Profile Forging Method for Transition Section of Hydrogenation Reactor

The technology of a hydrogenation reactor and a transition section is applied in the field of hot working and forging, and can solve the problems of low performance index value of forgings, large machining allowance and high production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

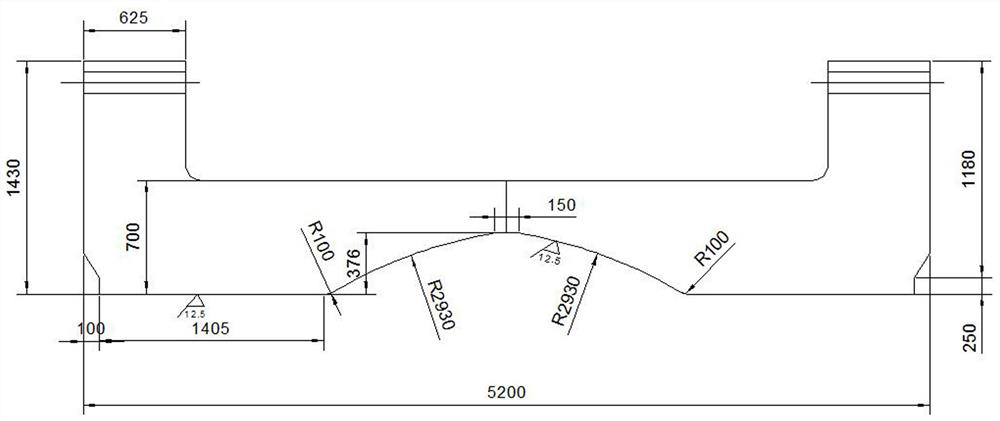

[0047] The profiling forging method and processing steps of the hydrogenation reactor transition section of the present invention are as follows: including: special accessories;

[0048] Step 1: Count the size of the hydrogenation transition section produced in previous years: Since the size of each hydrogenation reactor is different, by combing the size of the hydrogenation transition section over the years, the height of the transition section, the spherical radius, the outer Classify the data such as the diameter, step length, etc., find out the applicability size, and lay a solid foundation for the subsequent design of special accessories;

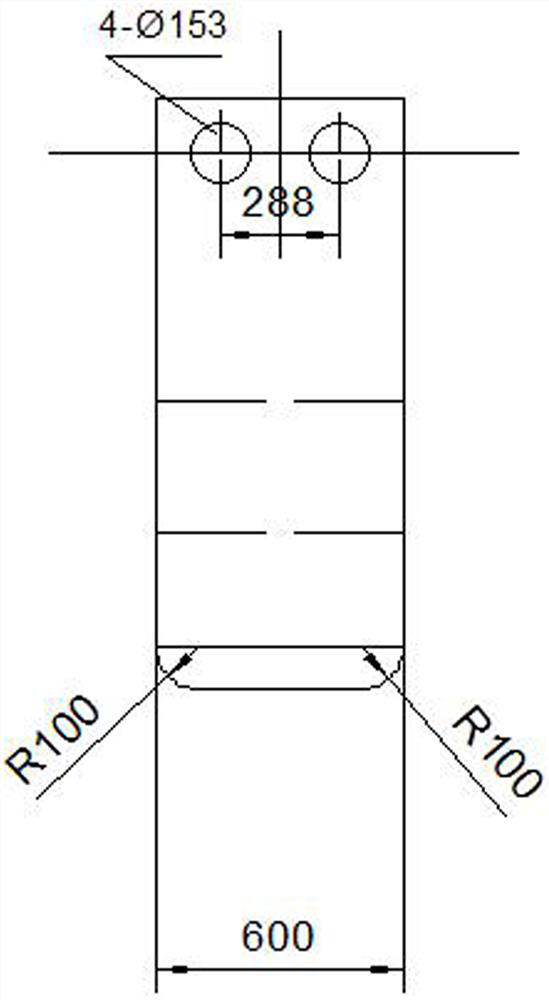

[0049] Step 2: Design special attachments: According to the calculated size, design a special upper anvil and a closing sleeve with a curved shape. In order to save production costs, the special upper anvil considers using the existing upper anvil for welding transformation, and the special mouth guard sleeve It is produced by casting,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com