Open blank forging method of near β titanium alloy ti-7333

A ti-7333, beta titanium alloy technology, applied in the field of titanium alloy forging, can solve the problems of coarse structure and uneven quality of forging billet, and achieve the effect of uniform structure, high flaw detection level and fine grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

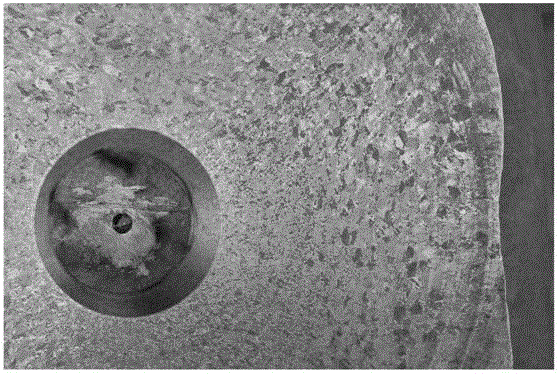

[0034] This embodiment is a billet forging method of near-β titanium alloy Ti-7333. The press machine used is a 1600T fast forging machine, and the hammer head of the forging hammer of the press machine has a flat surface and rounded edges. The specification of the Ti-7333 alloy billet is Φ265mm×330mm, and the phase transition temperature T of the billet is measured β is 850°C.

[0035] The specific implementation steps of this embodiment are as follows:

[0036] Step 1. Determine the height-to-diameter ratio of the billet and check the appearance; measure and calculate the ratio of the height to the diameter of the Ti-7333 alloy billet with a caliper, and the calculated height-to-diameter ratio is about 1.25, which meets the requirement that the height-to-diameter ratio is ≤ 2.0; inspect the billet , no sharp corners, chamfering the end of the billet 10×10mm; grinding and removing the surface defects of the billet, the ratio of the width of the billet surface defect cleanin...

Embodiment 2

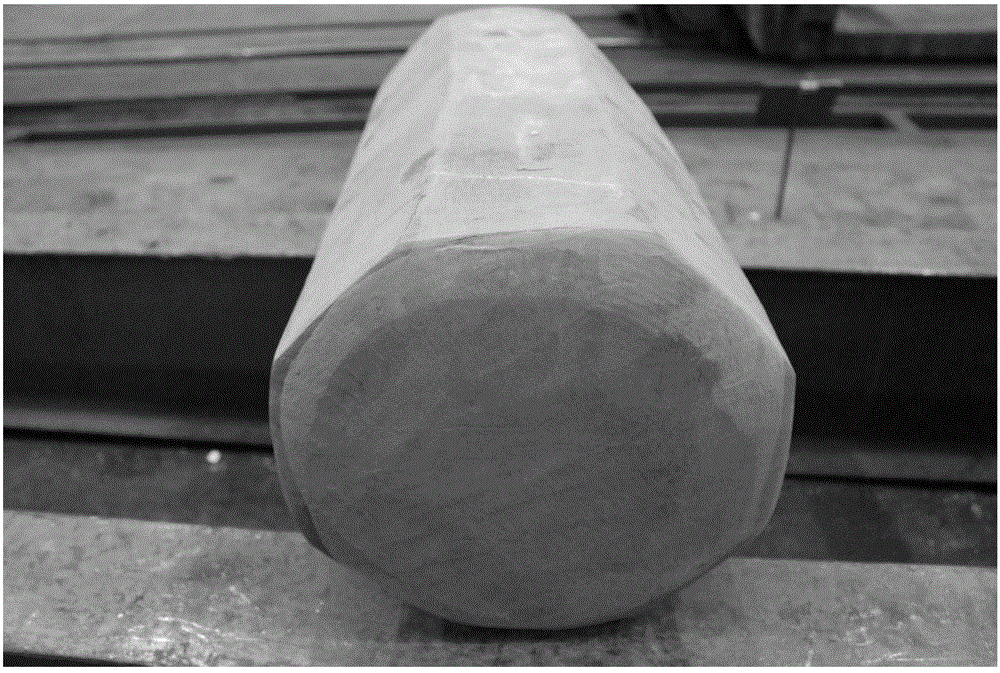

[0053] This embodiment is a billet forging method of near-β titanium alloy Ti-7333. The press machine used is a 1600T fast forging machine, and the hammer head of the forging hammer of the press machine has a flat surface and rounded edges. The specification of the Ti-7333 alloy billet is Φ340mm×480mm, and the phase transition temperature T of the billet is measured β is 850°C. The specific implementation steps are as follows:

[0054] Step 1. Determine the height-to-diameter ratio of the billet and check the appearance; measure and calculate the ratio of height to diameter of the Ti-7333 alloy billet with a caliper, and the calculated height-to-diameter ratio is about 1.41, which meets the requirement that the height-to-diameter ratio is ≤ 2.0; check the billet billet , no sharp corners, chamfering the end of the billet 10×10mm; grinding and removing the surface defects of the billet, the ratio of the width of the billet surface defect cleaning to the grinding depth of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com