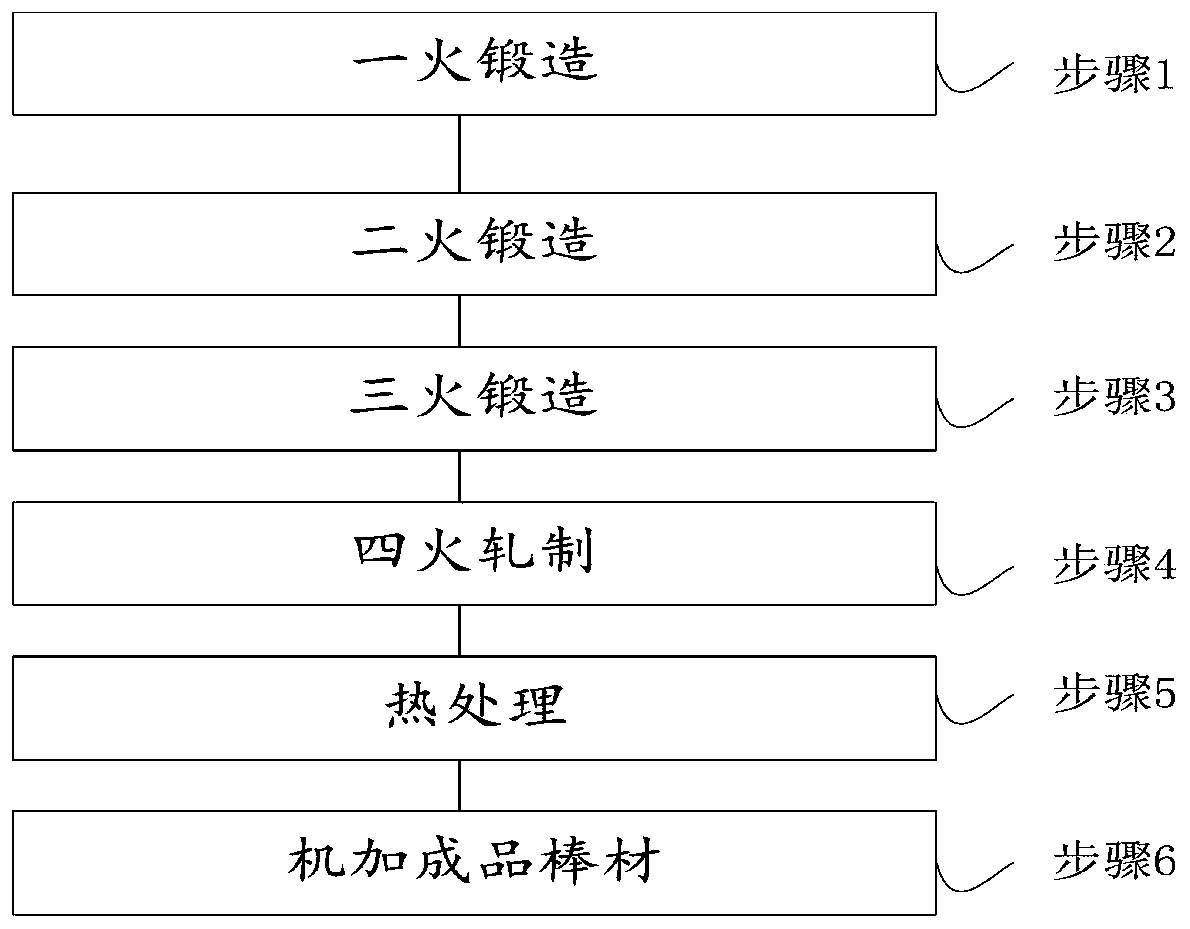

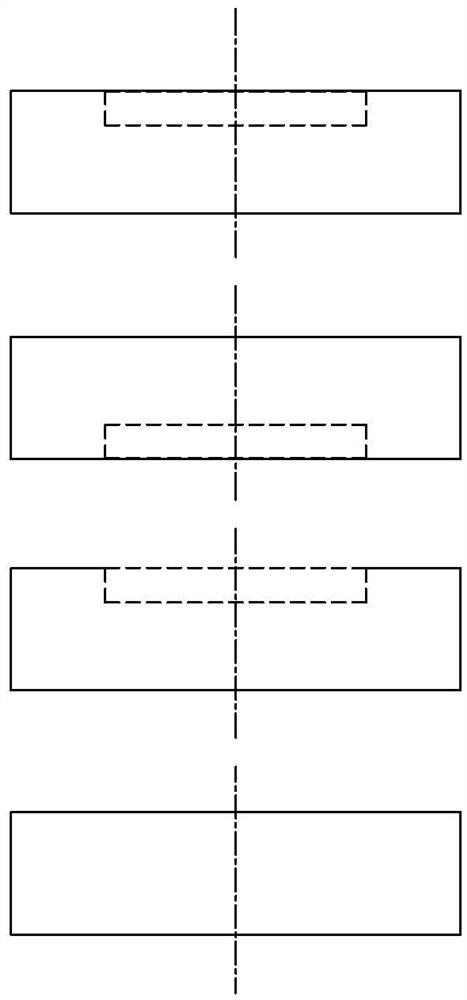

Forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy

InactiveCN104070125ALess investmentSave energyForging/hammering/pressing machinesElectric arc furnaceIngot casting

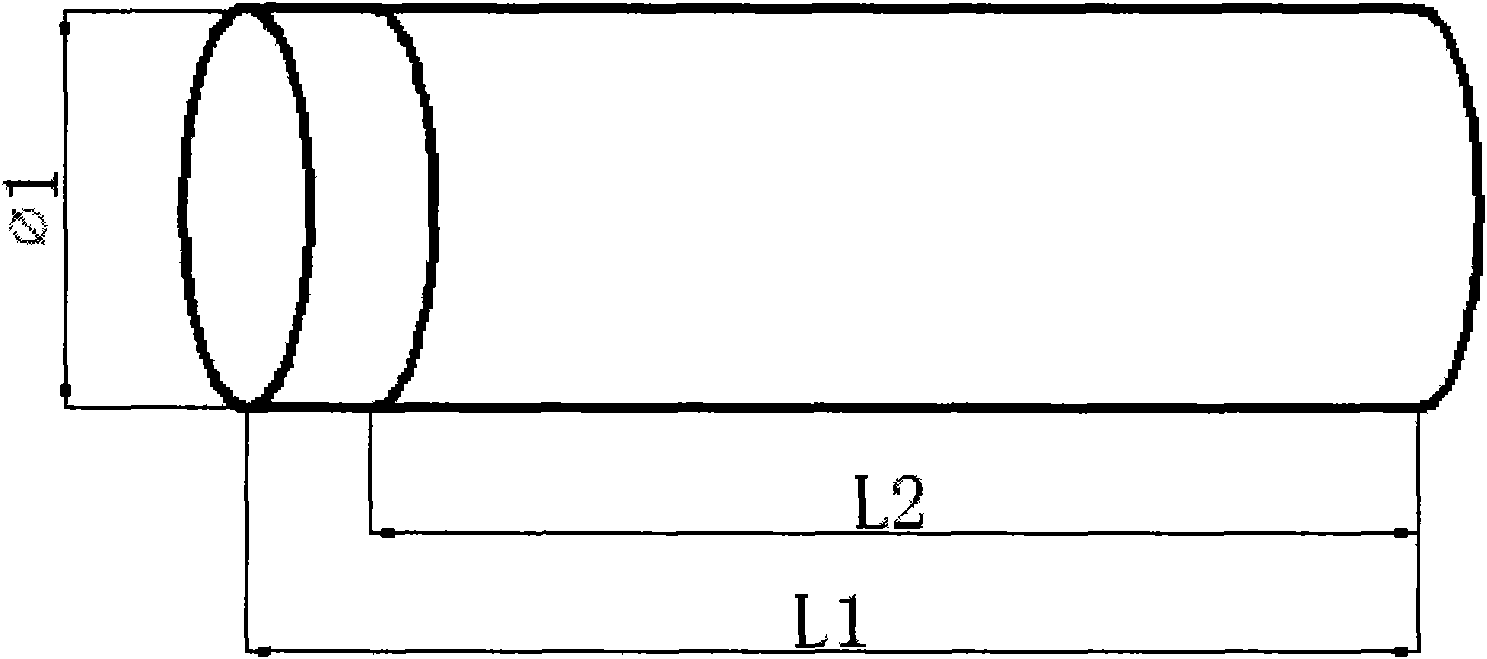

The invention relates to bar material forging machining method of titanium alloy, particularly to a forging machining method of large-sized bar materials of TC4 (Ti-6Al-4V) titanium alloy. The forging machining method is characterized by comprising the following steps of step 1, performing cogging forging, step 2, performing intermediate forging above a phase transformation point, step 3, performing intermediate forging below the phase transformation point, step 4 and step 5, performing finished product forging and obtaining the phi 200 to 300 mm and 2000 to 3000 mm length of large-sized bar materials of the TC4 titanium alloy finally. Compared with the prior art, a large-sized ingot casting and a large-tonnage forging device are not required and the industrialized production can be achieved through an ordinary industrial 3 ton ingot and a small-tonnage forging press and the equipment investment is small, only a 3 tons of electric arc furnace and a 3000 tons of forming oil press which is matched with the electric arc furnace need to be invested in the phi 600 of 3 ton ingot, the small-tonnage forging press such as a 1600 tons of forging press needs to be invested in the forging process, and accordingly the equipment investment is significantly reduced.

Owner:宁夏中色金航钛业有限公司

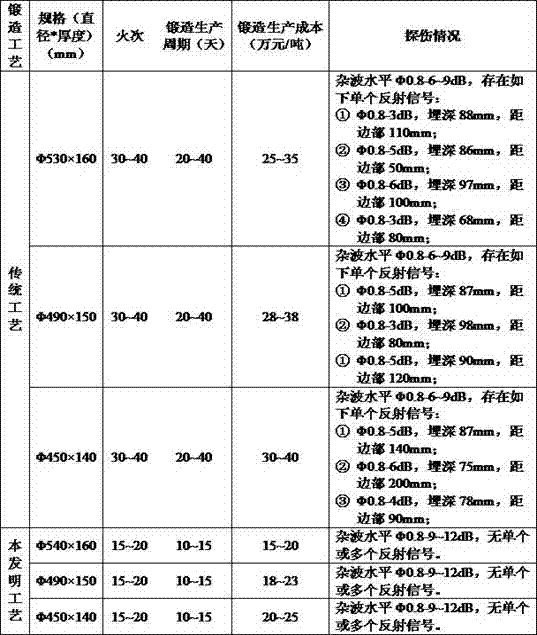

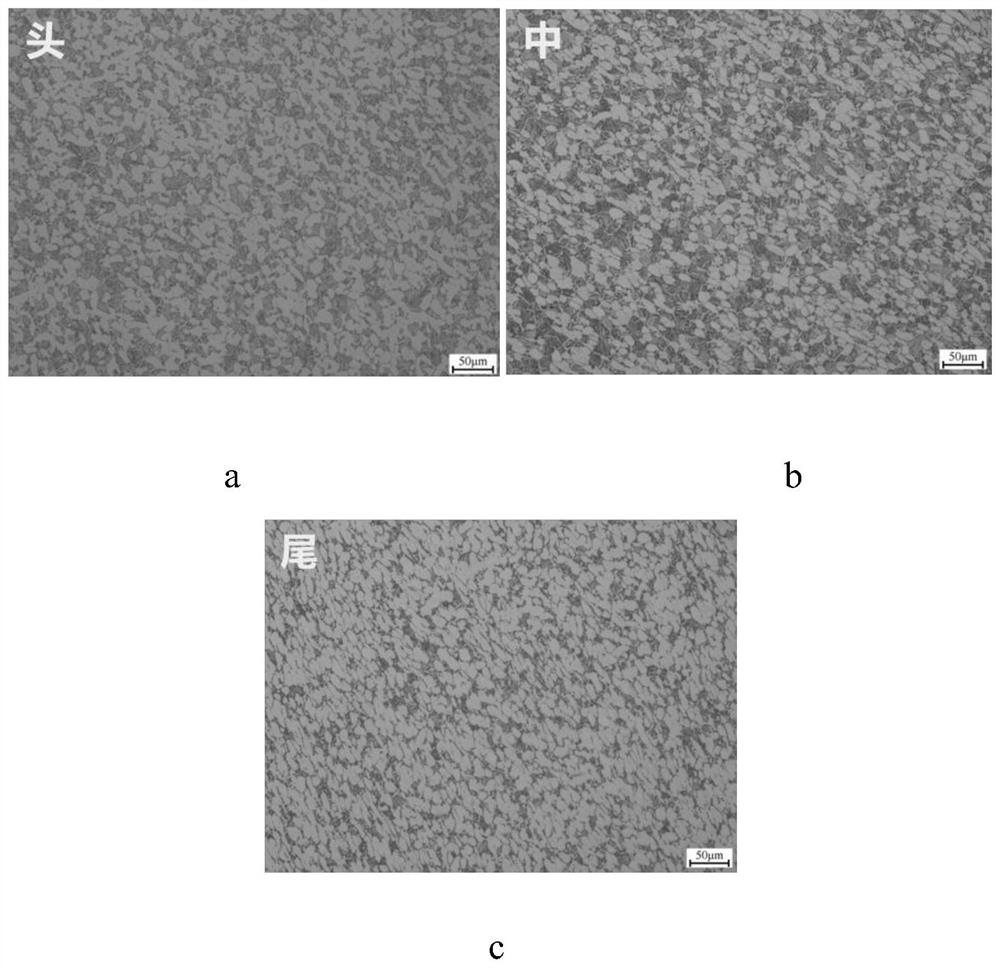

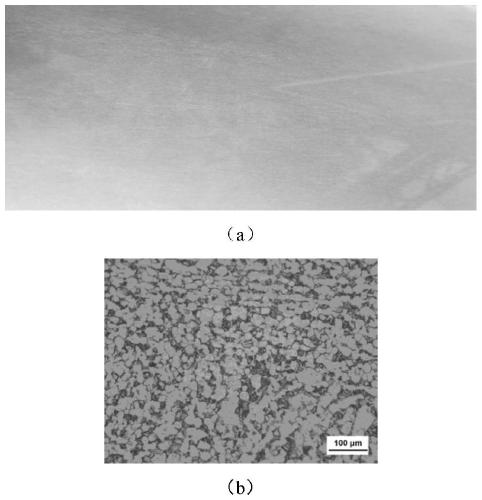

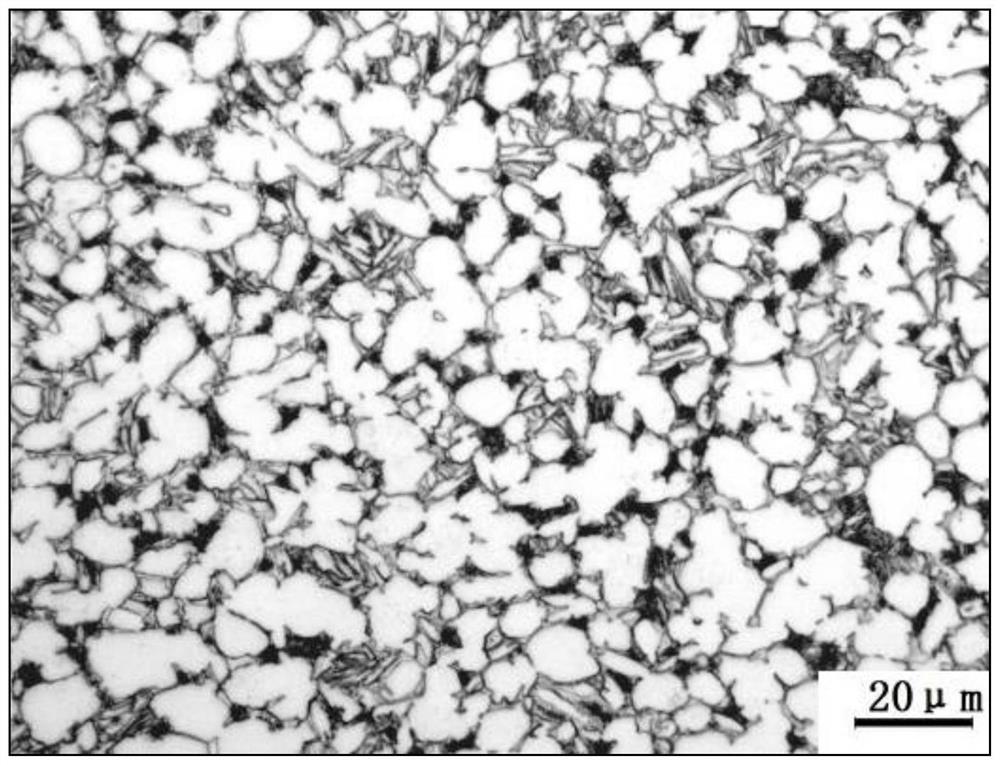

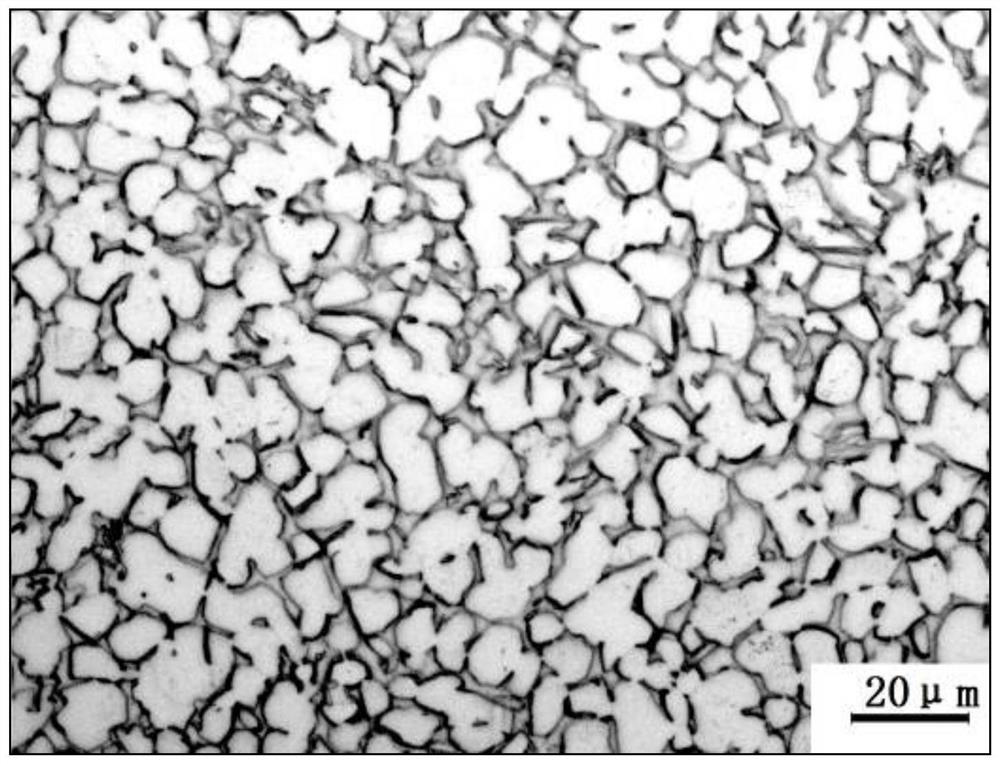

Forging method for high-microstructure-uniformity titanium alloy cake material

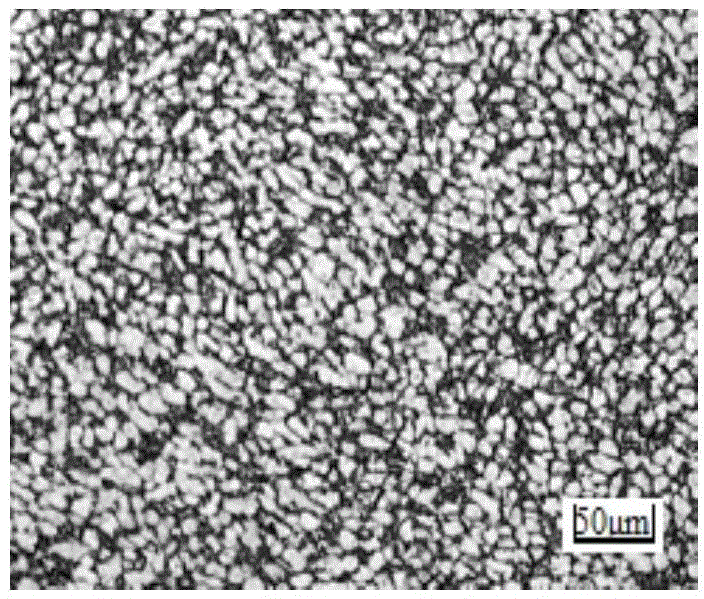

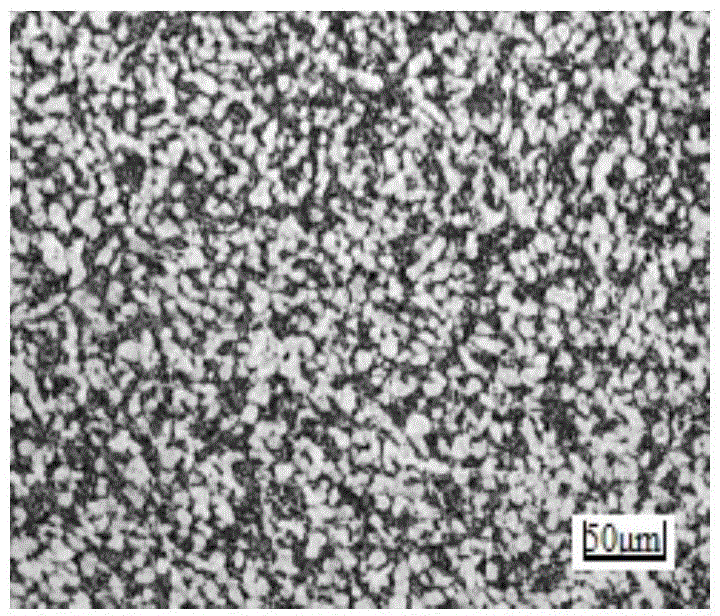

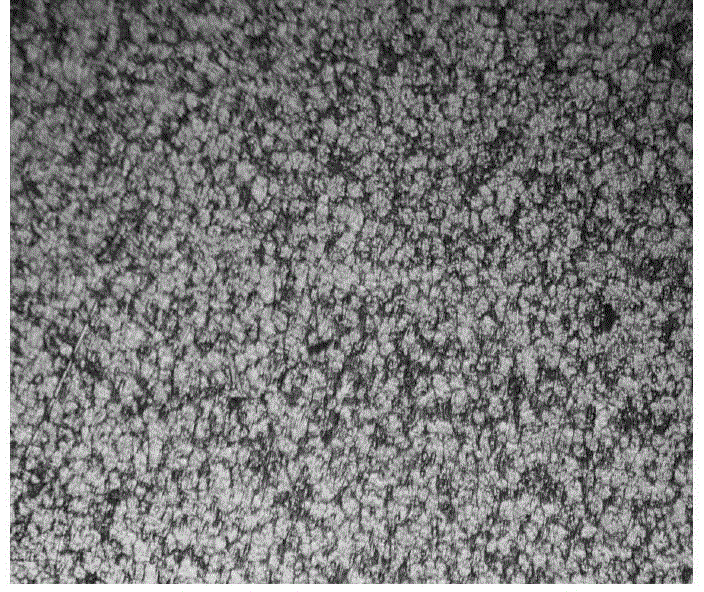

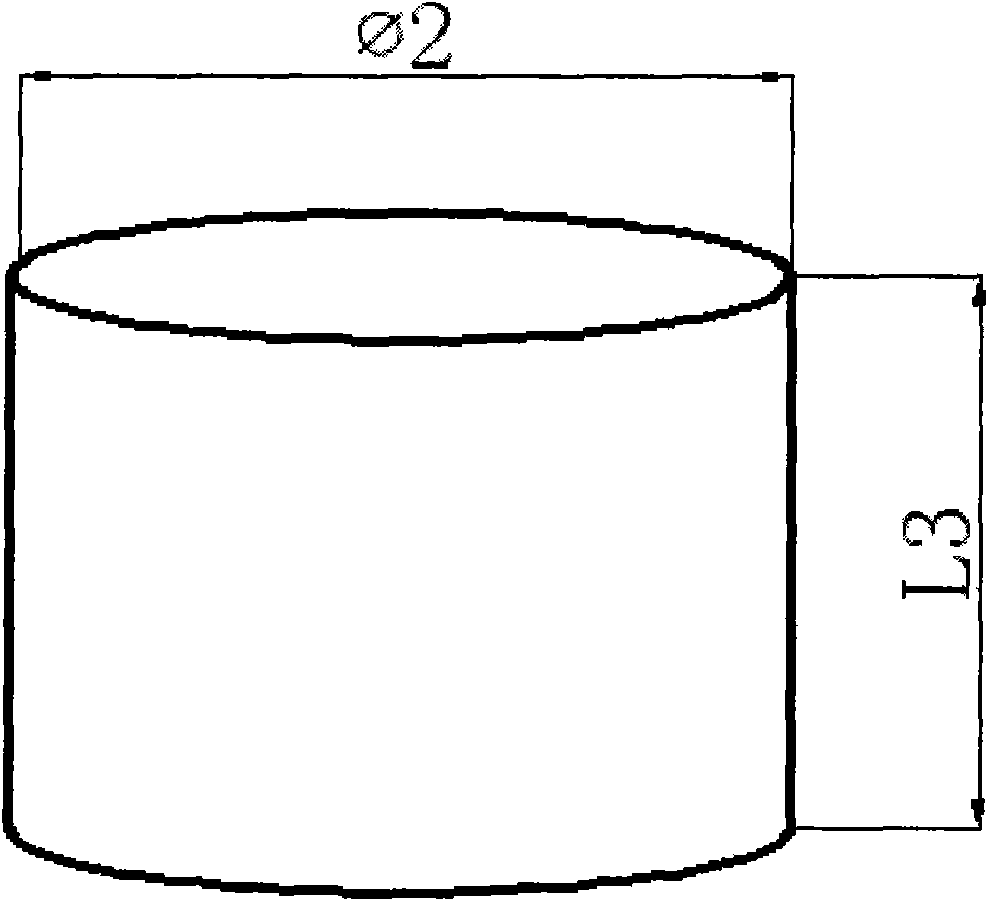

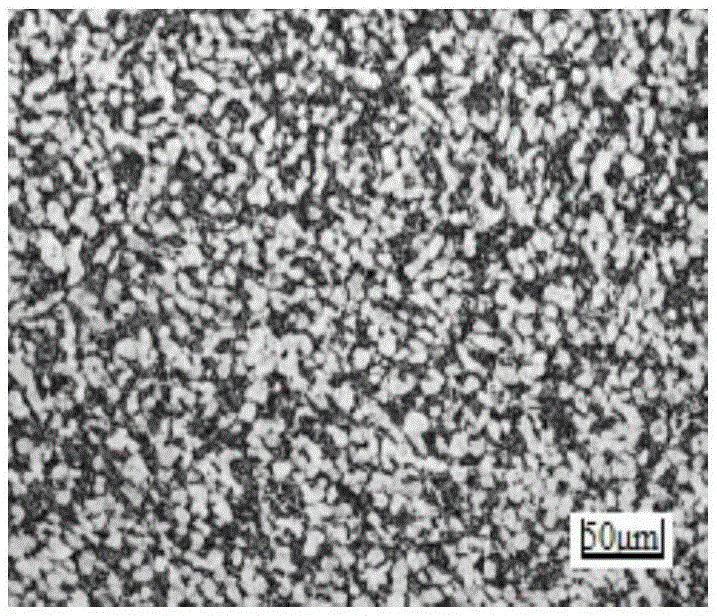

The invention discloses a forging method for a high-microstructure-uniformity titanium alloy cake material. The forging method includes the steps that a titanium alloy casting ingot is subject to high temperature homogenization treatment, one heating number of upsetting pulling forging is carried out after high temperature homogenization treatment is finished, and therefore an original as-cast structure is broken; then a blank is subject to upsetting pulling forging at the temperature higher than the beta phase inversion temperature and lower than the beta phase inversion temperature, and water cooling is carried out after forging is carried out; and finally, the blank is subject to 2-3 heating numbers of upsetting pulling forging at the temperature lower than the beta phase inversion temperature by 30 DEG C to 50 DEG C to mold the cake material with the diameter ranging from 400 mm to 700 mm and the thickness ranging from 100 mm to 200 mm. According to the forging method, the manners of high temperature homogenization treatment, water cooling after forging, reversing upsetting pulling, diagonal line drawing out and the like are matched, reasonable heating and heat preservation coefficients ate reasonably designed, and the uniformity of the blank is guaranteed to the maximum degree; two-phase region high-low-high forging process at the temperature below the beta phase inversion temperature by 30 DEG C to 50 DEG C-50 DEG C to 70 DEG C-30 DEG C to 50 DEG C is adopted, and the problem that single display signals are prone to occurrence during finished product flaw detection is solved.

Owner:湖南湘投金天钛业科技股份有限公司

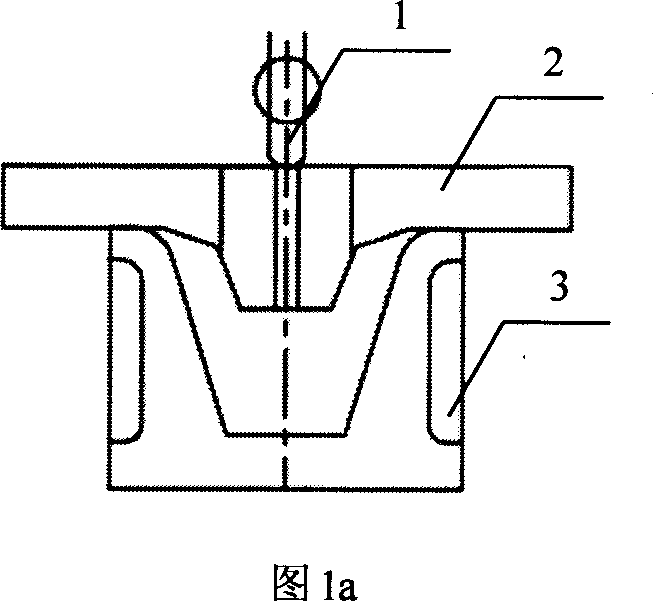

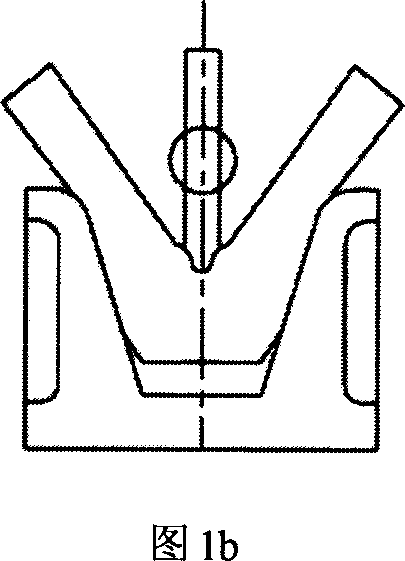

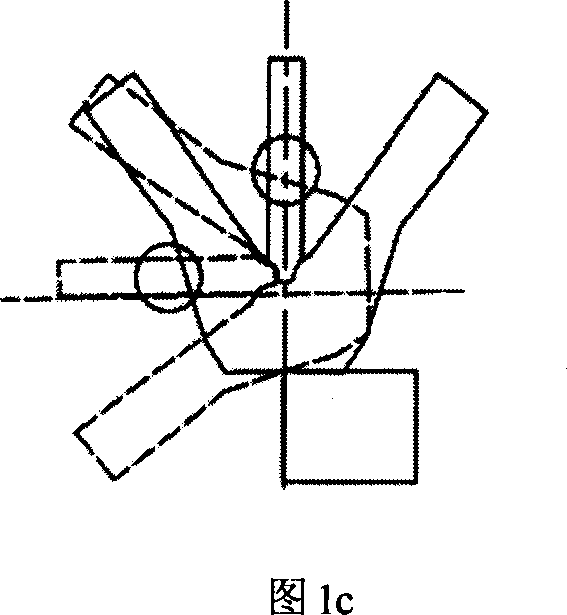

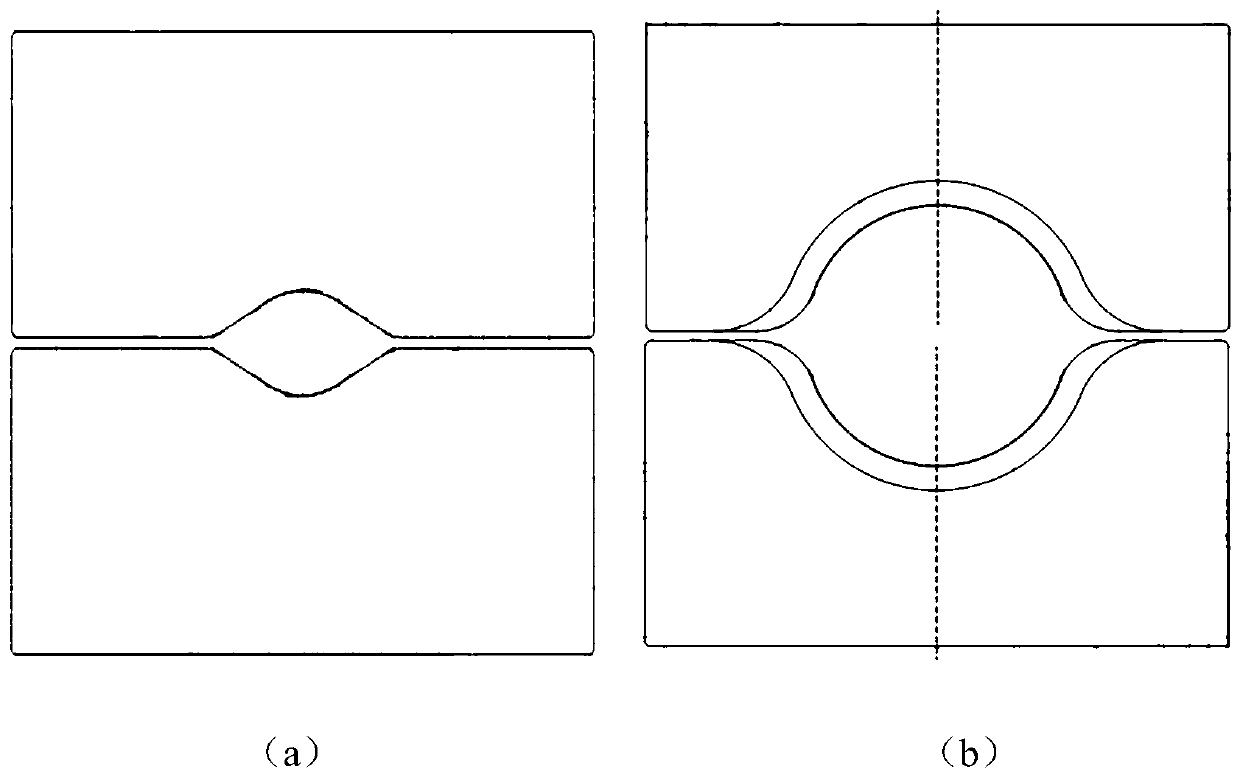

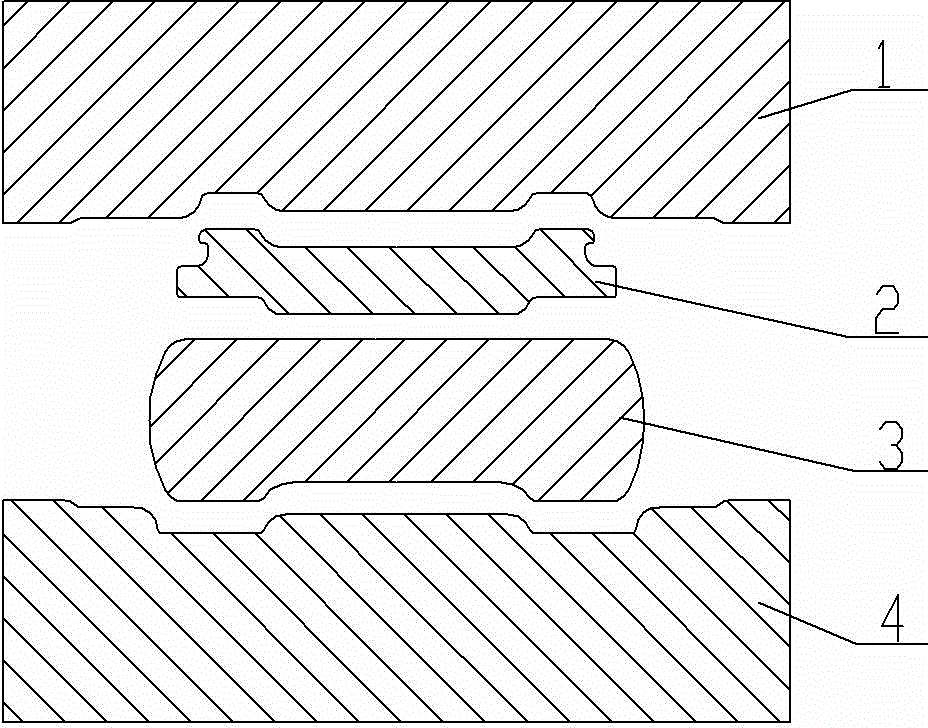

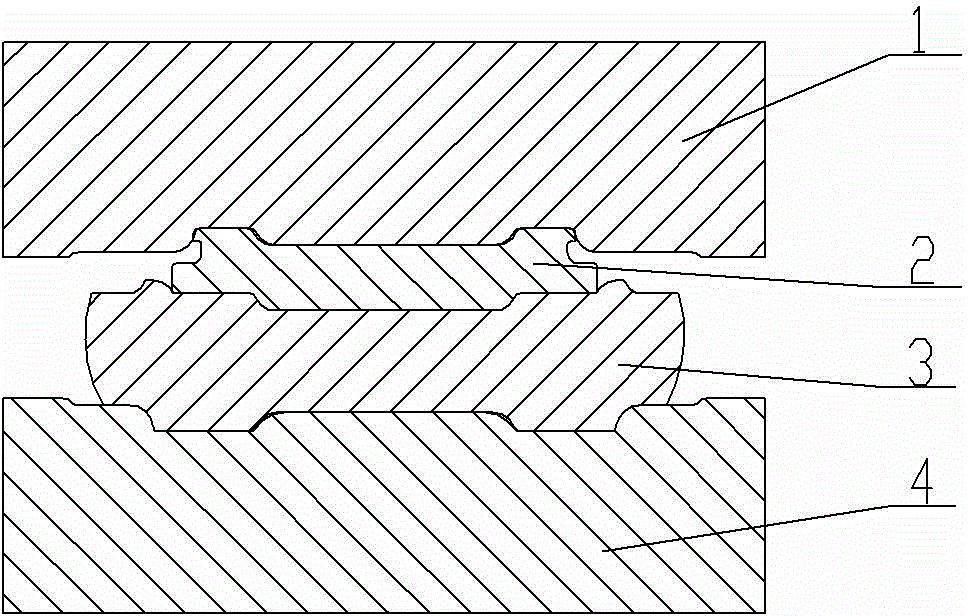

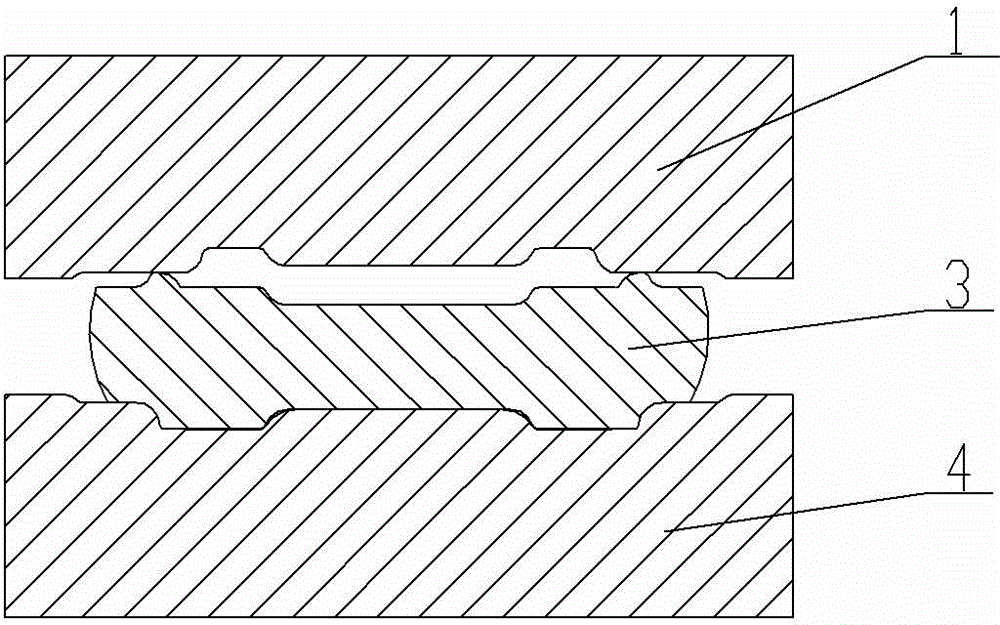

Equipment for bend-forging crank axle toggle of large ship and method for forging the same

ActiveCN1947886AUnder-forecastSimulation is accurateForging/hammering/pressing machinesEngine componentsMarine engineeringIngot

A bending-forging machine for manufacturing the large crankshaft or bellcrank used by ship is composed of upper die with lower arc end, bending lower die, upper and lower flat stocks, and insertion plate with lower arc end. Its forging method includes such steps as upsetting a steel ingot to become a flat square billet, drawing it to become a blank with shoulder, pressing V-shaped die on the middle of blank to form symmetric two V-shaped slots, bending by upper and lower dies, removing the upper and lower dies, inserting the insertion plate for finishing, trimming, and removing insertion plate.

Owner:SHANGHAI HEAVY MACHINERY PLANT +1

Forging method of AP1000 nuclear-power main pipeline forging piece

InactiveCN101954439AGuaranteed size requirementsGuarantee quality requirementsMetal-working apparatusEngine componentsNuclear powerMaterials science

The invention relates to a forging method of an AP1000 nuclear-power main pipeline forging piece, belonging to the technical field of forging. The forging method comprises the following steps of: firstly, forging an irregularly-shaped part of the forging piece; and then, integrally forging. The invention not only ensures the dimensional requirement of the irregularly-shaped part of the forging piece, but also ensures the quality requirement of the integral forging piece, can lower forging heating frequency, increases the utilization rate of raw materials and the qualified rate of the forging piece at the same time, achieves the expectation effect before forging and successfully solves the problem on forging the AP1000 nuclear-power main pipeline.

Owner:吉林昊宇电气股份有限公司

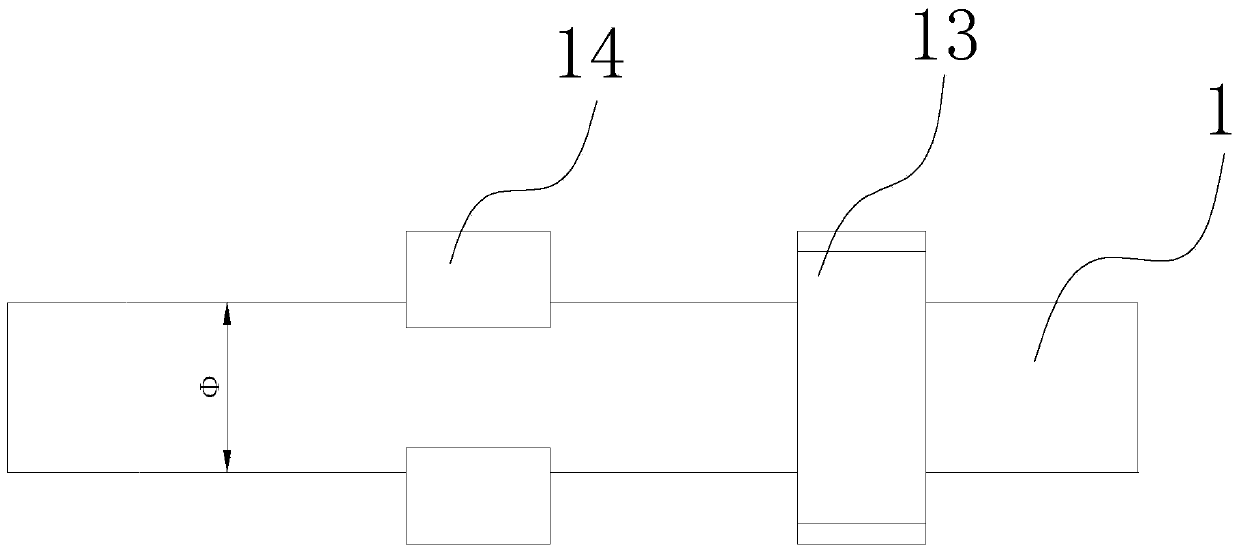

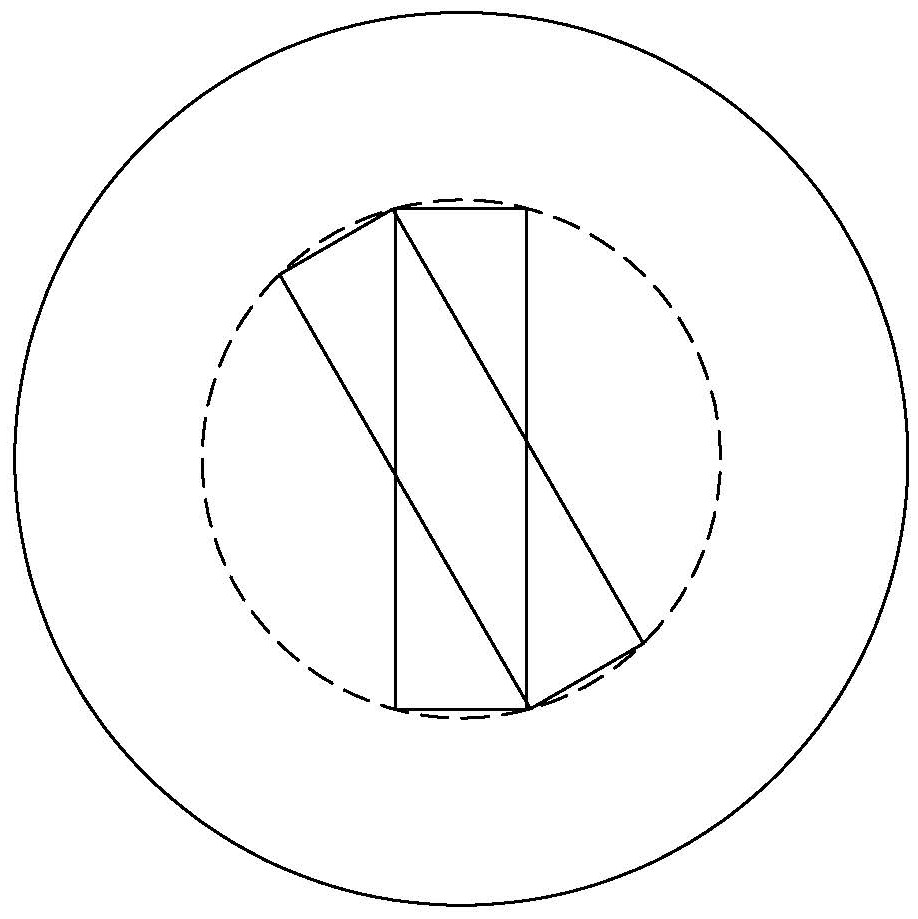

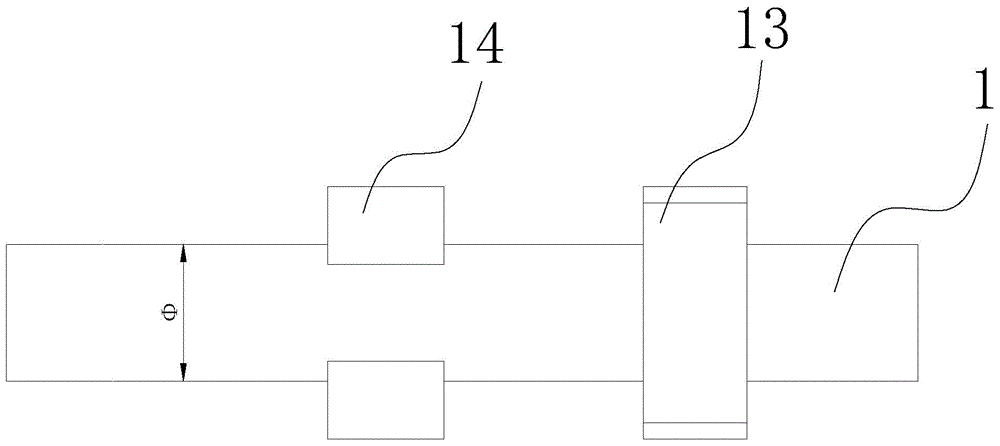

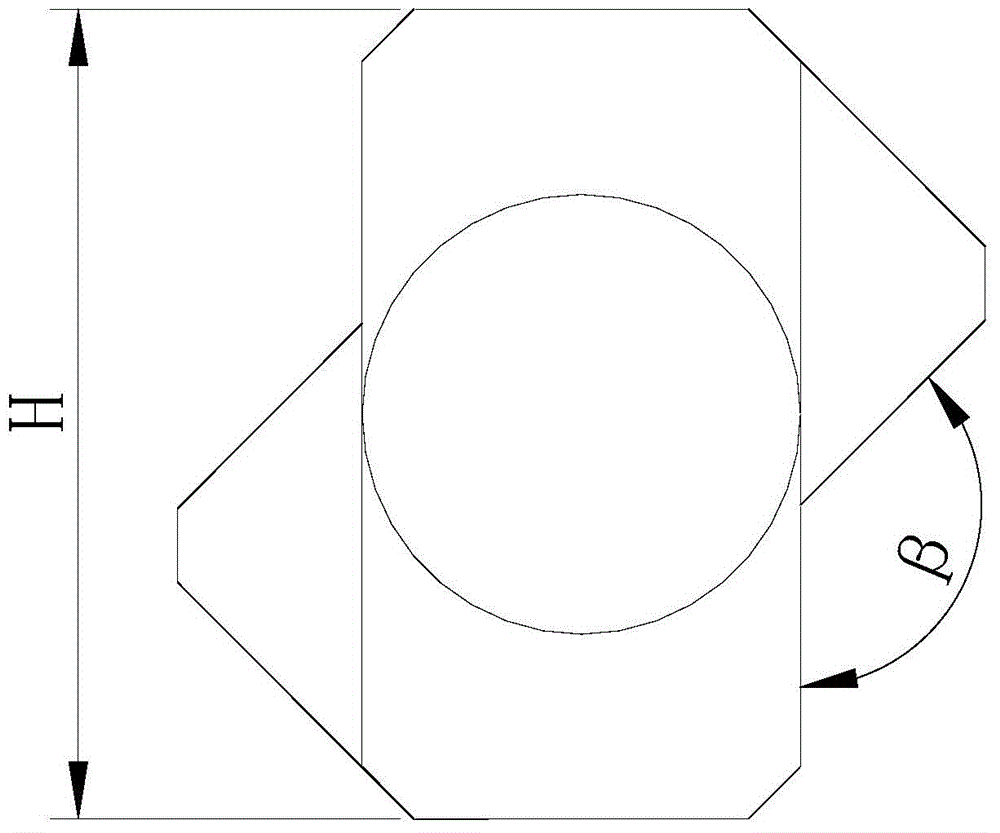

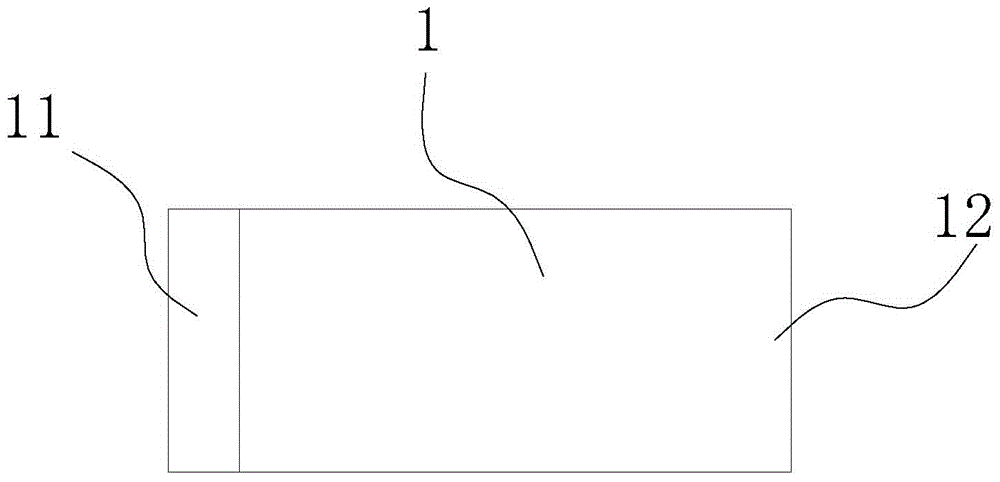

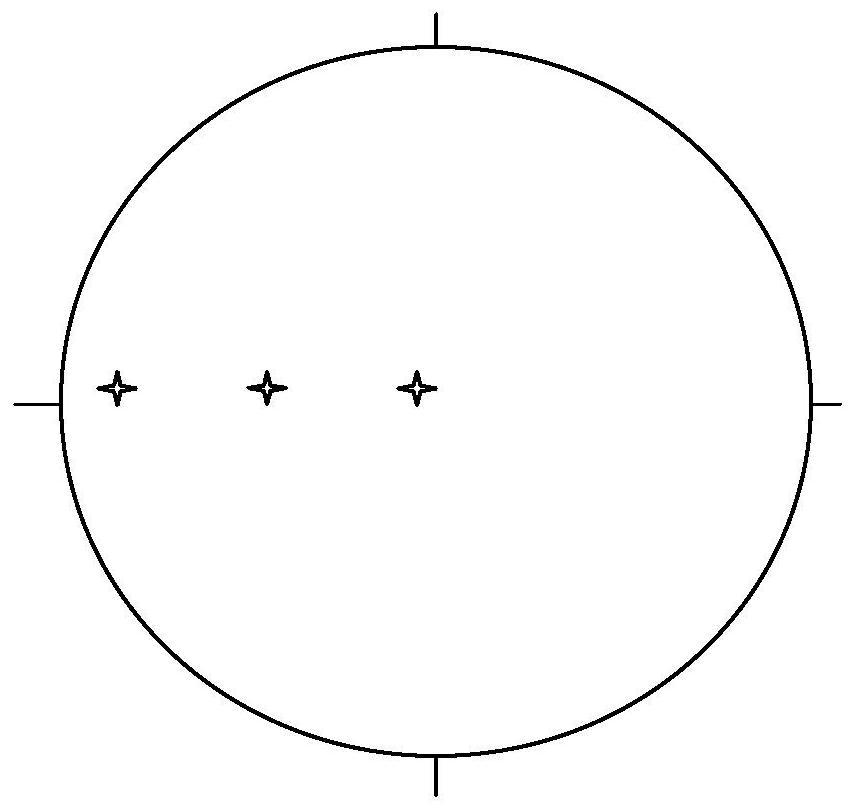

Short-process forging method for nuclear power main pipe billet channel

ActiveCN104174798AReduce forging difficultyReduce the number of forging firesMetal-working apparatusWater gapNuclear power

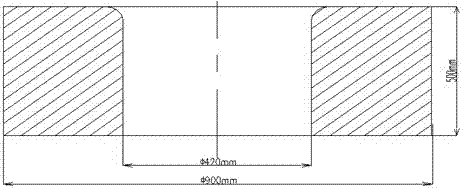

The invention discloses a short-process forging method for a nuclear power main pipe billet channel. The short-process forging method reduces forging difficulty and forging heating number and comprises the steps as follows: A, selecting steel ingots and removing damage of the steel ingots; B, pressing a plier handle and rolling; C, upsetting, swaging and octagonally forging; D, rolling, distributing and swaging; and E, locally upsetting a flange at a pipe mouth, and discharging a finished product. With the adoption of the method, the main pipe mouth part is subjected to local covering and local upsetting for forming, the forging difficulty and the forging heating number are reduced, the forging cost is reduced, and the forging efficiency is improved; meanwhile, the forge piece surface cracking is prevented from aspects of steel ingot surface quality, plier handle and end surface transition fillet, end surface inclination, forge piece water gap reservation, small rolling reduction forming, flame damage removing after forging and the like; and with the adoption of small rolling reduction forming, the forge piece surface quality is improved.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

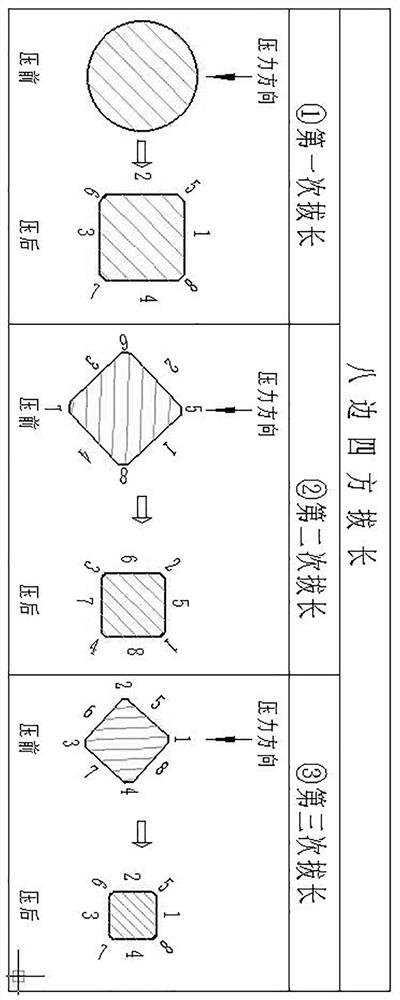

Low-cost efficient preparation method for two-phase titanium alloy round rod

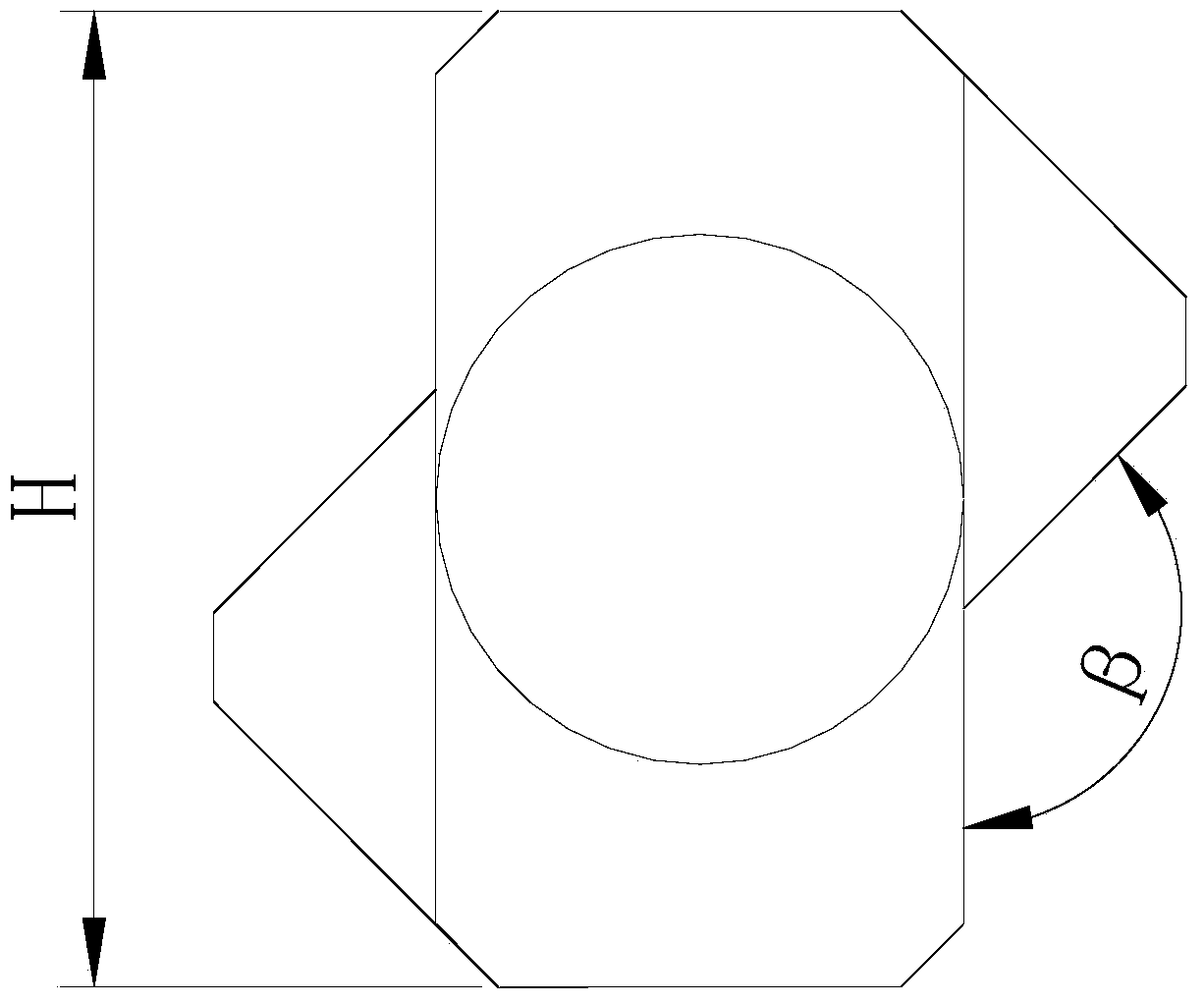

PendingCN111136473AAvoid the disadvantages of unevennessImprove uniformityMetal-working apparatusOther manufacturing equipments/toolsSquare cross sectionLarge deformation

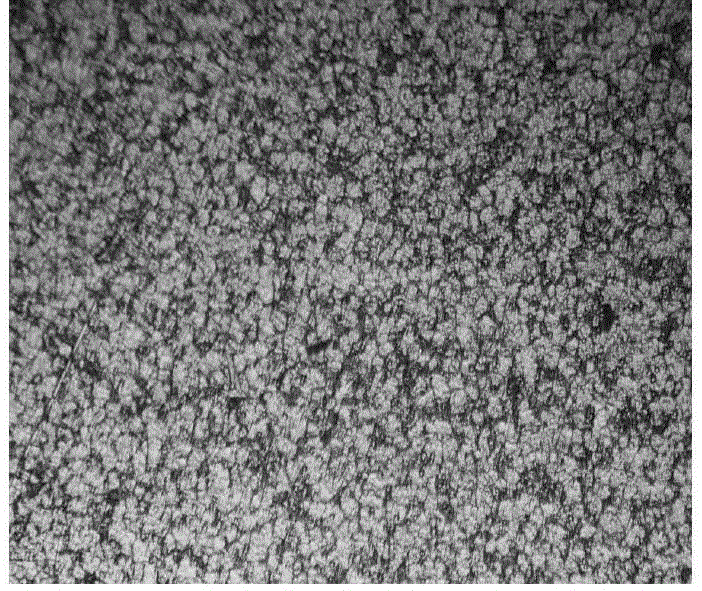

The invention provides a preparation method for a two-phase titanium alloy round rod, wherein three times of forging is realized according to a measured phase transformation point T[beta] of an ingotblank, and multi-directional thermo-plasticity forging deformation is realized according to heating temperature of three heating numbers in a high-to-low sequence; and forging with right-octagonal cross sections is used for two heating numbers under the phase transformation point. The forging mode avoids defects such as serious cracking caused by rapid cooling of corner angles of a forging blank with a right-square cross section as well as organizational unevenness caused by generation of deformation dead zones during forging with a right-square cross section can be avoided. Uniform and equal-axial alpha + beta two-phase processing organizations are obtained through polygonal multi-directional upsetting-stretching forging and large-deformation rolling under the phase transformation point Tbeta, so organizational evenness of the cross section of the round rod is improved; heating numbers of forging can be effectively reduced; surface cracking defects of forging can be reduced; intangible losses of materials are reduced; processing manufacturability and a yield are increased; production cost is reduced; production duration is reduced; production efficiency and a production capacity are increased; and requirements for industrial batched production can be better satisfied.

Owner:西安圣泰金属材料有限公司

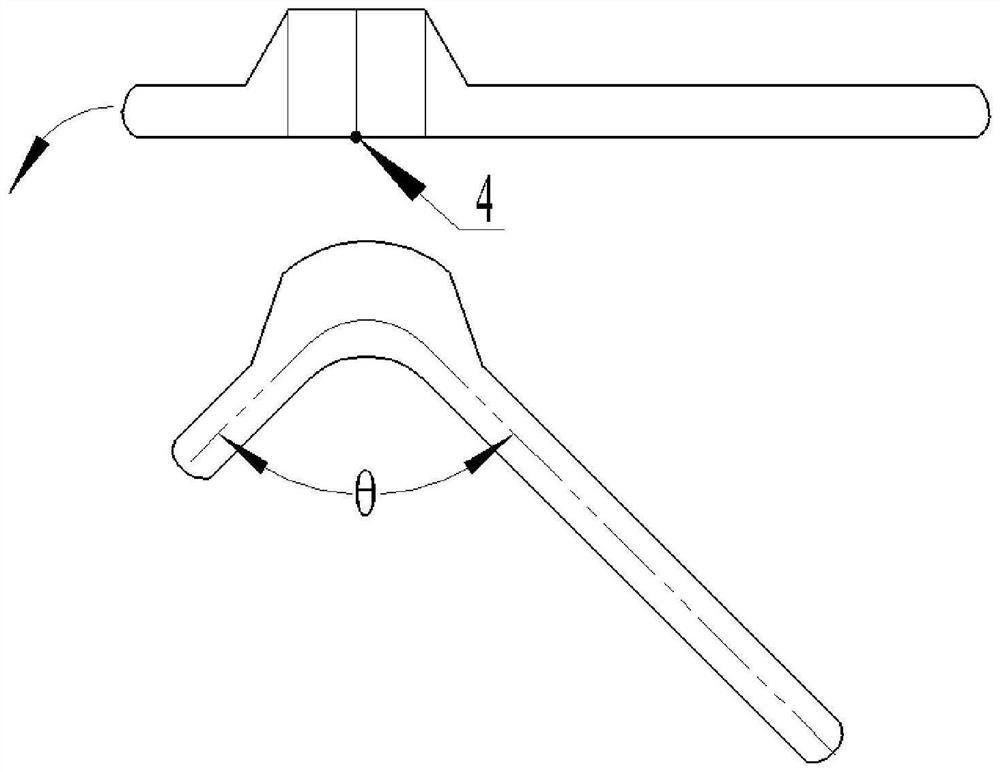

Forging method for Y-shaped blanks made of plastic materials

InactiveCN106607533AControl shapeSmall sizeMetal-working apparatusHigh volume manufacturingPlastic materials

The invention relates to a forging method, in particular to production of various Y-shaped blanks made of plastic forming materials. Through the forging method for manufacturing the Y-shaped blanks, the problems that the Y-shaped blanks are difficult to manufacture, boundary dimensions are inaccurate, the utilization rate of materials is low, macroscopic streamlines do not follow outlines, and energy is wasted are solved. In all links of forging operation, plate blank manufacturing, the lengths of kerfs and the positions of punched holes can be accurately controlled, and thus the outlines and dimensions of the Y-shaped blanks are easily controlled, and mass production is facilitated. The working procedures are simple, the forging heating number is small, and waste of energy for forging heating and consumption caused by self-heating of the materials are reduced. The dimensions of the blanks are easily controlled, and the maximum utilization rate of the materials can be achieved. The obtained Y-shaped blanks can maintain the original forging streamlines, and finally produced forgings can have good anti-fatigue ability.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Gamma'phase pre-adjusting plasticizing production process of high-performance high-temperature alloy

ActiveCN112746231AImprove high temperature plasticityReduce deformation resistanceMetal-working apparatusIngotHeat conservation

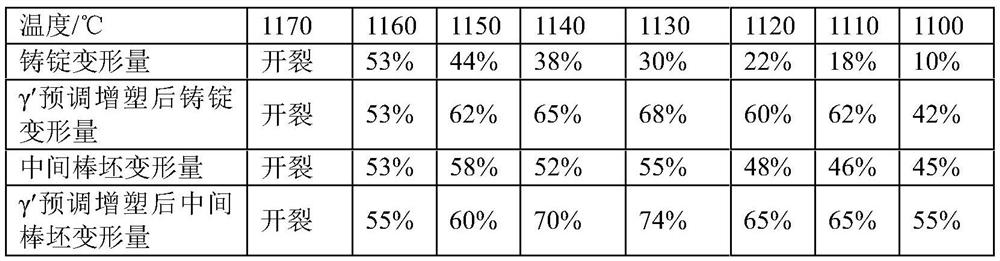

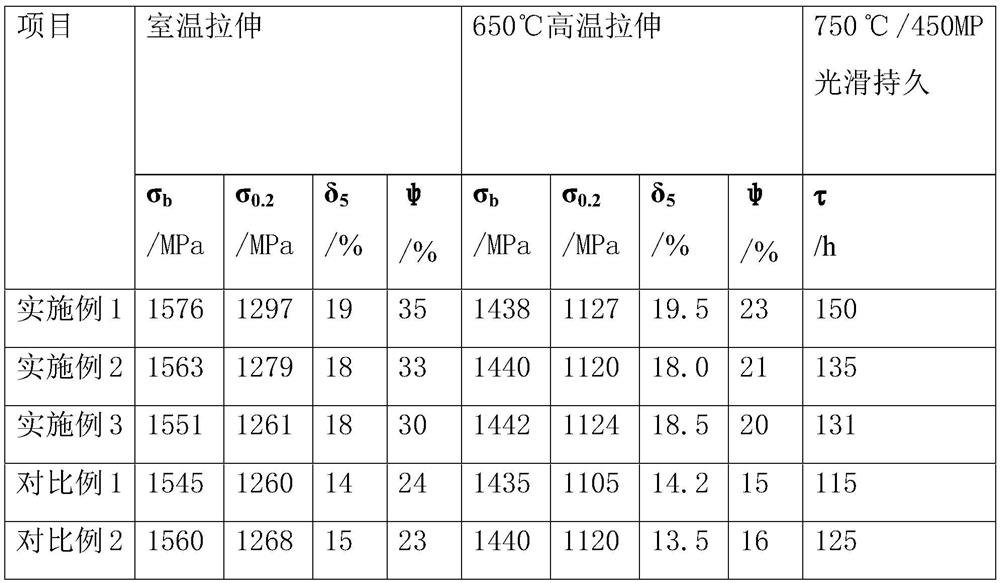

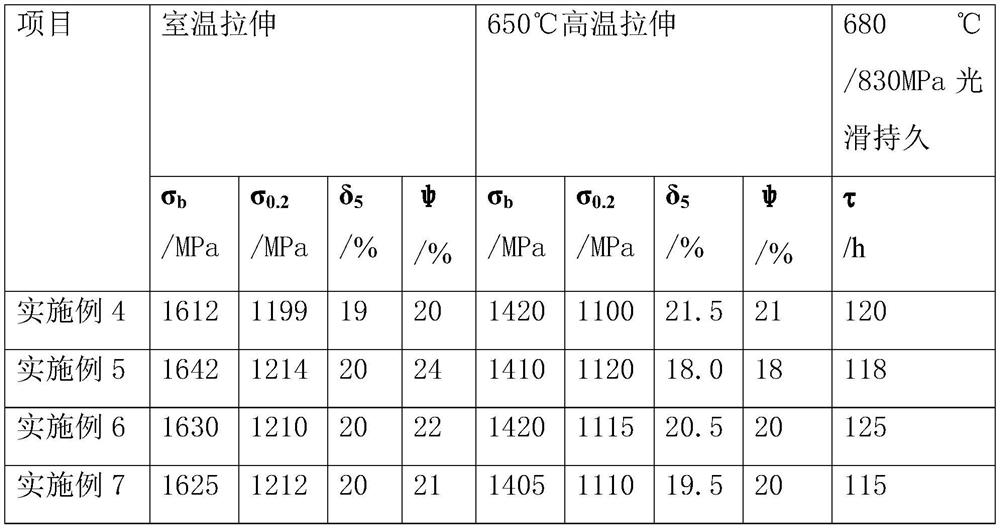

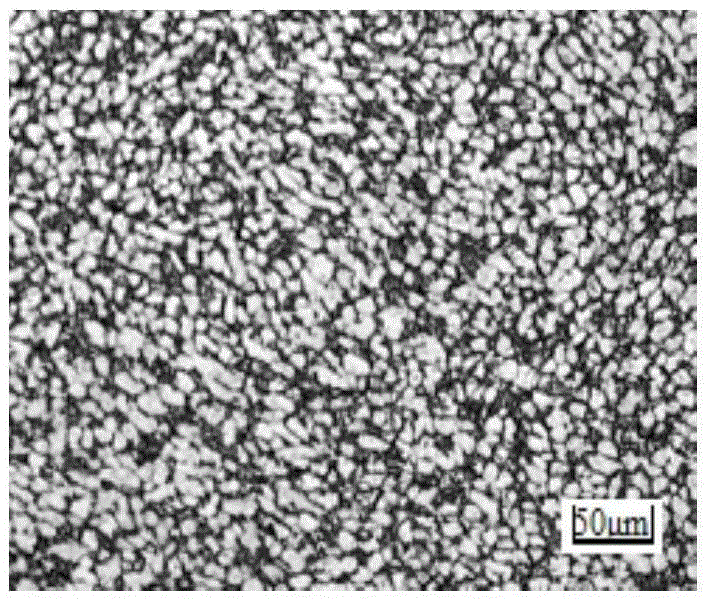

The invention discloses a gamma'phase pre-adjusting plasticizing production process of a high-performance high-temperature alloy, and belongs to the technical field of material processing. The gamma 'phase pre-adjusting plasticizing production process comprises the following preparation steps: 1, smelting is performed to prepare a cast ingot to form a fine-grain homogeneous bar after multi-heating forging; 2, before the bar is forged in a two-phase region, when the heating number forging deformation is higher than the critical cracking deformation, the bar is treated through the gamma'phase pre-adjusting plasticizing technology so as to improve the critical cracking deformation, gamma 'phase pre-adjusting plasticizing adjusts the temperature of the bar subjected to two-phase region forging to be the forging temperature Td, heat preservation is conducted for 2-12 h, then the temperature is reduced to 800-1000 DEG C at the speed of 5-50 DEG C / min, and heat preservation is conducted for 3-12 hours; and 3, the cast ingot or the bar billet obtained in the second step is heated to the forging temperature Td again, heat preservation is conducted, the cast ingot or the bar billet is taken out of a furnace and forged, and a homogeneous bar billet is obtained after multiple times of forging. The hot working high-temperature plasticity of the high-temperature alloy is improved.

Owner:BEIJING CISRI GAONA TECH +1

Method for processing pressure container forgeable piece

ActiveCN101264506AImprove the pass rate of flaw detectionCompaction defectMetal-working apparatusHollow articlesPass rateIngot

The invention relates to a machining method of pressure vessel forging pieces, which is characterized in that the following relationships must be met among the width of an anvil W0, a blanking diameter D, and a required minimum stretching diameter (stamping diameter) D0: the width of the anvil is equal to 0.77-1.0 by D, and the minimum stretching diameter (stamping diameter) D0 equals to 1.4 D by D / W0. The machining method is characterized in that the length H and diameter D of blanking are calculated according to the volume of a forming forging piece, H / D is approximately equal to 2.25, and the width of the anvil is selected according to the blanking diameter D; when stretching and casting the blanks, the percent reduction in each stretching ranges between 15 and 20%, and according to the percent reduction and minimal stretching times as well as forming numbers, the required minimal stretching diameter (stamping diameter) D0 can be determined; then the original blanks are stretched and turned to reach the blanking size for conducting blanking, subsequently, the blanked material is stamped to the required size, and finally, the processes of rounding and finishing are performed. The machining method has the advantages of reducing the forging duration to the maximal extent, effectively compacting the defects inside the steel ingots, and enjoying high pass rate of workpieces.

Owner:WUXI HONGDA HEAVY IND

A kind of forging processing method of tc4 titanium alloy large size bar

InactiveCN104070125BSlow down depreciationImprove performance uniformityForging/hammering/pressing machinesElectric arc furnaceIngot casting

Owner:宁夏中色金航钛业有限公司

Preparation process of high-performance low-cost titanium alloy

The invention relates to a preparation process of a high-performance low-cost titanium alloy. The preparation process comprises the following steps: carrying out bottoming and sealing on a small amount of sponge Ti, laying a layer of sponge Ti, recycled materials, intermediate alloy mixture, Al beans and Cr mixture, and extruding the mixture into an electrode block after repeating the laying for 3-4 times; smelting the electrode block twice, and peeling off the two end surfaces and the side surface after smelting to obtain a blank; sequentially carrying out no less than three heating times offorging and 3-4 heating times of rolling on the blank to obtain a titanium alloy semi-finished product; cutting the titanium alloy semi-finished product into the titanium alloy semi-finished product with required size and then carrying out annealing; and screening alloy titanium plates with qualified performance, and carrying out surface repair treatment to obtain the titanium alloy plates. The process is simple, large-batch stable production can be realized, and the comprehensive performance of the prepared titanium alloy plates is good; and through rolling and annealing, the tensile strengthis larger than or equal to 1050 MPa, the yield strength is 1000-1150 MPa, and the elongation rate is larger than or equal to 10%.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

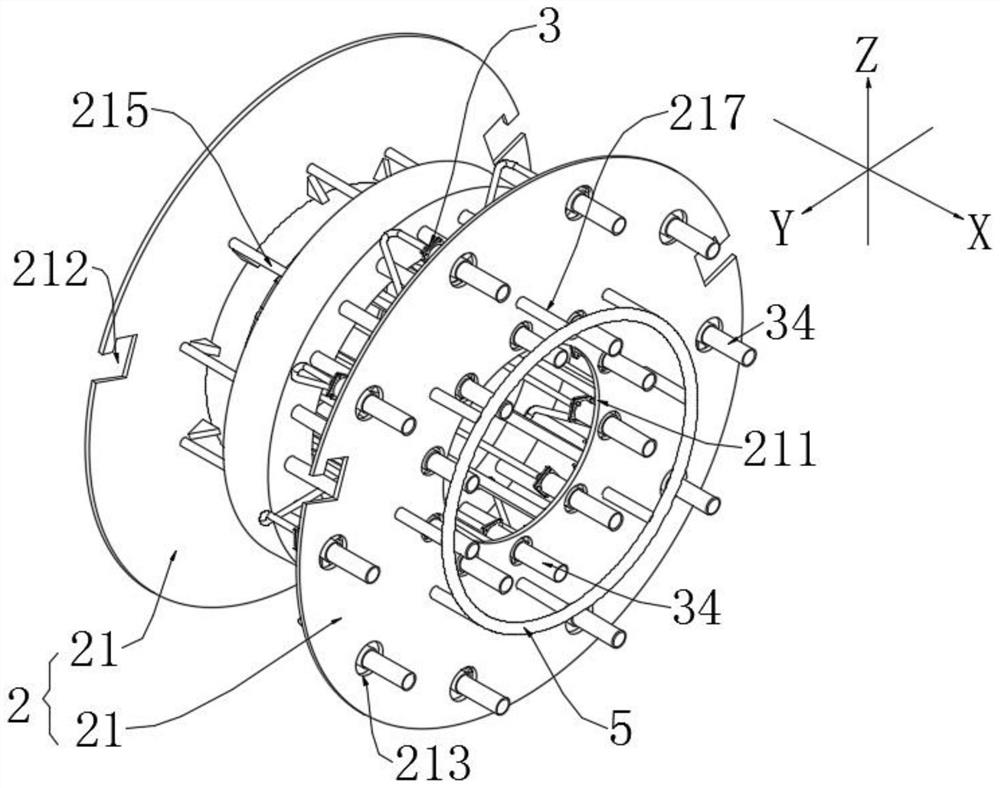

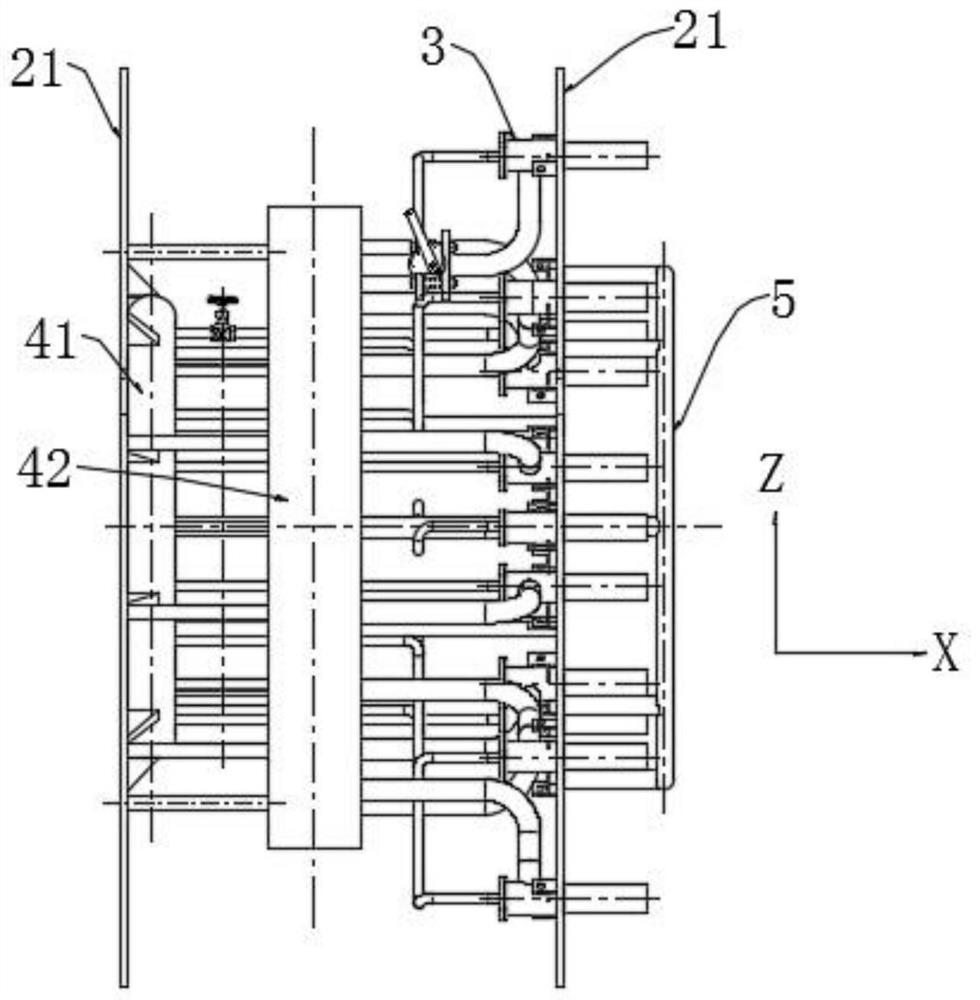

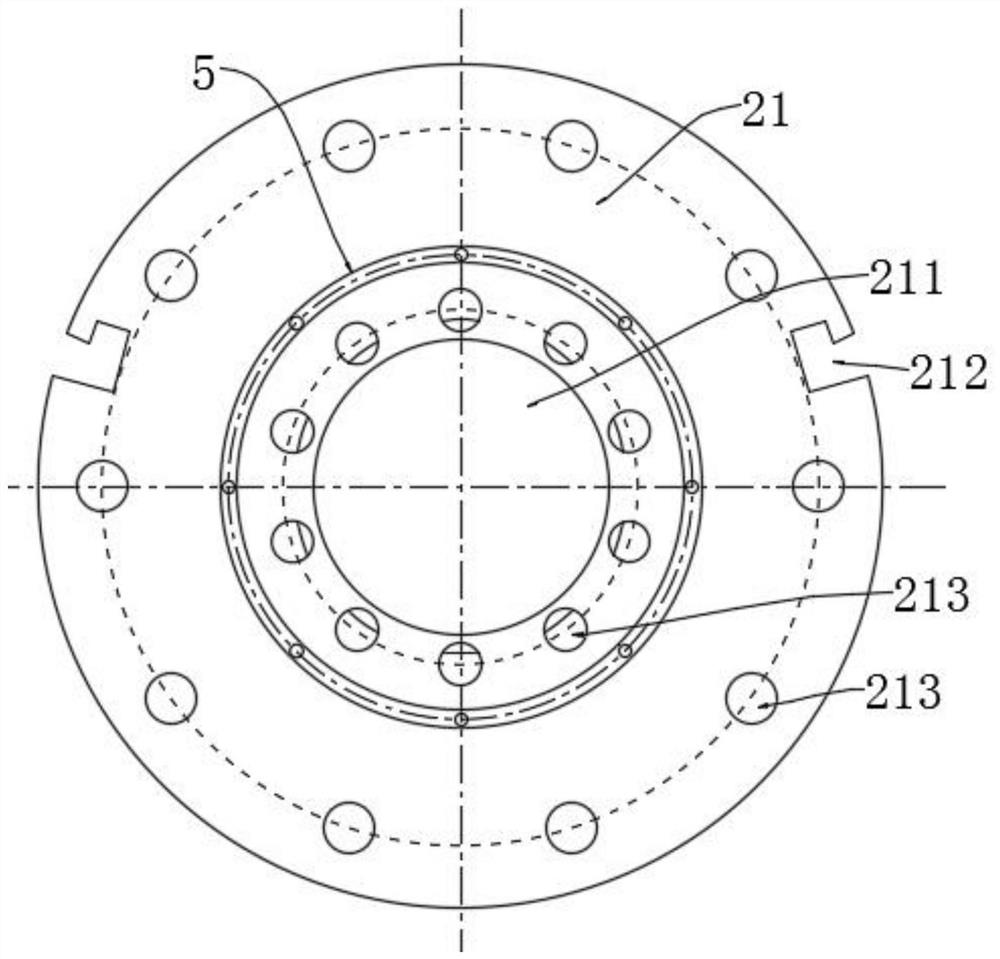

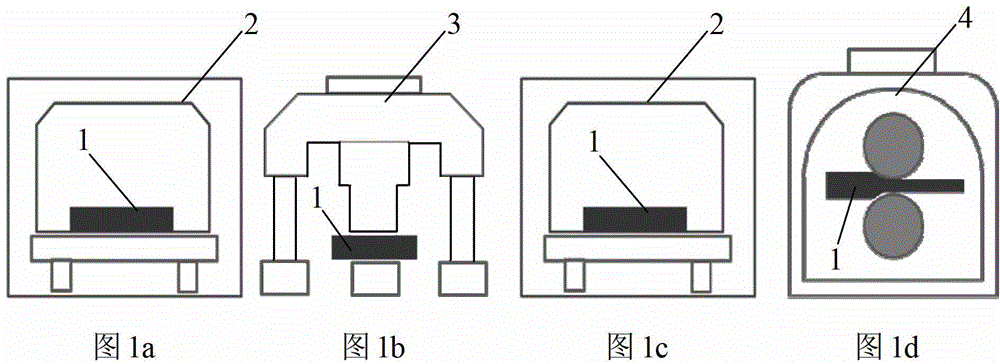

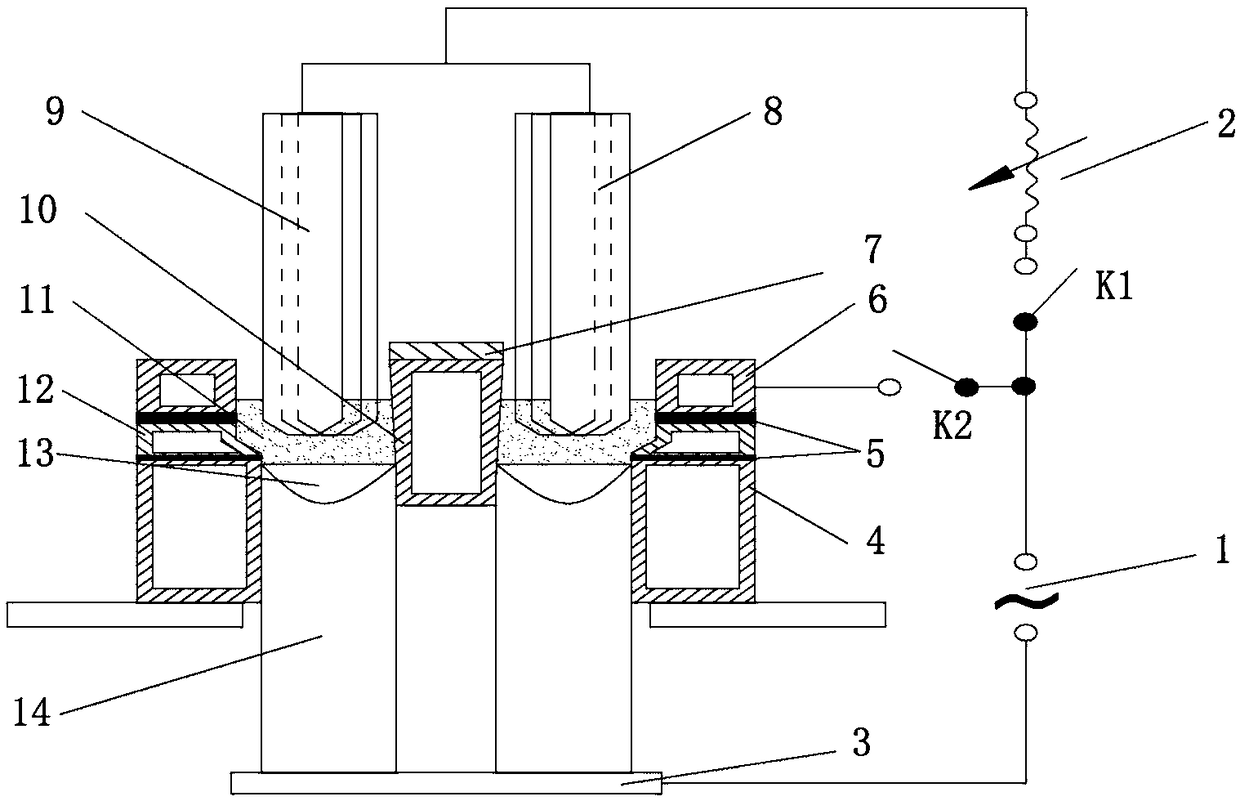

Heating device for forging hollow forge pieces and forging device

ActiveCN111618233AAvoid temperature dropCrack suppressionEngine componentsHeating/cooling devicesEngineeringForge

The invention provides a heating device for forging hollow forge pieces and a forging device, and particularly relates to the technical field of free forging. The heating device for forging the hollowforge pieces comprises a supporting mechanism and a plurality of heating mechanisms, wherein a first through hole is formed in the supporting mechanism; the plurality of heating mechanisms are connected with the supporting mechanism, the plurality of heating mechanisms are arranged around the first through hole, the heating ends of the plurality of heating mechanisms are arranged towards one sideof the supporting mechanism, and the first through hole penetrates through one side of the supporting mechanism; and the end part of the steel forge piece sleeving a mandrel is heated by the heatingdevice for forging the hollow forge piece. Compared with the prior art, the technical scheme has the advantage that the function of preserving heat of the end face of the steel forge piece at the endof the mandrel is realized.

Owner:CHINA FIRST HEAVY IND +1

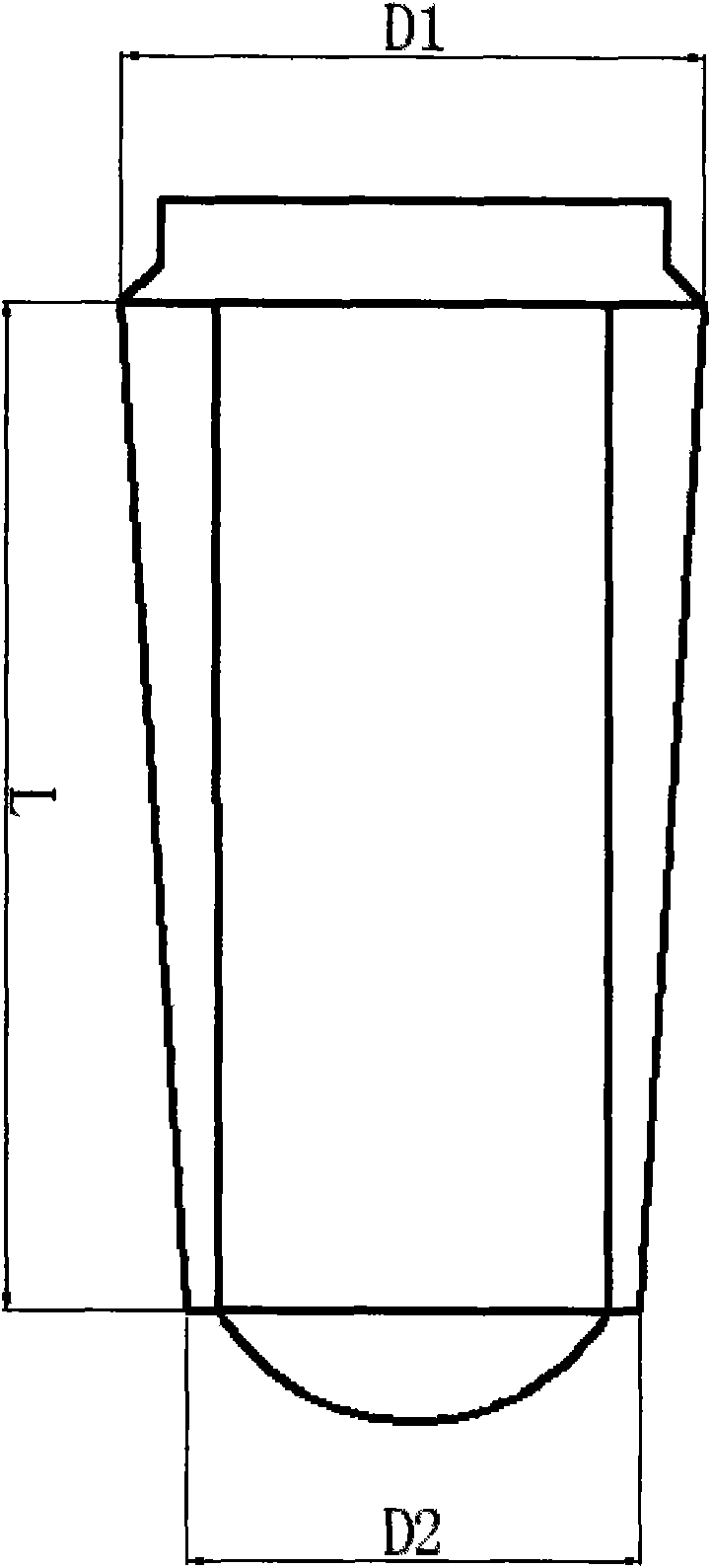

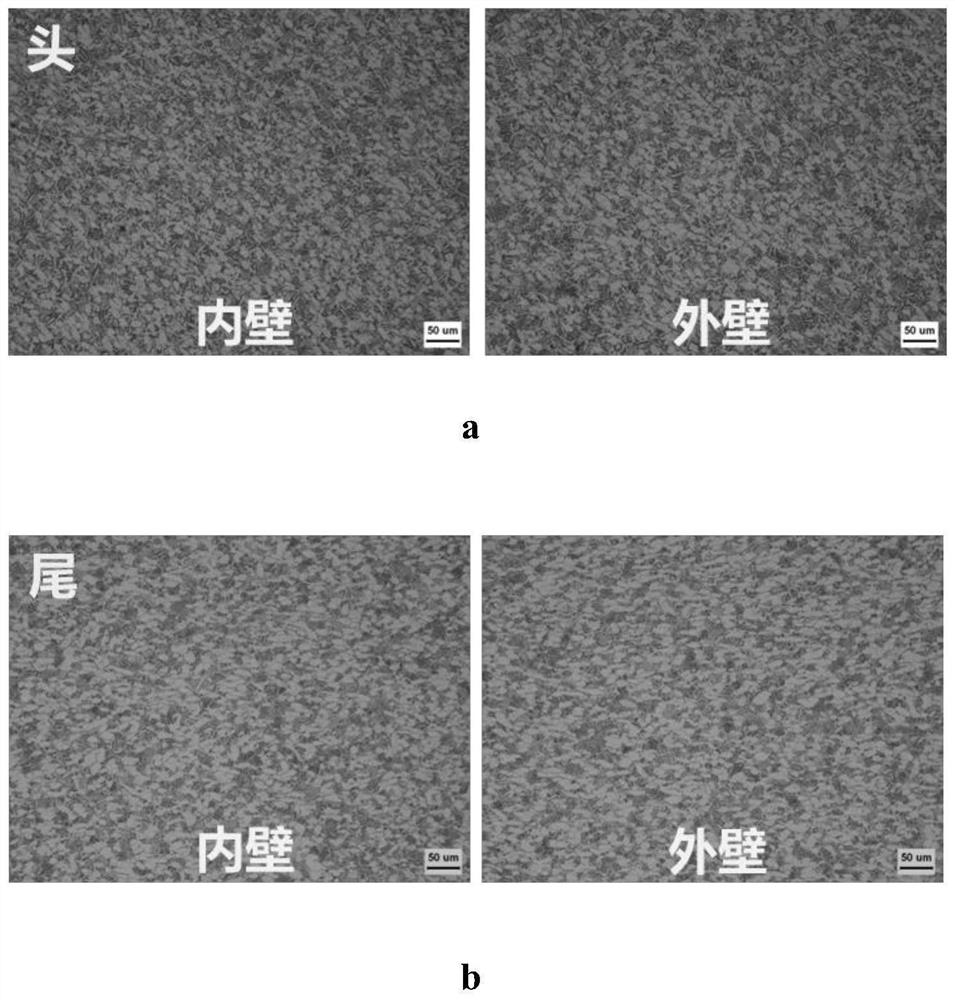

Preparation method of TC4 titanium alloy thin-wall high-barrel ring piece or pipe forging

ActiveCN113305261AImprove uniformityIncrease profitMetal-working apparatusEngine componentsTitanium alloyMaterials science

The invention relates to a preparation method of a TC4 titanium alloy thin-wall high-barrel ring piece or pipe forging. The preparation method comprises the steps of high-temperature forging, low-temperature forging, blank pipe preparation and low-temperature forming forging. According to the preparation method, a traditional technological scheme of free forging and multi-heating-number forming of the thin-wall high-barrel ring piece is abandoned, blank forging of a high temperature section and a low temperature section is adopted, a radial forming technology is adopted, and refining uniformity of the structure of the forging and the consistency of the forging process are effectively achieved.

Owner:西部超导材料科技股份有限公司

Forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks

ActiveCN103273272BPromote healingReduce scrapTemperature control deviceTension/compression control deviceThick plateRoom temperature

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

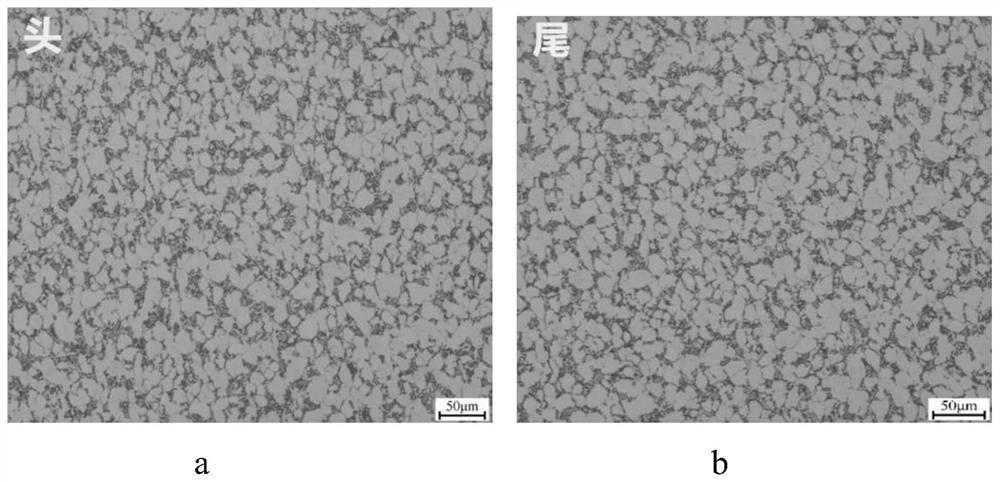

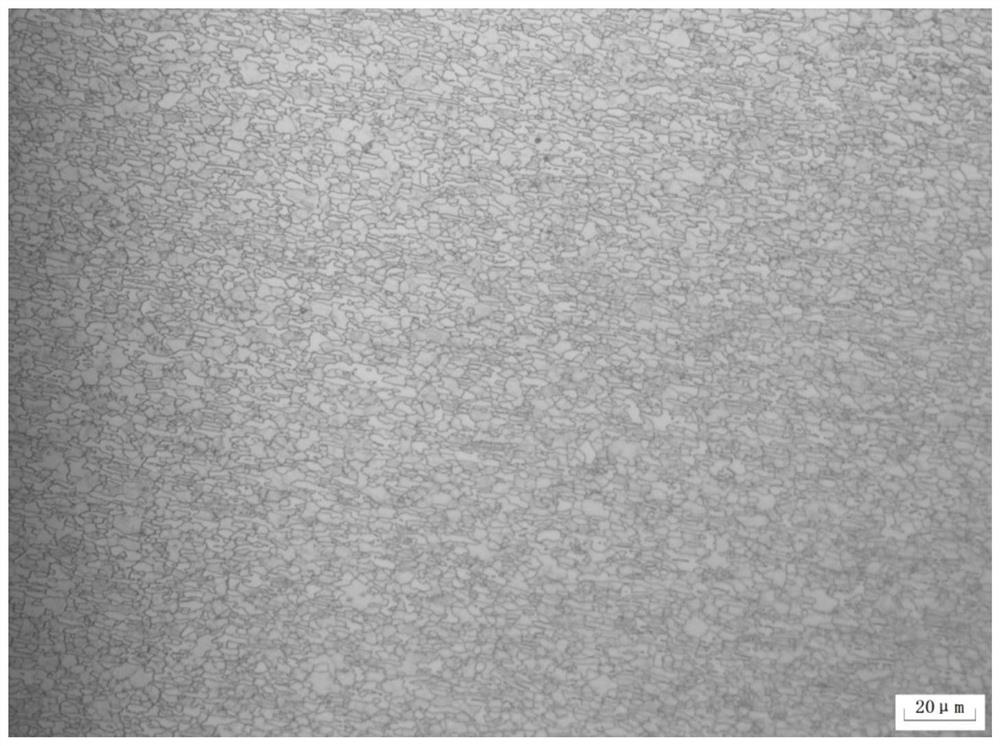

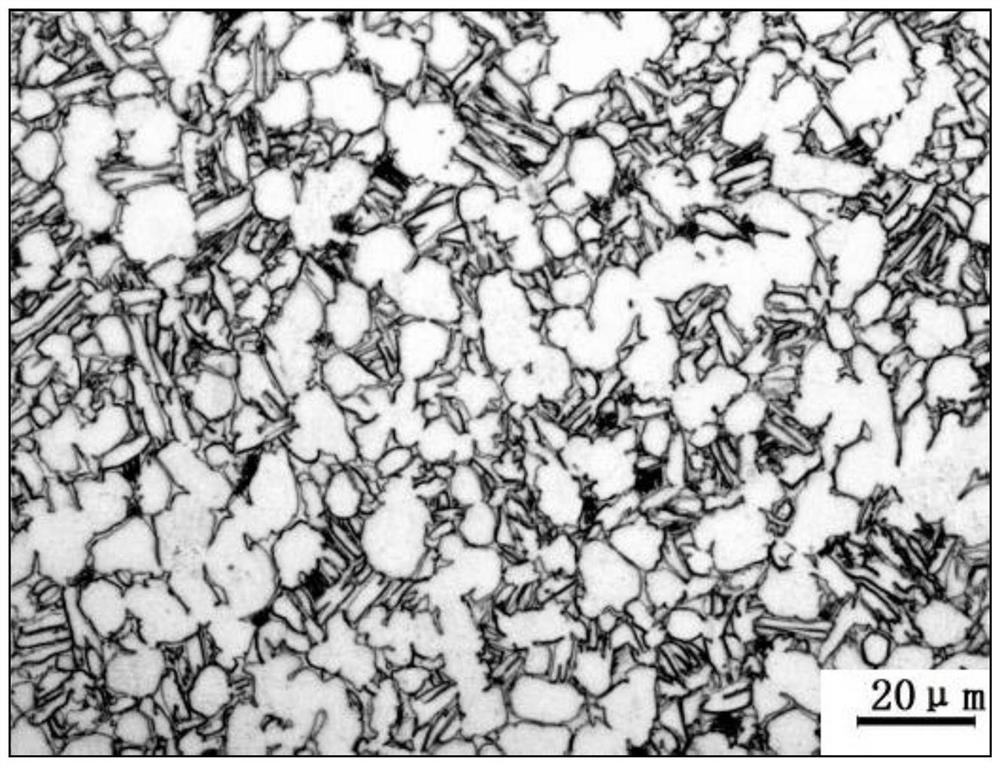

Forging method for improving alpha-beta two-phase titanium alloy forging blank structure uniformity

ActiveCN110216234AImprove uniformityReduce dissimilarityMetal-working apparatusMetallurgyModel selection

The invention discloses a forging method for improving alpha-beta two-phase titanium alloy forging blank structure uniformity. Based on a drawing-out forging process, before drawing-out forging is carried out, model selection of a swage block is firstly carried out, the swage block obtained by model selection is used for conducting homogenizing forging on a blank at the two-phase region temperature, and then the drawing-out forging process is carried out after the above operation is completed to obtain a forging blank finished product; and the forging heating temperature of the drawing-out forging process is below the phase transformation point temperature. According to the forging method, homogenizing forging at the two-phase region temperature is additionally carried out, the overall uniformity of the blank is effectively improved, and the purpose of improving the finished forging blank structure uniformity is achieved.

Owner:西部超导材料科技股份有限公司

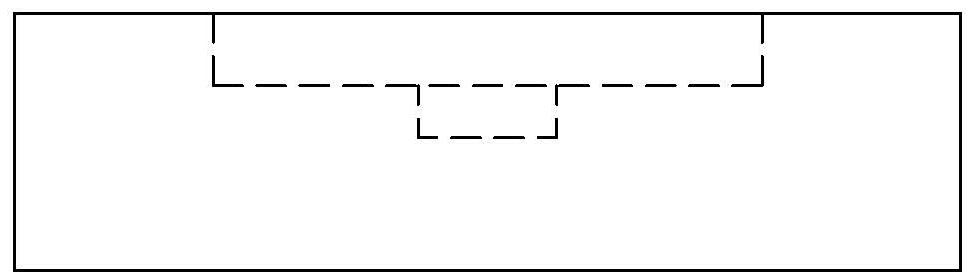

Forging method of large medium-thickness cake-like forging

InactiveCN111618218AEasy to loosenEasy to crackMetal-working apparatusIndustrial engineeringRaw material

The invention discloses a forging method of a large medium-thickness cake-like forging. On the premise of guaranteeing product quality, the heating number of forging can be reduced, the loss in heat treatment of raw materials is saved, forging time is shortened, and production cost is lowered. According to the forging method, the forging is heated to expected temperature, indenting is performed, and an outer edge is rotatably and flatly pressed. The forging method is characterized in that the indenting is double-surface continuous indenting, that is, after one surface is indented, the forgingis immediately turned over by 180 degrees to indent the other surface; and finally, rotatable flat-pressing, outer circle rolling, flattening of the two indented surfaces and forming are performed.

Owner:WUXI HONGDA HEAVY IND

Open blank forging method of near β titanium alloy ti-7333

ActiveCN103846377BFully brokenUniform tissueMetal-working apparatusRoom temperatureMechanical property

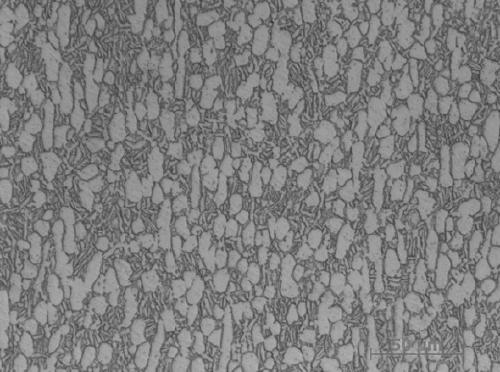

A cogging forging method for close beta Ti alloy Ti-7333 comprises the steps of placing a heated blank on a forging machine and forging with a normal two-rammering two-drawing mode; after the two-rammering two-drawing mode is finished, drawing the blank to eight directions by adopting a normal method, wherein the time for each rammering of the forging machine is 5s, and the total deformation quantity of the first heating number forging is greater than or equal to 40%; air-cooling the blank to the room temperature after the first heating number forging is finished; in the added heating numbers, finishing the forging of rest heating numbers by adopting the method the same as that in the secondary forging. As the technical route of the high-low-high-low forging temperature is adopted in the method, the obtained Ti-7333 alloy is uniform in texture, fine in crystal grain without obvious forging defects, higher in flaw detection level and excellent in mechanical properties, and provides well basis for the subsequent die forging and thermal treatment procedure, the forging heating numbers are reduced as the method adopts the technical route, and the energy and cost are effectively saved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

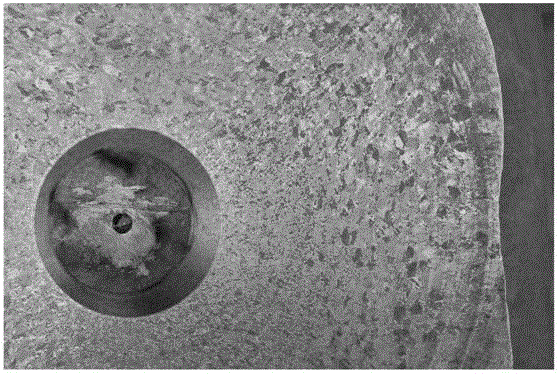

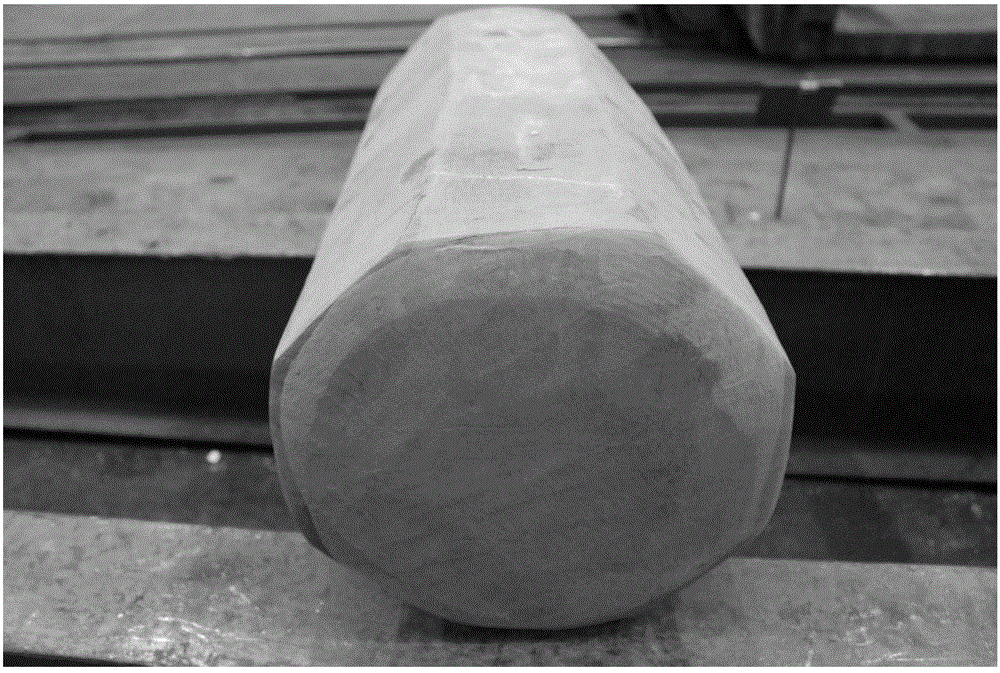

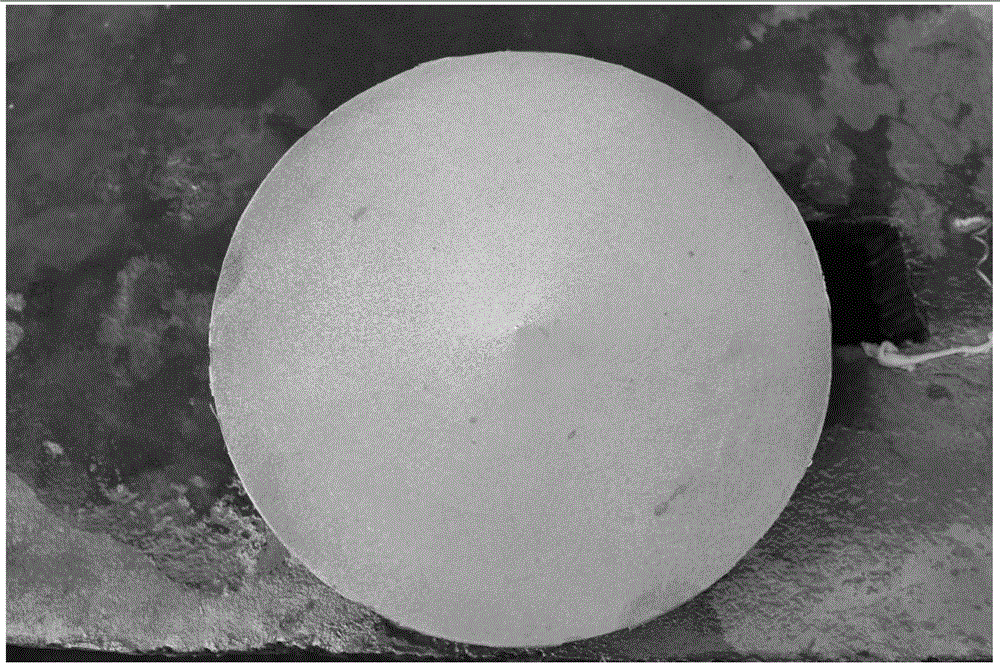

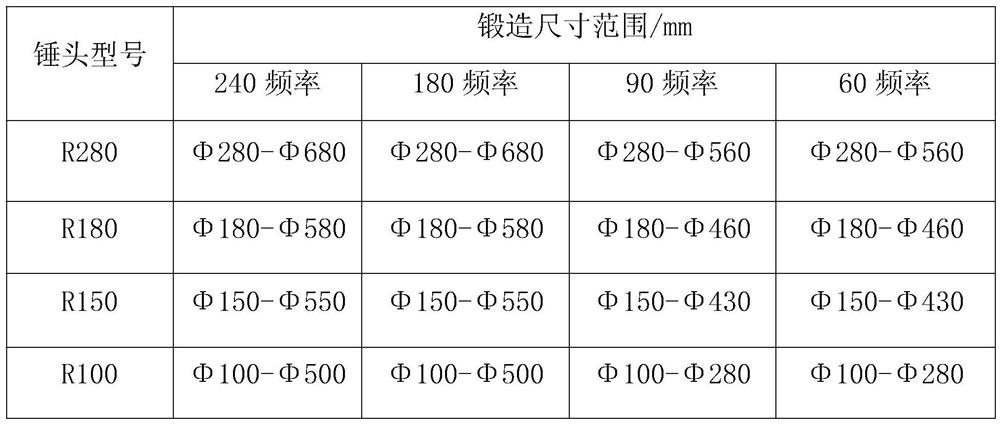

Forging method for refining grain size of long-bar-type steel forge piece

PendingCN113172189ARefined grain sizeGuaranteed final forging temperatureMetal-working apparatusIngotForge

The invention relates to a forging method for refining a grain size of a long-bar-type steel forge piece. The method comprises the following steps that 1) a steel ingot or an electroslag ingot is directly forged by using a radial precision forging machine, the forge piece is forged to enable a diameter of the forge piece to be 340 mm to 560 mm by using frequency of 180 or 240 and reduction of 40 mm to 60 mm per pass, and 3 passes to 5 passes of deformation is reserved for forging at frequency of 60 or 90; 2) the forge piece is forged to enable the diameter of the forge piece to be a diameter of a finished forge piece plus 30 mm to 100 mm by using frequency of 60 or 90 and reduction of 70 mm to 100 mm per pass, and 1 pass to 2 passes of deformation is reserved for finishing forging at frequency of 180 or 240; and 3) the grain size of the long-bar-type steel forge piece is effectively refined and surface quality of the forge piece is obviously improved by using frequency of 180 or 240 and reduction of 30 mm to 50 mm per pass.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Short-process forging method for nuclear power main pipe blank

ActiveCN104174798BQuality improvementReduce forging difficultyMetal-working apparatusNuclear powerIngot

The invention discloses a short-process forging method for a nuclear power main pipe billet channel. The short-process forging method reduces forging difficulty and forging heating number and comprises the steps as follows: A, selecting steel ingots and removing damage of the steel ingots; B, pressing a plier handle and rolling; C, upsetting, swaging and octagonally forging; D, rolling, distributing and swaging; and E, locally upsetting a flange at a pipe mouth, and discharging a finished product. With the adoption of the method, the main pipe mouth part is subjected to local covering and local upsetting for forming, the forging difficulty and the forging heating number are reduced, the forging cost is reduced, and the forging efficiency is improved; meanwhile, the forge piece surface cracking is prevented from aspects of steel ingot surface quality, plier handle and end surface transition fillet, end surface inclination, forge piece water gap reservation, small rolling reduction forming, flame damage removing after forging and the like; and with the adoption of small rolling reduction forming, the forge piece surface quality is improved.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

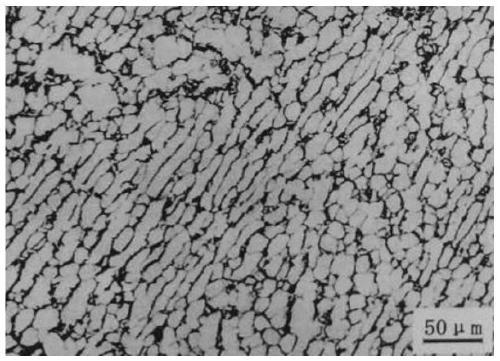

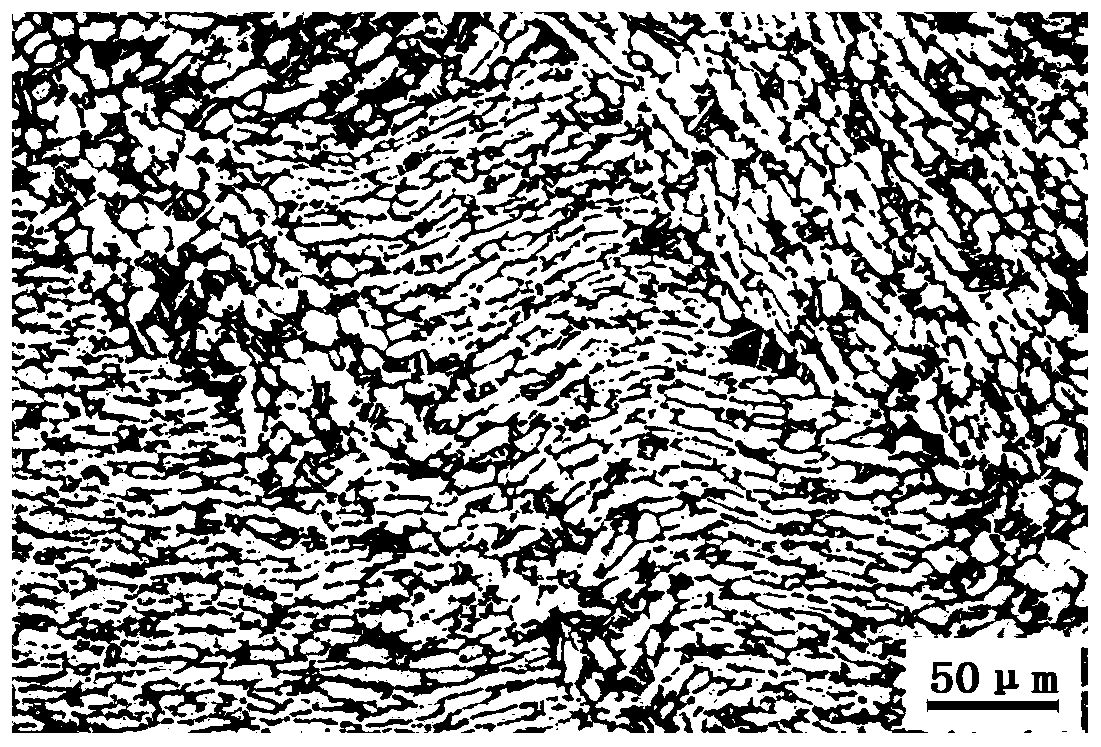

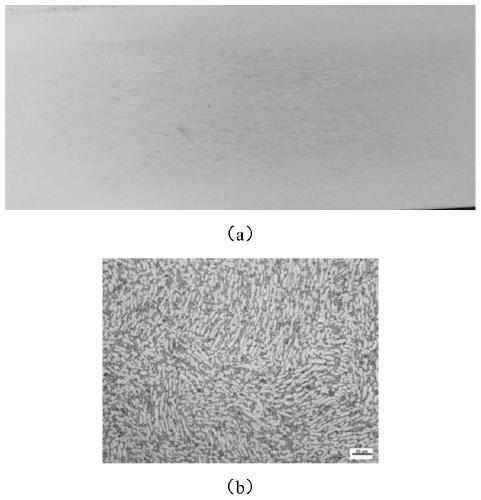

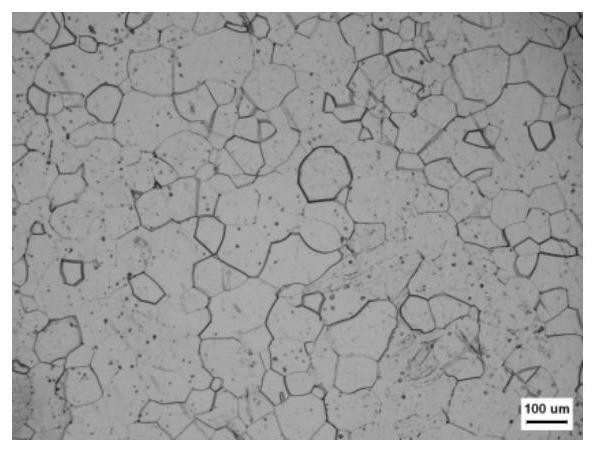

Forging method of Nb47Ti alloy large-size bar for superconducting wire

ActiveCN112692203AReduce the number of forging firesShorten the production cycleHeating/cooling devicesRadial forgingProduction cycle

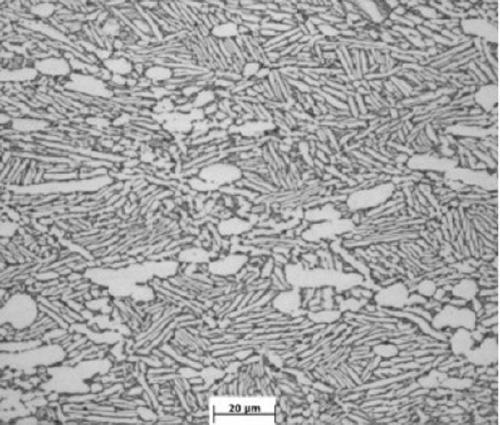

The invention discloses a forging method of an Nb47Ti alloy large-size bar for a superconducting wire. The method comprises the following steps: carrying out first heating number forging on an Nb47Ti alloy cast ingot, wherein the first heating number forging process comprises three times of upsetting, drawing and cooling after forging; performing second heating number forging on the Nb47Ti alloy ingot subjected to cogging forging, wherein the second heating number forging process comprises the steps of drawing out, rolling and cooling after forging; and performing third heating number forging on the Nb47Ti alloy ingot subjected to intermediate forging through a radial forging machine, conducting cooling after forging, and obtaining the Nb47Ti alloy large-size bar. By selecting the deformation mode, the deformation equipment and the deformation amount, the forging heating number and the production period are shortened, the cost is further reduced, and the large-size Nb47Ti alloy large-size bar with a uniform and fuzzy macrostructure and a uniform and fine microstructure can be obtained.

Owner:西部超导材料科技股份有限公司

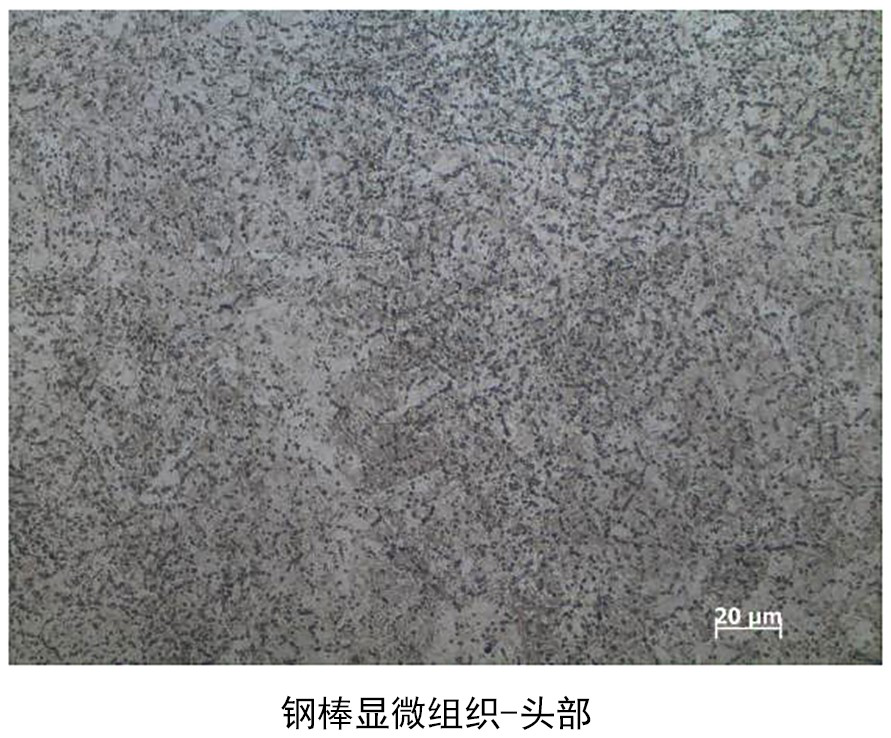

Forging production process of 30Cr15MoN high-nitrogen martensitic stainless steel bar

ActiveCN112496216AAvoid plastic dropUniform tissueMetal-working apparatusTemperature controlMartensitic stainless steel

The invention belongs to the technical field of metal pressure machining processes, and particularly discloses a forging production process of a 30Cr15MoN high-nitrogen martensitic stainless steel bar, which comprises the steps of electroslag remelting, heating, forging preparation, forging and red annealing. According to the method, the problems that 30Cr15MoN steel in an existing forging processis prone to cracking and uneven in structure are effectively solved by combining the optimized forging mode that drawing is directly conducted without upsetting and an eight-edge four-method is adopted for drawing with strict temperature control, meanwhile, the forging heating number is reduced, and the production efficiency is improved; The steel bar forged through the method is excellent in performance in all aspects and can meet the material requirements of high-precision sharp-end projects.

Owner:DEQING TIANMA BEARING CO LTD

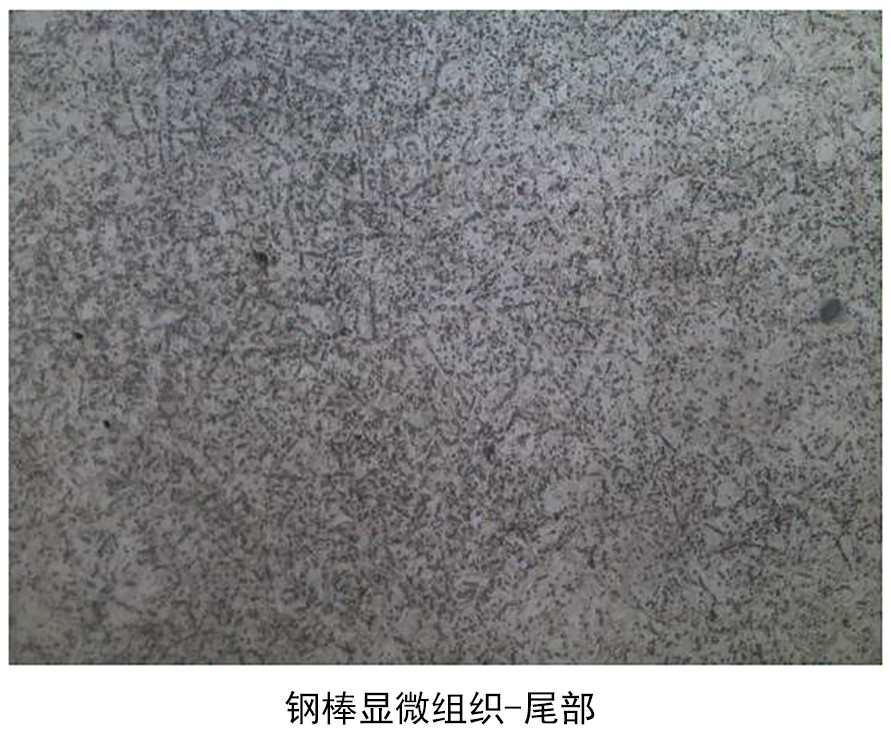

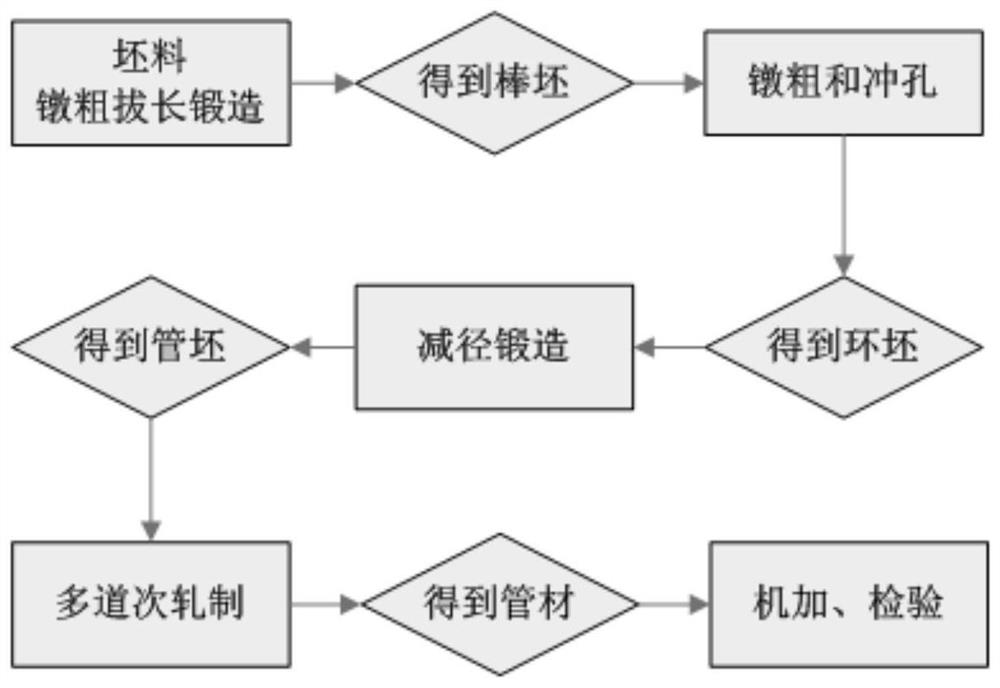

Grain refining processing method of titanium alloy tube blank for spinning

ActiveCN112275830AReduce the number of forging firesShort processing flowMaterials processingMetallurgy

The invention belongs to the technical field of titanium alloy material processing, and relates to a grain refining processing method of a titanium alloy tube blank for spinning. The method comprisesthe following steps: 1. forging at 150-200 DEG C and 50-120 DEG C above a phase transformation point to obtain a bar blank; 2, upsetting and drawing out are conducted at the temperature 20-50 DEG C below the phase transformation point, and obtaining a ring blank after punching; 3, performing reducing forging at the temperature 15-50 DEG C above the phase transformation point, and obtaining a pipeblank; and 4, rolling at the temperature of 25-90 DEG C below the phase transformation point, and obtaining a titanium alloy fine grain pipe with the wall thickness of 10-25 mm for spinning. The method is short in technological process, stable and controllable, the prepared titanium alloy pipe is fine in grain and uniform in structure, and the related technical requirements of the spinning formingprocess are met.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A kind of preparation method of tc6 titanium alloy large size bar

ActiveCN113172115BReduce the number of firesEfficient crushingMetal-working apparatusIngotTitanium alloy

Owner:WESTERN TITANIUM TECH

Forging method of battery pole piece roll blank

ActiveCN104942541BGuaranteed technical requirementsImprove performanceRollsMetal rolling arrangementsEngineeringRaw material

The invention discloses a method for forging a battery pole piece roll blank. The method comprises the following steps that (1) the roll blank is drawing out until the diameter is smaller than the size of a roll body technological diameter; (2) shoulder cutting is carried out on the drawn out roll blank, and roll necks at the two ends are forged after the shoulders are cut; (3) local upsetting is carried out on a roll body to enable the roll body diameter to be larger than the roll body technological diameter; (4) the roll body is drawn out to the technological diameter, and the roll necks are trimmed to technological sizes. According to the method, the specific value between the length and the diameter during shoulder cutting is enlarged, the effect of reducing shoulder cutting excess materials or even generating no excess material is achieved, meanwhile, due to the fact upsetting is carried out after shoulder cutting, the end faces at the joints of the roll body and the roll necks are flushed, the mass of hidden materials is reduced, the plier handle pressing procedure before upsetting is omitted, and forging times are reduced. The method for forging the battery pole piece roll blank reduces raw material waste and energy waste, and saves production cost.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Die forging and forming method of large-scale disc type forging piece

Owner:WUXI TURBINE BLADE

Forging method of aluminum alloy asymmetric Y-shaped die forging

PendingCN112658184AImprove performance indicatorsSolve the technical problem of simultaneous full moldingForging/hammering/pressing machinesManufactured materialMaterials science

The invention provides a forging method of an aluminum alloy asymmetric Y-shaped die forging. A limiting device is arranged, a middle forging similar to the asymmetric Y-shaped die forging is forged, asymmetric arms of the middle forging, arms of the asymmetric Y-shaped die forging and a rod cylinder have a certain proportional relation, the technical problems about asymmetric Y-shaped die forging molding and simultaneous filling molding of the two asymmetric arms are solved, raw materials are saved, the forging heating number is reduced, and the performance index of the forging is improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

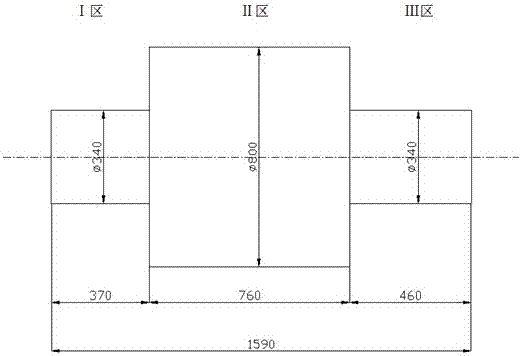

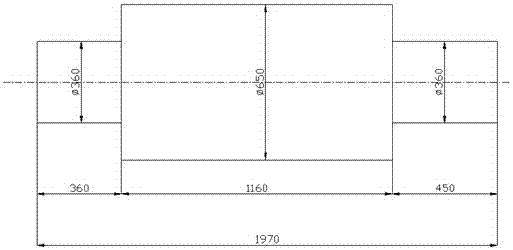

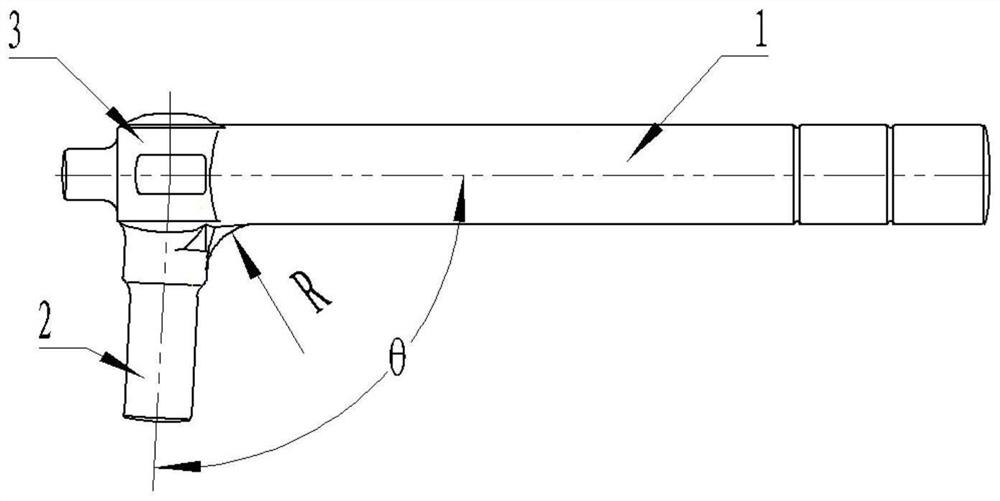

A non-magnetic stabilizer forging process

ActiveCN104325052BFast forgingUniform deformationMetal-working apparatusNon magneticMechanical property

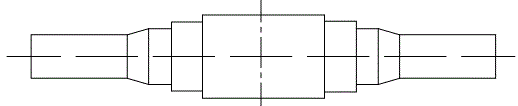

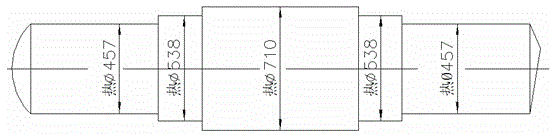

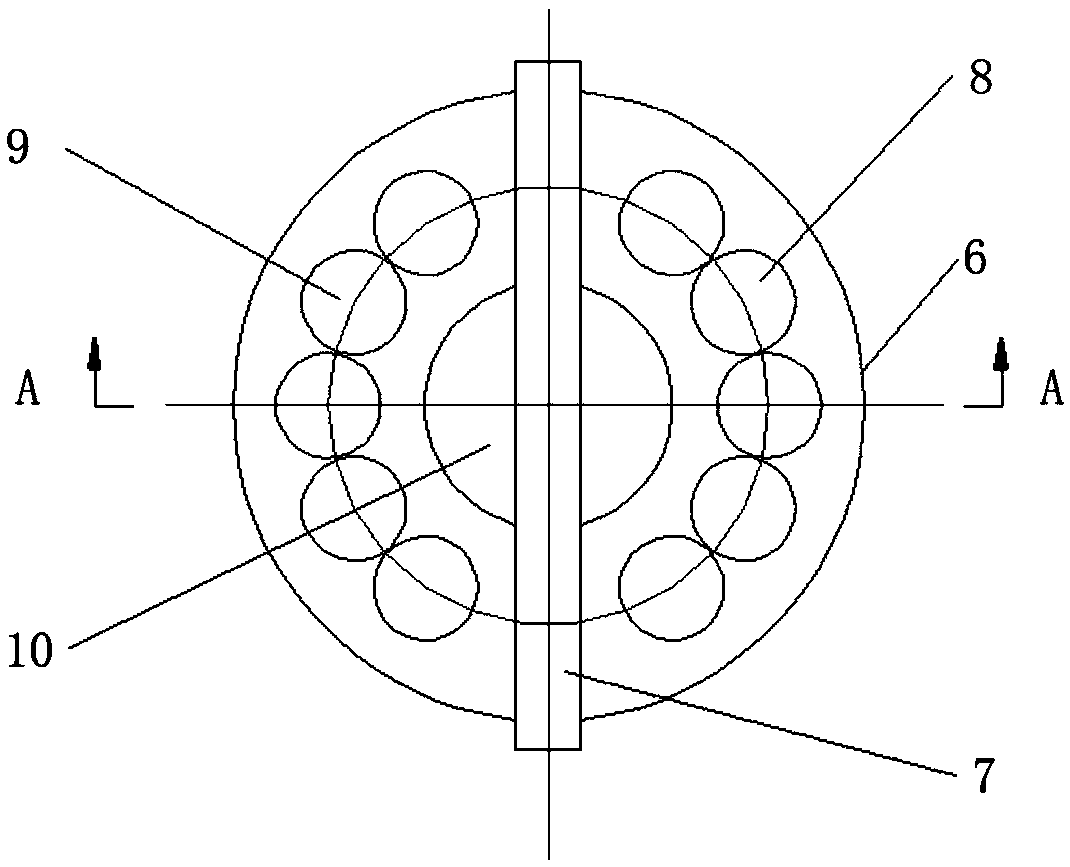

The invention relates to a non-magnetic stabilizer forging process. The steps of the process are as follows: (Step S01): blooming forging on an oil press: the 5000-ton oil press is utilized to do preliminary blooming work, a big step is drawn out to be hot Phi710, and small steps at both ends are drawn out to be hot Phi540; (Step S02): strengthening forging on a precision forging machine: the 1400-ton precision forging machine is adopted for forging forming, pull or push forging is performed after a clamp A and a clamp B are adopted for clamping, so that the small steps are forged into a preform size, the small steps at both ends are forged into a target size after temperature decreases to be lower than 800 DEG C, and finish forging temperature is not lower than 600 DEG C; (Step S03): strengthening forging on the oil press: the unstrengthened parts of the surface of the forging are forged at high speed to be strengthened under low pressure, deformation is 5 percent to 10 percent, and finish forging temperature is not lower than 500 DEG C; (Step S04): physical and chemical testing. The non-magnetic stabilizer forging process provided by the invention can produce non-magnetic stabilizers with uniform mechanical properties in each part and good magnetic property by utilizing the oil press and the precision forging machine for joint forging.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

A method for electroslag remelting to prepare hollow steel ingots of nickel-based superalloys

A method for preparing nickel-based high-temperature alloy hollow steel ingots by electroslag remelting, which belongs to the field of metallurgical technology. It is characterized in that the equipment adopts a single power supply and double circuit power supply, a T-shaped conductive crystallizer and an inner crystallizer. The preparation method includes: preparing a consumable electrode group, preparing a slag system with suitable composition, and pouring it after baking and melting. In the cavity formed by the T-shaped conductive crystallizer and the inner crystallizer, at the same time, first turn on the power supply of the conductive circuit II, then turn on the power supply of the conductive circuit I, insert the consumable electrode group into the slag for smelting, extraction, and automatic When the remaining amount of the consumable electrode group is small, replace it in time until the end of smelting. This method can produce nickel-based high-temperature alloy hollow steel ingots with uniform composition and good internal and external surface quality.

Owner:NORTHEASTERN UNIV LIAONING

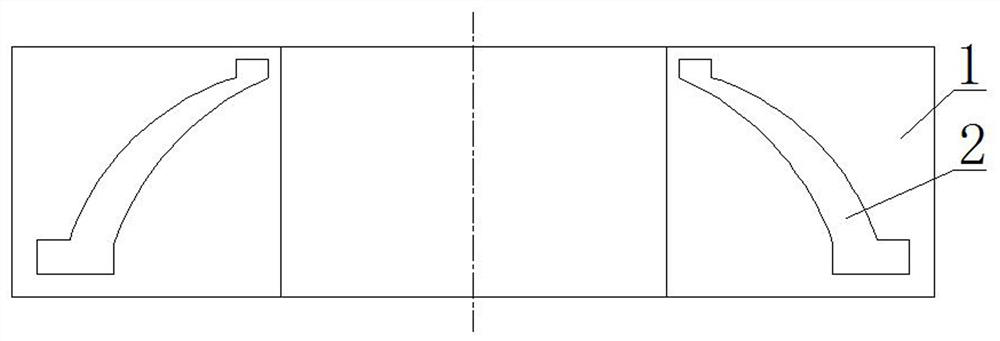

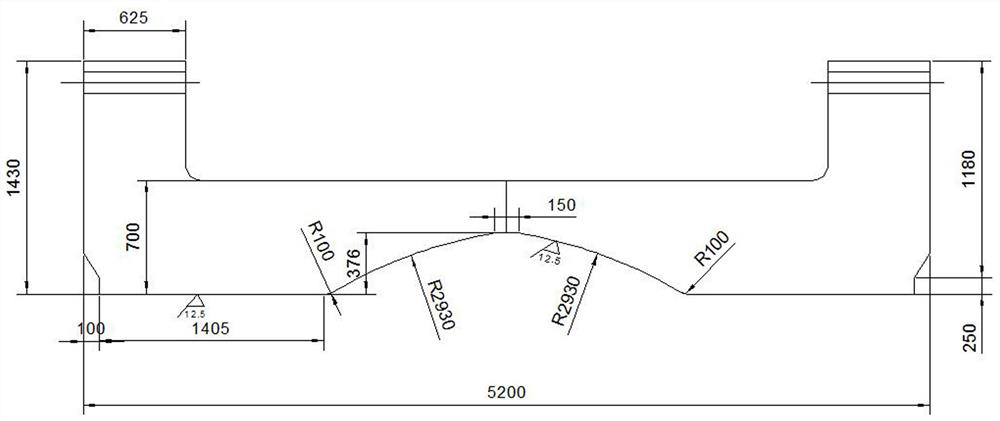

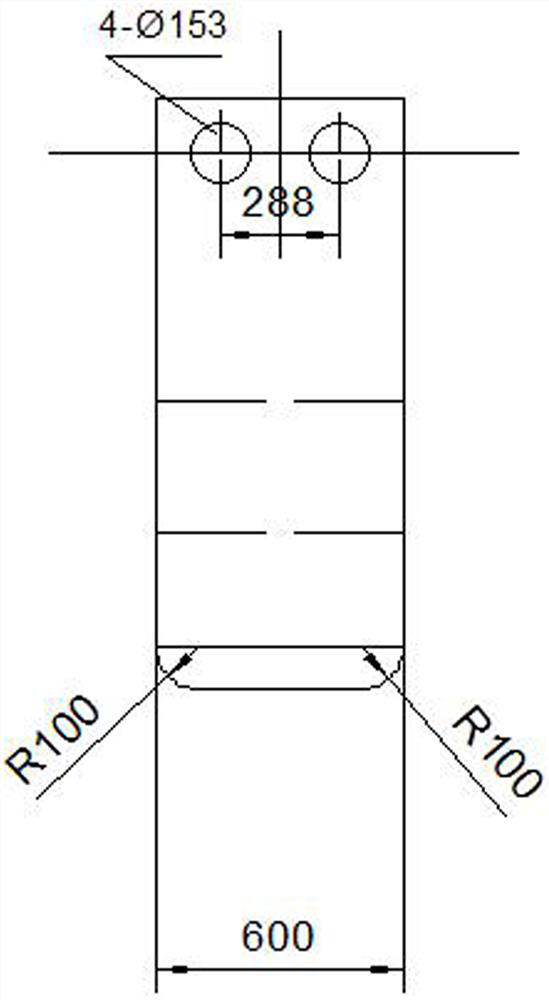

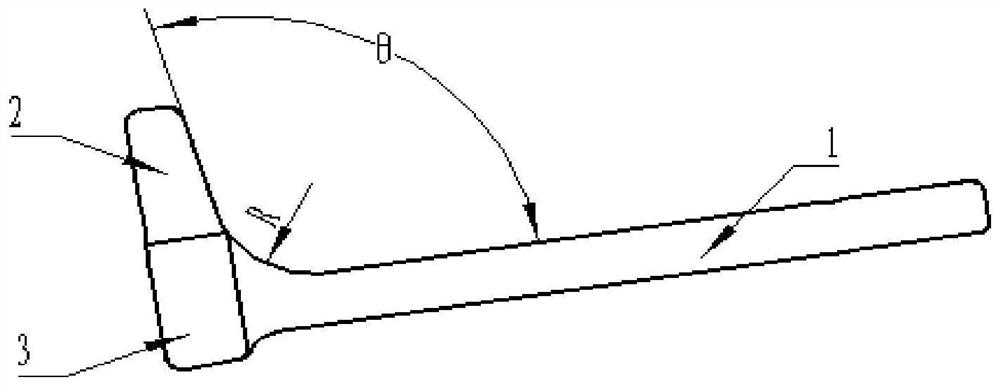

Profile Forging Method for Transition Section of Hydrogenation Reactor

ActiveCN110479947BNet Near ShapingWide size coverageForging/hammering/pressing machinesDomestic articlesProcess engineeringIngot

The invention discloses a profiling forging method for a transition section of a hydrogenation reactor, which belongs to the technical field of hot forging. The first step is to statistically sort out the size of the hydrogenation transition section produced in previous years to find out the applicability size; the second step: Design of special attachments; third part: simulation of deformation process; fourth step: special attachments into production; fifth step: trial production of test pieces; sixth step: forging process review; seventh step: formal product production; eighth step: Subsequent quality tracking; Step 9: Summarize the essentials of operation and the profiling production process of the solidification and hydrogenation transition section. The above method produces two hydrogenation transition sections for each steel ingot, which saves twice the number of forging fires compared with the conventional production method, reduces production costs, and improves material utilization. Efficiency has also been further improved.

Owner:CHINA FIRST HEAVY IND

Forging method of 7-type AerMet100 ultrahigh-strength steel forge piece

PendingCN114226613AReduce the difficulty of billet making operationGuaranteed performanceMetal-working apparatusEngine componentsEngineeringHot working

The invention belongs to the field of forging hot working, and relates to a forging method of a 7-shaped AerMet100 ultrahigh-strength steel forge piece. Comprising the following steps: step 1, selecting a bar as a blank, wherein the sectional area of the blank is 1.1-1.25 times of the sum of the sections of a forge piece and burrs; 2, a material distribution groove is machined, and the blank is divided into a head material and a rod material through the groove; 3, the blank is placed on a hammer anvil, and head material division is conducted with the groove as the boundary; eccentrically drawing out the rod part material, wherein one side face of the eccentric rod is flush with one side face of the head part; 4, after the blank is turned over by 90 degrees, head rods are distributed, and the head rods and the tips of the head rods are pressed; and 5, shaping the blank obtained in the step 4 to obtain a 7-shaped blank. And the qualified rate of products is improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com